EP0765680A1 - Element and device for holding a boot on a surf-board - Google Patents

Element and device for holding a boot on a surf-board Download PDFInfo

- Publication number

- EP0765680A1 EP0765680A1 EP96112650A EP96112650A EP0765680A1 EP 0765680 A1 EP0765680 A1 EP 0765680A1 EP 96112650 A EP96112650 A EP 96112650A EP 96112650 A EP96112650 A EP 96112650A EP 0765680 A1 EP0765680 A1 EP 0765680A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shoe

- slide

- movable

- jaw

- element according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C7/00—Devices preventing skis from slipping back; Ski-stoppers or ski-brakes

- A63C7/10—Hinged stoppage blades attachable to the skis in such manner that these blades can be moved out of the operative position

- A63C7/1006—Ski-stoppers

- A63C7/1013—Ski-stoppers actuated by the boot

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/003—Non-swivel sole plate fixed on the ski

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/08—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings

- A63C9/085—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable

- A63C9/08507—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable with a plurality of mobile jaws

- A63C9/08521—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable with a plurality of mobile jaws pivoting about a vertical axis, e.g. side release

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/08—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings

- A63C9/085—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable

- A63C9/08535—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable with a mobile body or base or single jaw

- A63C9/08542—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable with a mobile body or base or single jaw pivoting about a transversal axis

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/08—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings

- A63C9/085—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with sole hold-downs, e.g. swingable

- A63C9/08557—Details of the release mechanism

- A63C9/08564—Details of the release mechanism using cam or slide surface

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/005—Ski bindings with means for adjusting the position of a shoe holder or of the complete binding relative to the ski

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/08—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings

- A63C9/0805—Adjustment of the toe or heel holders; Indicators therefor

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/08—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings

- A63C9/084—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with heel hold-downs, e.g. swingable

- A63C9/0841—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with heel hold-downs, e.g. swingable with a single jaw

- A63C9/0842—Ski bindings yieldable or self-releasing in the event of an accident, i.e. safety bindings with heel hold-downs, e.g. swingable with a single jaw the jaw pivoting on the body or base about a transverse axis

Definitions

- the invention relates to a shoe retaining element on a gliding board, in particular on an alpine ski.

- the invention also relates to an assembly for retaining a boot on a gliding board, in particular an alpine ski.

- the invention relates to a fixing assembly intended to retain a boot bearing on a ski.

- Each retaining element generally has a jaw carried by a body, the body being connected to the ski by a base.

- the jaw is movable between a position where it retains the shoe, and a position where it allows the release of the shoe.

- An elastic return mechanism generally constituted by a compression spring, opposes a force of resistance to the movement of the jaw.

- the resistance force is determined by the stiffness of the spring, as well as by an adjustment means, usually a screw or a threaded plug, which makes it possible to adjust the initial compression of the spring.

- the adjusting means usually makes it possible to adjust the hardness of the fastening element on a hardness scale which is defined by the nature of the spring. The hardness is significant of the effort that the shoe must overcome to be released.

- the problem posed by the invention is to improve the operation of the existing retaining elements.

- the invention proposes to adapt, during skiing, the hardness of the binding element to the conditions of use of the binding element.

- Another object of the invention is to propose a device which adapts the hardness of the fastening element, the effect of which is neutralized under certain circumstances, in particular in certain configurations of falls.

- Another object of the invention is to propose a binding assembly which has an action on the pressure distribution of the ski on the snow.

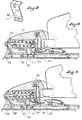

- Figure 1 is a general side view of a set of fasteners implementing the invention.

- Figure 2 is a partial top view of the assembly of Figure 1.

- FIG. 3 is a side view in section of the front fixing element of FIG. 1.

- FIG. 4 represents in top view and in two half-sections along different planes the fixing element of FIG. 3.

- Figure 5 is a view similar to Figure 1, in the presence of the shoe.

- Figure 6 shows in side view and in partial section the assembly of Figure 1 at the rear fixing element.

- FIG. 7 is a front view of a component of the fixing element shown in FIG. 3.

- Figure 8 is a view similar to Figure 1, and illustrates the mode of operation of the device.

- Figure 9 is a view similar to Figures 1 and 8 and illustrates another phase of operation of the device.

- Figure 10 shows an alternative embodiment of the device of the invention.

- FIG 11 shows schematically another alternative embodiment of the invention.

- FIG. 1 represents the middle part of a ski which is equipped with a set of fastening elements comprising a front retaining element and a rear retaining element, and an intermediate connection between the two elements.

- the front fixing element 1 represented in the embodiment of FIGS. 1 to 6 is essentially known from the French patent application published under the number FR 2 640 516.

- the base has a "U" shape open towards the rear, with two lateral branches 3a and 3b.

- the body is movable vertically relative to the base, for example by a deformable link, located in zone 9 at the junction between the body and the base.

- the body and the base are connected continuously by this deformable zone and form a one-piece element.

- the body has in its lower part a centering stud 2a, which is designed to be engaged between the two branches 3a and 3b of the base.

- the body 2 carries a jaw 4 for retaining the front end of the shoe.

- the jaw 4 comprises two lateral retaining wings 5 and 6, respectively articulated to the body 2 around axes 7 and 8.

- the jaw 4 also includes a sole clamp 12 for vertical retention of the shoe.

- the wings 5 and 6 are movable in response to the stresses of the shoe, against the restoring force applied to them by a spring 15.

- the spring 15 is housed in the body. It actuates a piston 16 also housed and guided in the body for a longitudinal translational movement.

- the figures show that the piston is housed and guided in a housing 17 of the body, and that the spring is engaged inside the piston. Its front end bears against the bottom of the piston, located on the front side of the fixing element.

- a screw 20, the head of which is retained at the front of the body moreover passes through the piston and the spring, and has a nut 21 towards the rear which retains the rear end of the spring. A rotation of the screw moves the rear end of the spring 15, which makes it possible to adjust the initial compression of the spring.

- the wings 5 and 6 have, beyond their axis of articulation to the body 7 and 8, a small arm 5a, 6a, which drives the piston 16 towards the rear, bearing against a shoulder 23 situated in the upper rear part of the piston 16.

- the fastening element 1 also comprises a support device for the front end of the shoe sole.

- the support device has a support plate 25 on which the shoe sole rests.

- the plate 25 can be equipped in its upper part with any suitable coating intended to facilitate lateral sliding of the shoe, for example a PTFE (polytetrafluoroethylene) plate. It has a width which is of the order of the width of the ski at this level.

- the plate 25 is articulated around a transverse axis 26, which is carried by a bearing secured to the base 3 or connected integrally to the ski.

- the element 1 shown in the embodiment of FIGS. 1 to 7 also has a compensation mechanism which alleviates the restoring force that the spring 15 exerts on the wings 5 and 6.

- This mechanism comprises a rocker 30 which is partly housed between the branches 3a and 3b of the base 3.

- the rocker is articulated around an axis 32 carried by these branches.

- the rocker 30 has an approximately horizontal wing 33 which is accessible on the rear of the fixing element between the branches 3a and 3b of the base.

- the front of the plate 25 is designed to be able to rest on the end of the branch 33.

- the rocker 30 also has an approximately vertical arm formed by two lateral pads which pass on each side of the piston 16, and which each carry on a shoulder 37 which the piston presents under the shoulder 23 of the wings. Only the shoe 35 is visible in FIGS. 4 and 5.

