EP0724673B1 - Schlauch zur chemikalieneinspritzung in beton - Google Patents

Schlauch zur chemikalieneinspritzung in beton Download PDFInfo

- Publication number

- EP0724673B1 EP0724673B1 EP94931704A EP94931704A EP0724673B1 EP 0724673 B1 EP0724673 B1 EP 0724673B1 EP 94931704 A EP94931704 A EP 94931704A EP 94931704 A EP94931704 A EP 94931704A EP 0724673 B1 EP0724673 B1 EP 0724673B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- concrete

- tube

- injection

- chemical injection

- feed portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000002347 injection Methods 0.000 title claims abstract description 17

- 239000007924 injection Substances 0.000 title claims abstract description 17

- 239000000126 substance Substances 0.000 title claims abstract description 5

- 239000000463 material Substances 0.000 claims abstract description 9

- 239000011148 porous material Substances 0.000 claims abstract description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- 238000000034 method Methods 0.000 description 6

- 238000005266 casting Methods 0.000 description 5

- 238000007789 sealing Methods 0.000 description 4

- 229920003023 plastic Polymers 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 239000004744 fabric Substances 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 239000010410 layer Substances 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D29/00—Independent underground or underwater structures; Retaining walls

- E02D29/16—Arrangement or construction of joints in foundation structures

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/66—Sealings

- E04B1/68—Sealings of joints, e.g. expansion joints

- E04B1/6816—Porous tubular seals for injecting sealing material

Definitions

- the present invention relates to a tube for chemical injection in concrete, comprising an injection material feed portion covered by a surrounding compressible, porous material attached thereto.

- the ideal joint between two concrete moulds would be without fissures, cracks, interstices between the rocks, and the like.

- the problem of leakage may particularly arise when concrete walls are poured on a previously cast concrete base.

- the search for better methods of sealing concrete joints has continued, and the method generally used today is an injection system which is based on tubes perforated in various ways and run in the longitudinal direction of the concrete joint, and according to which a sealer, usually a two-component polyurethane material, is injected into the tubes and distributed in the joint by means of the perforations, the material thereafter hardening and sealing the joint.

- a sealer usually a two-component polyurethane material

- EP 0,125,696-A3 which comprises one central, regularly perforated feed tube outside which there is placed a tubular filter layer which, in turn, is sheathed by a tubular, mesh-like protective layer.

- the purpose of the sheathing is to prevent that the concrete mass during the pouring blocks the perforations in the sealer distribution tube.

- a textile cloth has proved disadvantageous, the cloth itself being a surface element which during casting is sealed so that the injection mass is not let out from the perforated tube for sealing the fissures and cracks that have been formed.

- This system comprises a tube core of a solid and strong material along which, in the longitudinal direction thereof, are disposed grooves, through the bottom of which there are, in turn, formed perforations. These grooves are covered by loosely positioned slats so that the overall profile of the tube is almost circular.

- slats The purpose of these slats is to prevent the concrete mass during casting from blocking the perforations of the tube, while at the same time ensuring that the injection material, even at low pressure, can be pressed out of the feed tube and into the surrounding fissures and cracks.

- the "FUKO" system is provided with a circumferential woven, open plastic sleeve for holding the longitudinal slats in position.

- the present invention aims at advancing the state of the art to the point where it is possible to inject simultaneously at least two different components and, optionally, on a later occasion to inject further components if this should prove necessary.

- the invention is based on the discovery that only one injection duct may prove disadvantageous, and, further, on the consideration that the wider the area is across which the injection mass is sprayed, the better the seal will be secured, especially when the injection is made from an element further described below.

- the present invention therefore relates to a tube of the kind mentioned by way of introduction, and this tube is characterized in that the feed portion comprises at least two moulded channels running side by side, preferably in one piece and in the form of strips, in the outer walls of which microscopic apertures are formed for emission from the interior to the outside, at a predetermined interior overpressure.

- the compressible, porous material mentioned by way of introduction is preferably foamed plastic, but may be any material satisfying the requirements, for example, finely wired steel wool.

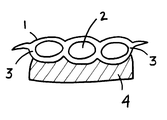

- the feed portion (1) in the depicted case comprises three channels (2) running side by side, each provided with microscopic apertures (3), which, because of the arched configuration of the tube, will open for emission at high pressure in the channels (2) but which will be sealed at low pressure in the channels.

- the surrounding cover (4) preferably of foamed plastic having pores running therethrough, is to ensure a further distribution of the injection material at the same time as it serves to keep the microscopic apertures open.

