EP0807787A2 - Burner - Google Patents

Burner Download PDFInfo

- Publication number

- EP0807787A2 EP0807787A2 EP97810221A EP97810221A EP0807787A2 EP 0807787 A2 EP0807787 A2 EP 0807787A2 EP 97810221 A EP97810221 A EP 97810221A EP 97810221 A EP97810221 A EP 97810221A EP 0807787 A2 EP0807787 A2 EP 0807787A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- burner

- fuel

- air inlet

- plane

- overlap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D17/00—Burners for combustion conjointly or alternatively of gaseous or liquid or pulverulent fuel

- F23D17/002—Burners for combustion conjointly or alternatively of gaseous or liquid or pulverulent fuel gaseous or liquid fuel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C7/00—Combustion apparatus characterised by arrangements for air supply

- F23C7/002—Combustion apparatus characterised by arrangements for air supply the air being submitted to a rotary or spinning motion

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2900/00—Special features of, or arrangements for combustion apparatus using fluid fuels or solid fuels suspended in air; Combustion processes therefor

- F23C2900/07002—Premix burners with air inlet slots obtained between offset curved wall surfaces, e.g. double cone burners

Definitions

- the invention relates to the field of combustion technology. It relates to a burner of the double-cone type, in which gaseous fuel is supplied to the combustion air flow before it flows into the interior of the burner.

- EP 0 321 809 B1 discloses the basic structure of a double-cone type burner to which the invention relates.

- This burner consists essentially of hollow, part-cone bodies that complement one another, with tangential air inlet slots and feeds for gaseous and liquid fuels, in which the central axes of the hollow part-cone bodies have a conical inclination widening in the flow direction and are offset in the longitudinal direction.

- a fuel nozzle is placed on the burner head.

- the gaseous fuel is supplied to the combustion air stream in advance of its inflow into the interior of the burner via gas injectors arranged along the inlet slots.

- the fuel / air mixture is thus formed directly at the end of the tangential air inlet slots.

- the air entry level and the gas entry level (Perforation level) thus coincide in this known prior art.

- the ignition of the flame is only initiated at the stagnation point of the return flow zone.

- the last gas injectors along the air inlet slots are very close to the burner outlet and thus also in the vicinity of the flame.

- the length of the pre-mixing section is therefore very short at these points, so that the fuel which is injected from these last nozzles located downstream can only mix poorly with the air.

- the poor premixing of the fuel with air creates local areas with a rich fuel / air mixture, which leads to higher flame temperatures and thus to higher NOx values.

- the additional load on the firing front in these regions becomes so high that overheating occurs and the material there has to be protected by an expensive zirconium coating.

- the invention tries to avoid all of these disadvantages. It is the object of the invention to create a burner of the double-cone type, which is simple in construction and therefore inexpensive to manufacture, and in which an improved premixing of the gaseous fuel from the downstream last gas injection nozzles with the combustion air takes place, so that compared to the known prior art NOx emissions are reduced and the burner front is subjected to less thermal stress, so that expensive special coatings on the burner front can be dispensed with.

- this is achieved in that the partial cone bodies overlap in a burner according to the preamble of claim 1, the overlap angle increasing in the flow direction of the burner and at the same time the distance of the fuel injectors from the air inlet plane into the burner increasing with an increase in the overlap angle.

- the fuel injection plane and the air inlet plane therefore no longer coincide, but the fuel injection plane changes along the burner in the position relative to the air inlet plane.

- the advantages of the invention are, inter alia, that the premixing of the gaseous fuel with the combustion air is improved in the area of the downstream fuel injectors due to the enlarged premixing section, so that the NOx emissions and the thermal load on the burner front are reduced.

- the burner is characterized by a more stable flame position and lower pulsations.

- the overlap angle in the cone tip is 0 ° and increases continuously up to the burner front, the maximum overlap angle being 90 °.

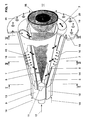

- FIG. 1 shows a perspective view of the burner according to the invention. For a better understanding, it is advantageous if the cuts in FIGS. 2 to 4 are used simultaneously with FIG. 1.

- the offset of the respective central axes 3, 4 of the partial cone bodies 1, 2 to each other creates a tangential air inlet slot 5, 6 on both sides in a mirror-image arrangement, through which the combustion air 7 enters the interior 8 of the burner.

- the two partial cone bodies 1, 2 each have a cylindrical starting part 9, 10, which likewise run offset from one another, so that the tangential air inlet slots 5, 6 are also present in this area.

