EP0806527B1 - A forced discharge compressed-air operated device for sanitary fixtures - Google Patents

A forced discharge compressed-air operated device for sanitary fixtures Download PDFInfo

- Publication number

- EP0806527B1 EP0806527B1 EP97106779A EP97106779A EP0806527B1 EP 0806527 B1 EP0806527 B1 EP 0806527B1 EP 97106779 A EP97106779 A EP 97106779A EP 97106779 A EP97106779 A EP 97106779A EP 0806527 B1 EP0806527 B1 EP 0806527B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- duct

- chamber

- piston

- cup

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03F—SEWERS; CESSPOOLS

- E03F1/00—Methods, systems, or installations for draining-off sewage or storm water

- E03F1/006—Pneumatic sewage disposal systems; accessories specially adapted therefore

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D5/00—Special constructions of flushing devices, e.g. closed flushing system

Definitions

- the invention refers to the field of forced discharge sanitary fixtures, as are widely used, for example, on means of transport such as ships, airplanes or trains.

- FR-A-1566133 discloses a forced discharge device for feeding concrete, comprising a body defining an inner chamber, an inlet and an outlet, a hollow cup-shaped shutting element movable between an extended closure position and a retracted opening position, a piston element including a stem, a working head, a drive head, said piston element being axially slidable in the cup-shaped shutting element, driven by the respective working head.

- the document does not disclose any means for operating the piston element'drive head, nor the possibility to apply a vacuum to facilitate entry of the material (concrete) in the inner chamber.

- the arrangement shown in the drawings and described would not be suitable for use in sanitary fixtures due to unavoidable overall dimensions and insufficient sealing.

- An aim of the present invention is to exclude the possibility of accidents due to dangerous backflow that might involve the user.

- a further aim is to eliminate or drastically reduce the possibility of damage to the sanitary fixtures or downtime thereof.

- a further aim is to achieve the above advantages with reduced water consumption and moderate power consumption.

- a further aim is to provide such devices that can also be adapted to foldaway fixtures.

- the new device comprises a body that can be mounted on the sanitary fixture, the body being provided with an inlet opening for entry of wastewater and an outlet opening for discharge thereof and defining an inner chamber in which a cup-shaped shutting element can move between an extended position, in which it shuts the inlet opening, and a retracted position in which it leaves said opening free, a distributor element, being fixed to the body, or fixed to a cover thereof, provided with input and output ducts for a fluid, generally compressed air, and further comprises a twin piston element, movable inside the cup-shaped element between an extended position (with the cup-element extended) and a retracted position.

- the new device achieves the above aims, and in particular it eliminates the possibility of backflow of expelled wastewater, it provides for a perfect separation, in a closed position, between the discharge network and the sanitary fixture; it can be adapted not only to fixed sanitary fixtures but also to foldaway sanitary fixtures; it requires reduced water consumption and reduced power consumption: its operation is efficient and reliable even in situations where the waste pipe has a very small section or an upward, long or winding course.

- a forced discharge device is indicated as a whole by reference number 10 and comprises a hollow body 11, generally but not necessarily cylindrical, that has an inlet opening 12 to let wastewater in and an outlet opening 13 to let wastewater out.

- a cup shaped element indicated as a whole by reference number 14 can slide axially (in a direction defined by the x axis of the body).

- a twin piston element indicated as a whole by 15 can slide axially inside and with respect to the cup-shaped element 14.

- a distributor element 16 is fixed with respect to the body 11 and more precisely is supported by a cover 18 fixed to the body 11.

- the body 11 is formed with an internal a chamber 21, in which said inlet opening 12 opens. This opening is made in the side wall of body 11.

- the body 11 also has a lower flange 22 for attachment of an outlet part 23, in which said outlet opening 13 opens.

- the body 11 also has an upper flange 24 on which said cover 18 is screwed.

- the coupling and fixing screws are not drawn but simply indicated with their axes drawn with dashed and dotted lines.

