EP0806527B1 - Eine mit Druckluft bediente Abflussvorrichtung für Sanitäranlagen - Google Patents

Eine mit Druckluft bediente Abflussvorrichtung für Sanitäranlagen Download PDFInfo

- Publication number

- EP0806527B1 EP0806527B1 EP97106779A EP97106779A EP0806527B1 EP 0806527 B1 EP0806527 B1 EP 0806527B1 EP 97106779 A EP97106779 A EP 97106779A EP 97106779 A EP97106779 A EP 97106779A EP 0806527 B1 EP0806527 B1 EP 0806527B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- duct

- chamber

- piston

- cup

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03F—SEWERS; CESSPOOLS

- E03F1/00—Methods, systems, or installations for draining-off sewage or storm water

- E03F1/006—Pneumatic sewage disposal systems; accessories specially adapted therefore

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D5/00—Special constructions of flushing devices, e.g. closed flushing system

Definitions

- the invention refers to the field of forced discharge sanitary fixtures, as are widely used, for example, on means of transport such as ships, airplanes or trains.

- FR-A-1566133 discloses a forced discharge device for feeding concrete, comprising a body defining an inner chamber, an inlet and an outlet, a hollow cup-shaped shutting element movable between an extended closure position and a retracted opening position, a piston element including a stem, a working head, a drive head, said piston element being axially slidable in the cup-shaped shutting element, driven by the respective working head.

- the document does not disclose any means for operating the piston element'drive head, nor the possibility to apply a vacuum to facilitate entry of the material (concrete) in the inner chamber.

- the arrangement shown in the drawings and described would not be suitable for use in sanitary fixtures due to unavoidable overall dimensions and insufficient sealing.

- An aim of the present invention is to exclude the possibility of accidents due to dangerous backflow that might involve the user.

- a further aim is to eliminate or drastically reduce the possibility of damage to the sanitary fixtures or downtime thereof.

- a further aim is to achieve the above advantages with reduced water consumption and moderate power consumption.

- a further aim is to provide such devices that can also be adapted to foldaway fixtures.

- the new device comprises a body that can be mounted on the sanitary fixture, the body being provided with an inlet opening for entry of wastewater and an outlet opening for discharge thereof and defining an inner chamber in which a cup-shaped shutting element can move between an extended position, in which it shuts the inlet opening, and a retracted position in which it leaves said opening free, a distributor element, being fixed to the body, or fixed to a cover thereof, provided with input and output ducts for a fluid, generally compressed air, and further comprises a twin piston element, movable inside the cup-shaped element between an extended position (with the cup-element extended) and a retracted position.

- the new device achieves the above aims, and in particular it eliminates the possibility of backflow of expelled wastewater, it provides for a perfect separation, in a closed position, between the discharge network and the sanitary fixture; it can be adapted not only to fixed sanitary fixtures but also to foldaway sanitary fixtures; it requires reduced water consumption and reduced power consumption: its operation is efficient and reliable even in situations where the waste pipe has a very small section or an upward, long or winding course.

- a forced discharge device is indicated as a whole by reference number 10 and comprises a hollow body 11, generally but not necessarily cylindrical, that has an inlet opening 12 to let wastewater in and an outlet opening 13 to let wastewater out.

- a cup shaped element indicated as a whole by reference number 14 can slide axially (in a direction defined by the x axis of the body).

- a twin piston element indicated as a whole by 15 can slide axially inside and with respect to the cup-shaped element 14.

- a distributor element 16 is fixed with respect to the body 11 and more precisely is supported by a cover 18 fixed to the body 11.

- the body 11 is formed with an internal a chamber 21, in which said inlet opening 12 opens. This opening is made in the side wall of body 11.

- the body 11 also has a lower flange 22 for attachment of an outlet part 23, in which said outlet opening 13 opens.

- the body 11 also has an upper flange 24 on which said cover 18 is screwed.

- the coupling and fixing screws are not drawn but simply indicated with their axes drawn with dashed and dotted lines.