- a nozzle 11 for atomizing the liquid fuel 12 is accommodated in this cylindrical starting part 9, 10.

- the burner can also be designed without the cylindrical starting parts 9, 10, so that it is designed to be purely conical. Then the fuel nozzle 11 is accommodated directly in the cone tip.

- the two partial cone bodies 1, 2 each have a fuel line 13, 14 which are provided with openings 15 which represent fuel injectors.

- the fuel injectors 15 add gaseous fuel 16 to the combustion air 7 flowing through the tangential air inlet slots 5,

- the burner has a front plate 18 serving as anchoring for the partial cone bodies 1, 2 with a number of bores 19 through which, if necessary, dilution or cooling air 20 can be supplied to the front part of the combustion chamber 17 or its wall.

- liquid fuel 12 If liquid fuel 12 is used to operate the burner, it flows through the nozzle 11 and is injected into the burner interior 17 at an acute angle, a homogeneous fuel spray being produced.

- the tapered liquid fuel profile 23 is of a tangentially flowing rotating combustion air flow 7 enclosed. In the axial direction, the concentration of the liquid fuel 12 is continuously reduced by the mixed-in combustion air 7.

- the optimum fuel concentration across the cross section is only achieved in the area of the vortex burst, ie in the area of the backflow zone 24.

- the ignition takes place at the tip of the backflow zone 24. Only at this point does a stable flame front 25 arise.

- the flame stabilization results from an increase in the number of swirls in the direction of flow along the cone axis. The flame does not kick back inside the burner.

- the two partial cone bodies 1, 2 partially overlap, the overlap angle ⁇ in the cone tip being 0 ° (ie there is no overlap) and ⁇ then increases continuously in the direction of flow up to the burner outlet, that is to say to the front plate 18. 90 ° can be specified as the maximum overlap angle ⁇ .

- the air flow 7 is channeled through the overlapped walls of the partial cone bodies 1, 2.

- the fuel injectors 15 are offset further upstream.

- the air inlet level 21 and the fuel injection level thus fall 22 no longer together.

- the fuel injection plane 22 changes its position along the double-cone burner in the direction of the burner front in relation to the air inlet plane 21 such that ever larger premixing distances are reached from the respective fuel injection of the gaseous fuel 16 to the air inlet plane 21.

- the flame has a more stable position compared to the previously known prior art, in which the partial cone bodies 1, 2 do not overlap and the fuel injection plane 22 corresponds to the air inlet plane 21.

- the burner according to the invention also has less tendency to pulsate. It is structurally fairly simple (e.g. without complicated transition pieces to extend the pre-mixing section) and is therefore inexpensive to manufacture.

- the invention is not limited to the embodiment just described.

- the solution according to the invention can also be used for burners which consist of more than two partial cone bodies, for example for so-called four-slot burners.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

Abstract

Description

Die Erfindung bezieht sich auf das Gebiet der Verbrennungstechnik. Sie betrifft einen Brenner der Doppelkegelbauart, bei welchem dem Verbrennungsluftstrom vor seiner Einströmung in den Brennerinnenraum gasförmiger Brennstoff zugeführt wird.The invention relates to the field of combustion technology. It relates to a burner of the double-cone type, in which gaseous fuel is supplied to the combustion air flow before it flows into the interior of the burner.

Aus EP 0 321 809 B1 ist der prinzipielle Aufbau eines Brenners der Doppelkegelbauart bekannt, auf den sich die Erfindung bezieht. Dieser Brenner besteht im wesentlichen aus hohlen, sich zu einem Körper ergänzenden Teilkegelkörpern, mit tangentialen Lufteintrittsschlitzen und Zuführungen für gasförmige und flüssige Brennstoffe, bei dem die Mittelachsen der hohlen Teilkegelkörper eine in Strömungsrichtung sich erweiternde Kegelneigung aufweisen und in Längsrichtung zueinander versetzt verlaufen. Im von den Teilkegelkörpern gebildeten kegelförmigen Innenraum ist am Brennerkopf eine Brennstoffdüse plaziert. Der gasförmige Brennstoff wird dem Verbrennungsluftstrom vorgängig seiner Einströmung in den Brennerinnenraum über entlang der Eintrittsschlitze angeordneten Gasinjektoren zugeführt. Die Bildung des Brennstoff/Luft-Gemisches geschieht somit direkt am Ende der tangentialen Lufteintrittsschlitze. Die Lufteintrittsebene und die Gaseintrittsebene (Belochungsebene) fallen somit bei diesem bekannten Stand der Technik zusammen.EP 0 321 809 B1 discloses the basic structure of a double-cone type burner to which the invention relates. This burner consists essentially of hollow, part-cone bodies that complement one another, with tangential air inlet slots and feeds for gaseous and liquid fuels, in which the central axes of the hollow part-cone bodies have a conical inclination widening in the flow direction and are offset in the longitudinal direction. In the conical interior formed by the partial cone bodies, a fuel nozzle is placed on the burner head. The gaseous fuel is supplied to the combustion air stream in advance of its inflow into the interior of the burner via gas injectors arranged along the inlet slots. The fuel / air mixture is thus formed directly at the end of the tangential air inlet slots. The air entry level and the gas entry level (Perforation level) thus coincide in this known prior art.

