EP0442318A2 - Filtre à particules régénérable par combustion pour les gaz d'échappement de moteurs à combustion interne - Google Patents

Filtre à particules régénérable par combustion pour les gaz d'échappement de moteurs à combustion interne Download PDFInfo

- Publication number

- EP0442318A2 EP0442318A2 EP91101119A EP91101119A EP0442318A2 EP 0442318 A2 EP0442318 A2 EP 0442318A2 EP 91101119 A EP91101119 A EP 91101119A EP 91101119 A EP91101119 A EP 91101119A EP 0442318 A2 EP0442318 A2 EP 0442318A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- filter

- exhaust gas

- pipes

- filter according

- overflow

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000002245 particle Substances 0.000 title claims abstract description 42

- 239000007789 gas Substances 0.000 title claims description 114

- 238000002485 combustion reaction Methods 0.000 title claims description 6

- 230000008929 regeneration Effects 0.000 claims description 13

- 238000011069 regeneration method Methods 0.000 claims description 13

- 239000000463 material Substances 0.000 claims description 12

- 238000002156 mixing Methods 0.000 claims description 9

- 241000722921 Tulipa gesneriana Species 0.000 claims description 5

- 238000004140 cleaning Methods 0.000 claims description 4

- 239000004071 soot Substances 0.000 abstract description 17

- 238000011068 loading method Methods 0.000 abstract description 3

- 239000000203 mixture Substances 0.000 description 8

- 238000001802 infusion Methods 0.000 description 6

- 230000035515 penetration Effects 0.000 description 4

- 238000011161 development Methods 0.000 description 3

- 230000018109 developmental process Effects 0.000 description 3

- 239000000654 additive Substances 0.000 description 2

- 238000013016 damping Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 238000001914 filtration Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 239000002283 diesel fuel Substances 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 238000001764 infiltration Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 239000012774 insulation material Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000007800 oxidant agent Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000003584 silencer Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/0212—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters with one or more perforated tubes surrounded by filtering material, e.g. filter candles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/023—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/023—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles

- F01N3/025—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles using fuel burner or by adding fuel to exhaust

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00

- F01N13/14—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00 having thermal insulation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2330/00—Structure of catalyst support or particle filter

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2470/00—Structure or shape of gas passages, pipes or tubes

- F01N2470/18—Structure or shape of gas passages, pipes or tubes the axis of inlet or outlet tubes being other than the longitudinal axis of apparatus

Definitions

- the invention relates to a particle filter for cleaning the exhaust gas of internal combustion engines with filter candles, which are arranged in a housing provided with an inlet chamber and an outlet funnel between holding plates and are formed from a support tube provided with exhaust gas passage openings and covered with filter material, and which also provide heat from a heat source is supplied for regeneration by burning.

- Particle filters of this type are required for cleaning exhaust gases from internal combustion engines, in particular in vehicles which are operated with diesel fuel, in order to filter out the soot particles, which are harmful to health and represent a high and dangerous environmental impact.

- These particle filters are known in two versions.

- the exhaust gas is filtered as it flows through a ceramic block (monolith) which has a large number of through channels, of which one channel is closed like a chessboard and one channel is closed on the outlet side, so that the exhaust gas flows into one channel, then through the surrounding monolith section acting as a filter flows into the adjacent channel and leaves it, freed from soot particles.

- a soot filter describes e.g. DE-OS 32 17 357.

- the other embodiment uses filter cartridges for particle filtering.

- These filter cartridges are preferably designed as a wound filter.

- a support tube provided with exhaust gas passage openings wrapped in multiple layers with filter material threads, so that an element comparable to a textile yarn spool is produced.

- Such an arrangement shows, for example, DE-OS 38 15 148 with a special representation of the storage of the filter candles in holding plates.

- the filter candles can also be formed by a hose cover made of filter material via a support tube according to DE-OS 38 23 205.

- the filter candles are also flowed through from the outside in, the exhaust gas to be cleaned enters the support tubes through the filter material, which are closed on the inlet side, the soot particles are retained when the wound filter material flows through, and the cleaned exhaust gas flows through the support tubes into the outlet funnel and becomes dissipated from there.