- the body 11 has an internal seat for an O-ring or sealing ring 26, whilst the part 23 itself has a seat for an abutment ring 25, thus allowing the cup-shaped shutting element 14 to seal the chamber 21 tightly.

- the cup-shaped shutting element 14 has a cylindrical skirt part 28, of a suitable size and shape to be able to slide inside the chamber 21 of the body, and an upper (in fig. 1) flange part 30, extending inside from the skirt part.

- the skirt part is preferably thinner at one end 31; at the opposite end it has a seat 32 opening towards the outside for an O-ring 33, and a seat 34, facing inwards, for an O-ring 35.

- the fixed distributor element 16 comprises a cylindrical portion 36, from which a lower (in fig. 1) plate portion 38 extends; it has a circumferential peripheral seat 40 for an O-ring 41 to provide a seal against the inner surface of the cup-shaped element 14 and a through hole 39 with seats for O-rings 42, 42, for a stem of piston 15.

- the cylindrical portion of distributor 16 has a plurality of ducts for an operating fluid, said ducts being circumferentially spaced apart and referenced respectively a , b , c and d as can be seen in the plan view in Figure 2.

- the operating fluid is preferably compressed air, supplied by a compressor or a special supply system (not illustrated).

- the ducts a , b , c and d have a threaded mouthpiece for connection to said supply system, by means of solenoid valves or opening and closing devices managed by an electronic, electrical or mechanical means.

- the duct a which can also be seen in Figure 3, extends with its axis parallel to the axis of the device and ends in the vicinity of plate 38 in a radial passage towards the outside, indicated by a ', which opens into an annular chamber 45 defined between the distributor 16 and the cup-shaped element 14.

- the duct b which can also be seen in Figure 5, has a limited axial extension and opens outwards radially at the top into the annular chamber 43 through a hole b' defined between the cup-shaped element 30 and the cover 18.

- the duct c which can also be seen in Figure 1, extends in an axial direction, has a radial opening c' in a chamber 46 between the cover and the piston and an end opening c " in the outermost surface of the distributor, facing the piston 15; that is to say, the opening c" opens into a chamber 47 defined between plate 38 and piston 15.

- the duct d which can also be seen in Figure 4, extends in an axial direction and has a radial opening d' at an end near the plate 38, facing towards the chamber 44 of the distributor (that is, with the device assembled, towards the chamber defined between the distributor and the piston).

- the piston 15 comprises a stem 51, a working head 52, a drive head 53 all integral with each other.

- the working head 52 slides inside the cup 14, forming a seal with O-ring 48; 49 is a stop on the cup.

- a seal is formed by the O-rings 42.

- the drive head slides along the inside wall of the distributor, a seal being formed by the upper O-ring 54 accommodated in the head 53.

- An axial duct for compressed air is defined inside the stem 51 and this duct is indicated as a whole by the letter e .

- a check valve 56 is situated on the bottom of the duct and indicated schematically by a spring-loaded ball.

- the forced discharge device is mounted downstream of the bowl of a sanitary fixture as can be seen in Figure 6 or in Figures 7 and 8.

- the sanitary fixture is indicated with the reference number 60 and is of a traditional type.

- the device 10 is mounted with the longitudinal axis x lying horizontally, with the opening 12 at the outlet of the bowl and the opening 13 connected to a per se known rotary exhaust valve 58 which will therefore not be described in detail.

- the sanitary fixture of Figures 7 and 8 is a tip-up foldaway fixture, which is shown in the position of use in Figure 7.

- the device 10 is mounted with the x axis vertical and the opening 12 at the opening of the bowl of the sanitary fixture 70.

- the device 10 is shown tipped with the sanitary fixture in the resting position.

- a vacuum is created in the chamber 21.

- Compressed air is then introduced through the duct a of the distributor and the opening a ' between the plate part 38 of the distributor and the flange 30 of the cup (Fig. 10).

- the distributor At the end of its stroke, the distributor is therefore in the position shown in Figure 11, with the cup-shaped shutting element completely retracted so as to free the opening 12.