Die Zunahme des Dralles entlang der Kegelachse, verbunden mit der plötzlichen Querschnittserweiterung am Brenneraustritt, führt dazu, dass sich stromab des Brenneraustrittes auf der Brennerachse eine Rückströmzone bildet, die die Flamme stabilisiert. Erst im Staupunkt der Rückströmzone wird die Zündung der Flamme eingeleitet.The increase in the swirl along the cone axis, combined with the sudden cross-sectional widening at the burner outlet, means that a backflow zone forms on the burner axis downstream of the burner outlet, which stabilizes the flame. The ignition of the flame is only initiated at the stagnation point of the return flow zone.

Die letzten Gasinjektoren entlang der Lufteintrittsschlitze liegen bei diesem bekannten Stand der Technik sehr nahe am Brenneraustritt und somit auch in der Nähe der Flamme. Die Länge der Vormischstrecke ist somit an diesen Stellen sehr kurz, so dass sich der Brennstoff, der aus diesen stromabwärts gelegenen letzten Düsen eingedüst wird, nur schlecht mit der Luft vermischen kann. Durch die schlechte Vormischung des Brennstoffes mit Luft entstehen örtlich Gebiete mit einem fetten Brennstoff/Luft-Gemisch, welches zu höheren Flammentemperaturen und damit auch zu höheren NOx-Werten führt. Ausserdem wird die zusätzliche Belastung für die Brennfront in diesen Regionen so hoch, dass es zu Überhitzungen kommt und das Material dort durch eine teure Zirkonbeschichtung geschützt werden muss.In this known prior art, the last gas injectors along the air inlet slots are very close to the burner outlet and thus also in the vicinity of the flame. The length of the pre-mixing section is therefore very short at these points, so that the fuel which is injected from these last nozzles located downstream can only mix poorly with the air. The poor premixing of the fuel with air creates local areas with a rich fuel / air mixture, which leads to higher flame temperatures and thus to higher NOx values. In addition, the additional load on the firing front in these regions becomes so high that overheating occurs and the material there has to be protected by an expensive zirconium coating.

Will man die Vormischstrecke entlang der Brennerachse verlängern, um die NOx-Emissionen zu reduzieren, so ist dazu ein kompliziertes Übergangsstück zwischen dem Brenner und dem nachfolgenden Teil, beispielsweise einem vor der Brennkammer angeordneten Rohr, notwendig. Durch das Strömungsfeld, das der Brenner stromab erzeugt, ergeben sich in dem nachgeschalteten Teil entweder am Rand oder im Zentrum Probleme mit der axialen Geschwindigkeit. Das führt zu Rückzündungen, so dass der Brenner auf diese Weise nicht betrieben werden kann.If one wants to extend the premixing section along the burner axis in order to reduce the NOx emissions, this requires a complicated transition piece between the burner and the subsequent part, for example a pipe arranged in front of the combustion chamber. The flow field generated by the burner downstream gives rise to problems with the axial speed in the downstream part either at the edge or in the center. This leads to reignitions so that the burner cannot be operated in this way.

Die Erfindung versucht, alle diese Nachteile zu vermeiden. Ihr liegt die Aufgabe zugrunde, einen Brenner der Doppelkegelbauart zu schaffen, welcher einfach aufgebaut und damit preiswert zu fertigen ist und bei welchem eine verbesserte Vormischung des gasförmigen Brennstoffes aus den stromabwärts gelegenen letzten Gasinjektionsdüsen mit der Verbrennungsluft stattfindet, so dass gegenüber dem bekannten Stand der Technik die NOx-Emissionen reduziert werden und die Brennerfront thermisch geringer beansprucht wird, so dass auf teure Spezialbeschichtungen der Brennerfront verzichtet werden kann.The invention tries to avoid all of these disadvantages. It is the object of the invention to create a burner of the double-cone type, which is simple in construction and therefore inexpensive to manufacture, and in which an improved premixing of the gaseous fuel from the downstream last gas injection nozzles with the combustion air takes place, so that compared to the known prior art NOx emissions are reduced and the burner front is subjected to less thermal stress, so that expensive special coatings on the burner front can be dispensed with.

