EP0499974A2 - Ventilated filter cigarette - Google Patents

Ventilated filter cigarette Download PDFInfo

- Publication number

- EP0499974A2 EP0499974A2 EP92102466A EP92102466A EP0499974A2 EP 0499974 A2 EP0499974 A2 EP 0499974A2 EP 92102466 A EP92102466 A EP 92102466A EP 92102466 A EP92102466 A EP 92102466A EP 0499974 A2 EP0499974 A2 EP 0499974A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- chamber

- filter

- air

- adsorbent

- cigarette

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000019504 cigarettes Nutrition 0.000 title claims abstract description 46

- 239000003463 adsorbent Substances 0.000 claims abstract description 21

- 238000009423 ventilation Methods 0.000 claims abstract description 18

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 17

- 239000000463 material Substances 0.000 claims abstract description 16

- 241000208125 Nicotiana Species 0.000 claims abstract description 11

- 235000002637 Nicotiana tabacum Nutrition 0.000 claims abstract description 11

- 239000000203 mixture Substances 0.000 claims abstract description 10

- 239000000126 substance Substances 0.000 claims abstract description 9

- 230000014759 maintenance of location Effects 0.000 claims abstract description 8

- 239000011148 porous material Substances 0.000 claims abstract description 6

- 239000010408 film Substances 0.000 claims description 15

- 150000001875 compounds Chemical class 0.000 claims description 7

- FERIUCNNQQJTOY-UHFFFAOYSA-N Butyric acid Chemical compound CCCC(O)=O FERIUCNNQQJTOY-UHFFFAOYSA-N 0.000 claims description 6

- 239000000123 paper Substances 0.000 claims description 5

- 229920002472 Starch Polymers 0.000 claims description 4

- 229920002678 cellulose Polymers 0.000 claims description 4

- 239000001913 cellulose Substances 0.000 claims description 4

- XBDQKXXYIPTUBI-UHFFFAOYSA-N dimethylselenoniopropionate Natural products CCC(O)=O XBDQKXXYIPTUBI-UHFFFAOYSA-N 0.000 claims description 4

- 239000008107 starch Substances 0.000 claims description 4

- 235000019698 starch Nutrition 0.000 claims description 4

- 229920002134 Carboxymethyl cellulose Polymers 0.000 claims description 2

- 108010010803 Gelatin Proteins 0.000 claims description 2

- 239000001768 carboxy methyl cellulose Substances 0.000 claims description 2

- 235000010948 carboxy methyl cellulose Nutrition 0.000 claims description 2

- 239000008112 carboxymethyl-cellulose Substances 0.000 claims description 2

- 239000011888 foil Substances 0.000 claims description 2

- 229920000159 gelatin Polymers 0.000 claims description 2

- 239000008273 gelatin Substances 0.000 claims description 2

- 235000019322 gelatine Nutrition 0.000 claims description 2

- 235000011852 gelatine desserts Nutrition 0.000 claims description 2

- 125000001997 phenyl group Chemical class [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 claims description 2

- 239000002985 plastic film Substances 0.000 claims description 2

- 229920006255 plastic film Polymers 0.000 claims description 2

- 235000019260 propionic acid Nutrition 0.000 claims description 2

- IUVKMZGDUIUOCP-BTNSXGMBSA-N quinbolone Chemical compound O([C@H]1CC[C@H]2[C@H]3[C@@H]([C@]4(C=CC(=O)C=C4CC3)C)CC[C@@]21C)C1=CCCC1 IUVKMZGDUIUOCP-BTNSXGMBSA-N 0.000 claims description 2

- 241000446313 Lamella Species 0.000 claims 1

- 239000004368 Modified starch Substances 0.000 claims 1

- 229920000881 Modified starch Polymers 0.000 claims 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims 1

- 150000004676 glycans Chemical class 0.000 claims 1

- 229910052751 metal Inorganic materials 0.000 claims 1

- 239000002184 metal Substances 0.000 claims 1

- 235000019426 modified starch Nutrition 0.000 claims 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 claims 1

- 229920001282 polysaccharide Polymers 0.000 claims 1

- 239000005017 polysaccharide Substances 0.000 claims 1

- 150000003151 propanoic acid esters Chemical class 0.000 claims 1

- 229910052624 sepiolite Inorganic materials 0.000 claims 1

- 235000019355 sepiolite Nutrition 0.000 claims 1

- 239000000741 silica gel Substances 0.000 claims 1

- 229910002027 silica gel Inorganic materials 0.000 claims 1

- 239000002245 particle Substances 0.000 abstract description 8

- 230000001007 puffing effect Effects 0.000 abstract 4

- 239000012071 phase Substances 0.000 description 22

- 239000000779 smoke Substances 0.000 description 19

- 230000009467 reduction Effects 0.000 description 10

- 239000000796 flavoring agent Substances 0.000 description 8

- 235000019634 flavors Nutrition 0.000 description 7

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 7

- 229920002301 cellulose acetate Polymers 0.000 description 4

- 239000003245 coal Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 238000000034 method Methods 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 230000000391 smoking effect Effects 0.000 description 3

- SNICXCGAKADSCV-JTQLQIEISA-N (-)-Nicotine Chemical compound CN1CCC[C@H]1C1=CC=CN=C1 SNICXCGAKADSCV-JTQLQIEISA-N 0.000 description 2

- AZUYLZMQTIKGSC-UHFFFAOYSA-N 1-[6-[4-(5-chloro-6-methyl-1H-indazol-4-yl)-5-methyl-3-(1-methylindazol-5-yl)pyrazol-1-yl]-2-azaspiro[3.3]heptan-2-yl]prop-2-en-1-one Chemical compound ClC=1C(=C2C=NNC2=CC=1C)C=1C(=NN(C=1C)C1CC2(CN(C2)C(C=C)=O)C1)C=1C=C2C=NN(C2=CC=1)C AZUYLZMQTIKGSC-UHFFFAOYSA-N 0.000 description 2

- HGINCPLSRVDWNT-UHFFFAOYSA-N Acrolein Chemical compound C=CC=O HGINCPLSRVDWNT-UHFFFAOYSA-N 0.000 description 2

- 125000003118 aryl group Chemical group 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 238000004817 gas chromatography Methods 0.000 description 2

- 229960002715 nicotine Drugs 0.000 description 2

- SNICXCGAKADSCV-UHFFFAOYSA-N nicotine Natural products CN1CCCC1C1=CC=CN=C1 SNICXCGAKADSCV-UHFFFAOYSA-N 0.000 description 2

- 230000001953 sensory effect Effects 0.000 description 2

- URAYPUMNDPQOKB-UHFFFAOYSA-N triacetin Chemical compound CC(=O)OCC(OC(C)=O)COC(C)=O URAYPUMNDPQOKB-UHFFFAOYSA-N 0.000 description 2

- 208000010470 Ageusia Diseases 0.000 description 1

- IKHGUXGNUITLKF-XPULMUKRSA-N acetaldehyde Chemical compound [14CH]([14CH3])=O IKHGUXGNUITLKF-XPULMUKRSA-N 0.000 description 1

- 235000019666 ageusia Nutrition 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000010790 dilution Methods 0.000 description 1

- 239000012895 dilution Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000001087 glyceryl triacetate Substances 0.000 description 1

- 235000013773 glyceryl triacetate Nutrition 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 238000005470 impregnation Methods 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 150000002825 nitriles Chemical class 0.000 description 1

- 239000005416 organic matter Substances 0.000 description 1

- 239000004848 polyfunctional curative Substances 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 150000003216 pyrazines Chemical class 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000002594 sorbent Substances 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 230000002195 synergetic effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 229960002622 triacetin Drugs 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/16—Use of materials for tobacco smoke filters of inorganic materials