- the filter candles are arranged on concentric circles in the filter housing and are of a uniform design. Instead of the holding plate on the inlet side provided with exhaust gas passage openings, a holding grille can also be arranged.

- sooting occurs when it flows through the particle filter, ie the filter material becomes increasingly clogged with soot particles and the soot has to be removed after a relatively short period of operation.

- Mechanical removal is practically out of the question because the entire filter would have to be removed and the soot would have to be disposed of. It is therefore necessary to burn off or burn off the enriched soot.

- oxidizing agents are added to the exhaust gas from a storage container as additives, so that the collected soot comes into contact with these soot reducing the soot ignition temperature and increasing the combustion rate and can be burned off.

- the invention has for its object to show a particle filter that enables regeneration while driving and in which a high degree of burning is achieved over the entire filter length, so that the re-infusion time is approximately constant and corresponds to the first infusion time.

- overflow pipes are arranged distributed in at least one holding plate over the cross section of the housing, and in that the inlet-side holding plate has exhaust gas openings in the area not occupied by filter core support pipes and overflow pipes.

- This solution can be applied to all particle filters, including those in which the filtering is carried out via channeled monoliths, after obvious modifications which may be necessary.

- the overflow pipes are formed by ducts which are open on both sides and open into the additional chamber - described here later.

- the filter cartridges are mounted in a downstream holding plate and a rear holding plate.

- the exhaust gas to be cleaned is fed to the filter candle area (the cleaning zone) through exhaust gas passage openings in the front holding plate and through the overflow pipes from the inlet funnel or the inlet chamber.

- the regeneration external heat is released to the exhaust gas, e.g. in the inlet chamber supplied by a burner operated with liquid fuel, so that the free-burning process is initiated via the exhaust gas heated to the ignition temperature.

- the overflow pipes which have exhaust gas outlet openings in the downstream area and are closed on the outlet side, conduct exhaust gas into the downstream lower area of the filter candles during the sooting phase and thus bring about a more uniform loading of the filter candles over their length.

- hot exhaust gas exhaust gas to be cleaned mixed with hot exhaust gas from the external heat source

- this section of the filter candles is regenerated simultaneously by free-burning.

- An expedient embodiment of the particle filter according to the invention shows the feature that an overflow pipe in the longitudinal axis of the housing and further overflow pipes are arranged concentrically thereto, the number of overflow pipes per circuit increasing to the outside.

- the overflow tubes are arranged in such a way that each overflow tube is surrounded by as many filter candles as possible, so that the filter candles are all flowed as evenly as possible over their length. This also ensures that the section of the particle filter equipped with filter cartridges is flowed through uniformly over the entire length even at low load conditions. This automatically ensures that the surrounding filter cartridges are loaded or burned free and that the re-infusion time is long enough and the infusion is uniform.

- the particle filters are part of the sound damping system of the vehicle engine, it is advantageous to also assign sound damping properties to the particle filter. It has been shown that this is possible with simultaneous improvement of the filter properties, both with respect to the sooting and the burning free, in that a further chamber is formed in the particle filter downstream behind the filter candle region by an inserted bottom, which of the ones carrying the filter material Pipes are penetrated and open into the overflow pipes open on both sides, so that the exhaust gas or exhaust gas / hot gas mixture can enter this chamber.

- This additional chamber acts with the support tubes as a resonator chamber, and at the same time serves to guide the unselected exhaust gas or the exhaust gas / hot gas mixture back into the filter section of the particle filter, so that the filter candles are also flowed to in the downstream area.

- the floor used is also provided with exhaust gas passage openings. The cleaned exhaust gas flows through the support tubes of the filter cartridges, which extend on the inlet side and penetrate this additional chamber, into the outlet funnel and from there via the exhaust pipe.

- a mixing chamber is arranged as an inlet chamber in the flow direction upstream of the filter chamber of the particle filter provided with filter candles and overflow pipes.

- the exhaust gas to be cleaned is preferably fed radially or tangentially into this mixing chamber and the hot gas is preferably fed axially.

