EP0557753B1 - Dispositif de protection d'un appareil - Google Patents

Dispositif de protection d'un appareil Download PDFInfo

- Publication number

- EP0557753B1 EP0557753B1 EP93101707A EP93101707A EP0557753B1 EP 0557753 B1 EP0557753 B1 EP 0557753B1 EP 93101707 A EP93101707 A EP 93101707A EP 93101707 A EP93101707 A EP 93101707A EP 0557753 B1 EP0557753 B1 EP 0557753B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heating element

- switches

- thermostatic

- switch

- thermostatic switches

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010438 heat treatment Methods 0.000 claims abstract description 53

- 238000013021 overheating Methods 0.000 claims 2

- JRPBQTZRNDNNOP-UHFFFAOYSA-N barium titanate Chemical class [Ba+2].[Ba+2].[O-][Ti]([O-])([O-])[O-] JRPBQTZRNDNNOP-UHFFFAOYSA-N 0.000 description 2

- 229910002113 barium titanate Inorganic materials 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005755 formation reaction Methods 0.000 description 1

- 239000007937 lozenge Substances 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000004321 preservation Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/50—Means for increasing contact pressure, preventing vibration of contacts, holding contacts together after engagement, or biasing contacts to the open position

- H01H1/504—Means for increasing contact pressure, preventing vibration of contacts, holding contacts together after engagement, or biasing contacts to the open position by thermal means

Definitions

- the present invention relates to a device for protecting a device, e.g. a discharge lamp, with an opening thermal switch connected in series with the device and its power supply to interrupt the power supply in the event of overtemperature, and a heating element which is connected to the power supply instead of the device in the event of overtemperature.

- a device e.g. a discharge lamp

- an opening thermal switch connected in series with the device and its power supply to interrupt the power supply in the event of overtemperature

- a heating element which is connected to the power supply instead of the device in the event of overtemperature.

- Such a device is known from FR-A-1 401 964.

- the thermal switch is a changeover switch that either connects the device to be protected or the heating resistor to the power supply.

- the device and the heating resistor are connected at one end and connected to the power supply, while the other two connections of the device and the heating element can optionally be connected to the other connection of the power supply via the thermal switch.

- the device to be protected is connected to the power supply below the response temperature of the thermal switch. If the temperature of the device now rises in an impermissible manner, the thermal switch switches over, i.e. disconnects the device from the power supply and instead connects the heating resistor to the power supply. The heating resistor now flowed through by the current develops a heat that is sufficient to keep the thermal switch open.

- the known thermal switch is a special component in which the heating resistor is integrated into the housing, but must nevertheless be connected separately.

- a thermal switch that opens when the temperature rises is provided in parallel with a heating element, both of which are connected in series with the load to be protected.

- the closed thermal switch has a low resistance, so that the current flows essentially through it, while practically no current flows through the heating element connected in parallel, so that it does not heat either. If the load to be protected reaches an excess temperature due to a fault, the temperature switch is opened so that no current can flow to the load through it.

- the very low residual current is not sufficient in the event of a fault to keep the thermal switch open, so that undesirable clocking occurs here.

- the thermal switch designed as a changeover switch is also a special component with all the associated disadvantages.

- this object is achieved according to the invention in that a further, closing thermal switch is provided, which is arranged in series with the heating element, the series circuit comprising the heating element and the thermal switch being arranged parallel to the series circuit comprising the device and the thermal switch.

- a pure closer in addition to the pure opener, a pure closer is also provided, both of which are constructed in the usual way.

- the thermal switch lying in series with the load is opened and, at the same time, the closing thermal switch lying parallel to the load and the opening thermal switch is closed, so that the heating connected in series with the supply voltage sets. Now there is a current flow through the heater, which heats up the heater so that it can open the opening thermal switch and keep the closing thermal switch closed.

- the heating element is self-stabilizing, the heating element in particular being a PTC thermistor.

- the switches are bimetallic switches.