- the body 11 has an internal seat for an O-ring or sealing ring 26, whilst the part 23 itself has a seat for an abutment ring 25, thus allowing the cup-shaped shutting element 14 to seal the chamber 21 tightly.

- the cup-shaped shutting element 14 has a cylindrical skirt part 28, of a suitable size and shape to be able to slide inside the chamber 21 of the body, and an upper (in fig. 1) flange part 30, extending inside from the skirt part.

- the skirt part is preferably thinner at one end 31; at the opposite end it has a seat 32 opening towards the outside for an O-ring 33, and a seat 34, facing inwards, for an O-ring 35.

- the fixed distributor element 16 comprises a cylindrical portion 36, from which a lower (in fig. 1) plate portion 38 extends; it has a circumferential peripheral seat 40 for an O-ring 41 to provide a seal against the inner surface of the cup-shaped element 14 and a through hole 39 with seats for O-rings 42, 42, for a stem of piston 15.

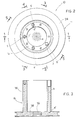

- the cylindrical portion of distributor 16 has a plurality of ducts for an operating fluid, said ducts being circumferentially spaced apart and referenced respectively a , b , c and d as can be seen in the plan view in Figure 2.

- the operating fluid is preferably compressed air, supplied by a compressor or a special supply system (not illustrated).

- the ducts a , b , c and d have a threaded mouthpiece for connection to said supply system, by means of solenoid valves or opening and closing devices managed by an electronic, electrical or mechanical means.

- the duct a which can also be seen in Figure 3, extends with its axis parallel to the axis of the device and ends in the vicinity of plate 38 in a radial passage towards the outside, indicated by a ', which opens into an annular chamber 45 defined between the distributor 16 and the cup-shaped element 14.

- the duct b which can also be seen in Figure 5, has a limited axial extension and opens outwards radially at the top into the annular chamber 43 through a hole b' defined between the cup-shaped element 30 and the cover 18.

- the duct c which can also be seen in Figure 1, extends in an axial direction, has a radial opening c' in a chamber 46 between the cover and the piston and an end opening c " in the outermost surface of the distributor, facing the piston 15; that is to say, the opening c" opens into a chamber 47 defined between plate 38 and piston 15.

- the duct d which can also be seen in Figure 4, extends in an axial direction and has a radial opening d' at an end near the plate 38, facing towards the chamber 44 of the distributor (that is, with the device assembled, towards the chamber defined between the distributor and the piston).

- the piston 15 comprises a stem 51, a working head 52, a drive head 53 all integral with each other.

- the working head 52 slides inside the cup 14, forming a seal with O-ring 48; 49 is a stop on the cup.

- a seal is formed by the O-rings 42.

- the drive head slides along the inside wall of the distributor, a seal being formed by the upper O-ring 54 accommodated in the head 53.

- An axial duct for compressed air is defined inside the stem 51 and this duct is indicated as a whole by the letter e .

- a check valve 56 is situated on the bottom of the duct and indicated schematically by a spring-loaded ball.

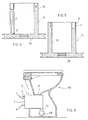

- the forced discharge device is mounted downstream of the bowl of a sanitary fixture as can be seen in Figure 6 or in Figures 7 and 8.

- the sanitary fixture is indicated with the reference number 60 and is of a traditional type.

- the device 10 is mounted with the longitudinal axis x lying horizontally, with the opening 12 at the outlet of the bowl and the opening 13 connected to a per se known rotary exhaust valve 58 which will therefore not be described in detail.

- the sanitary fixture of Figures 7 and 8 is a tip-up foldaway fixture, which is shown in the position of use in Figure 7.

- the device 10 is mounted with the x axis vertical and the opening 12 at the opening of the bowl of the sanitary fixture 70.

- the device 10 is shown tipped with the sanitary fixture in the resting position.

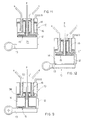

- a vacuum is created in the chamber 21.