- a spring 38 recalls the plate 25 in a rest position which places its front end above the wing 33 of the rocker. When the shoe is engaged, the plate is lowered until it comes into contact with the branch 33. An automatic adaptation of the fastening element to the thickness of the shoe sole is thus achieved.

- the rocker has dimensions such that a vertical downward force exerted on its branch 33 is transmitted to the piston 16 in the form of a rearward stress, that is to say in the same direction as the stresses from the wings.

- the rearward movement of the piston 17 is accompanied by a rotation of the rocker 30 about the axis 32.

- the stress transmitted by the rocker to the piston 17 decreases the force as much as one of the wings must itself even exercise on the piston to move it enough back so that the opening of the wing allows the release of the wing.

- This mechanism compensates for the increase in friction between the shoe sole and the support plate 26 in the event of a front fall.

- a connecting rod 39 also connects the rocker, in front of the axis 32, to the upper part of the body.

- the body 2 rises by deformation of the zone 9. This movement is transmitted to the rocker by the link 39.

- This causes a stress on the piston which goes in the same direction as the previous stress. . This compensates for the increase in friction between the shoe and the sole clamp. If the stress on the sole is strong enough, the sole clamp lets the shoe sole escape upwards.

- the construction of the fixing element in itself is not limiting. It shows a mode of construction of the fastening element with which the present invention is compatible. Other constructions are suitable, in particular other simplified constructions.

- the assembly shown in FIG. 1 also has a rear retaining element 40.

- This element is of a known type. It has in particular a movable jaw 41 carried by a body 42. In a manner also known, the body 42 is movable along a slide 43.

- the fastening assembly also has a support plate 44 for the rear of the shoe sole which is located in front of the slide 43.

- the device according to the invention has a feeler capable of picking up stresses on the shoe.

- connection is intended to increase the restoring force that the spring opposes to the opening of a wing with the intensity of the stress picked up by the probe.

- the probe is the support plate 44 located at the front of the slide 43.

- the connection between the probe and the front element comprises a plate 46, the front end of which is connected to the front fixing element, and the rear end of which is movable.

- the rear end has a pallet 45 on which the shoe rests which arrives at the support plate 44 in the presence of the shoe.

- the plate 46 is in two parts assembled together, to be able to adapt the length of the plate to the spacing of the front and rear retaining elements.

- the slide is connected to the ski by a base plate 48 to which it is articulated around a transverse axis 49.

- the transverse axis is materialized by the cooperation of the rear end of the slide with the rear edge of the base plate.

- a hinge pin formed by a pin or any other suitable means may also be suitable.

- the connection between the slide and the base is provided to allow the front end of the slide to lower vertically, and to impede the roll movements between the slide and the base, so as to allow vertical suspension of the shoe while preserving good transmission of lateral forces, in particular when taking edges.

- the block 50 can be replaced by any suitable means, for example a spring.

- the slide can thus oscillate vertically downwards from the position defined by the stop 51, against the return force of the block 50.

- the slide can oscillate towards the bottom under the impulse of the solicitations of the shoe.

- the support plate 44 then forms a feeler which picks up the vertical stresses on the shoe, or more precisely the variations in the support force exerted by the rear end of the shoe sole.

- Figure 6 best illustrates the connection between the plate 46 and the slide 43.

- a rocker 52 articulated around a transverse axis 53 carried by the base 48.

- the rocker has a horizontal branch 55 engaged under the slide, and it further has a substantially vertical bearing face 56 against which comes a complementary face 57 located at the rear end of the plate, when the plate is in the low position.

- the plate 46 is preferably connected at the front by a hinge, and at its rear end, it is urged upwards by a device forming a ski brake 58.

- this device comprises two articulated arms 59 recalled by a spring 60.

- the front fastening element is itself mounted on a base plate 62 integrally connected to the ski.

- the base plate extends between the base and the ski. It is provided with a longitudinal housing inside which a slide 63 is guided.

- the slide opens out at the rear of the base plate and it is connected to the front of the plate 46 by articulation produced for example by the cooperation of complementary forms.

- connection is also ensured by a flexible tongue 64, each end of which is secured to the base plate and to the plate, respectively. Any other means of connection may also be suitable.

- the slide is in abutment against the lower end of a lever 66.

- This part enters the body 3 by a vertical recess 67 located on the front, its central part is crossed by the screw 20 and takes support under the screw head. Its upper end rests on the body beyond the screw.

- the lever 66 acts on the screw head like a lever, resting on the body 2. At rest, the screw head presses the lever 66 against the wall 68 of the recess 67.

- the device comprises a means which neutralizes the action of the slide on the spring in certain circumstances, in particular in certain cases of fall.

- a rear fall for example, each shoe of the skier exerts an upward force on the jaw of the front retaining element, and a downward force on the support plate which supports the heel of the shoe, that is to say here the support plate 44.

- an increase in the hardness of the spring is not desirable in these circumstances.

- the neutralization means is shown in the form of a toggle 69, which is integrated in the slide 63.

- the toggle 69 comprises two levers 70 and 71 connected together by a joint.

- the joint is located under an element of the body which moves vertically when the body lifts.

- this element is the centering stud 2a which passes through the base 3 of the retaining element.

- the stud 2a maintains the knee switch in the flattened position in a position close to the total extension, without however reaching this extension.

- the articulation of the two levers can move longitudinally under the stud with the displacement of the slide 63.

- a wedge or any other suitable means can be provided to prevent the levers of the toggle joint from reaching and exceeding a fully extended position.

- the toggle joint is capable of transmitting the longitudinal forces coming from the connecting plate 46. It is also capable of imposing on the entire slide the longitudinal movement which is imparted by the connecting plate 46. Given the fact that the toggle is close to the extension, the vertical reaction induced in the pad 20 is relatively weak.

- the kneepad tends to fold back.

- the lever 66 and the screw 20, if they had previously moved, are returned by the spring 15 to the rest position, that is to say the position where the lever 66 is in abutment against the wall 68.

- the longitudinal movement of the connecting plate 46 is then absorbed in the folding of the toggle joint, and the vertical forces of the shoe on the plate 44 are taken up by the block 50.

- the compensation mechanism of the retaining element is activated due to the elevation of the body.

- the rod 30 translates upward, causing with it the rotation of the rocker 30.

- the rocker exerts a thrust on the piston 16 which adds to the stresses coming from one or the other of the wings which is requested upon opening. The release of the shoe is thus facilitated.

- This operating phase of the retaining element is illustrated in FIG. 9.

- the body In the event that the stress is not sufficient to cause the release of the shoe, the body returns to its initial position when the stress ceases.

- the rocker 30 pivots towards its initial position, the stud 2a, by lowering, recalls the two levers of the toggle joint substantially in alignment with one another, the toggle joint is again ready to transmit the forces and the longitudinal movements of the connecting plate.

- the compensation mechanism for the fastening element is also active in the case of a front fall, that is to say a fall where the front of the shoe exerts a strong pressure on its support plate 25.

- the support plate 25 exerts on the rocker 30 a force which has the same effect on the compensation mechanism as a force due to a rear fall.

- the support plate 25 transmits the support force to the rocker 30 which in turn transmits it to the piston 16. The opening of the wings is facilitated in this case.

- the body of the retaining element does not rise due to the link with play between the rocker 30 and the link 39.

- the opening of the toggle joint 69 is not modified in this case.