- the heating element is in direct thermal contact with the switches, the switches and the heating element in particular being arranged in a common envelope.

- the bimetallic switches are arranged in an electrically conductive housing which forms one of their contacts, in particular the heating element between the two metallic conductive housings of the switches being arranged in contact with them and only the circuit breaker but not the closing switch is provided with an electrical connection on its housing.

- a preferred specific embodiment provides that the two switches are arranged with their bottoms facing one another with the heating element being interposed, whereby an additional mechanical preservation can be achieved in that the entire unit consisting of the two switches and the heating element is arranged, for example, in a shrink tube .

- switches are arranged next to one another, the heating element being arranged below their bottoms and forming an electrical and thermal bridge, and that the two switches are next to each other are arranged and the heating element is arranged between them, in the latter case the heating element being arranged between two flat legs of electrically conductive transmission angles, the further angled leg of which touches the bottom of the switch at the bottom.

- a further embodiment provides that the switches are covered on their top by an insulating layer, which only has an opening in the central areas of the switches Contacting of electrical connections at the further contact of the switches are left free.

- the device according to the invention is used to protect against overtemperature in a load in which only a small residual current flows in the event of a fault that this does not result in the heating resistor being connected in parallel with this, but together with these in series with the heating resistor, for the usual self-holding of the thermal circuit breaker is sufficient.

- a heater 3 and a thermal switch 4 acting as a make contact are connected or arranged in parallel with the thermal protective switch designed in the usual manner as an opener or thermal protective switch 2 and the load, as shown in FIG. 1 .

- Thermal protection switch 2 acting as a make contact thermal switch 4 are preferably formed as a unit that is spatially arranged close to the load 1 becomes.

- the heater 3 is a self-stabilizing resistor, such as a PTC thermistor, in particular in the form of a barium titanate PTC element.

- the thermal protection switch 2 and the closing switch 4 have the same switchover temperatures. If the switching temperature is exceeded due to an accident on the load 1, heat build-up or the like, the thermal protection switch 2 opens on the one hand, and the closing switch 4 closes on the other hand. By opening the thermal protection switch 2, the load 1 is removed from the mains and therefore protected. By closing the closing switch 4, the heater 3 is applied to the network and thus heats. A sufficient temperature is achieved by heating the heater 3, even if, after the load 1 has been switched off, this no longer generates an increased temperature in order to keep the thermal protection switch 2 open continuously and to cycle and thus switch the load 1 on and off again prevent.

- the thermal switches 2,4 are preferably designed as bimetallic switches in a manner known per se.

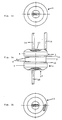

- FIGS. 2a to 2c A first specific embodiment of the device according to the invention is shown in FIGS. 2a to 2c.

- the thermal protection switch 2 and the closing switch 4 are bimetallic switches with a metallic housing 6 and 7, which are formed in the usual way and which form the one contact connection of the switches 2 and 4, respectively.

- the housings 6, 7 are flat pastille-like housings with a flat circular bottom.

- the switches 2, 4 are directed towards one another with their bases 8, 9 and that is between the bases 8, 9 Heating element 3 arranged. As I said, this consists of a PTC lozenge.

- the entire unit comprising switches 2, 4 and heating 3 are encased by a covering, such as a shrink tube, which holds the parts together and the switches 2, 4 from both sides against the heating 3 presses.

- the thermal protection switch 2 is provided on the one hand on its contact 13, which is insulated with respect to its housing 6 (on the end face opposite its base 8), with a connecting lead 14, and on the other hand with a connecting lead 16 on its housing, while the closing switch 4 is only insulated on its housing 7

- Contact 17 is provided with a lead 18.

- the connecting strands can be attached in the usual way, such as soldered or welded.

- the stranded wire 14 is connected to one side of the load 1, the stranded wire 16 to the one end of the network and the stranded wire 18 to the other side of the load and the other side of the network.

- the circuit of FIG. 1 is implemented in this way.