Erfindungsgemäss wird dies dadurch erreicht, dass sich bei einem Brenner gemäss dem Oberbegriff des Anspruchs 1 die Teilkegelkörper überlappen, wobei der Überlappungswinkel in Strömungsrichtung des Brenners zunimmt und gleichzeitig mit Zunahme des Überlappungswinkels der Abstand der Brennstoffinjektoren von der Lufteintrittsebene in den Brenner zunimmt. Die Brennstoffinjektionsebene und die Lufteintrittsebene fallen somit nicht mehr zusammen, sondern die Brennstoffinjektionsebene verändert sich entlang des Brenners in der Position zur Lufteintrittsebene.According to the invention, this is achieved in that the partial cone bodies overlap in a burner according to the preamble of

Die Vorteile der Erfindung bestehen unter anderem darin, dass im Bereich der stromab gelegenen Brennstoffinjektoren auf Grund der vergrösserten Vormischstrecke die Vormischung des gasförmigen Brennstoffes mit der Verbrennungsluft verbessert wird, so dass die NOx-Emissionen und die thermische Belastung der Brennerfront verringert werden. Der Brenner zeichnet sich durch eine stabilere Flammenposition und geringere Pulsationen aus.The advantages of the invention are, inter alia, that the premixing of the gaseous fuel with the combustion air is improved in the area of the downstream fuel injectors due to the enlarged premixing section, so that the NOx emissions and the thermal load on the burner front are reduced. The burner is characterized by a more stable flame position and lower pulsations.

Es ist besonders zweckmässig, wenn der Überlappungswinkel in der Kegelspitze 0° beträgt und stetig bis zur Brennerfront zunimmt, wobei der maximale Überlappungswinkel 90° beträgt.It is particularly expedient if the overlap angle in the cone tip is 0 ° and increases continuously up to the burner front, the maximum overlap angle being 90 °.

Wenn in der Kegelspitze keine Überlappung der Teilkegelkörper vorgesehen ist, dann kann weiterhin wie beim bekannten Stand der Technik eine hohe Axialgeschwindigkeit innerhalb des Brenners auf der Symmetrieachse erreicht werden.If no overlap of the partial cone bodies is provided in the cone tip, then a high axial speed can still be achieved within the burner on the axis of symmetry, as in the known prior art.

In der Zeichnung ist ein Ausführungsbeispiel der Erfindung anhand eines Brenners, welcher aus zwei Teilkegelkörpern aufgebaut ist, dargestellt.In the drawing, an embodiment of the invention is shown with the aid of a burner which is constructed from two partial cone bodies.

Es zeigen:

- Fig. 1

- einen Doppelkegelbrenner in perspektivischer Darstellung;

- Fig. 2

- einen schematischen Querschnitt des Brenners gemäss Fig. 1 entlang der Ebene II-II;

- Fig. 3

- einen schematischen Querschnitt des Brenners gemäss Fig. 1 entlang der Ebene III-III;

- Fig. 4

- einen schematischen Querschnitt des Brenners gemäss Fig. 1 entlang der Ebene IV-IV.

- Fig. 1

- a double cone burner in perspective;

- Fig. 2

- a schematic cross section of the burner of Figure 1 along the plane II-II.

- Fig. 3

- a schematic cross section of the burner of Figure 1 along the plane III-III.

- Fig. 4

- a schematic cross section of the burner according to FIG. 1 along the plane IV-IV.

Es sind nur die für das Verständnis der Erfindung wesentlichen Elemente gezeigt. Die Strömungsrichtungen der verschiedenen Medien sind mit Pfeilen bezeichnet.Only the elements essential for understanding the invention are shown. The flow directions of the different media are indicated by arrows.

Nachfolgend wird die Erfindung anhand eines Ausführungsbeispieles und der Fig. 1 bis 4 näher erläutert.The invention is explained in more detail below using an exemplary embodiment and FIGS. 1 to 4.