- the product according to the invention is simple and easy to produce compared with the most sophisticated embodiments of prior art, and can therefore be produced at a very low cost at the same time as the desired level of operational safety is maintained.

- the subject matter of the invention thus meets the market's need for an inexpensive product to be used with reasonable safety in all places where protection against water is necessary because of sporadic risk of water pressure outside the concrete structure, the main object, however, being not so much to shut out the water completely, as to delay water seepage, to the extent that the protection is proportional to the actual risk.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Architecture (AREA)

- Structural Engineering (AREA)

- Paleontology (AREA)

- Electromagnetism (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Physics & Mathematics (AREA)

- General Engineering & Computer Science (AREA)

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

- Building Environments (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Excavating Of Shafts Or Tunnels (AREA)

- Working Measures On Existing Buildindgs (AREA)

- Curing Cements, Concrete, And Artificial Stone (AREA)

- Forms Removed On Construction Sites Or Auxiliary Members Thereof (AREA)

- Acyclic And Carbocyclic Compounds In Medicinal Compositions (AREA)

Claims (1)

- Schlauch zur Chemikalieneinspritzung in Beton, mit einem für den Injektionsstoff vorgesehenen Zuführabschnitt (1), der von einem daran angebrachten umgebenden kompressiven, porösen Material umhüllt ist,

dadurch gekennzeichnet,

daß der Zuführabschnitt (1) wenigstens zwei geformte Kanäle (2) aufweist, die nebeneinander, vorzugsweise in einem Stück, verlaufen und in Form von Streifen gebildet sind, wobei in deren Außenwandungen mikroskopische Öffnungen (3) für einen Ausfluß von innen nach außen bei einem vorbestimmten inneren Überdruck gebildet sind.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| NO933815A NO178636C (no) | 1993-10-22 | 1993-10-22 | Slange for kjemisk injeksjon i betong |

| NO933815 | 1993-10-22 | ||

| PCT/NO1994/000164 WO1995011352A1 (en) | 1993-10-22 | 1994-10-12 | Hose for chemical injection in concrete |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0724673A1 EP0724673A1 (de) | 1996-08-07 |

| EP0724673B1 true EP0724673B1 (de) | 1999-09-08 |

Family

ID=19896529

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94931704A Expired - Lifetime EP0724673B1 (de) | 1993-10-22 | 1994-10-12 | Schlauch zur chemikalieneinspritzung in beton |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0724673B1 (de) |

| JP (2) | JPH09504585A (de) |

| AT (1) | ATE184346T1 (de) |

| AU (1) | AU8067994A (de) |

| DE (2) | DE69420575T2 (de) |

| DK (1) | DK0724673T3 (de) |

| NO (1) | NO178636C (de) |

| WO (1) | WO1995011352A1 (de) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO305806B1 (no) * | 1995-11-01 | 1999-07-26 | Bjarne Sem | FugebÕnd med injeksjonskanal |

| DE29712401U1 (de) | 1997-07-14 | 1997-10-02 | Contec Bauwerksabdichtungen GmbH, 32130 Enger | Abdichtungsformkörper aus flexiblem Material für die Arbeitsfugen zwischen Betonteilen |

| EP1236835B1 (de) * | 2001-02-16 | 2004-04-07 | Stekox GmbH | Verpressschlauch zum Abdichten von Bauwerksfugen |

| RU2007107955A (ru) * | 2004-08-03 | 2008-09-10 | Аграр Хеми Аг (Ch) | Уплотнительное устройство с имеющим полный профиль прессованным изделием для уплотнения стыка между двумя конструктивными элементами |

| DE202010008322U1 (de) * | 2010-08-20 | 2011-11-21 | Tremco Illbruck Produktion Gmbh | Schaumstoff-Dichtband in einer Bauwerksfuge und Schaumstoff-Dichtband |

| CN110700328A (zh) * | 2018-07-10 | 2020-01-17 | 青岛中科坤泰装配建筑科技有限公司 | 一种防水胶条 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59212244A (ja) * | 1983-05-17 | 1984-12-01 | エ−フア−マリ−ア・ラスバツハ | 多層有孔管 |

| NO163194C (no) * | 1988-03-04 | 1990-04-18 | Protan As | Injeksjonsslange. |

| NO177939C (no) * | 1991-03-19 | 1995-12-20 | Bjarne Sem | Injeksjonsslange for kjemisk injeksjon i betong |