- the wastewater can fill the chamber 21.

- Compressed air is then introduced through the duct b at the same time allowing air to evacuate through the duct a .

- the cup-shaped element 14 is thus again pushed into the extended position in Fig. 12, shutting the inlet opening 12 and preventing any return of wastewater or odors through the sanitary fixture.

- Compressed air may be introduced through the duct e at this stage to facilitate evacuation of the wastewater.

- the cycle is ended, and in any case can be repeated, on the basis of a programmable logic, until the wastewater has been completely evacuated.

Landscapes

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Aviation & Aerospace Engineering (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

- Nozzles (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Vehicle Waterproofing, Decoration, And Sanitation Devices (AREA)

- Self-Closing Valves And Venting Or Aerating Valves (AREA)

- Toys (AREA)

- Apparatus For Radiation Diagnosis (AREA)

- Compressor (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

Abstract

Description

- The invention refers to the field of forced discharge sanitary fixtures, as are widely used, for example, on means of transport such as ships, airplanes or trains.

- It is known that motorized systems, for evacuation of wastewater from sanitary fixtures for instance, have considerable drawbacks. For example, known systems that use a rotor are subject to breakage thereof when a hard object such as a fruit stone is accidentally thrown into the fixture.

- FR-A-1566133 discloses a forced discharge device for feeding concrete, comprising a body defining an inner chamber, an inlet and an outlet, a hollow cup-shaped shutting element movable between an extended closure position and a retracted opening position, a piston element including a stem, a working head, a drive head, said piston element being axially slidable in the cup-shaped shutting element, driven by the respective working head. The document does not disclose any means for operating the piston element'drive head, nor the possibility to apply a vacuum to facilitate entry of the material (concrete) in the inner chamber. Furthermore, the arrangement shown in the drawings and described would not be suitable for use in sanitary fixtures due to unavoidable overall dimensions and insufficient sealing.

- The vacuum systems currently in use in the sanitary field, which have been used for a long time in the shipping sector and more recently in the rail sector, have the drawback that reverse flow may occur when they are accidentally subjected to changes in the pressure situation.

- An aim of the present invention is to exclude the possibility of accidents due to dangerous backflow that might involve the user. A further aim is to eliminate or drastically reduce the possibility of damage to the sanitary fixtures or downtime thereof.

- A further aim is to achieve the above advantages with reduced water consumption and moderate power consumption.

- A further aim is to provide such devices that can also be adapted to foldaway fixtures.

- The above aims have been achieved with a device as stated in

claim 1. Further characteristics of the device are stated in the subsequent claims. - In other words, the new device comprises a body that can be mounted on the sanitary fixture, the body being provided with an inlet opening for entry of wastewater and an outlet opening for discharge thereof and defining an inner chamber in which a cup-shaped shutting element can move between an extended position, in which it shuts the inlet opening, and a retracted position in which it leaves said opening free, a distributor element, being fixed to the body, or fixed to a cover thereof, provided with input and output ducts for a fluid, generally compressed air, and further comprises a twin piston element, movable inside the cup-shaped element between an extended position (with the cup-element extended) and a retracted position.

- The new device achieves the above aims, and in particular it eliminates the possibility of backflow of expelled wastewater, it provides for a perfect separation, in a closed position, between the discharge network and the sanitary fixture; it can be adapted not only to fixed sanitary fixtures but also to foldaway sanitary fixtures; it requires reduced water consumption and reduced power consumption: its operation is efficient and reliable even in situations where the waste pipe has a very small section or an upward, long or winding course.