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B15/00—Chemical features or treatment of tobacco; Tobacco substitutes, e.g. in liquid form

- A24B15/18—Treatment of tobacco products or tobacco substitutes

- A24B15/28—Treatment of tobacco products or tobacco substitutes by chemical substances

- A24B15/30—Treatment of tobacco products or tobacco substitutes by chemical substances by organic substances

- A24B15/34—Treatment of tobacco products or tobacco substitutes by chemical substances by organic substances containing a carbocyclic ring other than a six-membered aromatic ring

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B15/00—Chemical features or treatment of tobacco; Tobacco substitutes, e.g. in liquid form

- A24B15/18—Treatment of tobacco products or tobacco substitutes

- A24B15/28—Treatment of tobacco products or tobacco substitutes by chemical substances

- A24B15/30—Treatment of tobacco products or tobacco substitutes by chemical substances by organic substances

- A24B15/36—Treatment of tobacco products or tobacco substitutes by chemical substances by organic substances containing a heterocyclic ring

- A24B15/38—Treatment of tobacco products or tobacco substitutes by chemical substances by organic substances containing a heterocyclic ring having only nitrogen as hetero atom

Definitions

- the invention relates to a ventilated filter cigarette according to the preamble main claim.

- Such filter cigarettes with a triple filter or three-chamber filter which is also referred to as a three-component filter

- DE-OS 3 635 958 which is primarily a filter with two filter elements, namely one discloses essentially air-impermeable filter element with a large pressure drop and a second air-permeable filter element with a relatively low pressure drop.

- the possibility is also discussed of arranging the two filter elements at a distance from one another and an adsorbent such as activated carbon in the intermediate space to reduce the vapor phase components.

- the total smoke of a commercially available, medium-strength filter cigarette is made up of approximately 5-10% by weight of a particle phase and about 90-95 wt .-% of a gas phase, of which about 2-5 wt .-% are biologically or taste relevant.

- the aim is to reduce smoke in the gas phase with less organically volatile gas phase components, so that the use of adsorbents such as activated carbon would be advantageous in principle if these adsorbents did not change the taste of the cigarette smoke in an undesirable direction.

- the object of the invention is to propose a filter cigarette which, while maintaining a qualitatively and quantitatively good range of flavors, has a disproportionately high gas phase reduction with a condensate and Nicotine reduction enables, and in the so far usual and perceived by consumers as annoying secondary taste or so-called "coal taste” is suppressed or completely prevented.

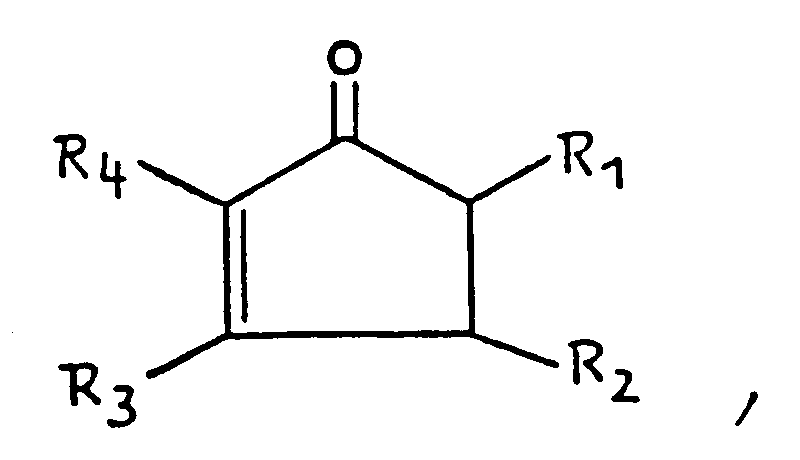

- the flavoring of the tobacco rod with flavorings may be known per se, however, according to the invention, a mixture of flavorings from two groups, namely one or more compounds of flavorings, is proposed for the ventilated filter cigarette with a triple filter or a three-chamber filter Group A according to the general formula in which R1 to R4 are the same or different and are H, CH3, CH3 - CH2, OH, butyric acid or propionic acid or CH3-O.

- Group B consists of one or more compounds of the general formula in which R1 to R4 are the same or different and are H, CH3, CH3 - CH2 or a cyclic hydrocarbon radical, R1 with R2 or R3 with R4 can form a benzene nucleus, consists.

- R1 to R4 are the same or different and are H, CH3, CH3 - CH2 or a cyclic hydrocarbon radical, R1 with R2 or R3 with R4 can form a benzene nucleus, consists.

- Preferred compounds of the flavorings according to group B are the pyrazines containing more than two methyl groups.

- flavorings namely additionally as third component, those of group C in amounts up to 200 ppm, namely compounds of the general formula, can preferably be used in which R1 and R2 are the same or different and are H, CH3 or CH3 - CH2.

- This impregnation of the tobacco rod with the aroma mixture from group A and group B and preferably additionally from group C is related to the adsorbents, which are arranged in a central chamber between two filter elements. These adsorbents should fill at least 70 to 95% by volume of the middle chamber. Furthermore, at least 80% by volume of this activated carbon adsorbent with a pore volume of 0.7 to 0.8 cm 3 / g and a predominant pore radius of 0.9 to 1.0 nm and a particle size distribution corresponding to the mesh size of 177 ⁇ m to 500 ⁇ m (in accordance with ASTM No. 35 and No. 80 or the corresponding ISO screens).

- the middle chamber is not completely filled with adsorbent, the secondary air, together with the formation of the first strand-side filter element and the perforation, brings about better contact of the mainstream smoke with the adsorbent, with the corresponding selection of the components of the mixture of flavoring substances in contrast to other more biologically relevant components in the gas phase.

- the adsorbent in the middle chamber not only with that from the first filter element the main smoke stream escaping almost linearly comes into contact, but is additionally whirled through with or from the ventilation air, which is achieved in that the air-impermeable covering by preferably continuous perforations - or online laser perforations - ventilation in the area of the middle chamber and / or previously in enables a downstream portion of the first strand-side filter component or filter chamber.

- Ventilation downstream of the first strand-side filter chamber is known per se. Because the ventilation takes place in the area of the middle chamber filled with adsorbents, in addition to a dilution of the main stream smoke, better turbulence and thus better contact of the main stream smoke with the adsorbent is achieved. If, alternatively or additionally, ventilation is also made possible in a downstream portion of the first strand-side chamber, the gas phase comes into even better contact with the adsorbent.

- the perforation which is usually done online by laser beams, should be such that the degree of filter ventilation is 30 to 80%.

- the first chamber-side chamber contains a filter material with high tensile resistance, which essentially only allows passage of the main flow smoke in the longitudinal direction and does not allow radial distribution of the main flow smoke in this first filter element, the main flow smoke emerges from this first filter component initially in a laminar manner, then induced by ventilation air relatively swirling into the middle chamber partially filled with sorbents and increases the adsorption of the gas phase. If the perforation occurs in a downstream portion of the first strand-side filter component, which, for example, accounts for half or a third of the filter length, this is not due to the high tensile resistance and the lamella-like configuration reckon that the secondary air entering through the perforations in this section is still accompanied by substantial amounts of mainstream smoke into the chamber.

- the first filter element has a relatively high tensile resistance of 0.8 to 1.6 kPa and, due to its preferred material design and configuration, shows a low tar retention.

- the third filter element located downstream of the middle chamber with the adsorbent has a much lower tensile resistance of 0.2 to 0.4 kPa and preferably consists of conventional filter material such as cellulose acetate.

- the filter material in the first strand-side chamber which is said to have a high tensile resistance and a lower tar retention, can consist of paper films, cellulose or cellulose derivative films cut lengthwise, cut in strips, flowed through in the longitudinal direction or rolled, or arranged in zigzag layers and flowed lengthways.