- the hot gas can be taken from an external heat source or the exhaust gas from a burner attached. However, this hot gas can also be supplied axially via an inlet funnel arranged axially on the inlet side of the mixing chamber. If necessary, flow-directing elements such as e.g. Baffles are attached.

- the overflow pipes can have exhaust gas passage openings over at least part of their length, so that additional exhaust gas can be supplied to the respectively adjacent filter candles over the entire length.

- the overflow pipes are closed on the outlet side in the arrangement without the additional chamber behind the filter section, so that all of the exhaust gas flowing through the overflow pipes is fed to the filter candles.

- the exhaust gas passage openings are arranged in the overflow pipes in such a way that the number of exhaust gas passage openings increases downstream. It is of course also equivalent that the size of the exhaust gas passage openings increases downstream. It is crucial that more exhaust gas is fed to the filter candles downstream, so that the entire length of the filter candles is recorded, especially when burning free.

- the overflow pipes have different diameters, for example as a function of the exhaust gas inflow from the inlet funnel or the inlet chamber, the diameters increasing radially outwards.

- the inlet chamber has at least one connection for the engine exhaust gases to be cleaned and one connection for the external supply of heat.

- This arrangement has the advantage over the known arrangements in which the engine exhaust gases and the hot gases are supplied via an inlet funnel that better mixing can be achieved. It has proven to be particularly advantageous that the inlet chamber has a connecting flange for a burner, the hot exhaust gases of which are mixed with the engine exhaust gases to be cleaned. It is particularly advantageous to use a flat burner as a burner. Such a burner is described for example in DE-OS 34 10 716.

- inlet pipes projecting into the filter space in the area not occupied by filter cartridge support tubes are arranged in the inlet side. This allows a more targeted supply of the exhaust gas to the filter candles, in particular in the downstream rear area, whereby according to a continuation these inflow tubes protrude to different degrees into the filter space. Since in the longitudinal axis of the housing, especially when burning free, with a central arrangement of the hot gas supply, for example through the burner, an approximately conical free-burned zone is created, i.e.

- the arrangement of the inflow pipes and their different ones can Penetration depth into the filter chamber a more uniform free burning can be achieved.

- the inflow tubes arranged on concentric circles arrange the radially outer parts projecting further into the filter space.

- the inflow pipes can also have exhaust gas passage openings, which can also be distributed unevenly over the length of the inlet pipes.

- the improvement of the free burning can also be supported by a particularly advantageous arrangement which has the feature that inlet tulips are integrally formed on at least some of the overflow pipes or the filter core support pipes. These are formed by expanding the corresponding pipes on the inlet side and improve the inflow of the exhaust gas or the exhaust gas / hot gas mixture. As a result, a certain control over the cross-section and also over the length of the filter space can be achieved by improving the inflow.

- both the filter core support tubes and the overflow tubes are each mounted on one side in a sliding seat in one of the holding plates. This means that every pipe can expand without causing tension in the overall system.

- Another expedient embodiment is characterized in that the filter core support tubes and the overflow tubes are mounted alternately with a sufficiently tight sliding seat in the inlet-side or outlet-side holding plate. This results in a particularly high stability of the filter arrangement even at different temperature loads, so that, if necessary, different - but of course heat-resistant - materials can be used even for the filter core support tubes and the overflow tubes, for example steels of different alloys.

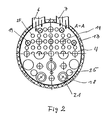

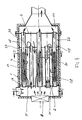

- the particle filter consists of a housing 1, in which the filter chamber 4 is formed between an inlet-side holding plate 2 and an outlet-side holding plate 3.

- the housing 1 can have any cross section, preferably round or oval.

- an inlet chamber 5 is arranged in front of the filter chamber 4, into which the exhaust gas of the engine to be cleaned is fed via connecting pieces 6, 7 - in the case of two-pipe systems.

- a further connection 8 is provided for the supply of external heat.

- this connection 8 is shown as a "black box" because of the external heat both generated further away and fed via a nozzle and also generated in a burner attached to the connecting flange 9 and can be fed directly.

- a flat burner is preferably provided as the burner.

- Patent application P 35 45 437.7 shows an example of an external supply of heat.

- An arrangement that can be used as a flat burner is shown, for example, in patent application P 34 10 716.9.