- the unit of FIGS. 2a to 2c is spatially closely arranged under the load, for example integrated in a discharge lamp luminaire.

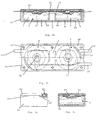

- FIGS 3a to 3d show a further embodiment of the device according to the invention.

- the switches 2, 4 are arranged side by side in a flat insulating housing 21, which is closed by a cover 22, for example by means of rivets 23.

- the heating element 3 is arranged between the two switches 2, 4.

- the switches 2, 4 are seated on a lower leg 26, 27 of electrically conductive angle parts 28, 29, the side legs 31, 32 of which are parallel to each other next to the mutually facing sides of the switches 2, 4 extend and between which the heating element 3 is arranged.

- a pressing pressure is achieved in that the switches 2, 4 are held on their sides opposite the legs 31, 32 by formations 33, 34 of the housing 21 and are pressed against one another, so that the legs 31, 32 are pressed firmly against the heating element. This results in the desired good electrical and thermal contact.

- connection contacts 14, 16, 18 are each designated with the same reference numerals as the corresponding connections in the configuration of FIGS. 2a to 2c. In the embodiment of FIGS. 3a to 3d, they are formed by flat tabs which, on the one hand, rest on connection 14, 18 on the upper contact of switches 2, 4, which is insulated from the respective housing 6, 7, and are pressed against them by cover 22, whereby tabs are led out of the side of the housing.

- the connection 16 has an arcuate contact part 36, which bears laterally within the form 33 on the side wall of the temperature protection switch 2.

- the contacts 14, 18 are provided with a resilient tab 37, 38.

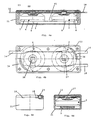

- FIGS. 4a to 4d The configuration of FIGS. 4a to 4d is similar to that of FIGS. 3a to 3d.

- the same elements are drawn with the same reference numerals; with regard to the same elements, reference is made to the explanation of FIGS. 3a to 3d.

- an elongated heating element in the form of a PTC barium titanate strip or the like is arranged below the two switches 2, 4, which are arranged next to one another, as in FIGS. 3 a to 3 d, so that its top 41 on the bases 8, 9 the housing 6,7 the switch 2,4 is present.

- the contact pressure is brought about by the cover 22 attached. This creates a direct good heat and electrical contact between the switches 2,4 and the heating element 3.

Landscapes

- Thermally Actuated Switches (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Protection Of Static Devices (AREA)

- Surgical Instruments (AREA)

- Electronic Switches (AREA)

- Noodles (AREA)

Claims (13)

- Dispositif pour la protection d'un appareil (1), par exemple d'une lampe à décharge, comportantun interrupteur thermique (2) à ouverture, monté en série avec l'appareil (1) et son alimentation électrique, pour l'interruption de l'alimentation électrique en cas de température anormalement élevée, etun élément chauffant (3), qui, en cas de température anormalement élevée, est raccordé, à la place de l'appareil (1), à l'alimentation électrique,caractérisé en ce qu'il est prévu un autre interrupteur thermique (4) à fermeture, qui est monté en série avec l'élément chauffant (3), le circuit en série constitué de l'élément chauffant et de l'interrupteur thermique (4), étant parallèle au circuit en série constitué de l'appareil (1) et de l'interrupteur thermique (2).

- Dispositif selon la revendication 1, caractérisé en ce que l'élément chauffant (3) est autostabilisant.

- Dispositif selon la revendication 1 ou 2, caractérisé en ce que l'élément chauffant (3) est un conducteur froid.

- Dispositif selon l'une des revendications 1 à 3, caractérisé en ce que les interrupteurs thermiques (2, 4) sont des interrupteurs à bilame.

- Dispositif selon l'une des revendications 1 à 4, caractérisé en ce que l'élément chauffant (3) est en contact thermique direct avec les interrupteurs thermiques (2, 4).

- Dispositif selon la revendication 4 ou la revendication 4 et la revendication 5, caractérisé en ce que les interrupteurs à bilame sont placés dans un boîtier (6, 7) électriquement conducteur, qui forme l'un de leurs contacts.