- the folding amplitude of the toggle joint 69 can be modified by varying the position of the stud relative to the hinge zone 9 of the body, or else the length of the links.

- the stud as an element which controls the means for neutralizing the toggle joint is not limiting, and any other appropriate element could provide this control function, for example one of the branches of the rocker 30, or still the support plate 25 or an element controlled by this support plate.

- FIG. 10 illustrates an alternative embodiment of the invention.

- This figure shows a front retaining element 81, of the same type as the previous element, to which a connection plate 83 is connected.

- the rest of the fixing assembly is identical to what has been previously described.

- the front fixing element 81 is essentially identical to the element previously described. The difference lies in the means which connect the slide 86 and the front retaining element. The function of these means is here to slow down, or even block, the movement of the slide when its effect is not desired.

- the retaining element shown has a centering stud 87 provided with an opening 88 which the slide 86 passes right through.

- the slide has a reduced thickness.

- the centering stud has in its lower part a shoe 89 which delimits the lower part of the opening 88.

- Braking can also be achieved progressively by inserting a block of deformable material, for example an elastomer block, between the pad and the slide.

- a block of deformable material for example an elastomer block

- the effect of the displacement of the connecting plate on the spring is neutralized in certain circumstances, for example in the case of a fall backwards.

- the same result can be achieved in the case of a forward fall, or any other type of fall.

- the braking action of the slide can be coupled to a compensation effect, for example according to one of the modes described above.

- FIG. 11 illustrates another variant implementation of the invention.

- the support plate 90 on which the front of the shoe rests, or one end thereof, is held suspended by a spring 91 or any other suitable means, for example an elastomer block.

- a lock 92 slidably mounted in a vertical direction.

- the lock has a central housing which is traversed by the slide 93. This housing is delimited downwards by the upper surface of a shoe 95 for braking the slide.

- a spring 96 or any other suitable means resiliently recalls the latch upwards.

- the set has dimensions and characteristics such that in the absence of a stress raised downwards exerted by the shoe on its support plate, the latch 92 is recalled upwards by the spring 96. It slows any movement of the slide forward.

- the surfaces of the shoe and of the slide in contact can be coated with complementary toothing or any suitable means for achieving unidirectional braking, which blocks the movement of the slide forwards while allowing it to return to the rear.

- the slide can drive the lever 97 forward, under the impulse of a force exerted on the rear support plate and transmitted by the connection plate.

- the invention is not limited to the front fastening element which has been described. It applies to any other known construction of a front retaining element.

- the invention is also not limited to the case where the probe is associated with the rear fixing element.

- the probe that causes the longitudinal displacement of the slide could be located in another area of the shoe.

- the movement of the probe is not necessarily vertical.

- the feeler could also pick up the rolling stresses of the front or rear end of the shoe.

Landscapes

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

Abstract

Description

L'invention concerne un élément de retenue d'une chaussure sur une planche de glisse, notamment sur un ski alpin. L'invention concerne également un ensemble de retenue d'une chaussure sur une planche de glisse, notamment un ski alpin. En second lieu, l'invention concerne un ensemble de fixation destiné à retenir une chaussure en appui sur un ski.The invention relates to a shoe retaining element on a gliding board, in particular on an alpine ski. The invention also relates to an assembly for retaining a boot on a gliding board, in particular an alpine ski. Secondly, the invention relates to a fixing assembly intended to retain a boot bearing on a ski.

Dans le cas du ski alpin, il est connu de retenir une chaussure en appui par un élément de retenue avant et un élément de retenue arrière, qui maintiennent respectivement les extrémités avant et arrière de la chaussure.In the case of alpine skiing, it is known to hold a boot in abutment by a front retaining element and a rear retaining element, which respectively hold the front and rear ends of the boot.

Chaque élément de retenue présente de façon globale une mâchoire portée par un corps, le corps étant relié au ski par une embase. La mâchoire est mobile entre une position où elle retient la chaussure, et une position où elle permet la libération de la chaussure. Un mécanisme de rappel élastique, constitué généralement par un ressort de compression, oppose une force de résistance au déplacement de la mâchoire.Each retaining element generally has a jaw carried by a body, the body being connected to the ski by a base. The jaw is movable between a position where it retains the shoe, and a position where it allows the release of the shoe. An elastic return mechanism, generally constituted by a compression spring, opposes a force of resistance to the movement of the jaw.

La force de résistance est déterminée par la raideur du ressort, ainsi que par un moyen de réglage, habituellement une vis ou un bouchon-fileté, qui permet de régler la compression initiale du ressort. Le moyen de réglage permet de façon usuelle de régler la dureté de l'élément de fixation sur une échelle de dureté qui est définie par la nature du ressort. La dureté est significative de l'effort que la chaussure doit vaincre pour être libérée.The resistance force is determined by the stiffness of the spring, as well as by an adjustment means, usually a screw or a threaded plug, which makes it possible to adjust the initial compression of the spring. The adjusting means usually makes it possible to adjust the hardness of the fastening element on a hardness scale which is defined by the nature of the spring. The hardness is significant of the effort that the shoe must overcome to be released.

Au cours de la pratique du ski, cette force n'est plus influencée que par les frottements de la chaussure dans sa mâchoire de retenue.During skiing, this force is only influenced by the friction of the boot in its retaining jaw.

On connaît d'après la demande de brevet allemand publiée sous le numéro 29 16 352 un mécanisme de rappel comprenant en parallèle un ressort et un organe d'amortissement qui oppose à la compression du ressort une résistance d'autant plus élevée que la sollicitation à l'ouverture de la mâchoire est plus violente.Known from the German patent application published under number 29 16 352 a return mechanism comprising in parallel a spring and a damping member which opposes the compression of the spring a resistance all the higher as the stress on the opening of the jaw is more violent.

Un tel mécanisme permet d'augmenter la force que la mâchoire doit vaincre pour libérer la chaussure en fonction de la vitesse à laquelle la chaussure sollicite la mâchoire à l'ouverture. Ainsi, pour des vitesse faibles, correspondant globalement à des situations où le skieur est à l'arrêt ou skie lentement, la force à vaincre est relativement faible. Au contraire, Si le skieur skie plus rapidement, sa chaussure sollicite la mâchoire de façon plus violente, et la mâchoire oppose une résistance plus forte à l'ouverture.Such a mechanism makes it possible to increase the force that the jaw must overcome to release the shoe as a function of the speed at which the shoe biases the jaw upon opening. Thus, for low speeds, corresponding overall to situations where the skier is stopped or skiing slowly, the force to be overcome is relatively low. On the contrary, If the skier skis faster, his shoe stresses the jaw more violently, and the jaw offers stronger resistance to opening.

La mise en oeuvre d'une telle construction se révèle délicate car il faut maîtriser l'organe d'amortissement qui doit être peu encombrant, et l'écoulement du fluide à l'intérieur de celui-ci. De plus, pour obtenir un effet fiable, il faut que la fluidité du fluide soit peu sensible aux variations de température.The implementation of such a construction proves to be difficult because it is necessary to control the damping member which must be compact, and the flow of the fluid inside of it. In addition, to obtain a reliable effect, the fluidity of the fluid must be insensitive to temperature variations.

Le problème posé par l'invention est d'améliorer le fonctionnement des éléments de retenue existants.The problem posed by the invention is to improve the operation of the existing retaining elements.