- An exemplary unrestrictive embodiment of the invention will be described below with reference to the appended drawings, in which:

- Figure 1 is an axial sectional view of the device according to the invention in a first embodiment; the plane of the sectional view is indicated by 1-1 in Figure 2;

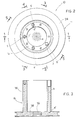

- Figure 2 is a top plan view of the device in Figure 1, with the cover removed to show underlying parts;

- Figure 3 is an axial sectional of the distributor element of the device alone, taken along a plane indicated by line 3-3 in Figure 2;

- Figure 4 is an axial sectional view of the distributor alone, taken along a plane indicated by line 4-4 in Figure 2;

- Figure 5 is an axial sectional view of the distributor alone, taken along the plane indicated by line 5-5 in Figure 2;

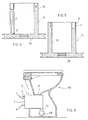

- Figure 6 shows the device fitted to a sanitary fixture of a traditional type;

- Figure 7 shows the device fitted to a tip-up foldaway sanitary fixture shown positioned for use;

- Figure 8 shows the fixture in Figure 7 in a raised idle position;

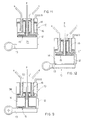

- Figures 9 to 12 are schematic pictures of the device, shown in various purely illustrative sectional views, which show four stages of operation of the forced discharge device.

-

- With reference first to Figures 1 to 5, a forced discharge device is indicated as a whole by

reference number 10 and comprises ahollow body 11, generally but not necessarily cylindrical, that has an inlet opening 12 to let wastewater in and an outlet opening 13 to let wastewater out. Inside the body 11 a cup shaped element indicated as a whole byreference number 14 can slide axially (in a direction defined by the x axis of the body). A twin piston element indicated as a whole by 15 can slide axially inside and with respect to the cup-shaped element 14. Adistributor element 16 is fixed with respect to thebody 11 and more precisely is supported by acover 18 fixed to thebody 11. - The above elements will now be described in detail.

- The

body 11 is formed with an internal achamber 21, in which said inlet opening 12 opens. This opening is made in the side wall ofbody 11. Thebody 11 also has alower flange 22 for attachment of anoutlet part 23, in which said outlet opening 13 opens. Thebody 11 also has anupper flange 24 on which saidcover 18 is screwed. The coupling and fixing screws are not drawn but simply indicated with their axes drawn with dashed and dotted lines. - At an end thereof towards

part 23, thebody 11 has an internal seat for an O-ring or sealingring 26, whilst thepart 23 itself has a seat for anabutment ring 25, thus allowing the cup-shaped shutting element 14 to seal thechamber 21 tightly. - The cup-

shaped shutting element 14 has acylindrical skirt part 28, of a suitable size and shape to be able to slide inside thechamber 21 of the body, and an upper (in fig. 1)flange part 30, extending inside from the skirt part. The skirt part is preferably thinner at oneend 31; at the opposite end it has aseat 32 opening towards the outside for an O-ring 33, and aseat 34, facing inwards, for an O-ring 35. - The

fixed distributor element 16 comprises acylindrical portion 36, from which a lower (in fig. 1)plate portion 38 extends; it has a circumferentialperipheral seat 40 for an O-ring 41 to provide a seal against the inner surface of the cup-shaped element 14 and a throughhole 39 with seats for O-rings piston 15. The cylindrical portion ofdistributor 16 has a plurality of ducts for an operating fluid, said ducts being circumferentially spaced apart and referenced respectively a, b, c and d as can be seen in the plan view in Figure 2. The operating fluid is preferably compressed air, supplied by a compressor or a special supply system (not illustrated). The ducts a, b, c and d have a threaded mouthpiece for connection to said supply system, by means of solenoid valves or opening and closing devices managed by an electronic, electrical or mechanical means. - The duct a, which can also be seen in Figure 3, extends with its axis parallel to the axis of the device and ends in the vicinity of

plate 38 in a radial passage towards the outside, indicated by a', which opens into anannular chamber 45 defined between thedistributor 16 and the cup-shaped element 14. - The duct b, which can also be seen in Figure 5, has a limited axial extension and opens outwards radially at the top into the

annular chamber 43 through a hole b' defined between the cup-shaped element 30 and thecover 18. - The duct c, which can also be seen in Figure 1, extends in an axial direction, has a radial opening c' in a

chamber 46 between the cover and the piston and an end opening c" in the outermost surface of the distributor, facing thepiston 15; that is to say, the opening c" opens into achamber 47 defined betweenplate 38 andpiston 15. - The duct d, which can also be seen in Figure 4, extends in an axial direction and has a radial opening d' at an end near the