Fig. 1 zeigt in perspektivischer Darstellung den erfindungsgemässen Brenner. Zum besseren Verständnis ist es vorteilhaft, wenn gleichzeitig zu Fig. 1 die Schnitte in den Fig. 2 bis 4 herangezogen werden.1 shows a perspective view of the burner according to the invention. For a better understanding, it is advantageous if the cuts in FIGS. 2 to 4 are used simultaneously with FIG. 1.

Der Brenner gemäss Fig. 1 besteht aus zwei hohlen Teilkegelkörpern 1, 2, die versetzt zueinander aufeinander liegen. Die Versetzung der jeweiligen Mittelachsen 3, 4 der Teilkegelkörper 1, 2 zueinander schafft auf beiden Seiten in spiegelbildlicher Anordnung jeweils einen tangentialen Lufteintrittsschlitz 5, 6, durch welche die Verbrennungsluft 7 in den Innenraum 8 des Brenners gelangt. Die beiden Teilkegelkörper 1, 2 haben jeweils einen zylindrischen Anfangsteil 9, 10, die ebenfalls versetzt zueinander verlaufen, so dass auch in diesem Bereich die tangentiale Lufteintrittsschlitze 5, 6 vorhanden sind. In diesem zylindrischen Anfangsteil 9, 10 ist eine Düse 11 zur Zerstäubung des flüssigen Brennstoffes 12 untergebracht. Der Brenner kann auch ohne die zylindrischen Anfangsteile 9, 10 ausgeführt sein, so dass er rein kegelig ausgebildet ist. Dann ist die Brennstoffdüse 11 direkt in der Kegelspitze untergebracht. Die beiden Teilkegelkörper 1, 2 weisen je eine Brennstoffleitung 13, 14 auf, die mit Öffnungen 15 versehen sind, welche Brennstoffinjektoren darstellen. Durch die Brennstoffinjektoren 15 wird gasförmiger Brennstoff 16 der durch die tangentialen Lufteintrittsschlitze 5, 6 strömenden Verbrennungsluft 7 zugemischt.1 consists of two hollow

Brennraumseitig 17 weist der Brenner eine als Verankerung für die Teilkegelkörper 1, 2 dienende Frontplatte 18 mit einer Anzahl Bohrungen 19 auf, durch welche nötigenfalls Verdünnungs- bzw. Kühlluft 20 dem vorderen Teil des Brennraumes 17 bzw. dessen Wand zugeführt werden kann.

Wird zum Betrieb des Brenners flüssiger Brennstoff 12 verwendet, so strömt dieser durch die Düse 11 und wird in einem spitzen Winkel in den Brennerinnenraum 17 eingedüst, wobei sich ein homogener Brennstoffspray einstellt. Das kegelige Flüssigbrennstoffprofil 23 wird von einem tangential einströmenden rotierenden Verbrennungsluftstrom 7 umschlossen. In axialer Richtung wird die Konzentration des Flüssigbrennstoffes 12 fortlaufend durch die eingemischte Verbrennungluft 7 verringert. Die optimale Brennstoffkonzentration über den Querschnitt wird erst im Bereich des Wirbelaufplatzens, d.h. im Bereich der Rückströmzone 24 erreicht. Die Zündung erfolgt an der Spitze der Rückströmzone 24. Erst an dieser Stelle entsteht eine stabile Flammenfront 25. Die Flammenstabilisation ergibt sich durch Zunahme der Drallzahl in Strömungsrichtung entlang der Kegelachse. Ein Rückschlagen der Flamme in das Innere des Brenners tritt nunmehr nicht auf.If

Wird gasförmiger Brennstoff 16 verbrannt, so geschieht die Gemischbildung mit der Verbrennungsluft 7 in den Lufteintrittsschlitzen 5, 6. Erfindungsgemäss überlappen sich die beiden Teilkegelkörper 1, 2 teilweise, wobei der Überlappungswinkel δ in der Kegelspitze 0° beträgt (d.h. dort liegt keine Überlappung vor) und δ dann in Strömungsrichtung bis zum Brennerausgang, also bis zur Frontplatte 18, stetig zunimmt. Als maximaler Überlappungswinkel δ können 90° angegeben werden.If

Wenn in der Kegelspitze bzw. im zylindrischen Anfangsteil 9, 10 der beiden Teilkegelkörper 1, 2 der Überlappungswinkel 0° beträgt, also die beiden Teilkegelkörper 1, 2 sich in diesem Bereich nicht überlappen, dann hat das den Vorteil, dass dadurch weiterhin eine hohe Axialgeschwindigkeit innerhalb des Brenners auf der Symmetrieachse erreicht wird.If the overlap angle in the cone tip or in the cylindrical