L'invention propose d'adapter au cours de la pratique du ski la dureté de l'élément de fixation aux conditions d'utilisation de l'élément de fixation.The invention proposes to adapt, during skiing, the hardness of the binding element to the conditions of use of the binding element.

Elle vise en fait à obtenir un effet de même type que celui obtenu avec le document 29 16 352, mais par d'autres moyens basant l'augmentation de la force de rappel de la mâchoire sur une source d'information différente, notamment la force d'appui que le skieur transmet au ski par l'appui du talon de la chaussure.It aims in fact to obtain an effect of the same type as that obtained with document 29 16 352, but by other means basing the increase in the restoring force of the jaw on a different source of information, in particular the force support that the skier transmits to the ski by supporting the heel of the boot.

Un autre but de l'invention est de proposer un dispositif qui adapte la dureté de l'élément de fixation dont l'effet est neutralisé dans certaines circonstances, notamment dans certaines configurations de chutes.Another object of the invention is to propose a device which adapts the hardness of the fastening element, the effect of which is neutralized under certain circumstances, in particular in certain configurations of falls.

Un autre but de l'invention est de proposer un ensemble de fixation qui ait une action sur la répartition de pression du ski sur la neige.Another object of the invention is to propose a binding assembly which has an action on the pressure distribution of the ski on the snow.

Ces buts et d'autres buts qui apparaîtront au cours de la description qui va suivre sont atteints par l'invention telle qu'elle est définie dans la revendication 1.These and other objects which will appear during the following description are achieved by the invention as defined in claim 1.

Il faut noter que l'on connaît des mécanismes de compensation mettant en oeuvre un palpeur situé sous la chaussure qui agit sur le mécanisme de rappel de la mâchoire. Un tel dispositif est par exemple décrit dans la demande de brevet allemand publiée sous le numéro 33 07 022.It should be noted that there are known compensation mechanisms using a feeler located under the shoe which acts on the jaw return mechanism. Such a device is for example described in the German patent application published under the

Ces mécanismes ont cependant un effet opposé à celui recherché par la présente invention. En effet, ces mécanismes abaissent la force de rappel que la mâchoire doit vaincre pour libérer la chaussure, afin de compenser l'augmentation des frottements entre la chaussure et la mâchoire. Comme cela apparaîtra au cours de la description qui va suivre, l'invention n'est pas incompatible avec de tels mécanismes.These mechanisms however have an opposite effect to that sought by the present invention. Indeed, these mechanisms lower the restoring force that the jaw must overcome to release the shoe, in order to compensate for the increase in friction between the shoe and the jaw. As will become apparent from the following description, the invention is not incompatible with such mechanisms.

L'invention sera mieux comprise en se référant à la description ci-dessous et aux dessins en annexe qui en font partie intégrante.The invention will be better understood by referring to the description below and to the accompanying drawings which form an integral part thereof.

La figure 1 est une vue générale de côté d'un ensemble de fixations mettant en oeuvre l'invention.Figure 1 is a general side view of a set of fasteners implementing the invention.

La figure 2 est une vue de dessus partielle de l'ensemble de la figure 1.Figure 2 is a partial top view of the assembly of Figure 1.

La figure 3 est une vue de côté en coupe de l'élément de fixation avant de la figure 1.FIG. 3 is a side view in section of the front fixing element of FIG. 1.

La figure 4 représente en vue de dessus et en deux demi-coupe selon des plans différents l'élément de fixation de la figure 3.FIG. 4 represents in top view and in two half-sections along different planes the fixing element of FIG. 3.

La figure 5 est une vue semblable à la figure 1, en présence de la chaussure.Figure 5 is a view similar to Figure 1, in the presence of the shoe.

La figure 6 représente en vue de côté et en coupe partielle l'ensemble de la figure 1 au niveau de l'élément de fixation arrière.Figure 6 shows in side view and in partial section the assembly of Figure 1 at the rear fixing element.

La figure 7 est une vue de face d'un constituant de l'élément de fixation représenté en figure 3.FIG. 7 is a front view of a component of the fixing element shown in FIG. 3.

La figure 8 est une vue semblable à la figure 1, et illustre le mode de fonctionnement du dispositif.Figure 8 is a view similar to Figure 1, and illustrates the mode of operation of the device.

La figure 9 est une vue semblable aux figures 1 et 8 et illustre une autre phase de fonctionnement du dispositif.Figure 9 is a view similar to Figures 1 and 8 and illustrates another phase of operation of the device.

La figure 10 montre une variante de réalisation du dispositif de l'invention.Figure 10 shows an alternative embodiment of the device of the invention.

La figure 11 schématise une autre variante de réalisation de l'invention.Figure 11 shows schematically another alternative embodiment of the invention.

La figure 1 représente la partie médiane d'un ski qui est équipée d'un ensemble d'éléments de fixation comprenant un élément de retenue avant et un élément de retenue arrière, et une liaison intermédiaire entre les deux éléments.FIG. 1 represents the middle part of a ski which is equipped with a set of fastening elements comprising a front retaining element and a rear retaining element, and an intermediate connection between the two elements.

L'élément de fixation avant 1 représenté dans le mode de réalisation des figures 1 à 6 est connu pour l'essentiel d'après la demande de brevet français publiée sous le numéro FR 2 640 516.The front fixing element 1 represented in the embodiment of FIGS. 1 to 6 is essentially known from the French patent application published under the

Il comprend un corps 2 relié à une embase 3 qui est reliée solidairement au ski par tout moyen approprié et par exemple par des vis. Vue de dessus, l'embase présente une forme de "U" ouvert vers l'arrière, avec deux branches latérales 3a et 3b.It comprises a

Le corps est mobile verticalement par rapport à l'embase par exemple par une liaison déformable, localisée dans la zone 9 à la jonction entre le corps et l'embase. Le corps et l'embase sont reliés en continu par cette zone déformable et forment un élément monobloc.The body is movable vertically relative to the base, for example by a deformable link, located in

De préférence, le corps présente dans sa partie inférieure un plot de centrage 2a, qui est prévu pour être engagé entre les deux branches 3a et 3b de l'embase.Preferably, the body has in its lower part a centering

Le corps 2 porte une mâchoire 4 de retenue de l'extrémité avant de la chaussure. La mâchoire 4 comprend deux ailes de retenue latérale 5 et 6, respectivement articulées au corps 2 autour d'axes 7 et 8. La mâchoire 4 comprend aussi un serre-semelle 12 de retenue verticale de la chaussure.The

Les ailes 5 et 6 sont mobiles en réponse aux sollicitations de la chaussure, contre la force de rappel que leur applique un ressort 15.The

Le ressort 15 est logé dans le corps. Il actionne un piston 16 également logé et guidé dans le corps pour un mouvement de translation longitudinal. Les figures montrent que le piston est logé et guidé dans un logement 17 du corps, et que le ressort est engagé à l'intérieur du piston. Son extrémité avant est en appui contre le fond du piston, situé du coté avant de l'élément de fixation. Une vis 20 dont la tête est retenue à l'avant du corps traverse par ailleurs le piston et le ressort, et présente vers l'arrière un écrou 21 qui retient l'extrémité arrière du ressort. Une rotation de la vis déplace l'extrémité arrière du ressort 15, ce qui permet d'ajuster la compression initiale du ressort.The

Les ailes 5 et 6 présentent au-delà de leur axe d'articulation au corps 7 et 8 un petit bras 5a, 6a, qui entraîne vers l'arrière le piston 16 en prenant appui contre un épaulement 23 situé dans la partie arrière supérieure du piston 16.The

L'élément de fixation 1 comprend par ailleurs un dispositif d'appui pour l'extrémité avant de la semelle de chaussure.The fastening element 1 also comprises a support device for the front end of the shoe sole.