plate 38, facing towards thechamber 44 of the distributor (that is, with the device assembled, towards the chamber defined between the distributor and the piston). - The

piston 15 comprises astem 51, a workinghead 52, adrive head 53 all integral with each other. The workinghead 52 slides inside thecup 14, forming a seal with O-ring 48; 49 is a stop on the cup. As the stem slides inside theplate 38 of the distributor, a seal is formed by the O-rings 42. The drive head slides along the inside wall of the distributor, a seal being formed by the upper O-ring 54 accommodated in thehead 53. An axial duct for compressed air is defined inside thestem 51 and this duct is indicated as a whole by the letter e. Acheck valve 56 is situated on the bottom of the duct and indicated schematically by a spring-loaded ball. - The forced discharge device is mounted downstream of the bowl of a sanitary fixture as can be seen in Figure 6 or in Figures 7 and 8. In Figure 6, the sanitary fixture is indicated with the

reference number 60 and is of a traditional type. Thedevice 10 is mounted with the longitudinal axis x lying horizontally, with theopening 12 at the outlet of the bowl and theopening 13 connected to a per se knownrotary exhaust valve 58 which will therefore not be described in detail. - The sanitary fixture of Figures 7 and 8 is a tip-up foldaway fixture, which is shown in the position of use in Figure 7. The

device 10 is mounted with the x axis vertical and theopening 12 at the opening of the bowl of thesanitary fixture 70. In figure 8 thedevice 10 is shown tipped with the sanitary fixture in the resting position. - With reference now to Figures 9 to 12 various stages of operation of the device will be described.

- At rest (Figure 9) the cup-

shaped shutting element 14 is in a fully extended position, so that it completely covers the inlet opening 12, thus closing it tightly, that is to say forming a seal on O-ring 26, on O-ring 33 and on theabutment ring 25. - When the

device 10 starts to operate (Fig. 9), compressed air is introduced through the duct d of the distributor and the opening d', between theplate part 38 of the distributor and thedrive head 53 of the piston. Since theplate part 38 is fixed, thehead 53 and thewhole piston 15 rise, expelling air through the openings c' and c" and the duct c (Fig. 12). - A vacuum is created in the

chamber 21. - Compressed air is then introduced through the duct a of the distributor and the opening a' between the

plate part 38 of the distributor and theflange 30 of the cup (Fig. 10). - Since the

plate part 38 is fixed, theflange 30 and thewhole cup 14 rise, expelling air through opening b' and duct b (which for simplicity's sake has been indicated in the scheme of Figures 9 to 12 as being connected directly to the body rather than made in the distributor, as is actually the case (Fig. 5)). - At the end of its stroke, the distributor is therefore in the position shown in Figure 11, with the cup-shaped shutting element completely retracted so as to free the

opening 12. - Through it, the wastewater can fill the

chamber 21. - Compressed air is then introduced through the duct b at the same time allowing air to evacuate through the duct a. The cup-shaped

element 14 is thus again pushed into the extended position in Fig. 12, shutting theinlet opening 12 and preventing any return of wastewater or odors through the sanitary fixture. - At this point the

piston 15 enters into operation and is pushed into the extended state (Fig. 9) to expel the wastewater through thedischarge opening 13. Operation of thepiston 15 is carried out by introducing compressed air through the duct c and the openings c' and c" (Fig. 12), so as to act simultaneously on the upper surfaces of the larger working head and of the smaller drive head ofpiston 15. - Compressed air may be introduced through the duct e at this stage to facilitate evacuation of the wastewater.

- The cycle is ended, and in any case can be repeated, on the basis of a programmable logic, until the wastewater has been completely evacuated.

- It will be understood that in this way a functional and efficient device has been provided to close the wastewater inflow opening completely and prevent any return of wastewater and odours.