Durch die überlappten Wände der Teilkegelkörper 1, 2 wird die Luftströmung 7 kanalisiert.The

Im gleichen Masse, wie sich der Überlappungswinkel δ ändert, sind die Brennstoffinjektoren 15 weiter stromauf versetzt. Damit fallen die Lufteintrittsebene 21 und die Brennstoffinjektionsebene 22 nicht mehr zusammen. Die Brennstoffinjektionsebene 22 ändert entlang des Doppelkegelbrenners in Richtung Brennerfront ihre Position zur Lufteintrittsebene 21 dermassen, dass immer grössere Vormischstrecken von der jeweiligen Brennstoffeindüsung des gasförmigen Brennstoffes 16 bis zur Lufteintrittsebene 21 erreicht werden.To the same extent as the overlap angle δ changes, the

Dadurch wird eine homogenere Mischung des gasförmigen Brennstoffes 16 und der Verbrennungsluft 7 erzielt, was zu tieferen Flammentemperaturen und damit zu tieferen Nox-Emissionen führt. Diese tieferen Flammentemperaturen im Bereich des Brenneraustrittes reduzieren auch die thermischen Belastungen für das Material an der Brennerfront und machen eine sonst notwendige Zirkonbeschichtung des Materials hinfällig.As a result, a more homogeneous mixture of the

Ausserdem hat die Flamme im Vergleich zum bisher bekannten Stand der Technik, bei dem sich die Teilkegelkörper 1, 2 nicht überlappen und die Brennstoffinjektionsebene 22 der Lufteintrittsebene 21 entspricht, eine stabilere Position. Zusätzlich ergibt sich als Vorteil, dass der erfindungsgemässe Brenner auch weniger zu Pulsationen neigt. Er ist konstruktiv recht einfach gestaltet (z.B. ohne komplizierte Übergangsstücke zur Verlängerung der Vormischstrecke) und daher kostengünstig zu fertigen.In addition, the flame has a more stable position compared to the previously known prior art, in which the

Selbstverständlich ist die Erfindung nicht auf das eben beschriebene Ausführungsbeispiel beschränkt. Die erfindungsgemässe Lösung kann ebenso auch für Brenner verwendet werden, die aus mehr als zwei Teilkegelkörpern bestehen, z.B. für sogenannte Vierschlitzbrenner.Of course, the invention is not limited to the embodiment just described. The solution according to the invention can also be used for burners which consist of more than two partial cone bodies, for example for so-called four-slot burners.

- 11

- TeilkegelkörperPartial cone body

- 22nd

- TeilkegelkörperPartial cone body

- 33rd

-

Mittelachse von Pos. 1Central axis of

item 1 - 44th

-

Mittelachse von Pos. 2Central axis of

item 2 - 55

- tangentialer Lufteintrittsschlitztangential air inlet slot

- 66

- tangentialer Lufteintrittsschlitztangential air inlet slot

- 77

- VerbrennungsluftCombustion air

- 88th

- BrennerinnenraumBurner interior

- 99

-

zylindrischer Anfangsteil von Pos. 1cylindrical starting part of

item 1 - 1010th

-

zylindrischer Anfangsteil von Pos. 2cylindrical starting part of

item 2 - 1111

- BrennstoffdüseFuel nozzle

- 1212th

- flüssiger Brennstoffliquid fuel

- 1313

-

Brennstoffleitung für Pos. 16Fuel line for

item 16 - 1414

-

Brennstoffleitung für Pos. 16Fuel line for

item 16 - 1515

-

Brennstoffinjektor für Pos. 16Fuel injector for

item 16 - 1616

- gasförmiger Brennstoffgaseous fuel

- 1717th

- BrennraumCombustion chamber

- 1818th

- FrontplatteFront panel

- 1919th

- Bohrungdrilling

- 2020th

- Verdünnungs- bzw. KühlluftDilution or cooling air

- 2121

- LufteintrittsebeneAir inlet level

- 2222

- BrennstoffinjektionsebeneFuel injection level

- 2323

- FlüssigbrennstoffprofilLiquid fuel profile

- 2424th

- RückströmzoneBackflow zone

- 2525th

- FlammenfrontFlame front

- δδ

- ÜberlappungswinkelOverlap angle

Claims (2)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19619873 | 1996-05-17 | ||

| DE19619873A DE19619873A1 (en) | 1996-05-17 | 1996-05-17 | burner |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0807787A2 true EP0807787A2 (en) | 1997-11-19 |