- Compressed air is then introduced through the duct a of the distributor and the opening a ' between the plate part 38 of the distributor and the flange 30 of the cup (Fig. 10).

- the distributor At the end of its stroke, the distributor is therefore in the position shown in Figure 11, with the cup-shaped shutting element completely retracted so as to free the opening 12.

- the wastewater can fill the chamber 21.

- Compressed air is then introduced through the duct b at the same time allowing air to evacuate through the duct a .

- the cup-shaped element 14 is thus again pushed into the extended position in Fig. 12, shutting the inlet opening 12 and preventing any return of wastewater or odors through the sanitary fixture.

- Compressed air may be introduced through the duct e at this stage to facilitate evacuation of the wastewater.

- the cycle is ended, and in any case can be repeated, on the basis of a programmable logic, until the wastewater has been completely evacuated.

Landscapes

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Aviation & Aerospace Engineering (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Vehicle Waterproofing, Decoration, And Sanitation Devices (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Nozzles (AREA)

- Self-Closing Valves And Venting Or Aerating Valves (AREA)

- Apparatus For Radiation Diagnosis (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Toys (AREA)

- Compressor (AREA)

Claims (9)

- Eine Zwangsabflußvorrichtung für sanitäre Einrichtungen, die folgendes umfaßt:dadurch gekennzeichnet, daß sie desweiteren folgendes umfaßt:einen Körper (11), der eine innere Körperkammer (21) umfaßt, eine Ein- (12) und eine Auslaßöffnung (13),ein hohles, muffenförmiges Schieberelement (14), das axial in der genannten Körperkammer zwischen einer ausgestreckten Stellung, in der es die genannte Einlaßöffnung verschließt, und einer eingezogenen Stellung, in der es die genannte Einlaßöffnung zumindest teilweise freiläßt, verschoben werden kann,ein Kolbenelement (15), das einen Schaft (51), einen Betriebskopf (52), und einen Steuerkopf (53) umfaßt, die jeweils einteilig sind, wobei das genannte Kolbenelement axial im Verhältnis zu dem genannten muffenförmigen Schieberelement (14) verschoben werden kann,ein Verteilerelement (16), das im Verhältnis zum Körper (11) fest ist und einen Plattenabschnitt (38) umfaßt, der zwischen dem genannten Betriebs- und dem genannten Steuerkopf des Kolbenelements liegt, wobei das genannte Verteilerelement (16) dicht mit dem genannten Schieberelement (14) eingreift und das genannte Kolbenelement (15) eine ringförmige Kammer (45) mit dem genannten Schieberelement (14) bildet, eine Verteilerkammer (44) mit Kolbenelement (15), eine weitere ringförmige Kammer (47) mit Kolbenelement und eine weitere Kammer (43) mit Schieberelement (14),sowie desweiteren eine Vielzahl von Rohrleitungen (a, b, c, d) für ein Betriebsfluid in dem besagten Verteilerelement (16), wobei das genannte Betriebsfluid für die Verschiebung des genannten Schieberelements (14) zwischen einer ausgestreckten Stellung und einer eingezogenen Stellung und für die Verschiebung des genannten Kolbenelements (15) zwischen einer ausgestreckten Stellung und einer eingezogenen Stellung bestimmt ist.

- Eine Vorrichtung gemäß Anspruch 1, dadurch gekennzeichnet, daß sie eine zusätzliche Rohrleitung (e) für ein Entleerungsfluid im Kolbenschaft umfaßt, wobei die genannte zusätzliche Rohrleitung eine Öffnung zur Körperkammer (21) aufweist.

- Eine Vorrichtung gemäß Anspruch 2, wobei die genannte zusätzliche Rohrleitung (e) ein Rückschlagventil (56) umfaßt.

- Eine Vorrichtung gemäß Anspruch 1, wobei der genannte Verteiler an einem Deckel (18) befestigt ist.