Claims (9)

- A forced discharge device for sanitary fixtures comprisingcharacterised in that it further comprisesa body (11)defining an inner body chamber (21), an inlet opening (12) and an outlet opening (13),a hollow cup-shaped shutting element (14) axially slidable in said body chamber between an extended position in which it closes said inlet opening and a retracted position in which it leaves said inlet opening at least partly free,a piston element (15) including a stem (51), a working head (52), a drive head (53) integral to each other, said piston element being axially slidable with respect to said cup-shaped shutting element (14)further comprising a plurality of ducts (a, b, c, d) for an operating fluid in said distributor element (16), said operating fluid being for sliding said shutting element (14) between an extended position and a retracted position and for sliding said piston element (15) between an extended position and a retracted position.a distributor element (16) fixed with respect to the body (11) and comprising a plate portion (38) positioned between said working head and said driving head of the piston element, said distributor element (16) being in sealing engagement with said shutting element (14) and said piston element (15) and defining an annular chamber (45)with said shutting element (14), a distributor chamber (44) with the piston element (15), a further annular chamber (47) with the piston element and a further chamber (43) with the shutter element (14)

- A device according to claim 1, characterised in that it comprises an additional duct (e) for an evacuation fluid in the piston stem, said additional duct having an opening to body chamber (21).

- A device as said in claim 2, wherein said additional duct (e) comprises a check valve (56).

- A device according to claim 1, wherein said distributor is fixed to a body cover (18).

- A device according to claim 1, characterised in that said ducts for an operating or driving fluid comprisea first duct (a) extending between a duct end and said annular chamber (45) for supplying operating fluid for driving said cup shaped element (14) to its retracted positiona second duct (b) extending between a duct end and said further chamber (43) for supplying operating fluid for driving cup-shaped element (14) to its extended positiona third duct (c) extending between a duct end and said further chamber (47) for supplying operating fluid for driving the said piston element to the extended position -a fourth duct (d) extending between a duct end and said distribution chamber (44) for supplying operating fluid for driving the piston element to the retracted position.

- A device according to claim 1, wherein the operating fluid is compressed air.

- A device according to claim 1, that can be mounted on fixed sanitary fixtures or tip-up foldaway sanitary fixtures.

- A device as said in claim 1, wherein

said duct (a) has a radial opening (a') in the vicinity of the distributor plate portion (38) for acting on a surface of the cup-shaped element which is part of annular chamber (45)

said duct (b) has an opening (b') at a position near the body cover (18)

said duct (c) has openings (c', c") to act on surfaces of the piston heads (52,53)

said duct (d) has an opening (d') in the vicinity of the distributor plate and facing toward the piston stem (51) for acting on a surface of the piston head (53) which is part of chamber (44). - A device as said in claim 5 characterised in that vacuum is created in internal chamber (21) of the body when said piston element is moved to its retracted position; cup-shaped element (14) is in its extended position wherein it obstructs inlet opening (12) and rotary exhaust valve (58) connected to opening (13) is closed.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITPG960013 | 1996-05-08 | ||

| IT96PG000013A IT1295231B1 (en) | 1996-05-08 | 1996-05-08 | FORCED FLUSH SYSTEM PREFERRED FOR WC AND SIMILAR, WORKING WITH COMPRESSED AIR, ALSO SUITABLE FOR CONCEALED SWIVEL TOILETS |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0806527A2 EP0806527A2 (en) | 1997-11-12 |

| EP0806527A3 EP0806527A3 (en) | 1998-08-12 |

| EP0806527B1 true EP0806527B1 (en) | 2002-09-18 |

Family

ID=11393418

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97106779A Expired - Lifetime EP0806527B1 (en) | 1996-05-08 | 1997-04-24 | A forced discharge compressed-air operated device for sanitary fixtures |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0806527B1 (en) |

| AT (1) | ATE224486T1 (en) |

| DE (1) | DE69715507T2 (en) |

| ES (1) | ES2184001T3 (en) |

| IT (1) | IT1295231B1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20000515U1 (en) * | 2000-01-14 | 2000-05-04 | Sanivac Vakuumtechnik GmbH, 22880 Wedel | Intermediate container for vacuum toilet |

| WO2002059432A1 (en) | 2001-01-26 | 2002-08-01 | Geberit Technik Ag | Toilet system with a toilet pan |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1566133A (en) * | 1968-05-29 | 1969-05-02 | ||

| FI55550C (en) * | 1973-12-29 | 1979-08-10 | Waertsilae Oy Ab | VAKUUMAVLOPPSSYSTEM |