- swellable films are used, namely those made of gelatin, carboxymethyl cellulose, carboxymethylated starch or polyoxymethacrylates, it also being possible to use non-swellable carrier films which are coated with a swellable material.

- the films which are strongly swellable with water or made swellable by coating Foils have the advantage that even small amounts of condensed moisture, which can be up to 10 mg H2O per cigarette according to DIN 10240, increase the draft resistance in the course of smoking the cigarette, which not only compensates for the gradually decreasing draft resistance of the tobacco rod , but also an increased ventilation is made possible by increasing the tensile resistance before the perforations in the downstream ventilated partial area of the first strand-side filter component or in the ventilated middle chamber. Designed accordingly, this leads to an approximately constant gas and particle phase supply per train.

- the first strand-side filter element already ensures a high tensile resistance due to the material or the geometrical arrangement and thus favors ventilation in the downstream portion of this first strand-side filter element, in that the "channels" or “gaps" in the peripheral region of the filter preferably with ventilation air are supplied, it is also possible to provide specially embossed channels in the peripheral part of this section, which are closed upstream, so that no main current smoke can penetrate.

- the third filter component on the mouth side consists of a conventional filter element with low tensile resistance, which results in a laminar flow pattern with low retention.

- This mouth-side chamber preferably contains conventional, air-permeable cellulose acetate fiber cable.

- the filter components were assembled by hand to form a three-chamber filter according to the invention, the term "chamber" generally also being used in the sense of a filter section.

- the degree of ventilation or air intake of the filter cigarettes produced in this way was 55%, and the consumer-relevant final pull resistance resulting from this and the listed individual pulling resistances was 0.95 kPa mm WS.

- Example 1 Three-chamber filter cigarettes according to Example 1 were smoked in addition to machine-made reference cigarettes (mono filter cigarettes without activated carbon, but with the same tobacco mixture) in accordance with DIN 10240.

- the CO content was determined according to DIN draft 10248, the NO content according to the chemiluminescence method common in the cigarette industry.

- the gas phase reduction of the test cigarette determined by the internal method was on average about 65% compared to the comparison cigarette for 18 representative substances.

- the cigarettes are smoked according to DIN 10240 on an RM 20 (from Borgwaldt).

- the particle phase is separated by means of an electrostatic smoke trap; the gas phase is collected in a glass cylinder.

- the separation into individual substances is carried out by gas chromatography via a separating capillary 60 m ⁇ 0.32 mm inside diameter, coated with 0.5 ⁇ DB-Wax (J & W, gas chromatograph 4160 from Carlo Erba).

- Test cigarettes according to Example 1 were sensory-checked in comparison with the comparison cigarettes from a tested smoking panel of 10 people. Surprisingly, this resulted in the almost complete absence of the undesired "off button” effect (10 corresponding smoke judgments in this regard), but with somewhat reduced aroma and filling values.

- Three-chamber filter cigarettes according to Example 1 the strands of which, however, were provided with the flavoring substances according to the invention (150 ppm Flavor Class A; 15 ppm Flavor Class B; 10 ppm Flavor Class C), were smoke analysis as in Example 1, in addition to the same reference cigarettes and checked sensory.

- the analytical-physical data were as expected as in Example 1.

- the sensory evaluation was carried out by the same team of experts. Finding: The experimental cigarettes were judged to be full, tobacco-like and aromatic with other equivalence to the reference cigarettes. An "off button / off flavor" effect was not found. (9 matching, 1 different smoking judgment).

- Three-chamber filter cigarettes according to the invention were produced in accordance with Example 1a, but, in deviation from this, contained 100 mg of activated carbon 30-70 mesh in the middle chamber, and whose filter section on the strand side consisted of starch film arranged in a zigzag layer.

- the gas phase reduction compared to the comparative cigarette for 18 representative substances averaged about 85%, e.g. 79% for acetaldehyde, 87% for HCN, 90% for acrolein.

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

- Manufacture Of Tobacco Products (AREA)

- Fats And Perfumes (AREA)

Abstract

Description

Die Erfindung betrifft eine ventilierte Filtercigarette gemäß Oberbegriff Hauptanspruch.The invention relates to a ventilated filter cigarette according to the preamble main claim.

Derartige Filtercigaretten mit einem Dreifach-Filter oder Drei-Kammer-Filter, der auch als Drei-Komponenten-Filter bezeichnet wird, sind beispielsweise aus der DE-OS 3 635 958 bekannt, die zwar in erster Linie einen Filter mit zwei Filterelementen, nämlich einem im wesentlichen luftundurchlässiges Filterelement mit großem Druckabfall und einem zweiten luftdurchlässigen Filterelement mit relativ niedrigem Druckabfall offenbart. Um einerseits einen sehr hohen Grad an Ventilation und damit eine Verminderung des CO-Gehaltes zu ermöglichen ohne andererseits Geschmack und Druckabfall auf unannehmbar niedrige Werte herabzusetzen, wird auch die Möglichkeit erörtert, die beiden Filterelemente mit Abstand voneinander anzuordnen und in dem Zwischenraum ein Adsorptionsmittel wie Aktivkohle zur Verringerung der Dampfphasenkomponenten einzufügen.Such filter cigarettes with a triple filter or three-chamber filter, which is also referred to as a three-component filter, are known for example from DE-OS 3 635 958, which is primarily a filter with two filter elements, namely one discloses essentially air-impermeable filter element with a large pressure drop and a second air-permeable filter element with a relatively low pressure drop. In order to enable a very high degree of ventilation on the one hand and thus a reduction in the CO content without reducing the taste and pressure drop to unacceptably low values on the other hand, the possibility is also discussed of arranging the two filter elements at a distance from one another and an adsorbent such as activated carbon in the intermediate space to reduce the vapor phase components.

Der Gesamtrauch einer marktgängigen, mittelkräftigen Filtercigarette setzt sich zusammen aus etwa 5-10 Gew.-% einer Partikelphase und etwa 90-95 Gew.-% einer Gasphase, wovon etwa 2-5 Gew.-% biologisch bzw. geschmacklich relevant sind. Anzustreben ist ein in der Gasphase reduzierter Rauch mit weniger organischflüchtigen Gasphase-Anteilen, so daß der Einsatz von Adsorptionsmittel wie Aktivkohle im Prinzip vorteilhaft wäre, wenn diese Adorptionsmittel nicht den Geschmack des Cigarettenrauches in eine unerwünschte Richtung verändern würden. Diese unerwünschte Geschmacksveränderung, die als "Nebengeschmack" oder "Kohlegeschmack" erkannt wird, hat man versucht einzuschränken, und zwar durch Beschichtung der Kohlenstoffteilchen gemäß DE-PS 2 527 569 oder durch Einsatz von Diaphragmen aus dampfdurchlässigem Material, z.B. gemäß DE-OS 2 355 493.The total smoke of a commercially available, medium-strength filter cigarette is made up of approximately 5-10% by weight of a particle phase and about 90-95 wt .-% of a gas phase, of which about 2-5 wt .-% are biologically or taste relevant. The aim is to reduce smoke in the gas phase with less organically volatile gas phase components, so that the use of adsorbents such as activated carbon would be advantageous in principle if these adsorbents did not change the taste of the cigarette smoke in an undesirable direction. This undesirable change in taste, which is recognized as a "secondary taste" or "coal taste", has been attempted to be restricted by coating the carbon particles in accordance with DE-PS 2 527 569 or by using diaphragms made of vapor-permeable material, for example in accordance with DE-OS 2 355 493.

Derartige Versuche haben sich jedoch wegen des komplizierten Aufbaus des Adsorptionsmaterials oder des Filters nicht durchgesetzt.However, such attempts have not been successful because of the complicated structure of the adsorbent material or the filter.