- Eine Vorrichtung gemäß Anspruch 1, dadurch gekennzeichnet, daß die genannten Rohrleitungen für ein Betriebs- oder Steuerfluid folgendes umfassen:eine erste Rohrleitung (a), die sich zwischen einem Rohrleitungsende und der genannten ringförmigen Kammer (45) erstreckt, um das Betriebsfluid zu liefern, das das genannte muffenförmige Element (14) in seine ausgestreckte Stellung bringteine zweite Rohrleitung (b), die sich zwischen einen Leitungsende und der genannten weiteren Kammer (43) zwecks Lieferung des Betriebsfluids erstreckt, das das muffenförmige Element in seine ausgestreckte Stellung bringteine dritte Rohrleitung (c), die sich zwischen einem Leitungsende und der genannten weiteren Kammer (47) zwecks Lieferung des Betriebsfluids erstreckt, das das genannte Kolbenelement in die ausgestreckte Stellung bringteine vierte Rohrleitung (d), die sich zwischen einem Rohrleitungsende und der genannten Verteilerkammer (44) für die Lieferung des Betriebsfluids erstreckt, das das genannte Kolbenelement in die eingezogene Stellung bringt.

- Eine Vorrichtung gemäß Anspruch 1, wobei das Betriebsfluid Druckluft ist.

- Eine Vorrichtung gemäß Anspruch 1, die an feste oder drehbare Klapp-Sanitäreinrichtungen montiert werden kann.

- Eine Vorrichtung gemäß Anspruch 1, wobei die genannte Rohrleitung (a) eine radiale Öffnung (a') in der Nähe des Verteilerplattenabschnitts (38) aufweist, um auf eine Oberfläche des muffenförmigen Elements einzuwirken, das Teil der ringförmigen Kammer (45) ist,

die genannte Rohrleitung (b) eine Öffnung (b') in der Nähe des Deckels (18) aufweist, die genannte Rohrleitung (c) Öffnungen (c', c") aufweist, um auf Oberflächen des Kolbenkopfs (52, 53) einzuwirken,

die genannte Rohrleitung (d) eine Öffnung (d') in der Nähe der Verteilerplatte und dem Kolbenschaft (51) zugewandt aufweist, um auf eine Oberfläche des Kolbenkopfs (53) einzuwirken, der Teil der Kammer (44) ist. - Eine Vorrichtung gemäß Anspruch 5, dadurch gekennzeichnet, daß ein Vakuum in der inneren Kammer

(21) des Körpers erzeugt wird, wenn das genannte Kolbenelement in seine eingezogene Stellung bewegt wird; das muffenförmige Element (14) sich in seiner ausgezogenen Stellung befindet, in der es die Einlaßöffnung (12) versperrt und das Dreh-Ablaßventil (58), das mit der Öffnung (13) verbunden ist, geschlossen ist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITPG960013 | 1996-05-08 | ||

| IT96PG000013A IT1295231B1 (it) | 1996-05-08 | 1996-05-08 | Sistema di scarico forzato di preferenza per wc e simili, funzionante ad aria compressa, adatto anche ai sanitari girevoli a scomparsa |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0806527A2 EP0806527A2 (de) | 1997-11-12 |

| EP0806527A3 EP0806527A3 (de) | 1998-08-12 |

| EP0806527B1 true EP0806527B1 (de) | 2002-09-18 |

Family

ID=11393418

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97106779A Expired - Lifetime EP0806527B1 (de) | 1996-05-08 | 1997-04-24 | Eine mit Druckluft bediente Abflussvorrichtung für Sanitäranlagen |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0806527B1 (de) |

| AT (1) | ATE224486T1 (de) |

| DE (1) | DE69715507T2 (de) |

| ES (1) | ES2184001T3 (de) |

| IT (1) | IT1295231B1 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20000515U1 (de) * | 2000-01-14 | 2000-05-04 | Sanivac Vakuumtechnik GmbH, 22880 Wedel | Zwischenbehälter für Vakuumtoilette |

| ATE390525T1 (de) | 2001-01-26 | 2008-04-15 | Geberit Technik Ag | Toilettenanlage mit einer toilettenschüssel |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1566133A (de) * | 1968-05-29 | 1969-05-02 | ||

| FI55550C (fi) * | 1973-12-29 | 1979-08-10 | Waertsilae Oy Ab | Vakuumavloppssystem |

