EP0392593A2 - Dispositif pour la correction automatique de l'homogénéité du pressage dans la fabrication de tuiles - Google Patents

Dispositif pour la correction automatique de l'homogénéité du pressage dans la fabrication de tuiles Download PDFInfo

- Publication number

- EP0392593A2 EP0392593A2 EP90200795A EP90200795A EP0392593A2 EP 0392593 A2 EP0392593 A2 EP 0392593A2 EP 90200795 A EP90200795 A EP 90200795A EP 90200795 A EP90200795 A EP 90200795A EP 0392593 A2 EP0392593 A2 EP 0392593A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- mold

- density

- tiles

- scrapers

- manufacture

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000003825 pressing Methods 0.000 title claims description 19

- 238000004519 manufacturing process Methods 0.000 title claims description 10

- 238000012937 correction Methods 0.000 title claims description 9

- 239000004927 clay Substances 0.000 claims abstract description 9

- 239000000843 powder Substances 0.000 claims abstract description 3

- 230000007547 defect Effects 0.000 claims description 7

- 230000001276 controlling effect Effects 0.000 claims 1

- 239000008187 granular material Substances 0.000 abstract description 7

- 238000009826 distribution Methods 0.000 abstract description 2

- 230000003455 independent Effects 0.000 abstract description 2

- 239000000919 ceramic Substances 0.000 description 8

- 239000000047 product Substances 0.000 description 7

- 230000000875 corresponding effect Effects 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 238000005429 filling process Methods 0.000 description 3

- 238000010304 firing Methods 0.000 description 3

- 238000000926 separation method Methods 0.000 description 3

- 238000010521 absorption reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000001033 granulometry Methods 0.000 description 2

- 230000002035 prolonged effect Effects 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 241001676573 Minium Species 0.000 description 1

- BUGBHKTXTAQXES-UHFFFAOYSA-N Selenium Chemical compound [Se] BUGBHKTXTAQXES-UHFFFAOYSA-N 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 210000003298 dental enamel Anatomy 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- YGSDEFSMJLZEOE-UHFFFAOYSA-N salicylic acid Chemical compound OC(=O)C1=CC=CC=C1O YGSDEFSMJLZEOE-UHFFFAOYSA-N 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 229910052711 selenium Inorganic materials 0.000 description 1

- 239000011669 selenium Substances 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B13/00—Feeding the unshaped material to moulds or apparatus for producing shaped articles; Discharging shaped articles from such moulds or apparatus

- B28B13/02—Feeding the unshaped material to moulds or apparatus for producing shaped articles

- B28B13/0215—Feeding the moulding material in measured quantities from a container or silo

- B28B13/023—Feeding the moulding material in measured quantities from a container or silo by using a feed box transferring the moulding material from a hopper to the moulding cavities

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B13/00—Feeding the unshaped material to moulds or apparatus for producing shaped articles; Discharging shaped articles from such moulds or apparatus

- B28B13/02—Feeding the unshaped material to moulds or apparatus for producing shaped articles

- B28B13/0295—Treating the surface of the fed layer, e.g. removing material or equalization of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B17/00—Details of, or accessories for, apparatus for shaping the material; Auxiliary measures taken in connection with such shaping

- B28B17/0063—Control arrangements

- B28B17/0072—Product control or inspection

Definitions

- the present invention refers to a system for automatic correction of the pressing density in the manufacture of tiles.

- an object of the invention is attainment of automatic correction in pressing, the differences of density found in different areas of a ceramic tile, so that it is as uniform as possible.

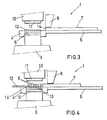

- the pressing of the granular or wet powder ceramic product is done in presses which are comprised of a mold holder bed, the mold being prolonged into a platform upon which a slidable slide related to some screens which fill up with wet granular clay, contained in a hopper, rests.

- the feed slide moves forward with its screens full of granular material until it is over the mold, where it will be subsequently compacted once a scraper bar connected to the slide cleans the surface of the mold so that the clay is leveled with the mouth of the mold.

- This mold filling process is a dynamic process which is carried out at a high speed, since a press can operate at a rate of more than 20 pressings per minute. This means that the feed slide hardly has one second to effect its path forward to fill the mold and to return. When the granular material falls, this granular matter tends to fall horizontally forward and therefore falls according to the inertia of its mass in an inclined manner.

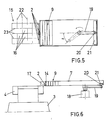

- the scraper bar that removed the excess material from the mold, during the return of the slide is replaced by a support for a series of independent scrapers, whose height can be adjusted.

- Each independent scraper is hung vertically and can move thus upon the slide moving back, those square portions of the piece that would have a qualitative and quantitative compacting defect have a larger amount of product placed in them.