Eine weitere Möglichkeit zur Erzielung von guten, in der Gasphase reduzierenden Filtern wird mit ventilierten Filtern, z.B. gemäß DE-OS 3 625 593 erreicht, der allein durch die Ventilierung eine bis zu 80%ige Absenkung des Gesamtgasphasenbereiches bewirkt, wenngleich einzelne Komponenten unterschiedlich stark abgesenkt werden und gleichfalls auch eine etwa 80%ige Reduzierung der Gesamtpartikelphase bewirkt wird. Dieses führt naturgemäß zu einem entsprechend hohen Geschmacksverlust, der auch durch die nicht unbeträchtliche Retention der Kondensate erzielt wird. Derartige Filter eignen sich für extrem leichte Cigaretten der "Ultra-Leicht"-Sorten mit vergleichsweise geringem Geschmacksvolumen, welches nur durch einen besonders hohen Nikotingehalt der Tabakmischung oder auf andere Weise kompensiert werden kann.Another way to achieve good filters that reduce in the gas phase is with ventilated filters, e.g. achieved according to DE-OS 3 625 593, which brings about an up to 80% reduction in the total gas phase range solely through the ventilation, although individual components are lowered to different extents and also an approximately 80% reduction in the total particle phase. This naturally leads to a correspondingly high loss of taste, which is also achieved by the not inconsiderable retention of the condensates. Filters of this type are suitable for extremely light cigarettes of the “ultra-light” types with a comparatively low taste volume, which can only be compensated for by a particularly high nicotine content of the tobacco mixture or in some other way.

Die Erfindung hat sich die Aufgabe gestellt, eine Filtercigarette vorzuschlagen, die bei Aufrechterhaltung eines qualitativ und quantitativ guten Geschmacksangebotes eine überproportional hohe Gasphasenreduktion bei einer gleichzeitig üblichen Kondensat- und Nikotinreduktion ermöglicht, und bei der der bislang übliche und von den Verbrauchern als störend empfundene Nebengeschmack oder sogenannte "Kohlegeschmack" unterdrückt oder völlig verhindert wird.The object of the invention is to propose a filter cigarette which, while maintaining a qualitatively and quantitatively good range of flavors, has a disproportionately high gas phase reduction with a condensate and Nicotine reduction enables, and in the so far usual and perceived by consumers as annoying secondary taste or so-called "coal taste" is suppressed or completely prevented.

Zur Lösung dieser Aufgabe wird daher eine Filtercigarette der eingangs erwähnten Art vorgeschlagen, welche gemäß Kennzeichen Hauptanspruch ausgebildet ist, wobei besonders bevorzugte Ausführungsformen in den Unteransprüchen erwähnt sind.To achieve this object, a filter cigarette of the type mentioned at the outset is therefore proposed, which is designed according to the characterizing part of the main claim, particularly preferred embodiments being mentioned in the subclaims.

Durch die Kombination von (a) Aromatisierung des Tabakstranges mit einem Gemisch von Aromastoffen aus zwei bestimmten Gruppen und (b) Einsatz eines bestimmten Adsorptionsmittels und (c) Ermöglichung einer bestimmten Ventilierung und (d) Kombination zweier Filterelemente erreicht man überraschenderweise eine Gasphasenphasenmenge, die einer modernen Cigarette im "Ultra-Leicht"-Bereich, von unter 2 mg Kondensat/Cigarette entspricht, während die Partikelphasenmenge dieser erfindungsgemäßen Cigarette im "Leicht"-Bereich liegend mit etwa 5 bis 6 mg Kondensat/Cigarette bestimmt wurde, und wobei ferner insgesamt ein guter Geschmack ohne "Neben- oder Kohle-Geschmack" auftritt.The combination of (a) flavoring the tobacco rod with a mixture of flavorings from two specific groups and (b) using a specific adsorbent and (c) enabling a certain ventilation and (d) combining two filter elements surprisingly achieves a gas phase quantity that one corresponds to modern cigarettes in the "ultra-light" range, of less than 2 mg of condensate / cigarette, while the particle phase quantity of this cigarette according to the invention in the "light" range was determined to be about 5 to 6 mg of condensate / cigarette, and further a good taste without "side or coal taste" occurs.

Wenngleich einzelne Merkmale der erfindungsgemäßen Kombination zum Teil bekannt sind, ergibt sich durch die Kombination aller dieser Merkmale auf synergistische Weise der oben erwähnte überraschende Effekt.Although individual features of the combination according to the invention are known in part, the combination of all of these features in a synergistic manner results in the above-mentioned surprising effect.

So mag an sich die Aromatisierung des Tabakstranges mit Aromastoffen bekannt sein, jedoch wird erfindungsgemäß für die vorliegende ventilierte Filtercigarette mit einem Dreifach-Filter oder einem Drei-Kammer-Filter eine Mischung von Aromastoffen aus zwei Gruppen vorgeschlagen, nämlich ein oder mehrerer Verbindungen von Aromastoffen der Gruppe A gemäß der allgemeinen Formel

in der R₁ bis R₄ gleich oder verschieden sind und H, CH₃, CH₃ - CH₂, OH, Buttersäureester- oder Propionsäureesterrest oder CH₃-O bedeuten.The flavoring of the tobacco rod with flavorings may be known per se, however, according to the invention, a mixture of flavorings from two groups, namely one or more compounds of flavorings, is proposed for the ventilated filter cigarette with a triple filter or a three-chamber filter Group A according to the general formula

in which R₁ to R₄ are the same or different and are H, CH₃, CH₃ - CH₂, OH, butyric acid or propionic acid or CH₃-O.

Diese Aromastoffe werden in Mengen von 10 bis 500 ppm eingesetzt.These flavors are used in amounts of 10 to 500 ppm.

Ferner ist es erforderlich, ein oder mehrere Aromastoffe der Gruppe B in der Mischung von Aromastoffen vorzusehen, wobei die Gruppe B aus ein oder mehreren Verbindungen der allgemeinen Formel

in der R₁ bis R₄ gleich oder verschieden sind und H, CH₃, CH₃ - CH₂ oder einen cyclischen Kohlenwasserstoffrest bedeuten, R₁ mit R₂ odere R₃ mit R₄ einen Benzolkern bilden können,

besteht. Diese Aromastoffe der Gruppe B werden in Mengen von 0,1 bis 100 ppm eingesetzt.It is also necessary to provide one or more Group B flavorings in the mixture of flavorings, where Group B consists of one or more compounds of the general formula

in which R₁ to R₄ are the same or different and are H, CH₃, CH₃ - CH₂ or a cyclic hydrocarbon radical, R₁ with R₂ or R₃ with R₄ can form a benzene nucleus,

consists. These Group B flavorings are used in amounts of 0.1 to 100 ppm.

Bevorzugte Verbindungen der Aromastoffe gemäß Gruppe B sind die mehr als zwei Methylgruppen enthaltenden Pyrazine.Preferred compounds of the flavorings according to group B are the pyrazines containing more than two methyl groups.

Vorzugsweise können noch weitere Aromastoffe, nämlich zusätzlich als dritte Komponente die der Gruppe C in Mengen bis zu 200 ppm eingesetzt werden, nämlich Verbindungen der allgemeinen Formel

in der R₁ und R₂ gleich oder verschieden sind und H, CH₃ oder CH₃ - CH₂ bedeuten.Other flavorings, namely additionally as third component, those of group C in amounts up to 200 ppm, namely compounds of the general formula, can preferably be used

in which R₁ and R₂ are the same or different and are H, CH₃ or CH₃ - CH₂.