-

1993

- 1993-10-22 NO NO933815A patent/NO178636C/no not_active IP Right Cessation

-

1994

- 1994-10-12 EP EP94931704A patent/EP0724673B1/de not_active Expired - Lifetime

- 1994-10-12 JP JP7511629A patent/JPH09504585A/ja active Pending

- 1994-10-12 DK DK94931704T patent/DK0724673T3/da active

- 1994-10-12 DE DE69420575T patent/DE69420575T2/de not_active Expired - Lifetime

- 1994-10-12 AU AU80679/94A patent/AU8067994A/en not_active Abandoned

- 1994-10-12 WO PCT/NO1994/000164 patent/WO1995011352A1/en not_active Ceased

- 1994-10-12 AT AT94931704T patent/ATE184346T1/de active

- 1994-10-20 DE DE9416927U patent/DE9416927U1/de not_active Expired - Lifetime

- 1994-10-21 JP JP1994012996U patent/JP3011894U/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| NO178636B (no) | 1996-01-22 |

| JPH09504585A (ja) | 1997-05-06 |

| NO933815D0 (no) | 1993-10-22 |

| ATE184346T1 (de) | 1999-09-15 |

| DE69420575T2 (de) | 2000-02-17 |

| DK0724673T3 (da) | 1999-12-20 |

| NO178636C (no) | 1996-05-02 |

| WO1995011352A1 (en) | 1995-04-27 |

| EP0724673A1 (de) | 1996-08-07 |

| AU8067994A (en) | 1995-05-08 |

| NO933815L (no) | 1995-04-24 |

| JP3011894U (ja) | 1995-06-06 |

| DE69420575D1 (de) | 1999-10-14 |

| DE9416927U1 (de) | 1994-12-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4621941A (en) | Manhole riser having integral flexible waterlock for manhole covers and having a water tight seal for sealed manhole covers | |

| US4737220A (en) | Method of making a manhole riser having integral flexible waterlock for manhole covers and having a water tight seal for sealed manhole covers | |

| EP0724673B1 (de) | Schlauch zur chemikalieneinspritzung in beton | |

| NO982386D0 (no) | FremgangsmÕte for fremstilling av en stor tank, anvendelse av en slik tank og fremgangsmÕte for Õ bygge en nedsenket tunnel | |

| FI68894C (fi) | Saett foer framstaellning av ett roer | |

| US3917285A (en) | Collar for joint of underground pipe | |

| WO1992016696A1 (en) | Injection tube for chemical injection in concrete | |

| US3376629A (en) | Method and means for support of cementitious materials on sloping surfaces during cure | |

| EP0646681A2 (de) | Wasserdichtmachen von Verbindungen zwischen Betonteilen | |

| EP0372027A1 (de) | Verfahren zum abdichten von schadhaften rohrleitungen. | |

| USRE29394E (en) | Corrosion protective band for underground pipe joints with metal parts | |

| US3904213A (en) | Corrosion protective band for underground pipe joints with metal parts | |

| US4268047A (en) | Underground pipe joint with hydratable cement in polyurethane gasket | |

| AU590266B2 (en) | Reusable casing system for creating free spaces in building materials | |

| JPH0516289Y2 (de) | ||

| JPH03107099A (ja) | 防水シート及びそれを用いた地下構造物のコンクリート施工方法 | |

| JP3715039B2 (ja) | 無漏水地下連続壁のシール装置 | |

| JPH0310460Y2 (de) | ||

| JPH0431360Y2 (de) | ||

| JPS63251528A (ja) | 地下構造物用蓋受枠の設置方法 | |

| JPS6259686A (ja) | 静的破砕材および破砕方法 | |

| JP2567722Y2 (ja) | 建設工事用養生材 | |

| JPH0633121Y2 (ja) | 配管用孔の補修用型枠 | |

| CA2043265C (en) | Heat transfer cement containment channel | |

| JPS6443668A (en) | Method of cut-off construction of concrete wall |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19960502 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19981103 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990908 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19990908 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990908 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990908 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990908 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19990908 |

|

| REF | Corresponds to: |

Ref document number: 184346 Country of ref document: AT Date of ref document: 19990915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991012 |

|

| REF | Corresponds to: |

Ref document number: 69420575 Country of ref document: DE Date of ref document: 19991014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991108 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: HEPP, WENGER & RYFFEL AG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19991209 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20041014 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20051012 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051031 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20061012 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061012 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20091007 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101013 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20130919 Year of fee payment: 20 Ref country code: DE Payment date: 20131029 Year of fee payment: 20 Ref country code: CH Payment date: 20131029 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69420575 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 184346 Country of ref document: AT Kind code of ref document: T Effective date: 20141012 |