- the electronic control of the tester sends the information to the control of the slide so that the scrapers compensate for these defects, upon moving vertically during the return of the slide, occupying the highest position upon exceeding the squares of the mold where there would be the least compacting.

- a single press can therefore include an aligned series of bottom plates 5, top plates 11 and screens 9 which are capable of being confronted so that they simultaneously form a repeated series of tiles 12, once the material which descends the transversal support 10 has been compacted.

- the feed slide 7 moves forward with its screens 9 full of wet granular material, until this screen is over the bottom plate 5.

- the bottom plate 5 moves downward to form a chamber that is to be filled with granular material 13 which falls by gravity and is drawn by the vacuum that the descent of the bottom plate 5 causes, as is clearly observed in figure 2.

- the slide 7 returns and since it has a scraper bar 14 it cleans the surface of the mold 4 leaving only the clay contained in it, leveling with the top edge of the mold.

- the transversal support 10 of the press descends and the top plate 11 is inserted in the recess of the mold 4 in order to compress the granular material 13 and convert it into a tile 12.

- an already pressed piece such as a square tile referred to as 15 in figure 5, it is cut into a certain number of equal parts, following longitudinal and transversals alignments.

- the number of parts into which the tile 15 is divided is sixteen, forming a square of four by four individual portions, each one of which has been referred to as no. 16.

- the ceramic piece 15 is ideally divided into this same number of portions 16, each one of which has to have the same density. Therefore it has means that can make it vary during the return stage of the feed slide 7, which we specify in detail hereinafter.

- the bar 14 remains situated above the mold 4 so that it does not act as a scraper.

- the independent scrapers 2 coincide in their width and position with the theoretical separation of piece 15 longitudinally, in other words, the end scrapers sweep the end longitudinal bands of piece 15 divided into sixteen portions, while the intermediate scrapers 2 sweep the respective center bands of piece 15 or recess of the mold 4.

- Each scraper 2 can move vertically with its corresponding cylinder head 17 that contains a valvular system and hydraulic piston for movement thereof, not represented in the figures as they are already known.

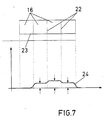

- the slide 7 In order to locate when the slide 7 has its scrapers 2 over the transversal lines 22 of separation of the portions 16 of the tile 15, it has a detector of the angle corresponding to each one of these positions.

- the length of the independent scrapers 2 defines the longitudinal readings or those of the distance between the longitudinal lines 23 of the square of the tile 15.

- Each cylinder head 17 contains a distance detector in order to also know the individual vertical position of each scraper, this position being automatically selected by the electronic control of the apparatus.

- the corresponding scraper 2 will move vertically each time that the slide moves backward after having filled the mold 4, as is indicated in the curve 24 of this figure 7, rising in the squares with a density less than the stipulated one and descending in the ones with a greater density, proportionally.

- portion 16 located on the left, taken as "zero" is the one with the greatest density and remains situated over the abscissa axis.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Devices For Post-Treatments, Processing, Supply, Discharge, And Other Processes (AREA)

- Press-Shaping Or Shaping Using Conveyers (AREA)

- Sampling And Sample Adjustment (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES8901280A ES2013172A6 (es) | 1989-04-12 | 1989-04-12 | Sistema de correccion automatica de la densidad de prensado, en la fabricacion de azulejos. |

| ES8901280 | 1989-04-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0392593A2 true EP0392593A2 (fr) | 1990-10-17 |

| EP0392593A3 EP0392593A3 (fr) | 1991-09-18 |

| EP0392593B1 EP0392593B1 (fr) | 1994-08-31 |

Family

ID=8261439

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90200795A Expired - Lifetime EP0392593B1 (fr) | 1989-04-12 | 1990-04-03 | Dispositif pour la correction automatique de l'homogénéité du pressage dans la fabrication de tuiles |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0392593B1 (fr) |

| AT (1) | ATE110618T1 (fr) |

| DE (1) | DE69011924T2 (fr) |

| ES (1) | ES2013172A6 (fr) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0659527A1 (fr) * | 1993-12-21 | 1995-06-28 | MASS S.p.A. | Méthode et machine pour fabriquer des carreaux de densité et d'épaisseur constantes, et carreaux ainsi obtenus |

| EP0686843A1 (fr) | 1994-06-08 | 1995-12-13 | Iberditan S.L. | Dispositif pour la mesure automatique de la flottabilité d'ébauches céramiques en mercure |

| EP1354679A1 (fr) * | 2002-04-18 | 2003-10-22 | Euroditan S.L. | Dispositif pour une correction automatique de densité des ébauches non cuites de carreaux en céramique |

| EP1510311A1 (fr) * | 2003-08-23 | 2005-03-02 | Euroditan S.L. | Procédéde production de carreaux en céramique |