- the inlet chamber 5 can also be preceded by an inlet funnel (not shown) via which both the engine exhaust gas and the external heat are then supplied.

- the inlet chamber 5 is at the same time designed as a mixing chamber for mixing the supplied engine exhaust gas and the supplied external heat as hot gas for the free-burning phase. Good mixing can be achieved, for example, by tangential introduction of one of the media; flow-directing means can of course also be arranged in the inlet chamber 5.

- the inlet funnel or the inlet chamber is flanged to the filter chamber 4 by means of a flange (9).

- the inlet chamber 5 can also be a section of the inlet funnel.

- an outlet chamber 11 with an outlet funnel 12 adjoins the filter chamber 4 via a flange connection 10, via which the cleaned exhaust gas flows out.

- the entire particle filter is protected against heat loss through radiation by an insulation 13 made of thermal insulation material.

- the filter chamber 4 is delimited on the inlet side by the holding plate 2, on the outlet side by the holding plate 3.

- the filter candles 14 penetrating the filter chamber 4 are arranged in these holding plates 2, 3. These consist of a filter core support tube 15 which is covered with filter material 16. This assignment can be applied as a winding or in the form of individual knitted hoses.

- the filter support pipes 15 have exhaust gas passage openings 17 through which the exhaust gas or the exhaust gas / hot gas mixture can enter from the outside through the filter material 16.

- the filter core support tubes 15 are closed on the inlet side and open on the outlet side.

- the outlet-side holding plate 3 is in the two arrangements according to FIG. 1 formed without exhaust gas openings.

- overflow pipes 18, 19 are also arranged in the two holding plates 2, 3. These overflow pipes 18, 19 are closed on the outlet side.

- the overflow pipes 18 are provided with exhaust gas passage openings 20 over their entire length and have an inlet tulip 21.

- the overflow tubes 18 and 19 are flowed through from the inside to the outside and conduct the hot exhaust gas to the filter candles 14, in particular in the free-burning phase, whereby hot exhaust gas is also guided through the perforation of the overflow tubes 18, 19 to the lower region of the filter candles 14, thereby causing a uniform free burning is achieved.

- Fig. 1 - upper half - overflow pipes 19 are shown, which have exhaust gas outlet openings 21 only in their downstream area.

- the hot exhaust gas is fed into the downstream rear area of the filter space 4 and thus to the filter candles 14, which leads to the fact that this area, which is not burned free in an arrangement without overflow pipes, is now free from soot particles by burning free is cleaned, which results in the desired long sooting time.

- the arrangement of the exhaust gas passage openings 21 in the downstream section of the overflow pipes 19 can take place progressively, ie a larger exhaust gas outlet area can be achieved at the end of the overflow pipe 19. This can be achieved either by a progression of the number or the size of the exhaust gas outlet openings 20.

- the overflow pipes 18, 19 are distributed over the cross section of the filter chamber 4 in such a way that the filter cartridges 14 are acted on as uniformly as possible, ie that the distance to the nearest filter cartridges 14 is short and in each case the same. Since the free burning profile without Overflow tubes 18, 19 approximately conical in shape, can also have different diameters distributed over the cross section of the filter space 4, namely a larger diameter on the outside than the inside, for stronger supply of the hot exhaust gas to the edge region of the filter space 4.

- the filter core support tubes 15 and the overflow tubes 18, 19 are therefore mounted alternately in the inlet-side holding plate 2 and the outlet-side holding plate 3 with a sufficiently tight sliding seat because of the risk of soot particles escaping.

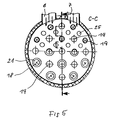

- FIGS. 5 and 6 shows a further variant in which a further chamber 22 is arranged downstream.

- a further chamber 22 is arranged downstream.

- This is formed by an inserted floor 23 and, as a resonator chamber, contributes to better sound absorption of the particle filter, which is integrated in the exhaust line of a silencer system.

- the bottom 23 closes off the filter space 4 and, as in the previously described variants, is designed as a holding plate for the filter candles 14 and is provided with exhaust gas passage openings 24.

- FIGS. 5 and 6 a variant with smooth, non-perforated overflow pipes 19 is shown.