- Dispositif selon l'une des revendications précédentes, caractérisé en ce que les interrupteurs thermiques (2, 4) et l'élément chauffant (3) sont placés dans une enveloppe commune.

- Dispositif selon la revendication 6, caractérisé en ce que l'élément chauffant (3) est placé entre les deux boîtiers (6, 7) métalliques conducteurs des interrupteurs thermiques (2, 4), de manière à toucher ceux-ci et seul l'interrupteur thermique (2) à ouverture, mais non l'interrupteur thermique (4) à fermeture, est pourvu sur son boîtier (6, 7) d'un branchement électrique (16).

- Dispositif selon la revendication 8, caractérisé en ce que les deux interrupteurs thermiques (2, 4) avec leurs fonds (8, 9) sont dirigés l'un contre l'autre avec insertion de l'élément chauffant (3).

- Dispositif selon la revendication 8, caractérisé en ce que les interrupteurs thermiques (2, 4) sont disposés côte à côte, l'élément chauffant (3) étant situé au-dessous de leurs fonds (8, 9) et formant un pont électrique ainsi qu'un pont thermique.

- Dispositif selon la revendication 8, caractérisé en ce que les deux interrupteurs thermiques (2, 4) sont disposés côte à côte et l'élément chauffant (3) est placé entre eux.

- Dispositif selon la revendication 11, caractérisé en ce que l'élément chauffant (3) est placé entre deux branches (31, 32) planes de pièces d'angle de transmission (28, 29) électriquement conductrices, dont une autre branche (26, 27) coudée touche le fond (8, 9) des interrupteurs thermiques (2, 4).

- Dispositif selon l'une des revendications 9 à 11, caractérisé en ce que les interrupteurs thermiques (2, 4) sont recouverts sur leur face supérieure par une couche isolante, qui est laissée libre uniquement dans des zones centrales des interrupteurs thermiques (2, 4) avec une ouverture en vue du contact de branchements électriques sur l'autre contact des interrupteurs thermiques (2, 4).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4205699 | 1992-02-25 | ||

| DE4205699A DE4205699A1 (de) | 1992-02-25 | 1992-02-25 | Vorrichtung zum Schützen eines Geräts |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0557753A2 EP0557753A2 (fr) | 1993-09-01 |

| EP0557753A3 EP0557753A3 (fr) | 1994-01-05 |

| EP0557753B1 true EP0557753B1 (fr) | 1997-05-02 |

Family

ID=6452503

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93101707A Expired - Lifetime EP0557753B1 (fr) | 1992-02-25 | 1993-02-04 | Dispositif de protection d'un appareil |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0557753B1 (fr) |

| AT (1) | ATE152545T1 (fr) |

| DE (2) | DE4205699A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4406533A1 (de) * | 1993-06-11 | 1994-12-15 | Tridonic Bauelemente Ges Mbh | Temperatur-Schutzschaltung für eine Drossel |

| DE4406534C2 (de) * | 1993-06-11 | 1998-10-29 | Tridonic Bauelemente | Zündgerät für Kaltstartentladungslampen |

| US7395825B2 (en) | 2002-02-26 | 2008-07-08 | Bsh Bosch Und Siemens Hausgeraete Gmbh | Method and device for activating an element made of a shape memory alloy |

| DE10208213A1 (de) * | 2002-02-26 | 2003-09-18 | Bsh Bosch Siemens Hausgeraete | Verfahren und Vorrichtung zum Ansteuern eines Elements aus einer Formgedächtnislegierung |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE452864A (fr) * | 1942-10-27 | |||

| US2930959A (en) * | 1958-09-26 | 1960-03-29 | Stubnitz Greene Corp | Motor overload protection system |

| FR1401964A (fr) * | 1963-07-19 | 1965-06-11 | Otter Controls Ltd | Interrupteur électrique sensible à la température |

| US3718879A (en) * | 1971-05-19 | 1973-02-27 | Texas Instruments Inc | Apparatus for starting and protecting of electrical motors |

| DE8806648U1 (de) * | 1988-05-20 | 1989-06-22 | Hofsäss, Peter, 7530 Pforzheim | Temperaturschalteinrichtung |

| DE59008766D1 (de) * | 1990-04-25 | 1995-04-27 | Hofsaes Geb Zeitz Ulrika | Temperaturschalter. |