Le dispositif d'appui présente une plaque de support 25 sur laquelle la semelle de chaussure repose. La plaque 25 peut être équipée dans sa partie supérieure de tout revêtement approprié destiné à faciliter le glissement latéral de la chaussure, par exemple une plaquette de PTFE (polytétrafluoréthylène). Elle présente une largeur qui est de l'ordre de la largeur du ski à ce niveau. Dans le mode de représentation illustré, la plaque 25 est articulée autour d'un axe transversal 26, qui est porté par un palier solidaire de l'embase 3 ou relié solidairement au ski.The support device has a

L'élément 1 représenté dans le mode de réalisation des figures 1 à 7 présente en outre un mécanisme de compensation qui allège la force de rappel que le ressort 15 exerce sur les ailes 5 et 6.The element 1 shown in the embodiment of FIGS. 1 to 7 also has a compensation mechanism which alleviates the restoring force that the

Ce mécanisme comprend un basculeur 30 qui est logé en partie entre les branches 3a et 3b de l'embase 3. Le basculeur est articulé autour d'un axe 32 porté par ces branches.This mechanism comprises a

Le basculeur 30 présente une aile approximativement horizontale 33 qui est accessible sur l'arrière de l'élément de fixation entre les branches 3a et 3b de l'embase. L'avant de la plaque 25 est prévu pour pouvoir reposer sur l'extrémité de la branche 33.The

Le basculeur 30 présente en outre un bras approximativement vertical formé par deux patins latéraux qui passent de chaque côté du piston 16, et qui portent chacun sur un épaulement 37 que le piston présente sous l'épaulement 23 des ailes. Seul le patin 35 est visible dans les figures 4 et 5.The

Avantageusement, un ressort 38 rappelle la plaque 25 dans une position de repos qui place son extrémité avant au-dessus de l'aile 33 du basculeur. A l'engagement de la chaussure, la plaque s'abaisse jusqu'au contact avec la branche 33. On réalise ainsi une adaptation automatique de l'élément de fixation à l'épaisseur de la semelle de chaussure.Advantageously, a

Le basculeur présente des dimensions telles qu'une force verticale vers le bas exercée sur sa branche 33 est transmise au piston 16 sous la forme d'une sollicitation vers l'arrière, c'est-à-dire dans le même sens que les sollicitations en provenance des ailes. Le déplacement vers l'arrière du piston 17 s'accompagne d'une rotation du basculeur 30 autour de l'axe 32. La sollicitation transmise par le basculeur au piston 17 diminue d'autant la force que l'une des ailes doit elle-même exercer sur le piston pour le déplacer suffisamment vers l'arrière afin que l'ouverture de l'aile permette la libération de l'aile.The rocker has dimensions such that a vertical downward force exerted on its

Ce mécanisme compense l'augmentation des frottements entre la semelle de chaussure et la plaque d'appui 26 dans le cas d'une chute avant.This mechanism compensates for the increase in friction between the shoe sole and the

Une biellette de liaison 39 relie par ailleurs le basculeur, en avant de l'axe 32, à la partie supérieure du corps. En cas de chute vers l'arrière, le corps 2 s'élève par déformation de la zone 9. Ce mouvement est transmis au basculeur par la biellette 39. Ceci provoque une sollicitation sur le piston qui va dans le même sens que la sollicitation précédente. On compense ainsi l'augmentation des frottements entre la chaussure et le serre-semelle. Si la sollicitation de la semelle est suffisamment forte, le serre-semelle laisse échapper la semelle de chaussure vers le haut.A connecting

Naturellement, d'autres mécanismes de compensation ou d'adaptation à l'épaisseur de la semelle peuvent convenir.Naturally, other compensation or adaptation mechanisms to the thickness of the sole may be suitable.

De plus, la construction de l'élément de fixation en elle-même n'est pas limitative. Elle montre un mode de construction de l'élément de fixation avec lequel la présente invention est compatible. D'autres constructions conviennent, en particulier d'autres constructions simplifiées.In addition, the construction of the fixing element in itself is not limiting. It shows a mode of construction of the fastening element with which the present invention is compatible. Other constructions are suitable, in particular other simplified constructions.

L'ensemble représenté en figure 1 présente aussi un élément de retenue arrière 40. Cet élément est d'un type connu. Il présente notamment une mâchoire mobile 41 portée par un corps 42. De façon également connue, le corps 42 est mobile le long d'une glissière 43.The assembly shown in FIG. 1 also has a

L'ensemble de fixation présente aussi une plaque d'appui 44 pour l'arrière de la semelle de chaussure qui est située en avant de la glissière 43.The fastening assembly also has a

Le dispositif selon l'invention présente un palpeur apte à capter des sollicitations de la chaussure.The device according to the invention has a feeler capable of picking up stresses on the shoe.

Il présente en outre une liaison entre le palpeur et l'élément de fixation avant. Cette liaison est prévue pour augmenter la force de rappel que le ressort oppose à l'ouverture d'une aile avec l'intensité de la sollicitation captée par le palpeur.It also has a connection between the probe and the front fixing element. This connection is intended to increase the restoring force that the spring opposes to the opening of a wing with the intensity of the stress picked up by the probe.

Dans le mode de réalisation illustré, le palpeur est la plaque d'appui 44 située à l'avant de la glissière 43. La liaison entre le palpeur et l'élément avant comprend une plaque 46 dont l'extrémité avant est reliée à l'élément de fixation avant, et dont l'extrémité arrière est mobile. L'extrémité arrière présente une palette 45 sur laquelle repose la chaussure qui arrive au niveau de la plaque d'appui 44 en présence de la chaussure. Ceci est visible en figure 5. Eventuellement, comme représenté, la plaque 46 est en deux parties assemblées entre elles, pour pouvoir adapter la longueur de la plaque à l'écartement des éléments de retenue avant et arrière.In the illustrated embodiment, the probe is the

En outre, la glissière est reliée au ski par une plaque de base 48 à laquelle elle est articulée autour d'un axe transversal 49. L'axe transversal est matérialisé par la coopération de l'extrémité arrière de la glissière avec le rebord arrière de la plaque de base. Un axe d'articulation formé par une goupille ou tout autre moyen approprié peut aussi convenir. De préférence, la liaison entre la glissière et l'embase est prévue pour permettre à l'extrémité avant de la glissière de s'abaisser verticalement, et pour entraver les mouvements de roulis entre la glissière et l'embase, de façon à permettre une suspension verticale de la chaussure en préservant une bonne transmission des efforts latéraux, notamment lors des prises de carres.In addition, the slide is connected to the ski by a

Un bloc de matériau amortissant 50 situé entre la glissière et la plaque de base ramène élastiquement la glissière 43 vers le haut, contre une butée 51 par exemple solidaire de la plaque de base. Le bloc 50 peut être remplacé par tout moyen approprié, par exemple un ressort.A block of damping