- both the inlet-side holding plate 2 and the base 23 acting as a holding plate for the overflow pipes 19 are provided with exhaust gas passage openings 24 and 25, respectively.

- part of the exhaust gas flows through the exhaust gas passage openings 25 into the filter chamber 4 and from there through the filter candles 14 into the outlet chamber 11, partly through the overflow pipes 19 into the chamber 22 and from there back through the exhaust gas passage openings 24 into the filter chamber 14 and from there via the filter candles 14.

- FIG. 5 A variant is shown in the lower half of FIG. 4 and the associated sections FIGS. 5 and 6, in which the overflow pipe 18 is open on both sides, has an inlet tulip 21 and exhaust gas outlet openings 20 on the inlet side. These exhaust gas outlet openings 20 are arranged over the entire length of the overflow pipe 18, possibly with a progression downstream. In FIG. 5, lower half, the exhaust gas passage openings 25 are not shown.

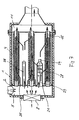

- FIG. 7 shows variants in which the overflow pipes 18, 19 of the previous figures are replaced by inflow pipes 26, 27, which are designed as shortened overflow pipes.

- the other structure corresponds to the figures discussed above, in particular FIG. 1 with the associated sections according to FIGS. 2 and 3.

- an embodiment is shown in which the exhaust gas from the inlet chamber 5 is partly via the Exhaust gas passage openings 25 is fed to the filter chamber 4 and the other part via an inflow tube 27, which is designed as a smooth tube open on both sides.

- the penetration depth of this inflow tube 27 extends to at least half of the filter space 4.

- the penetration depth can vary, the penetration depth going further downstream in the edge zones than e.g. in the case of the tube arranged in the longitudinal axis or adjacent to the longitudinal axis.

- inflow pipe 27 has exhaust gas passage openings 28 and an inlet tulip 21.

- outlet-side cross-sectional reduction acting on a nozzle on an end piece 29 is also shown, with which the inflow conditions in If necessary, can be improved.

- exhaust gas through openings 30 optionally provided in the inlet-side holding plate 2 are shown in the edge region of the inflow into the filter space 4.

- All of the exemplary embodiments have in common that the exhaust gas to be cleaned is supplied to the filter chamber 4 equipped with filter candles 14 via the overflow pipes 18, 19 or the inlet pipes 26, 27 - additionally also through exhaust gas passage openings 25 in the inlet-side holding plate 2 - and that during which, when the engine is operating, allows a mixture of exhaust gas and hot gas, the latter from an external heat source or a burner attached, to be supplied.

- This enables an approximately uniform loading and free burning that extends over the entire length and the entire cross section of the particle filter. In particular, a long sooting phase is achieved by completely burning off the particle filter.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Processes For Solid Components From Exhaust (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

- Filtering Materials (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT91101119T ATE97994T1 (de) | 1990-02-16 | 1991-01-29 | Durch abbrennen regenerierbarer partikelfilter fuer die abgase von brennkraftmaschinen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4004861 | 1990-02-16 | ||

| DE4004861A DE4004861A1 (de) | 1990-02-16 | 1990-02-16 | Durch abbrennen regenerierbarer partikelfilter fuer die abgase von brennkraftmaschinen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0442318A2 true EP0442318A2 (fr) | 1991-08-21 |

| EP0442318A3 EP0442318A3 (en) | 1992-01-02 |

| EP0442318B1 EP0442318B1 (fr) | 1993-12-01 |

Family

ID=6400310

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91101119A Expired - Lifetime EP0442318B1 (fr) | 1990-02-16 | 1991-01-29 | Filtre à particules régénérable par combustion pour les gaz d'échappement de moteurs à combustion interne |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0442318B1 (fr) |

| AT (1) | ATE97994T1 (fr) |

| DE (2) | DE4004861A1 (fr) |

| ES (1) | ES2047958T3 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0549851A1 (fr) * | 1992-01-03 | 1993-07-07 | ERNST-APPARATEBAU GmbH & Co. | Filtre à suie pour moteurs diesel |