Diese Imprägnierung des Tabakstranges mit dem Aromagemisch aus der Gruppe A und Gruppe B und vorzugsweise zusätzlich der Gruppe C steht in einem Zusammenhang mit den Adsorptionsmitteln, die in einer mittleren Kammer zwischen zwei Filterelementen angeordnet sind. Diese Adsorptionsmittel sollen mindestens 70 bis zu 95% der mittleren Kammer volumenmäßig ausfüllen. Ferner sollen mindestens 80 Vol.-% dieses Adsorptionsmittels aus Aktivkohle mit einem Porenvolumen von 0,7 bis 0,8 cm³/g und einem überwiegenden Porenradius von 0,9 bis 1,0 nm und einer Korngrößenverteilung entsprechend der Siebmaschenweite von 177 µm bis 500 µm (gemäß den A.S.T.M-Sieben Nr. 35 und Nr. 80 bzw. den damit korrespondierenden I.S.O.-Sieben) bestehen. Dadurch, daß die mittlere Kammer nicht vollständig mit Adsorptionsmittel angefüllt ist, bewirkt die Nebenluft zusammen mit der Ausbildung des ersten strangseitigen Filterelements und der Perforierung einen besseren Kontakt des Hauptstromrauches mit dem Adsorptionsmittel, wobei durch die entsprechende Auswahl der Komponenten der Mischung von Aromastoffen diese im Gegensatz zu anderen mehr biologisch relevanten Bestandteile in der Gasphase weniger zurückgehalten werden.This impregnation of the tobacco rod with the aroma mixture from group A and group B and preferably additionally from group C is related to the adsorbents, which are arranged in a central chamber between two filter elements. These adsorbents should fill at least 70 to 95% by volume of the middle chamber. Furthermore, at least 80% by volume of this activated carbon adsorbent with a pore volume of 0.7 to 0.8 cm 3 / g and a predominant pore radius of 0.9 to 1.0 nm and a particle size distribution corresponding to the mesh size of 177 μm to 500 µm (in accordance with ASTM No. 35 and No. 80 or the corresponding ISO screens). Because the middle chamber is not completely filled with adsorbent, the secondary air, together with the formation of the first strand-side filter element and the perforation, brings about better contact of the mainstream smoke with the adsorbent, with the corresponding selection of the components of the mixture of flavoring substances in contrast to other more biologically relevant components in the gas phase.

Ferner ist es wesentlich, daß das Adsorptionsmittel in der mittleren Kammer nicht nur mit dem aus dem ersten Filterelement nahezu linear austretenden Hauptrauchstrom in Kontakt gerät, sondern zusätzlich mit oder von der Ventilationsluft durchgewirbelt wird, was dadurch erreicht wird, daß die luftundurchlässige Umhüllung durch vorzugsweise durchgängige Perforationen - bzw. online Laserperforationen - eine Ventilation im Bereich der mittleren Kammer und/oder bereits vorher in einem stromabwärts liegenden Teilbereich der ersten strangseitigen Filter-Komponente oder Filterkammer ermöglicht.It is also essential that the adsorbent in the middle chamber not only with that from the first filter element the main smoke stream escaping almost linearly comes into contact, but is additionally whirled through with or from the ventilation air, which is achieved in that the air-impermeable covering by preferably continuous perforations - or online laser perforations - ventilation in the area of the middle chamber and / or previously in enables a downstream portion of the first strand-side filter component or filter chamber.

Eine Ventilation stromabwärts der ersten strangseitigen Filterkammer ist an sich bekannt. Dadurch, daß die Ventilation jedoch im Bereich der mit Adsorptionsmitteln angefüllten mittleren Kammer erfolgt, wird zusätzlich zu einer Verdünnung des Hauptstromrauches auch eine bessere Verwirbelung und somit ein besserer Kontakt des Hauptstromrauches mit dem Adsorptionsmittel erreicht. Wenn alternativ oder zusätzlich in einem stromabwärts liegenden Teilbereich der ersten strangseitigen Kammer ebenfalls eine Ventilation ermöglicht wird, ergibt sich ein noch besserer Kontakt der Gasphase mit dem Adsorptionsmittel. Die Perforierung, die meist online durch Laserstrahlen erfolgt, soll so bemessen sein, daß der Filterventilationsgrad 30 bis 80% beträgt.Ventilation downstream of the first strand-side filter chamber is known per se. Because the ventilation takes place in the area of the middle chamber filled with adsorbents, in addition to a dilution of the main stream smoke, better turbulence and thus better contact of the main stream smoke with the adsorbent is achieved. If, alternatively or additionally, ventilation is also made possible in a downstream portion of the first strand-side chamber, the gas phase comes into even better contact with the adsorbent. The perforation, which is usually done online by laser beams, should be such that the degree of filter ventilation is 30 to 80%.

Da die erste strangseitige Kammer ein Filtermaterial mit hohem Zugwiderstand enthält, das im wesentlichen nur einen Durchgang des Hauptstromrauches in Längsrichtung ermöglicht und nicht eine radiale Verteilung des Hauptstromrauches in diesem ersten Filterelement gestattet, tritt der Hauptstromrauch aus dieser ersten Filterkomponente anfangs laminar, danach durch Ventilationsluft induziert verhältnismäßig stark wirbelnd in die mit Sorptionsmitteln teilgefüllte mittlere Kammer ein und erhöht die Adsorption der Gasphase. Wenn die Perforation in einem stromabwärts liegenden Teilbereich der ersten strangseitigen Filterkomponente erfolgt, der beispielsweise die Hälfte oder ein Drittel der Filterlänge ausmacht, ist aufgrund des hohen Zugwiderstandes sowie der lamellenartigen Konfiguration nicht damit zu rechnen, daß die durch die Perforationen in diesem Teilbereich eindringende Nebenluft noch von erheblichen Mengen an Hauptstromrauch in die Kammer begleitet wird. Dieses bedeutet, daß im peripheren Bereich beim Übergang zwischen erstem Filterelement und mittleren Kammer die Hauptverwirbelung der Nebenluft erfolgt. Vorzugsweise kann natürlich durch einer entsprechenden Ausbildung von Längsrillen unterhalb des perforierten Umhüllungsblattes dafür gesorgt werden, daß in diese Längsrillen ausschließlich Nebenluft eintritt.Since the first chamber-side chamber contains a filter material with high tensile resistance, which essentially only allows passage of the main flow smoke in the longitudinal direction and does not allow radial distribution of the main flow smoke in this first filter element, the main flow smoke emerges from this first filter component initially in a laminar manner, then induced by ventilation air relatively swirling into the middle chamber partially filled with sorbents and increases the adsorption of the gas phase. If the perforation occurs in a downstream portion of the first strand-side filter component, which, for example, accounts for half or a third of the filter length, this is not due to the high tensile resistance and the lamella-like configuration reckon that the secondary air entering through the perforations in this section is still accompanied by substantial amounts of mainstream smoke into the chamber. This means that the main turbulence of the secondary air takes place in the peripheral area at the transition between the first filter element and the middle chamber. Preferably, of course, by appropriately designing longitudinal grooves below the perforated wrapping sheet, it is ensured that only secondary air enters these longitudinal grooves.

Aus diesem Grunde ist es auch erforderlich, daß das erste Filterelement einen verhältnismäßig hohen Zugwiderstand von 0,8 bis 1,6 kPa hat und aufgrund seiner bevorzugten Materialausbildung und Konfiguration eine geringe Teerretention zeigt.For this reason, it is also necessary that the first filter element has a relatively high tensile resistance of 0.8 to 1.6 kPa and, due to its preferred material design and configuration, shows a low tar retention.

Das stromabwärts von der mittleren Kammer mit dem Adsorptionsmittel liegende dritte Filterelement hat dagegen einen sehr viel geringeren Zugwiderstand von 0,2 bis 0,4 kPa und besteht vorzugsweise aus üblichem Filtermaterial wie Celluloseacetat.The third filter element located downstream of the middle chamber with the adsorbent, on the other hand, has a much lower tensile resistance of 0.2 to 0.4 kPa and preferably consists of conventional filter material such as cellulose acetate.