| WO2005068143A1 (fr) * | 2003-10-29 | 2005-07-28 | Jimian Chen | Equipement de distribution de materiau a tuyaux multiples pour le compactage de tuiles et procede de distribution |

| WO2016161253A1 (fr) | 2015-04-03 | 2016-10-06 | Ecolab Usa Inc. | Amélioration de la stabilité du peroxygène à l'aide d'un surfactant anionique dans des composés peroxygénés solides contenant du taed |

| WO2016161249A1 (fr) | 2015-04-03 | 2016-10-06 | Ecolab Usa Inc. | Stabilité améliorée du peroxygène dans du peroxygène solide contenant de la taed et destiné à être distribué en plusieurs fois |

| WO2019182856A1 (fr) | 2018-03-19 | 2019-09-26 | Ecolab Usa Inc. | Compositions de détergent liquide contenant un catalyseur de blanchiment |

| WO2019241629A1 (fr) | 2018-06-15 | 2019-12-19 | Ecolab Usa Inc. | Stabilité améliorée du peroxygène à l'aide d'acide gras dans un solide peroxygéné contenant un agent d'activation de blanchiment |

| US20210114254A1 (en) * | 2018-03-26 | 2021-04-22 | System Ceramics S.P.A. | Method for pressing ceramic slabs |

| CN118219406A (zh) * | 2024-05-22 | 2024-06-21 | 佛山东海诺德科技有限公司 | 一种密度调节装置及数码喷粉布料设备 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2046114B1 (es) * | 1992-05-08 | 1995-08-01 | Iberditan Sa | Sistema de control automatico de compactacion en prensas. |

| ES2125799B1 (es) * | 1996-03-14 | 1999-08-01 | Pesudo Arquimedes V Bono | Dispositivo electronico para compensar la carga de arcillas en los moldes. |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3184818A (en) * | 1953-10-19 | 1965-05-25 | Eugene E Crile | Automatic mix regulating devices for cement block molding machines |

| DE1255554B (de) * | 1963-10-16 | 1967-11-30 | Dorst Keramikmasch | Verfahren zum Pressen von Wand-, Fussboden-oder Mosaikplatten mit zueinander planparallelen Ober- und Unterseiten aus pulverfoermigem, insbesondere keramischem Material, und Presse zum Durchfuehren des Verfahrens |

| DE2605514A1 (de) * | 1976-02-12 | 1977-08-18 | Dorstener Eisengiesserei U Mas | Pressenanlage zum herstellen konischer steine |

| GB2143467A (en) * | 1983-07-19 | 1985-02-13 | Charcon Ltd | Moulding apparatus |

| EP0161323A1 (fr) * | 1984-04-16 | 1985-11-21 | Bison-Werke Bähre & Greten GmbH & Co. KG | Procédé et dispositif pour obtenir une répartition prédéterminée de poids par unité de surface dans une couche de fibres |

| EP0197916A1 (fr) * | 1985-04-01 | 1986-10-15 | Simmering-Graz-Pauker Aktiengesellschaft | Dispositif pour le chargement et le déchargement d'une presse, en particulier une presse hydraulique à colonnes |

-

1989

- 1989-04-12 ES ES8901280A patent/ES2013172A6/es not_active Expired - Fee Related

-

1990

- 1990-04-03 DE DE69011924T patent/DE69011924T2/de not_active Expired - Fee Related

- 1990-04-03 AT AT90200795T patent/ATE110618T1/de not_active IP Right Cessation

- 1990-04-03 EP EP90200795A patent/EP0392593B1/fr not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3184818A (en) * | 1953-10-19 | 1965-05-25 | Eugene E Crile | Automatic mix regulating devices for cement block molding machines |

| DE1255554B (de) * | 1963-10-16 | 1967-11-30 | Dorst Keramikmasch | Verfahren zum Pressen von Wand-, Fussboden-oder Mosaikplatten mit zueinander planparallelen Ober- und Unterseiten aus pulverfoermigem, insbesondere keramischem Material, und Presse zum Durchfuehren des Verfahrens |

| DE2605514A1 (de) * | 1976-02-12 | 1977-08-18 | Dorstener Eisengiesserei U Mas | Pressenanlage zum herstellen konischer steine |

| GB2143467A (en) * | 1983-07-19 | 1985-02-13 | Charcon Ltd | Moulding apparatus |

| EP0161323A1 (fr) * | 1984-04-16 | 1985-11-21 | Bison-Werke Bähre & Greten GmbH & Co. KG | Procédé et dispositif pour obtenir une répartition prédéterminée de poids par unité de surface dans une couche de fibres |