| EP0616833A1 (fr) * | 1993-03-24 | 1994-09-28 | ERNST APPARATEBAU GmbH & Co. | Filtre à suie pour moteurs diesel |

| EP0623738A1 (fr) * | 1993-02-05 | 1994-11-09 | ERNST-APPARATEBAU GmbH & Co. | Filtre de suie pour moteurs diesel |

| EP0668437A1 (fr) * | 1994-02-17 | 1995-08-23 | Firma J. Eberspächer | Méthode et dispositif pour posttraitement à brûleur thermique de gaz d'échappement de moteur |

| EP2146062A1 (fr) * | 2008-07-19 | 2010-01-20 | Grywotz Automobiltechnik GmbH Karl-Heinz | Filtre à particules pour moteurs diesel et Otto |

| CN110792496A (zh) * | 2019-10-14 | 2020-02-14 | 东莞材料基因高等理工研究院 | 一种柴油颗粒捕捉器的成像检测装置 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4111029C2 (de) * | 1991-04-05 | 1995-08-31 | Eberspaecher J | Durch Freibrennen regenerierbarer Partikelfilter für die Abgase von Brennkraftmaschinen |

| DE19746814A1 (de) * | 1997-10-23 | 1999-04-29 | Behr Gmbh & Co | Pumpeneinrichtung, damit ausgerüstete Abgasreinigungsanlage und Betriebsverfahren hierfür |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4478618A (en) * | 1983-08-01 | 1984-10-23 | General Motors Corporation | Diesel exhaust particulate trap with plural filter tubes |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3217357C2 (de) * | 1982-05-08 | 1987-03-12 | Fa. J. Eberspächer, 7300 Esslingen | Einrichtung zur Verminderung des Rußanteils im Abgas von Brennkraftmaschinen |

| DE3410716A1 (de) * | 1984-03-23 | 1985-10-03 | Fa. J. Eberspächer, 7300 Esslingen | Brennkammer fuer heizeinrichtungen |

| DE3815148A1 (de) * | 1988-05-04 | 1989-11-16 | Eberspaecher J | Anordnung zur lagerung eines von abgas durchstroemten filters in einem metallischen gehaeuse |

| DE3823205A1 (de) * | 1988-07-08 | 1990-01-11 | Eberspaecher J | Russfilterkerze fuer die reinigung von abgasen und aus russfilterkerzen gebildete russfilteranordnung |

-

1990

- 1990-02-16 DE DE4004861A patent/DE4004861A1/de active Granted

-

1991

- 1991-01-29 AT AT91101119T patent/ATE97994T1/de not_active IP Right Cessation

- 1991-01-29 EP EP91101119A patent/EP0442318B1/fr not_active Expired - Lifetime

- 1991-01-29 DE DE91101119T patent/DE59100641D1/de not_active Expired - Fee Related

- 1991-01-29 ES ES91101119T patent/ES2047958T3/es not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4478618A (en) * | 1983-08-01 | 1984-10-23 | General Motors Corporation | Diesel exhaust particulate trap with plural filter tubes |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0549851A1 (fr) * | 1992-01-03 | 1993-07-07 | ERNST-APPARATEBAU GmbH & Co. | Filtre à suie pour moteurs diesel |

| US5279630A (en) * | 1992-01-03 | 1994-01-18 | Ernst-Apparatebau Gmbh & Co. | Soot filter for diesel engines |

| EP0623738A1 (fr) * | 1993-02-05 | 1994-11-09 | ERNST-APPARATEBAU GmbH & Co. | Filtre de suie pour moteurs diesel |

| EP0616833A1 (fr) * | 1993-03-24 | 1994-09-28 | ERNST APPARATEBAU GmbH & Co. | Filtre à suie pour moteurs diesel |

| EP0668437A1 (fr) * | 1994-02-17 | 1995-08-23 | Firma J. Eberspächer | Méthode et dispositif pour posttraitement à brûleur thermique de gaz d'échappement de moteur |

| EP2146062A1 (fr) * | 2008-07-19 | 2010-01-20 | Grywotz Automobiltechnik GmbH Karl-Heinz | Filtre à particules pour moteurs diesel et Otto |