| EP0807787A3 EP0807787A3 (en) | 1999-03-24 |

| EP0807787B1 EP0807787B1 (en) | 2003-05-28 |

Family

ID=7794546

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97810221A Expired - Lifetime EP0807787B1 (en) | 1996-05-17 | 1997-04-14 | Burner |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5921766A (en) |

| EP (1) | EP0807787B1 (en) |

| JP (1) | JP3863631B2 (en) |

| CN (1) | CN1117243C (en) |

| DE (2) | DE19619873A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0918191A1 (en) * | 1997-11-21 | 1999-05-26 | Abb Research Ltd. | Burner for the operation of a heat generator |

| EP0959298A3 (en) * | 1998-05-18 | 2000-02-23 | United Technologies Corporation | Premixing fuel injector and method of operation |

| US8516825B2 (en) | 2003-07-24 | 2013-08-27 | Alstom Technology Ltd | Method for reducing the NOx emissions from a burner arrangement comprising a plurality of burners, and burner arrangement for carrying out the method |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1262714A1 (en) * | 2001-06-01 | 2002-12-04 | ALSTOM (Switzerland) Ltd | Burner with exhausts recirculation |

| US7097448B2 (en) * | 2004-05-07 | 2006-08-29 | Peter Chesney | Vortex type gas lamp |

| CA2786597A1 (en) | 2010-01-06 | 2011-07-14 | The Outdoor Greatroom Company LLLP | Fire container assembly |

| US10281140B2 (en) | 2014-07-15 | 2019-05-07 | Chevron U.S.A. Inc. | Low NOx combustion method and apparatus |

| US11852319B2 (en) * | 2021-02-26 | 2023-12-26 | Armando Parra | Control means for vortex flame device |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5340306A (en) * | 1991-12-23 | 1994-08-23 | Asea Brown Boveri Ltd. | Device for mixing two gaseous components and burner in which this device is employed |

| EP0641971A2 (en) * | 1993-09-06 | 1995-03-08 | Abb Research Ltd. | Method for operating a premix burner |

| WO1995023316A1 (en) * | 1994-02-24 | 1995-08-31 | United Technologies Corporation | Tangential entry fuel nozzle |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3570471A (en) * | 1969-02-14 | 1971-03-16 | Thermo Electron Corp | Radiant tube having uniform high-temperature distribution |

| DE3662462D1 (en) * | 1985-07-30 | 1989-04-20 | Bbc Brown Boveri & Cie | Dual combustor |

| CH674561A5 (en) * | 1987-12-21 | 1990-06-15 | Bbc Brown Boveri & Cie | |

| EP0481111B1 (en) * | 1990-10-17 | 1995-06-28 | Asea Brown Boveri Ag | Gas-turbine combustion chamber |

| US5307634A (en) * | 1992-02-26 | 1994-05-03 | United Technologies Corporation | Premix gas nozzle |

| DE4304213A1 (en) * | 1993-02-12 | 1994-08-18 | Abb Research Ltd | Burner for operating an internal combustion engine, a combustion chamber of a gas turbine group or a combustion system |

| DE19502796B4 (en) * | 1995-01-30 | 2004-10-28 | Alstom | burner |

-

1996

- 1996-05-17 DE DE19619873A patent/DE19619873A1/en not_active Withdrawn

-

1997

- 1997-04-14 DE DE59710156T patent/DE59710156D1/en not_active Expired - Lifetime

- 1997-04-14 EP EP97810221A patent/EP0807787B1/en not_active Expired - Lifetime

- 1997-05-07 US US08/852,548 patent/US5921766A/en not_active Expired - Lifetime

- 1997-05-16 JP JP12659797A patent/JP3863631B2/en not_active Expired - Lifetime

- 1997-05-16 CN CN97111195A patent/CN1117243C/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5340306A (en) * | 1991-12-23 | 1994-08-23 | Asea Brown Boveri Ltd. | Device for mixing two gaseous components and burner in which this device is employed |

| EP0641971A2 (en) * | 1993-09-06 | 1995-03-08 | Abb Research Ltd. | Method for operating a premix burner |

| WO1995023316A1 (en) * | 1994-02-24 | 1995-08-31 | United Technologies Corporation | Tangential entry fuel nozzle |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0918191A1 (en) * | 1997-11-21 | 1999-05-26 | Abb Research Ltd. | Burner for the operation of a heat generator |

| US6155820A (en) * | 1997-11-21 | 2000-12-05 | Abb Research Ltd. | Burner for operating a heat generator |