-

1992

- 1992-02-25 DE DE4205699A patent/DE4205699A1/de not_active Ceased

-

1993

- 1993-02-04 DE DE59306306T patent/DE59306306D1/de not_active Expired - Lifetime

- 1993-02-04 AT AT93101707T patent/ATE152545T1/de not_active IP Right Cessation

- 1993-02-04 EP EP93101707A patent/EP0557753B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0557753A2 (fr) | 1993-09-01 |

| ATE152545T1 (de) | 1997-05-15 |

| EP0557753A3 (fr) | 1994-01-05 |

| DE59306306D1 (de) | 1997-06-05 |

| DE4205699A1 (de) | 1994-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0634888B1 (fr) | Unité enfichable, en particulier module de relais pour véhicules automobiles | |

| DE102010036909B3 (de) | Thermische Überlastschutzvorrichtung | |

| EP0557744B1 (fr) | Interrupteur thermique | |

| DE4336564C2 (de) | Temperaturwächter | |

| DE19752581C2 (de) | Schalter mit einem temperaturabhängigen Schaltwerk | |

| DE69208705T2 (de) | Elektrothermisches Relais mit Schichtheizelement | |

| DE19922633A1 (de) | Thermostat | |

| DE19717802A1 (de) | Funkenstrecke | |

| DE19816807C2 (de) | Temperaturabhängiger Schalter | |

| DE69702719T2 (de) | Elektrische sicherung | |

| DE1915721B2 (de) | Thermostatische schaltvorrichtung | |

| EP0557753B1 (fr) | Dispositif de protection d'un appareil | |

| EP0951041B1 (fr) | Interrupteur à commande thermique | |

| DE69505884T2 (de) | Geräte mit Widerstandselemeten und Temperaturschutzvorrichtung zum Gebrauch dafür | |

| DE19705410C2 (de) | Temperaturabhängiger Schalter mit Haltebügel | |

| DE1690287A1 (de) | Elektrischer Schalter | |

| DE1590760A1 (de) | Thermoschalter | |

| EP1043805B1 (fr) | Borne à connexion électrique | |

| DE3023644C2 (de) | Gehäuse für einen elektrischen keramischen Kaltleiter zum Verdampfen von chemischen Desinfektions- und/oder Insektizidsubstanzen | |

| EP1224714A2 (fr) | Borne de raccord | |

| DE2262276A1 (de) | Hochbelastbarer elektrischer widerstand | |

| DE2907763A1 (de) | Zeitschalter zum verzoegerten ein- und ausschalten von elektrischen geraeten | |

| DE19953954B4 (de) | Anschlußklemme | |

| DE1219579B (de) | Thermoschutzschalter | |

| DE2743147A1 (de) | Vorrichtung mit einem hochbelastbaren elektrischen widerstand |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE FR GB IT LI SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19940616 |

|

| 17Q | First examination report despatched |

Effective date: 19950928 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 152545 Country of ref document: AT Date of ref document: 19970515 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG Ref country code: CH Ref legal event code: EP |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970508 |

|

| REF | Corresponds to: |

Ref document number: 59306306 Country of ref document: DE Date of ref document: 19970605 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080215 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20080214 Year of fee payment: 16 Ref country code: IT Payment date: 20080220 Year of fee payment: 16 Ref country code: GB Payment date: 20080220 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080215 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080214 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090228 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090204 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090204 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090302 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090205 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110323 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59306306 Country of ref document: DE Effective date: 20120901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120901 |