La glissière peut ainsi osciller verticalement vers le bas à partir de la position définie par la butée 51, contre la force de rappel du bloc 50. En particulier, lorsque la plaque 46 est dans la position de la figure 6, la glissière peut osciller vers le bas sous l'impulsion des sollicitations de la chaussure. La plaque d'appui 44 forme alors un palpeur qui capte les sollicitations verticales de la chaussure, ou plus précisément les variations de l'effort d'appui exercée par l'extrémité arrière de la semelle de chaussure.The slide can thus oscillate vertically downwards from the position defined by the

La figure 6 illustre le mieux la liaison entre la plaque 46 et la glissière 43. Sous la plaque d'appui 44 se trouve un basculeur 52 articulé autour d'un axe transversal 53 porté par l'embase 48. Le basculeur présente une branche horizontale 55 engagée sous la glissière, et il présente en outre une face d'appui sensiblement verticale 56 contre laquelle vient porter une face complémentaire 57 située à l'extrémité arrière de la plaque, lorsque la plaque est en position basse.Figure 6 best illustrates the connection between the

De cette façon, l'oscillation vers le bas de la glissière provoque la rotation du basculeur et le mouvement vers l'avant de la plaque 46, par appui du basculeur 52 sur la face arrière 57 de la plaque.In this way, the downward oscillation of the slide causes the rocker to rotate and the forward movement of the

La plaque 46 est de préférence reliée à l'avant par une articulation, et au niveau de son extrémité arrière, elle est sollicitée vers le haut par un dispositif formant un frein de ski 58. Notamment, ce dispositif comprend deux bras articulés 59 rappelés par un ressort 60.The

L'élément de fixation avant est quant à lui monté sur une plaque de base 62 reliée de façon solidaire au ski. La plaque de base s'étend entre l'embase et le ski. Elle est pourvue d'un logement longitudinal à l'intérieur duquel est guidé une coulisse 63. La coulisse débouche à l'arrière de la plaque de base et elle est connectée à l'avant de la plaque 46 par articulation réalisée par exemple par la coopération de formes complémentaires.The front fastening element is itself mounted on a

La liaison est par ailleurs assurée par une languette souple 64 dont chaque extrémité est solidarisée à la plaque de base et à la plaque, respectivement. Tout autre moyen de liaison peut aussi convenir.The connection is also ensured by a

A l'avant, la coulisse est en appui contre l'extrémité inférieure d'un levier 66. Cette pièce pénètre dans le corps 3 par un évidement vertical 67 situé sur l'avant, sa partie centrale est traversée par la vis 20 et prend appui sous la tête de vis. Son extrémité supérieure repose sur le corps au-delà de la vis. Sous l'action de la coulisse 63, le levier 66 agit sur la tête de vis à la manière d'un levier, en prenant appui sur le corps 2. Au repos, la tête de vis plaque le levier 66 contre la paroi 68 de l'évidement 67.At the front, the slide is in abutment against the lower end of a

Un appui du skieur plus prononcé sur l'arrière, par exemple en phase de conduite, à la sortie d'un virage, provoque un abaissement du palpeur 44, une oscillation vers le bas de la glissière 43, contre la force de rappel élastique du bloc 50. La plaque de liaison 46 est repoussée vers l'avant par la rotation du basculeur 52. Ce mouvement est transmis au levier 66 qui force la vis 20 à se déplacer vers l'avant. Le ressort 15 subit une compression additionnelle qui rend les ailes 5 et 6 plus difficiles à ouvrir. Cette phase de fonctionnement du dispositif est illustrée dans la figure 9.A more pronounced support of the skier on the rear, for example during the driving phase, at the end of a turn, causes the

Dès que la sollicitation de la chaussure cesse, la vis 20 et le levier 66 sont rappelés dans leur position initiale, c'est-à-dire la position où le levier est en appui contre la paroi 68 du corps.As soon as the solicitation of the shoe ceases, the

Selon une caractéristique de l'invention, le dispositif comprend un moyen qui neutralise l'action de la coulisse sur le ressort dans certaines circonstances, notamment dans certains cas de chute. Dans le cas d'une chute arrière, par exemple, chaque chaussure du skieur exerce un effort vers le haut sur la mâchoire de l'élément de retenue avant, et un effort vers le bas sur la plaque d'appui qui supporte le talon de la chaussure, c'est-à-dire ici la plaque d'appui 44. Mais une augmentation de la dureté du ressort n'est pas souhaitable dans ces circonstances.According to a characteristic of the invention, the device comprises a means which neutralizes the action of the slide on the spring in certain circumstances, in particular in certain cases of fall. In the case of a rear fall, for example, each shoe of the skier exerts an upward force on the jaw of the front retaining element, and a downward force on the support plate which supports the heel of the shoe, that is to say here the

Dans le mode de réalisation illustré dans les figures, le moyen de neutralisation est représenté sous la forme d'une genouillère 69, qui est intégrée dans la coulisse 63. La genouillère 69 comprend deux leviers 70 et 71 reliés entre eux par une articulation. L'articulation se trouve située sous un élément du corps qui se déplace verticalement lorsque le corps se soulève. Avantageusement, cet élément est le plot de centrage 2a qui traverse l'embase 3 de l'élément de retenue. En position de repos du corps, le plot 2a maintient la genouillère en position aplatie dans une position proche de l'extension totale, sans toutefois atteindre cette extension. En outre, l'articulation des deux leviers peut se déplacer longitudinalement sous le plot avec le déplacement de la coulisse 63. Eventuellement, on peut prévoir une cale ou tout autre moyen approprié pour empêcher les leviers de la genouillère d'atteindre et de dépasser une position d'extension totale.In the embodiment illustrated in the figures, the neutralization means is shown in the form of a

Ainsi, dans la position représentée en figure 3, la genouillère est apte à transmettre les efforts longitudinaux en provenance de la plaque de liaison 46. Elle est également capable d'imposer à l'ensemble de la coulisse le mouvement longitudinal qui est imprimé par la plaque de liaison 46. Compte tenu du fait que la genouillère est proche de l'extension, la réaction verticale induite dans le plot 20 est relativement faible.Thus, in the position represented in FIG. 3, the toggle joint is capable of transmitting the longitudinal forces coming from the connecting

En cas de soulèvement du plot 2a, par exemple à la suite d'une chute arrière sollicitant le corps vers le haut, la genouillère tend à se replier. Le levier 66 et la vis 20, s'ils avaient bougé auparavant, sont rappelés par le ressort 15 en position de repos, c'est-à-dire la position où le levier 66 est en appui contre la paroi 68. Le mouvement longitudinal de la plaque de liaison 46 est alors absorbé dans le repliement de la genouillère, et les efforts verticaux de la chaussure sur la plaque 44 sont repris par le bloc 50.In the event of lifting of the

L'effet qu'aurait pu provoquer le déplacement de la plaque de liaison sur la compression du ressort se trouve ainsi neutralisé.The effect that the displacement of the connecting plate could have caused on the compression of the spring is thus neutralized.

Parallèlement, le mécanisme de compensation de l'élément de retenue est activé du fait de l'élévation du corps. La biellette 30 se translate vers le haut, entraînant avec elle la rotation du basculeur 30. Par ses patins, le basculeur exerce une poussée sur le piston 16 qui s'additionne aux sollicitations provenant de l'une ou l'autre des ailes qui est sollicitée à l'ouverture. La libération de la chaussure se trouve ainsi facilitée.In parallel, the compensation mechanism of the retaining element is activated due to the elevation of the body. The

Cette phase de fonctionnement de l'élément de retenue est illustrée en figure 9.This operating phase of the retaining element is illustrated in FIG. 9.