Das Filtermaterial in der ersten strangseitigen Kammer, das einen hohen Zugwiderstand und eine geringere Teerretention bewirken soll, kann aus in Streifen geschnittenen, in Längsrichtung durchströmten oder gerollten axial durchströmten oder in Zick-Zack-Lagen angeordenten, längs durchströmten Papierfolien, Cellulose- oder Cellulosederivatfolien, Stärkefolien, Wachspapier und ähnlichen Folien einschließlich Aluminiumfolie oder Kunststoffolie oder Polyolefinfolien gemäß DE-OS 3 635 958 bestehen.The filter material in the first strand-side chamber, which is said to have a high tensile resistance and a lower tar retention, can consist of paper films, cellulose or cellulose derivative films cut lengthwise, cut in strips, flowed through in the longitudinal direction or rolled, or arranged in zigzag layers and flowed lengthways. Starch films, wax paper and similar films including aluminum film or plastic film or polyolefin films according to DE-OS 3 635 958 exist.

Bei einer besonders bevorzugten Ausführungsform werden quellbare Folien verwendet, und zwar solche aus Gelatine, Carboxymethylcellulose, carboxymethylierter Stärke oder Polyoxymethacrylaten, wobei auch nicht quellbare Trägerfolien einsetzbar sind, die mit einem quellbaren Material beschichtet sind. Die mit Wasser stark quellbaren Folien bzw. durch Beschichtung quellbar gemachten Folien haben den Vorteil, daß bereits geringe Mengen an kondensierter Feuchtigkeit, die nach DIN 10240 etwa bis zu 10 mg H₂O je Cigarette betragen können, den Zugwiderstand im Laufe des Abrauchens der Cigarette erhöhen, wodurch nicht nur der sich allmählich verringernde Zugwiderstand des Tabakstranges ausgeglichen wird, sondern auch eine vermehrte Belüftung durch Erhöhung des Zugwiderstandes vor den Perforationen im stromabwärts liegenden ventilierten Teilbereich der ersten strangseitigen Filterkomponente bzw. in der ventilierten mittleren Kammer ermöglicht wird. Dies führt entsprechend ausgelegt zu einem näherungsweise konstanten Gas- und Partikelphaseangebot pro Zug.In a particularly preferred embodiment, swellable films are used, namely those made of gelatin, carboxymethyl cellulose, carboxymethylated starch or polyoxymethacrylates, it also being possible to use non-swellable carrier films which are coated with a swellable material. The films which are strongly swellable with water or made swellable by coating Foils have the advantage that even small amounts of condensed moisture, which can be up to 10 mg H₂O per cigarette according to DIN 10240, increase the draft resistance in the course of smoking the cigarette, which not only compensates for the gradually decreasing draft resistance of the tobacco rod , but also an increased ventilation is made possible by increasing the tensile resistance before the perforations in the downstream ventilated partial area of the first strand-side filter component or in the ventilated middle chamber. Designed accordingly, this leads to an approximately constant gas and particle phase supply per train.

Wenngleich das erste strangseitige Filterelement durch das Material oder die geometrische Anordnung bereits einen hohen Zugwiderstand gewährleistet und damit eine Ventilation in dem stromabwärts liegenden Teilbereich dieses ersten strangseitigen Filterelementes begünstigt, indem die "Kanäle" bzw. "Spalten" im peripheren Bereich des Filters bevorzugt mit Ventilationsluft versorgt werden, ist es auch möglich, im peripheren Teil dieses Teilbereiches besonders eingeprägte Kanäle vorzusehen, die stromaufwärts geschlossen sind, so daß kein Hauptstromrauch eindringen kann.Although the first strand-side filter element already ensures a high tensile resistance due to the material or the geometrical arrangement and thus favors ventilation in the downstream portion of this first strand-side filter element, in that the "channels" or "gaps" in the peripheral region of the filter preferably with ventilation air are supplied, it is also possible to provide specially embossed channels in the peripheral part of this section, which are closed upstream, so that no main current smoke can penetrate.

Die dritte mundseitig gelegene Filterkomponente besteht aus einem üblichen Filterelement mit geringem Zugwiderstand, das einen laminaren Strömungsverlauf bei niedriger Retention ergibt. Diese mundseitige Kammer enthält vorzugsweise herkömmliches, luftdurchlässiges Celluloseacetatfaserkabel.The third filter component on the mouth side consists of a conventional filter element with low tensile resistance, which results in a laminar flow pattern with low retention. This mouth-side chamber preferably contains conventional, air-permeable cellulose acetate fiber cable.

Durch diese - wie oben beschrieben - Multi-Filterausbildung erhält man im strangseitigen Filterelement eine unüblich hohe Geschwindigkeit des wenig gefilterten, in parallele Teilströme aufgeteilten Hauptstromrauches, der in der mittleren Kammer entweder durch Hinzutritt von Beiluft in Höhe dieser mittleren Kammer oder durch Hinzutritt von Beiluft in dem stromabwärts liegenden Teilbereich des ersten strangseitigen Filterelementes eine entsprechende Turbulenz bewirkt, derart, daß die Beiluft erst in gebündelten und dann in verwirbelten Luftstrahlen auf die langsamer werdenden Hauptstromrauch-Teilströme trifft, wodurch eine bessere Gasphasenabsenkung durch das Adsorptionsmittel geschaffen wird. Bei gleichzeitig näherungsweise konstanten Hauptstromrauchangebot pro Zug wird somit über die Zuge ein gleichbleibender Geschmack ohne Störfaktoren ("Kohlegeschmack", "off taste", "off flavor") erzielt.This multi-filter design, as described above, gives the line-side filter element an unusually high speed of the little-filtered main flow smoke, which is divided into parallel partial flows and which in the middle chamber either by adding additional air at the level of this middle chamber or by adding additional air in the downstream portion of the first strand-side filter element A corresponding turbulence causes such that the incoming air hits the slowing main stream smoke streams first in bundled and then in swirled air jets, whereby a better gas phase reduction is created by the adsorbent. With the main electricity smoke supply per train being approximately constant at the same time, the trains achieve a constant taste without disruptive factors ("coal taste", "off taste", "off flavor").

Von Hand wurden die unten näher bezeichneten, zum Teil maschinell gefertigten, Filterkomponenten zu einem Drei-Kammerfilter gemäß Erfindung zusammengesetzt, wobei der Begriff "Kammer" allgemein auch im Sinne eines Filterabschnittes verewendet wird.

Die durch nichtporöses Filterumhüllungspapier verbundenen Filterabschnitte wurden von Hand mittels üblichem, nicht luftdurchlässigen Belagpapier an maschinell gefertigten "American-Blend"-Stränge (ZW = 0,47 kPa) angesetzt und in Höhe der Filterkammer manuell perforiert.The filter sections connected by non-porous filter wrapping paper were attached by hand using conventional, non-air-permeable covering paper to machine-made "American blend" strands (ZW = 0.47 kPa) and perforated manually at the level of the filter chamber.

Der Ventilations- bzw. Beiluftgrad der derart gefertigten Filtercigaretten betrug 55%, der aus diesem und den aufgeführten Einzelzugwiderständen resultierende, konsumentenrelevante Endzugwiderstand betrug 0,95 kPa mm WS.The degree of ventilation or air intake of the filter cigarettes produced in this way was 55%, and the consumer-relevant final pull resistance resulting from this and the listed individual pulling resistances was 0.95 kPa mm WS.