-

1996

- 1996-05-08 IT IT96PG000013A patent/IT1295231B1/en active IP Right Grant

-

1997

- 1997-04-24 EP EP97106779A patent/EP0806527B1/en not_active Expired - Lifetime

- 1997-04-24 AT AT97106779T patent/ATE224486T1/en not_active IP Right Cessation

- 1997-04-24 DE DE69715507T patent/DE69715507T2/en not_active Expired - Fee Related

- 1997-04-24 ES ES97106779T patent/ES2184001T3/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ES2184001T3 (en) | 2003-04-01 |

| DE69715507D1 (en) | 2002-10-24 |

| ATE224486T1 (en) | 2002-10-15 |

| EP0806527A2 (en) | 1997-11-12 |

| EP0806527A3 (en) | 1998-08-12 |

| IT1295231B1 (en) | 1999-05-04 |

| DE69715507T2 (en) | 2003-05-22 |

| ITPG960013A1 (en) | 1997-11-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100327630B1 (en) | Portable Vacuum Toilet System | |

| KR890001017B1 (en) | Four-way poppet valve | |

| KR0173500B1 (en) | Vacuum toilet system and discharge valve thereof | |

| JP5266052B2 (en) | Valve for controlling high-pressure air pulse | |

| EP0806527B1 (en) | A forced discharge compressed-air operated device for sanitary fixtures | |

| CA2484022A1 (en) | Valve seat for piston-type flushometer | |

| US4951702A (en) | Bidet valve | |

| SK164697A3 (en) | Method of controlling the function of a centrifugal pump and vacuum pump combination, and a gas-separating centrifugal pump | |

| US6761183B1 (en) | Back flow preventing adjustable valve apparatus with fluid escape | |

| JPH07269739A (en) | Valve assembly | |

| JP2002180515A (en) | Volume control of flushing stool | |

| JP4307117B2 (en) | Pipeline venting device | |

| US20030150516A1 (en) | Arrangement in connection with circulation lubrication system | |

| CN218094556U (en) | Novel pneumatic rotary sleeve type valve device | |

| JPH0560253A (en) | Speed controller | |

| KR102208930B1 (en) | Automatic valve for draining dondensed water | |

| JPH0668355B2 (en) | Steam trap with valve | |

| JPS5830151Y2 (en) | Structure of oil pump discharge part | |

| CN116517091A (en) | Drainage device and drainage pipeline system | |

| CN104007446B (en) | A kind of conformal structure gas circuit anti-return blow device | |

| KR200303275Y1 (en) | valve | |

| JP2884033B2 (en) | Gate valve in vacuum valve mass | |

| KR0136788Y1 (en) | Air-driver pump | |

| JP2001141087A (en) | Flush valve | |

| JPH093985A (en) | Device for connecting piping of city water equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19990122 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SANYGEN S.R.L. |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: DR. ING. A. RACHELI & C. |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TECNOLOGIE FERROVIARIE S.R.L. |

|

| 17Q | First examination report despatched |

Effective date: 20010220 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: PRODUCTION S.R.L. |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: LI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020918 Ref country code: CH Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020918 |

|

| REF | Corresponds to: |

Ref document number: 224486 Country of ref document: AT Date of ref document: 20021015 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 69715507 Country of ref document: DE Date of ref document: 20021024 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: PRODUCTION S.P.A. |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2184001 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030424 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030424 |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030619 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060430 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070508 Year of fee payment: 11 Ref country code: DE Payment date: 20070508 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081101 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20080425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070424 |