Au cas où la sollicitation n'est pas suffisante pour provoquer la libération de la chaussure, le corps reprend sa position initiale lorsque la sollicitation cesse. Le basculeur 30 pivote vers sa position initiale, le plot 2a en se rabaissant rappelle les deux leviers de la genouillère sensiblement dans l'alignement l'un de l'autre, la genouillère est de nouveau prête pour transmettre au levier 66 les efforts et les déplacements longitudinaux de la plaque de liaison.In the event that the stress is not sufficient to cause the release of the shoe, the body returns to its initial position when the stress ceases. The

Le mécanisme de compensation de l'élément de fixation est par ailleurs actif dans le cas d'une chute avant, c'est-à-dire une chute où l'avant de la chaussure exerce une forte pression sur sa plaque de support 25. Dans ce cas, en effet, la plaque de support 25 exerce sur le basculeur 30 un effort qui a le même effet sur le mécanisme de compensation qu'un effort dû à une chute arrière. Notamment, la plaque de support 25 transmet l'effort d'appui au basculeur 30 qui le transmet à son tour au piston 16. L'ouverture des ailes est facilitée dans ce cas.The compensation mechanism for the fastening element is also active in the case of a front fall, that is to say a fall where the front of the shoe exerts a strong pressure on its

Cependant, le corps de l'élément de retenue ne s'élève pas à cause de la liaison avec jeu entre le basculeur 30 et la biellette 39. L'ouverture de la genouillère 69 n'est pas modifiée dans ce cas.However, the body of the retaining element does not rise due to the link with play between the

Les cas de chute, les mécanismes de compensation qui viennent d'être décrits et leur mode de fonctionnement ne sont pas limitatifs pour l'invention. Il se pourrait que la neutralisation du mouvement de la plaque de liaison se produise également en chute avant. Il suffirait en effet de remplacer la liaison avec jeu entre le basculeur 30 et la biellette 39 par une liaison sans jeu. Il se pourrait aussi qu'il n'y ait aucun moyen de compensation, ou bien qu'un mécanisme de compensation actif dans le cas d'une chute vers l'avant ou d'une chute vers l'arrière, ou bien tout autre mécanisme de compensation approprié.The cases of fall, the compensation mechanisms which have just been described and their mode of operation are not limiting for the invention. It may be that the neutralization of the movement of the connecting plate also occurs in forward fall. It would suffice to replace the link with play between the

En outre, il convient de remarquer que l'amplitude de repliement de la genouillère 69 peut être modifiée en jouant sur la position du plot par rapport à la zone de charnière 9 du corps, ou bien la longueur des biellettes. A ce sujet, le plot en tant qu'élément qui contrôle le moyen de neutralisation de la genouillère n'est pas limitatif, et tout autre élément approprié pourrait assurer cette fonction de contrôle, par exemple l'une des branches du basculeur 30, ou encore la plaque de support 25 ou un élément commandé par cette plaque de support.In addition, it should be noted that the folding amplitude of the toggle joint 69 can be modified by varying the position of the stud relative to the

On pourrait aussi remplacer la genouillère par une zone flexible d'une lame dont on contrôle le flambage sous l'effet des efforts transmis par la plaque 46, en fonction de la position verticale d'un élément du corps situé dans la zone du ventre de déformation de la lame.One could also replace the knee brace by a flexible zone of a blade whose buckling is controlled under the effect of the forces transmitted by the

La figure 10 illustre une variante de réalisation de l'invention. Cette figure représente un élément de retenue avant 81, de même type que l'élément précédent, auquel est connectée une plaque de liaison 83. Le reste de l'ensemble de fixation est identique à ce qui a été précédemment décrit.FIG. 10 illustrates an alternative embodiment of the invention. This figure shows a

L'élément de fixation avant 81 est pour l'essentiel identique à l'élément précédemment décrit. La différence se situe au niveau des moyens qui relient la coulisse 86 et l'élément de retenue avant. La fonction de ces moyens est ici de freiner, voire de bloquer, le déplacement de la coulisse lorsque son effet n'est pas souhaité.The

Pour illustrer cela, l'élément de retenue représenté présente un plot de centrage 87 muni d'une ouverture 88 que la coulisse 86 traverse de part en part. Eventuellement, comme le montre la figure, dans cette zone, et vers l'avant, la coulisse présente une épaisseur réduite.To illustrate this, the retaining element shown has a centering

Le plot de centrage présente dans sa partie inférieure un patin 89 qui délimite la partie inférieure de l'ouverture 88.The centering stud has in its lower part a

Lorsque le corps se trouve en position normale c'est-à-dire la position de la figure 10, il existe un espace entre le patin 89 et la surface inférieure de la coulisse 86.When the body is in the normal position, that is to say the position in FIG. 10, there is a space between the

Dans le cas d'une chute arrière, par exemple, le plot 87 remonte, ce qui amène le patin au contact de la coulisse. Le déplacement de la coulisse se trouve ainsi freiné. Le freinage peut être plus ou moins accentué selon la nature des surfaces du patin et de la coulisse en contact. On peut également réaliser un freinage unidirectionnel avec des reliefs en denture dissymétrique, c'est-à-dire un freinage qui bloque la coulisse dans le sens d'un mouvement vers l'avant, mais permet un mouvement de retour vers l'arrière.In the case of a rear fall, for example, the

Le freinage peut également être réalisé de façon progressive en intercalant un bloc de matériau déformable, par exemple un bloc d'élastomère, entre le patin et la coulisse.Braking can also be achieved progressively by inserting a block of deformable material, for example an elastomer block, between the pad and the slide.

D'autres variantes ou modes de construction différents peuvent aussi convenir.Other variants or different construction methods may also be suitable.

Comme dans le cas précédent, l'effet du déplacement de la plaque de liaison sur le ressort se trouve neutralisé dans certaines circonstances, par exemple dans le cas d'une chute vers l'arrière. Comme dans le cas précédemment décrit, le même résultat peut être atteint dans le cas d'une chute vers l'avant, ou de tout autre type de chute. En outre, l'action de freinage de la coulisse peut être couplée à un effet de compensation, par exemple selon l'un des modes décrits précédemment.As in the previous case, the effect of the displacement of the connecting plate on the spring is neutralized in certain circumstances, for example in the case of a fall backwards. As in the previously described case, the same result can be achieved in the case of a forward fall, or any other type of fall. In addition, the braking action of the slide can be coupled to a compensation effect, for example according to one of the modes described above.