Drei-Kammer-Filtercigaretten nach Bsp. 1 wurden nebst maschinell gefertigten Referenzcigaretten (Mono-Filtercigaretten ohne Aktivkohle, jedoch gleicher Tabakmischung) gemäß DIN 10240 abgeraucht. Zusätzlich wurde der CO-Gehalt nach DIN-Entwurf 10248 bestimmt, der NO-Gehalt nach der in der Cigaretten-Industrie üblichen Chemilumineszenz-Methode.Three-chamber filter cigarettes according to Example 1 were smoked in addition to machine-made reference cigarettes (mono filter cigarettes without activated carbon, but with the same tobacco mixture) in accordance with DIN 10240. In addition, the CO content was determined according to DIN draft 10248, the NO content according to the chemiluminescence method common in the cigarette industry.

Die Daten der Versuchscigarette zeigen bei einem vergleichsweise geringen Filterretentionsgrad von 38% einen Trockenkondensatgehalt von 6,6 mg, der dem "Leicht"-Bereich zugeordnet ist. Der bei herkömmlichen Cigaretten dieser Klasse bzw. dieses Kondensatgehaltes (siehe Vergleich) übliche CO-Wert von etwa 7 ml wird mit 4,5 ml deutlich unterschritten und ist wie der NO-Wert eher dem "Ultra-Leicht"-Bereich zugehörig, was auf eine überproportionale Gasphasenreduktion hinweist.With a comparatively low degree of filter retention of 38%, the data of the experimental cigarette show a dry condensate content of 6.6 mg, which is assigned to the "light" range. The CO value of about 7 ml, which is usual for conventional cigarettes of this class or this condensate content (see comparison), is clearly undercut with 4.5 ml and, like the NO value, belongs more to the "ultra-light" range, which is due to indicates a disproportionate gas phase reduction.

Die nach interner Methode bestimmte Gasphasenabsenkung der Versuchscigarette betrug gegenüber der Vergleichscigarette für 18 repräsentative Substanzen im Mittel sogar etwa 65%.The gas phase reduction of the test cigarette determined by the internal method was on average about 65% compared to the comparison cigarette for 18 representative substances.

Die Cigaretten werden nach DIN 10240 auf einer RM 20 (Fa. Borgwaldt) abgeraucht. Die Abscheidung der Partikelphase erfolgt mittels einer elektrostatischen Rauchfalle; die Gasphase wird in einem Glaszylinder aufgefangen.The cigarettes are smoked according to DIN 10240 on an RM 20 (from Borgwaldt). The particle phase is separated by means of an electrostatic smoke trap; the gas phase is collected in a glass cylinder.

Die Auftrennung in Einzelsubstanzen erfolgt gaschromatographisch über eine Trennkapillare 60 m x 0,32 mm Innendurchmesser, belegt mit 0,5 µ DB-Wax (Fa. J & W, Gaschromatograph 4160 Fa. Carlo Erba).The separation into individual substances is carried out by gas chromatography via a separating capillary 60 m × 0.32 mm inside diameter, coated with 0.5 μ DB-Wax (J & W, gas chromatograph 4160 from Carlo Erba).

18 repräsentative Hauptsubstanzen aus den Stoffklassen der Kohlenwasserstoffe, Aldehyde, Ketone, Nitrile, Alkohole u.a. werden quantifiziert und in ng/Cigarette ausgedruckt (Datenstation Spetra Physics).18 representative main substances from the classes of hydrocarbons, aldehydes, ketones, nitriles, alcohols etc. are quantified and printed out in ng / cigarette (data station Spetra Physics).

Von einem erprobten Raucherpanel von 10 Personen wurden Versuchscigaretten gemäß Beispiel 1 gegenüber den Vergleichscigaretten sensorisch überprüft. Hierbei ergab sich überraschenderweise das fast gänzliche Ausbleiben des unerwünschten "off taste"-Effekts (10 diesbezüglich übereinstimmende Rauchurteile), bei jedoch etwas verringerten Aroma und Füllewerten.Test cigarettes according to Example 1 were sensory-checked in comparison with the comparison cigarettes from a tested smoking panel of 10 people. Surprisingly, this resulted in the almost complete absence of the undesired "off button" effect (10 corresponding smoke judgments in this regard), but with somewhat reduced aroma and filling values.

Drei-Kammer-Filtercigaretten nach Beispiel 1, deren Stränge jedoch abweichend davon mit den erfindungsgemäßen Aromastoffen versehen waren (150 ppm Flavor Klasse A; 15 ppm Flavor Klasse B; 10 ppm Flavor Klasse C), wurden wie in Beispiel 1 nebst den gleichen Referenzcigaretten rauchanalytisch und sensorisch überprüft.Three-chamber filter cigarettes according to Example 1, the strands of which, however, were provided with the flavoring substances according to the invention (150 ppm Flavor Class A; 15 ppm Flavor Class B; 10 ppm Flavor Class C), were smoke analysis as in Example 1, in addition to the same reference cigarettes and checked sensory.

Die analytisch-physikalischen Daten stellten sich erwartungsgemäß wie in Beispiel 1 dar. Die sensorische Bewertung wurde vom gleichen Expertenteam durchgeführt. Befund: Die Versuchscigaretten wurden als voller, tabakartiger und aromatischer bei sonstiger Gleichwertigkeit gegenüber den Referenzcigaretten beurteilt. Ein "off Taste/off Flavor"-Effekt wurde nicht festgestellt. (9 übereinstimmende, 1 abweichendes Rauchurteil).The analytical-physical data were as expected as in Example 1. The sensory evaluation was carried out by the same team of experts. Finding: The experimental cigarettes were judged to be full, tobacco-like and aromatic with other equivalence to the reference cigarettes. An "off button / off flavor" effect was not found. (9 matching, 1 different smoking judgment).

Entsprechend Beispiel 1a wurden erfindungsgemäße Drei-Kammerfilter-Cigaretten gefertigt, die jedoch abweichend davon in der mittleren Kammer 100 mg Aktivkohle 30 - 70 mesh enthielten, und deren strangseitiger Filterabschnitt aus in Zick-Zack-Lage angeordneter Stärkefolie bestand.Three-chamber filter cigarettes according to the invention were produced in accordance with Example 1a, but, in deviation from this, contained 100 mg of activated carbon 30-70 mesh in the middle chamber, and whose filter section on the strand side consisted of starch film arranged in a zigzag layer.

Auch diese Multifilter-Cigaretten wurden nebst Referenzcigaretten entsprechend denen nach und wie bei Beispiel 1 abgeraucht und gaschromatographisch sowie sensorisch überprüft.These multifilter cigarettes, in addition to reference cigarettes, were also smoked according to and according to example 1 and checked by gas chromatography and sensors.

Diese Daten zeigen entsprechend denen von Beispiel 1 vergleichbare K- und N-Werte sowie zu erwartende CO/NO-Reduzierungen.These data show K and N values comparable to those of Example 1 and expected CO / NO reductions.

Die Gasphasenabsenkung betrug gegenüber der Vergleichscigarette für 18 repräsentative Substanzen im Mittel etwa 85%, z.B. für Acetaldehyd um 79%, für HCN um 87%, für Acrolein um 90%.The gas phase reduction compared to the comparative cigarette for 18 representative substances averaged about 85%, e.g. 79% for acetaldehyde, 87% for HCN, 90% for acrolein.

Trotz hoher Gasphasen-Reduzierung wurde kein "off-Taste/off-Flavor"-Effekt festgestellt (12 Urteile). Bei sonstiger Gleichwertigkeit gegenüber der Referenzcigarette wurden die Versuchscigaretten als etwas voller und aromatischer beurteilt (10 Urteile).Despite a high gas phase reduction, no "off-key / off-flavor" effect was found (12 judgments). With other equivalence compared to the reference cigarette, the test cigarettes were judged to be somewhat fuller and more aromatic (10 judgments).