| CN110792496A (zh) * | 2019-10-14 | 2020-02-14 | 东莞材料基因高等理工研究院 | 一种柴油颗粒捕捉器的成像检测装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2047958T3 (es) | 1994-03-01 |

| EP0442318A3 (en) | 1992-01-02 |

| DE4004861A1 (de) | 1991-08-22 |

| DE4004861C2 (fr) | 1992-01-16 |

| DE59100641D1 (de) | 1994-01-13 |

| ATE97994T1 (de) | 1993-12-15 |

| EP0442318B1 (fr) | 1993-12-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4111029C2 (de) | Durch Freibrennen regenerierbarer Partikelfilter für die Abgase von Brennkraftmaschinen | |

| DE602004011176T2 (de) | Vorrichtung zum Filtern und Brennen von Teilchenmaterial | |

| DE3788421T2 (de) | Apparat zur Behandlung von Teilchen im Abgas aus einem Dieselmotor. | |

| EP1691045B1 (fr) | Système de purification des gaz d'échappement | |

| DE3914758C2 (fr) | ||

| DE2953010C2 (fr) | ||

| EP0438682B1 (fr) | Système d'échappement avec filtre à particules et brûleur de régénération | |

| EP0504719A1 (fr) | Filtre pour gaz d'échappement et/ou convertisseur catalytique | |

| DE4026375C1 (fr) | ||

| DE4005189A1 (de) | Abgasreinigungsvorrichtung fuer einen dieselmotor | |

| WO2012130796A1 (fr) | Module de chauffage pour une installation d'épuration de gaz d'échappement | |

| DE3823205C2 (fr) | ||

| DE3614812C2 (fr) | ||

| EP0442318B1 (fr) | Filtre à particules régénérable par combustion pour les gaz d'échappement de moteurs à combustion interne | |

| DE3528445A1 (de) | Vorrichtung und verfahren zum beseitigen von russ o.dgl. aus den abgasen einer brennkraftmaschine | |

| EP0638776B1 (fr) | Dispositif de réduction de l'émission d'odeur et de polluants pour des appareils de chauffage pour véhicules | |

| DE4405045C2 (de) | Vorrichtung zur brennerthermischen Motorabgas-Nachbehandlung sowie deren Verwendung | |

| EP0128463A2 (fr) | Appareil de chauffage des locaux pour des locaux de petite dimension | |

| DE3600373C2 (de) | Partikelfiltersystem mit porösem Filtermaterial für gasförmige Medien | |

| DE2418108C3 (de) | Thermisch-katalytische Abgas-Reinigungsvorrichtung | |

| DE19933442B4 (de) | Partikelfilter mit einem Filtermedium und einem Katalysator | |

| DE102005049690A1 (de) | Temperaturvergleichmässigender Innenkanal für ein Filterelement und Filter zur Abgasnachbehandlung | |

| DE1476633C3 (de) | Abgasreinigungsvorrichtung für Brennkraftmaschinen | |

| DE10123358A1 (de) | Abgasstrang einer Brennkraftmaschine, insbesondere Dieselmotor eines Nutzfahrzeuges wie Lastkraftwagen oder Omnibus, mit integrierten Abgasnachbehandlungs- und Schalldämpfungsvorrichtungen | |

| DE102017215563A1 (de) | Partikelfilter für die Abgasnachbehandlung eines Verbrennungsmotors |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE DE DK ES FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE DE DK ES FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920123 |

|

| 17Q | First examination report despatched |

Effective date: 19921102 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE DK ES FR GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19931201 Ref country code: DK Effective date: 19931201 |

|

| REF | Corresponds to: |

Ref document number: 97994 Country of ref document: AT Date of ref document: 19931215 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931215 |

|

| REF | Corresponds to: |

Ref document number: 59100641 Country of ref document: DE Date of ref document: 19940113 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2047958 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 91101119.5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19961202 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19970116 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19970128 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19971204 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980120 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980131 |

|

| BERE | Be: lapsed |

Owner name: EBERSPACHER G.M.B.H. & CO. Effective date: 19980131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990129 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20000503 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CJ |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CJ |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030115 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050129 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050131 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060801 |