La figure 11 illustre une autre variante de mise en oeuvre de l'invention. Selon cette variante, la plaque de support 90 sur laquelle l'avant de la chaussure repose, ou une extrémité de celle-ci, est maintenue suspendue par un ressort 91 ou tout autre moyen approprié, par exemple un bloc élastomère. Sous l'extrémité suspendue de la plaque de support se trouve un verrou 92 monté coulissant selon une direction verticale. Le verrou présente un logement central qui est traversé par la coulisse 93. Ce logement est délimité vers le bas par la surface supérieure d'un patin 95 de freinage de la coulisse. Un ressort 96 ou tout autre moyen approprié rappelle élastiquement le verrou vers le haut. L'ensemble présente des dimensions et des caractéristiques telles qu'en l'absence d'une sollicitation élevée vers le bas exercée par la chaussure sur sa plaque de support, le verrou 92 est rappelé vers le haut par le ressort 96. Il freine tout mouvement de la coulisse vers l'avant. Eventuellement, les surfaces du patin et de la coulisse en contact peuvent être revêtues de dentures complémentaires ou de tout moyen approprié pour réaliser un freinage unidirectionnel, qui bloque le mouvement de la coulisse vers l'avant tout en autorisant son retour vers l'arrière.FIG. 11 illustrates another variant implementation of the invention. According to this variant, the

En cas de fortes sollicitations exercées sur la plaque de support, celle-ci s'abaisse suffisamment pour que le patin 95 libère la coulisse. Alors, la coulisse peut entraîner vers l'avant le levier 97, sous l'impulsion d'un effort exercé sur la plaque d'appui arrière et transmis par la plaque de liaison.In the event of high stresses exerted on the support plate, the latter is lowered enough for the

L'invention n'est pas limitée aux différentes constructions qui ont été décrites, elle englobe les variantes, les équivalents, et d'une façon générale toutes les constructions qui sont définies par les revendications en annexe.The invention is not limited to the various constructions which have been described, it encompasses the variants, the equivalents, and in general all the constructions which are defined by the appended claims.

Notamment, l'invention n'est pas limitée à l'élément de fixation avant qui a été décrit. Elle s'applique à tout autre construction connue d'un élément de retenue avant.In particular, the invention is not limited to the front fastening element which has been described. It applies to any other known construction of a front retaining element.

L'invention n'est pas limitée non plus au cas où le palpeur est associé à l'élément de fixation arrière. Le palpeur qui provoque le déplacement longitudinal de la coulisse pourrait être situé dans une autre zone de la chaussure.The invention is also not limited to the case where the probe is associated with the rear fixing element. The probe that causes the longitudinal displacement of the slide could be located in another area of the shoe.

Le mouvement du palpeur n'est pas nécessairement vertical. Le palpeur pourrait aussi capter les sollicitations en roulis de l'extrémité avant ou arrière de la chaussure.The movement of the probe is not necessarily vertical. The feeler could also pick up the rolling stresses of the front or rear end of the shoe.

Claims (10)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9511640 | 1995-09-28 | ||

| FR9511640A FR2739301B1 (en) | 1995-09-28 | 1995-09-28 | ELEMENT AND ASSEMBLY FOR RETAINING A SHOE ON A SNOWBOARD |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0765680A1 true EP0765680A1 (en) | 1997-04-02 |

Family

ID=9483208

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96112650A Withdrawn EP0765680A1 (en) | 1995-09-28 | 1996-08-06 | Element and device for holding a boot on a surf-board |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0765680A1 (en) |

| JP (1) | JPH09117544A (en) |

| FR (1) | FR2739301B1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2965187A1 (en) * | 2010-09-28 | 2012-03-30 | Rossignol Sa | DEVICE FOR FIXING A SHOE ON A SKI WITH SAFETY INTERFACE |

| EP2907556A1 (en) * | 2014-02-13 | 2015-08-19 | Tyrolia Technology GmbH | Front jaw for a safety ski-binding |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2633994A1 (en) * | 1988-07-08 | 1990-01-12 | Salomon Sa | HYDRAULIC SHOCK ABSORBER |

| WO1993014837A1 (en) * | 1992-01-31 | 1993-08-05 | Salomon S.A. | Device for altering pressure distribution over the sliding surface of a ski |

| FR2688144A1 (en) * | 1991-10-10 | 1993-09-10 | Tyrolia Freizeitgeraete | Front jaw for ski boot binding |

| EP0674925A1 (en) * | 1994-03-30 | 1995-10-04 | Salomon S.A. | Skibinding |

-

1995

- 1995-09-28 FR FR9511640A patent/FR2739301B1/en not_active Expired - Fee Related

-

1996

- 1996-08-06 EP EP96112650A patent/EP0765680A1/en not_active Withdrawn

- 1996-09-26 JP JP8254223A patent/JPH09117544A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2633994A1 (en) * | 1988-07-08 | 1990-01-12 | Salomon Sa | HYDRAULIC SHOCK ABSORBER |

| FR2688144A1 (en) * | 1991-10-10 | 1993-09-10 | Tyrolia Freizeitgeraete | Front jaw for ski boot binding |

| WO1993014837A1 (en) * | 1992-01-31 | 1993-08-05 | Salomon S.A. | Device for altering pressure distribution over the sliding surface of a ski |

| EP0674925A1 (en) * | 1994-03-30 | 1995-10-04 | Salomon S.A. | Skibinding |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2965187A1 (en) * | 2010-09-28 | 2012-03-30 | Rossignol Sa | DEVICE FOR FIXING A SHOE ON A SKI WITH SAFETY INTERFACE |

| EP2438969A1 (en) * | 2010-09-28 | 2012-04-11 | Skis Rossignol | Ski binding with safety interface |

| US8585074B2 (en) | 2010-09-28 | 2013-11-19 | Skis Rossignol | Boot-attachment device on a ski with safety interface |

| EP2907556A1 (en) * | 2014-02-13 | 2015-08-19 | Tyrolia Technology GmbH | Front jaw for a safety ski-binding |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2739301A1 (en) | 1997-04-04 |

| FR2739301B1 (en) | 1997-12-12 |

| JPH09117544A (en) | 1997-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0556610B1 (en) | Device for modifying the natural pressure distribution of a ski on its surface-sole | |

| EP0530449B1 (en) | Device for modifying the pressure distribution of a ski on its sliding surface | |

| EP0624113B1 (en) | Device for altering pressure distribution over the sliding surface of a ski | |

| FR2471795A1 (en) | STOP-FRONT OF SKI FIXING | |

| EP0617638B1 (en) | Device for distributing the pressure of a ski on a sliding surface | |

| EP0674925B1 (en) | Skibinding | |

| EP0102868B1 (en) | Front jaw for a safety ski binding | |

| EP0692288B1 (en) | Alpine ski-binding | |

| EP0653231B1 (en) | Binding element for skis | |

| WO1996032992A1 (en) | Safety binding for telemark, cross-country and ski-jumping skis | |

| EP0658360A1 (en) | Intermediate device between a ski and the binding | |

| EP0641233B1 (en) | Device for altering pressure distribution over the sliding surface of a ski | |

| EP0634196B1 (en) | Binding element for alpine skis | |

| CH660976A5 (en) | SECURITY FIXING FOR SKIING. | |

| EP0765680A1 (en) | Element and device for holding a boot on a surf-board | |

| CH673776A5 (en) | ||

| EP0667174B1 (en) | Safety bindings for skis having a compensation device | |

| EP0639393A1 (en) | Ski binding component | |

| EP0660740B1 (en) | Device for varying the natural pressure distribution of a ski on a sliding surface, and ski provided therewith | |

| EP0627947B1 (en) | Bearing device for a ski shoe onto a ski, and associated to a safety front stop | |

| EP0495737B1 (en) | Skibrake | |

| EP0829278B1 (en) | Toe piece binding for a safety sliding board | |

| EP4393559A1 (en) | Ski brake | |

| FR2582951A1 (en) | Ski brake | |

| FR2754727A1 (en) | Ski boot fastening |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE IT LI |

|

| 17P | Request for examination filed |

Effective date: 19970917 |

|

| 17Q | First examination report despatched |

Effective date: 20000503 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20000914 |