Claims (6)

und

und/oder

derart perforiert ist, daß der Filterventilationsgrad 30 bis 80% beträgt,

and

and or

is perforated in such a way that the degree of filter ventilation is 30 to 80%,

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4105500 | 1991-02-19 | ||

| DE4105500A DE4105500C1 (en) | 1991-02-19 | 1991-02-19 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0499974A2 true EP0499974A2 (en) | 1992-08-26 |

| EP0499974A3 EP0499974A3 (en) | 1992-12-23 |

| EP0499974B1 EP0499974B1 (en) | 1994-11-30 |

Family

ID=6425607

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92102466A Expired - Lifetime EP0499974B1 (en) | 1991-02-19 | 1992-02-14 | Ventilated filter cigarette |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0499974B1 (en) |

| JP (1) | JP2647298B2 (en) |

| DE (2) | DE4105500C1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0880906A1 (en) * | 1997-05-30 | 1998-12-02 | SOCIETE NATIONALE D'EXPLOITATION INDUSTRIELLE DES TABACS ET ALLUMETTES Société Anonyme française | Cigarette with a very low level of tar and having a tabacco taste comparable with a normal cigarette having a high level of tar |

| CN109793263A (en) * | 2019-03-21 | 2019-05-24 | 红云红河烟草(集团)有限责任公司 | Method for predicting cigarette ventilation rate |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| HU228293B1 (en) | 1997-11-13 | 2013-08-28 | Reemtsma H F & Ph | Cigarette with reduced gas phase |

| PL353568A1 (en) | 1999-02-26 | 2003-12-01 | H.F.& Ph.F.Reemtsma Gmbhh.F.& Ph.F.Reemtsma Gmbh | Smokable product |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2202065A1 (en) * | 1971-01-19 | 1972-08-03 | Firmenich & Cie | Tobacco, food and beverages - aromatised by treatment with amides, esters, ketones and phenol derivs |

| GB1364103A (en) * | 1971-12-15 | 1974-08-21 | Ici Ltd | Smoking mixtures |

| GB1364104A (en) * | 1971-12-15 | 1974-08-21 | Ici Ltd | Smoking mixtures |

| DE3439907A1 (en) * | 1984-10-31 | 1986-04-30 | Alexei 8000 München Filippenko | Filter for smoking nicotine-free and pollutant-free cigarettes |

| DE3635958A1 (en) * | 1985-10-22 | 1987-04-23 | Cigarette Components Ltd | VENTILATED CIGARETTE FILTER |

-

1991

- 1991-02-19 DE DE4105500A patent/DE4105500C1/de not_active Expired - Fee Related

-

1992

- 1992-02-14 EP EP92102466A patent/EP0499974B1/en not_active Expired - Lifetime

- 1992-02-14 DE DE59200817T patent/DE59200817D1/en not_active Expired - Fee Related

- 1992-02-19 JP JP4032370A patent/JP2647298B2/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2202065A1 (en) * | 1971-01-19 | 1972-08-03 | Firmenich & Cie | Tobacco, food and beverages - aromatised by treatment with amides, esters, ketones and phenol derivs |

| GB1364103A (en) * | 1971-12-15 | 1974-08-21 | Ici Ltd | Smoking mixtures |

| GB1364104A (en) * | 1971-12-15 | 1974-08-21 | Ici Ltd | Smoking mixtures |

| DE3439907A1 (en) * | 1984-10-31 | 1986-04-30 | Alexei 8000 München Filippenko | Filter for smoking nicotine-free and pollutant-free cigarettes |

| DE3635958A1 (en) * | 1985-10-22 | 1987-04-23 | Cigarette Components Ltd | VENTILATED CIGARETTE FILTER |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0880906A1 (en) * | 1997-05-30 | 1998-12-02 | SOCIETE NATIONALE D'EXPLOITATION INDUSTRIELLE DES TABACS ET ALLUMETTES Société Anonyme française | Cigarette with a very low level of tar and having a tabacco taste comparable with a normal cigarette having a high level of tar |

| FR2763797A1 (en) * | 1997-05-30 | 1998-12-04 | Tabacs & Allumettes Ind | VERY LOW TAR RATE CIGARETTE WITH A TOBACCO TASTE COMPARABLE TO THAT OF A CLASSIC CIGARETTE WITH HIGHER TAR RATE |

| CN109793263A (en) * | 2019-03-21 | 2019-05-24 | 红云红河烟草(集团)有限责任公司 | Method for predicting cigarette ventilation rate |

| CN109793263B (en) * | 2019-03-21 | 2021-05-11 | 红云红河烟草(集团)有限责任公司 | Method for predicting cigarette ventilation rate |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59200817D1 (en) | 1995-01-12 |

| JP2647298B2 (en) | 1997-08-27 |

| DE4105500C1 (en) | 1992-06-17 |

| EP0499974B1 (en) | 1994-11-30 |

| EP0499974A3 (en) | 1992-12-23 |

| JPH05260943A (en) | 1993-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69306323T2 (en) | Smoking articles | |

| DE69411288T2 (en) | Concentric smoke filter with an outer jacket made of a cellulose acetate strand and with a core made of a filter web containing activated carbon | |

| EP0558166B1 (en) | Ventilated cigarette filter | |

| EP1796488B1 (en) | Tobacco smoking filter or filter element with a content of adjuncts | |

| DE69409590T2 (en) | Smoking articles with controlled release and procedures | |

| AT400997B (en) | FILTER WITH PARTICULATE ADDITIVE AND ITS USE | |

| DE2849904A1 (en) | FILTER SYSTEM FOR CIGARETTES | |

| DD297548A5 (en) | PARTICLE FILTER SORPTION FILTER AND METHOD FOR THE PRODUCTION THEREOF | |

| DE69015185T3 (en) | Concentric smoke filter with filter media made of thread material and web material. | |

| AT394928B (en) | VENTILATED CIGARETTE FILTER AND FILTER CIGARETTE | |

| EP0716816B1 (en) | Segmented filter cigarette | |

| EP0365882A1 (en) | Coaxial cigarette | |

| DE3311902A1 (en) | FILTER MOUTHPIECE FOR CIGARETTES | |

| DE69112928T2 (en) | Tobacco flavored filter for smoking products and process for making the same. | |

| EP1921934A2 (en) | Filter or filter element for tobacco smoke. cigarette containing such a filter or filter element and method for producing such a filter or filter element | |

| EP0528186B1 (en) | Coaxial filter cigarette | |

| EP1014813B1 (en) | Thin cigarettes | |

| DE69700458T2 (en) | Ventilated double filter for cigarettes with flavored wrapping | |

| DE68923079T2 (en) | Cigarette and filter for it. | |

| DE60308877T2 (en) | BIODEGRADABLE FILTER CIGARETTE WITH TWO SEALS | |

| DE3225071C2 (en) | Ventilated cigarette filter | |

| EP0499974B1 (en) | Ventilated filter cigarette | |

| WO1995007633A1 (en) | Ventilated filter cigarette | |

| DE69512791T2 (en) | FILTER WITH CONCENTRIC CORE | |

| WO2002045531A1 (en) | Smoking product comprising a tobacco filter with a hollow mouthpiece |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE IT LI |

|

| 17P | Request for examination filed |

Effective date: 19921217 |

|

| 17Q | First examination report despatched |

Effective date: 19940308 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE IT LI |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 59200817 Country of ref document: DE Date of ref document: 19950112 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: H. F. & PH. F. REEMTSMA GMBH & CO TRANSFER- REEMTSMA CIGARETTENFABRIKEN GMBH Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: REEMTSMA CIGARETTENFABRIKEN GMBH Free format text: REEMTSMA CIGARETTENFABRIKEN GMBH#PARKSTRASSE 51#22605 HAMBURG (DE) -TRANSFER TO- REEMTSMA CIGARETTENFABRIKEN GMBH#MAX-BORN-STRASSE 4#22761 HAMBURG (DE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080214 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080226 Year of fee payment: 17 Ref country code: DE Payment date: 20080207 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090214 |