| EP0959298A3 (en) * | 1998-05-18 | 2000-02-23 | United Technologies Corporation | Premixing fuel injector and method of operation |

| US8516825B2 (en) | 2003-07-24 | 2013-08-27 | Alstom Technology Ltd | Method for reducing the NOx emissions from a burner arrangement comprising a plurality of burners, and burner arrangement for carrying out the method |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0807787B1 (en) | 2003-05-28 |

| CN1117243C (en) | 2003-08-06 |

| DE59710156D1 (en) | 2003-07-03 |

| US5921766A (en) | 1999-07-13 |

| DE19619873A1 (en) | 1997-11-20 |

| CN1172227A (en) | 1998-02-04 |

| JP3863631B2 (en) | 2006-12-27 |

| JPH1068511A (en) | 1998-03-10 |

| EP0807787A3 (en) | 1999-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0321809B1 (en) | Process for combustion of liquid fuel in a burner | |

| EP0433790B1 (en) | Burner | |

| EP0387532B1 (en) | Gas turbine combustion chamber | |

| EP0503319B1 (en) | Burner for a premixing combustion of a liquid and/or a gaseous fuel | |

| EP0401529B1 (en) | Gas turbine combustion chamber | |

| EP0911583B1 (en) | Method of operating a premix burner | |

| DE19545310B4 (en) | premix | |

| DE19730617A1 (en) | Pressure atomizer nozzle | |

| CH680157A5 (en) | ||

| DE19640198A1 (en) | Premix burner | |

| EP0778445B1 (en) | Premix burner | |

| EP0394800B1 (en) | Premix burner for generating a hot gas | |

| EP0816759B1 (en) | Premix burner and method of operating the burner | |

| EP0433789A1 (en) | Method for a premix burning of a liquid fuel | |

| EP0851172A2 (en) | Burner for operating a combustion chamber with a liquid and/or gaseous fuel | |

| EP0742411B1 (en) | Air supply for a premix combustor | |

| EP0483554B1 (en) | Method for minimising the NOx emissions from a combustion | |

| EP0807787B1 (en) | Burner | |

| EP0924458B1 (en) | Burner | |

| DE4412315B4 (en) | Method and device for operating the combustion chamber of a gas turbine | |

| EP0730121A2 (en) | Premix burner | |

| EP0780628A2 (en) | Premix burner for a heat generator | |

| DE19721937A1 (en) | Burner for operating a unit for generating a hot gas | |

| DE19542164A1 (en) | Burner with premixing of gaseous or liquid fuel in air | |

| EP0881431A2 (en) | Burner for operating a hot gas generating unit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19990824 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALSTOM |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20020605 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALSTOM (SWITZERLAND) LTD |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030528 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59710156 Country of ref document: DE Date of ref document: 20030703 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040302 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59710156 Country of ref document: DE Representative=s name: UWE ROESLER, DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20120802 AND 20120808 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59710156 Country of ref document: DE Representative=s name: ROESLER, UWE, DIPL.-PHYS.UNIV., DE Effective date: 20120713 Ref country code: DE Ref legal event code: R081 Ref document number: 59710156 Country of ref document: DE Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH, CH Free format text: FORMER OWNER: ALSTOM (SWITZERLAND) LTD., BADEN, CH Effective date: 20120713 Ref country code: DE Ref legal event code: R081 Ref document number: 59710156 Country of ref document: DE Owner name: ALSTOM TECHNOLOGY LTD., CH Free format text: FORMER OWNER: ALSTOM (SWITZERLAND) LTD., BADEN, CH Effective date: 20120713 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: ALSTOM TECHNOLOGY LTD., CH Effective date: 20120918 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160421 Year of fee payment: 20 Ref country code: GB Payment date: 20160421 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59710156 Country of ref document: DE Representative=s name: ROESLER, UWE, DIPL.-PHYS.UNIV., DE Ref country code: DE Ref legal event code: R081 Ref document number: 59710156 Country of ref document: DE Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH, CH Free format text: FORMER OWNER: ALSTOM TECHNOLOGY LTD., BADEN, CH |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20160427 Year of fee payment: 20 Ref country code: FR Payment date: 20160421 Year of fee payment: 20 Ref country code: SE Payment date: 20160420 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: ALSTOM TECHNOLOGY LTD, CH Effective date: 20161110 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59710156 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170413 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170413 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: ANSALDO ENERGIA IP UK LIMITED, GB Effective date: 20171221 |