-

1996

- 1996-05-08 IT IT96PG000013A patent/IT1295231B1/it active IP Right Grant

-

1997

- 1997-04-24 EP EP97106779A patent/EP0806527B1/de not_active Expired - Lifetime

- 1997-04-24 AT AT97106779T patent/ATE224486T1/de not_active IP Right Cessation

- 1997-04-24 ES ES97106779T patent/ES2184001T3/es not_active Expired - Lifetime

- 1997-04-24 DE DE69715507T patent/DE69715507T2/de not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ES2184001T3 (es) | 2003-04-01 |

| ATE224486T1 (de) | 2002-10-15 |

| IT1295231B1 (it) | 1999-05-04 |

| EP0806527A3 (de) | 1998-08-12 |

| DE69715507T2 (de) | 2003-05-22 |

| DE69715507D1 (de) | 2002-10-24 |

| EP0806527A2 (de) | 1997-11-12 |

| ITPG960013A1 (it) | 1997-11-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100327630B1 (ko) | 이동식진공변기시스템 | |

| US4125124A (en) | Sequencing valve | |

| KR0173500B1 (ko) | 진공식 양변기 시스템과 이것의 배출밸브 | |

| CN102656003A (zh) | 用于吹气模制阀块的吹气模制阀门 | |

| US4499921A (en) | Three-way air valve | |

| CA2484022A1 (en) | Valve seat for piston-type flushometer | |

| JP2012087936A (ja) | 高圧空気パルスを制御するための弁 | |

| SK164697A3 (en) | Method of controlling the function of a centrifugal pump and vacuum pump combination, and a gas-separating centrifugal pump | |

| EP0806527B1 (de) | Eine mit Druckluft bediente Abflussvorrichtung für Sanitäranlagen | |

| US4951702A (en) | Bidet valve | |

| US5038814A (en) | Back flow preventer and integral vacuum breaker | |

| US6171495B1 (en) | Automatic three-way valve | |

| CN218094556U (zh) | 一种新型的气动旋套式阀门装置 | |

| CN1754056A (zh) | 气囊阀 | |

| JPH07269739A (ja) | 弁組立体 | |

| JP2002180515A (ja) | 水洗便器の容積制御 | |

| KR200204010Y1 (ko) | 공기압을 이용한 슬러지 배출장치 | |

| JP4307117B2 (ja) | 管路の空気抜き装置 | |

| JPH0560253A (ja) | スピードコントローラ | |

| US20030150516A1 (en) | Arrangement in connection with circulation lubrication system | |

| JPH0668355B2 (ja) | バルブ付スチームトラップ | |

| JPS5830151Y2 (ja) | 給油ポンプの吐出部の構造 | |

| CN104007446B (zh) | 一种共形结构气路防回流吹扫装置 | |

| JP2022128877A (ja) | 弁装置の弁体作動機構 | |

| JP2884033B2 (ja) | 真空弁マス内仕切弁 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19990122 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SANYGEN S.R.L. |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: DR. ING. A. RACHELI & C. |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TECNOLOGIE FERROVIARIE S.R.L. |

|

| 17Q | First examination report despatched |

Effective date: 20010220 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: PRODUCTION S.R.L. |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020918 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 |

|

| REF | Corresponds to: |

Ref document number: 224486 Country of ref document: AT Date of ref document: 20021015 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69715507 Country of ref document: DE Date of ref document: 20021024 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: PRODUCTION S.P.A. |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2184001 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030424 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030424 |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030619 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060430 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070508 Year of fee payment: 11 Ref country code: DE Payment date: 20070508 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081101 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20080425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070424 |