| EP0197916A1 (fr) * | 1985-04-01 | 1986-10-15 | Simmering-Graz-Pauker Aktiengesellschaft | Dispositif pour le chargement et le déchargement d'une presse, en particulier une presse hydraulique à colonnes |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0659527A1 (fr) * | 1993-12-21 | 1995-06-28 | MASS S.p.A. | Méthode et machine pour fabriquer des carreaux de densité et d'épaisseur constantes, et carreaux ainsi obtenus |

| EP0686843A1 (fr) | 1994-06-08 | 1995-12-13 | Iberditan S.L. | Dispositif pour la mesure automatique de la flottabilité d'ébauches céramiques en mercure |

| DE4419960A1 (de) * | 1994-06-08 | 1995-12-14 | Dietrich Engmann | Vorrichtung zum automatischen Messen der Auftriebskraft keramischer Rohlinge in Quecksilber |

| EP1354679A1 (fr) * | 2002-04-18 | 2003-10-22 | Euroditan S.L. | Dispositif pour une correction automatique de densité des ébauches non cuites de carreaux en céramique |

| EP1510311A1 (fr) * | 2003-08-23 | 2005-03-02 | Euroditan S.L. | Procédéde production de carreaux en céramique |

| WO2005068143A1 (fr) * | 2003-10-29 | 2005-07-28 | Jimian Chen | Equipement de distribution de materiau a tuyaux multiples pour le compactage de tuiles et procede de distribution |

| WO2016161253A1 (fr) | 2015-04-03 | 2016-10-06 | Ecolab Usa Inc. | Amélioration de la stabilité du peroxygène à l'aide d'un surfactant anionique dans des composés peroxygénés solides contenant du taed |

| WO2016161249A1 (fr) | 2015-04-03 | 2016-10-06 | Ecolab Usa Inc. | Stabilité améliorée du peroxygène dans du peroxygène solide contenant de la taed et destiné à être distribué en plusieurs fois |

| EP4446400A2 (fr) | 2015-04-03 | 2024-10-16 | Ecolab USA Inc. | Stabilité améliorée du peroxygène à l'aide d'un tensioactif anionique dans un solide de peroxygène contenant du taed |

| WO2019182856A1 (fr) | 2018-03-19 | 2019-09-26 | Ecolab Usa Inc. | Compositions de détergent liquide contenant un catalyseur de blanchiment |

| US20210114254A1 (en) * | 2018-03-26 | 2021-04-22 | System Ceramics S.P.A. | Method for pressing ceramic slabs |

| US12109725B2 (en) * | 2018-03-26 | 2024-10-08 | System Ceramics S.P.A. | Method for pressing ceramic slabs |

| WO2019241629A1 (fr) | 2018-06-15 | 2019-12-19 | Ecolab Usa Inc. | Stabilité améliorée du peroxygène à l'aide d'acide gras dans un solide peroxygéné contenant un agent d'activation de blanchiment |

| EP4349951A2 (fr) | 2018-06-15 | 2024-04-10 | Ecolab USA Inc. | Stabilité améliorée du peroxygène à l'aide d'acide gras dans un solide peroxygéné contenant un agent d'activation de blanchiment |

| CN118219406A (zh) * | 2024-05-22 | 2024-06-21 | 佛山东海诺德科技有限公司 | 一种密度调节装置及数码喷粉布料设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0392593B1 (fr) | 1994-08-31 |

| ATE110618T1 (de) | 1994-09-15 |

| DE69011924T2 (de) | 1995-04-13 |

| EP0392593A3 (fr) | 1991-09-18 |

| ES2013172A6 (es) | 1990-04-16 |

| DE69011924D1 (de) | 1994-10-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0392593B1 (fr) | Dispositif pour la correction automatique de l'homogénéité du pressage dans la fabrication de tuiles | |

| US4482307A (en) | Press for producing true-to-size workpieces using powder materials | |

| EP0849572B1 (fr) | Procédé et dispositif de contrôle des paramètres des comprimés | |

| EP0623517B1 (fr) | Méthode et machine pour le remplissage de récipients avec des produits cosmétiques même avec des caracteristiques différentes | |

| EP0659527B1 (fr) | Méthode et machine pour fabriquer des carreaux de densité et d'épaisseur constantes, et carreaux ainsi obtenus | |

| US3970223A (en) | Material metering units | |

| US5082438A (en) | Press for manufacturing stones | |

| UA34431C2 (uk) | Спосіб управління і/або регулювання процесу пресування виробів з сипучих матеріалів і пристрій для його здійснення | |

| EP0290953B1 (fr) | Dispositif pour charger automatiquement et uniformément des moules de presses pour mouler des pièces céramiques, en particulier des carreaux | |

| DK166949B1 (da) | Fremgangsmaade og apparat til fremstilling af tagplader, som har en tvaergaaende flange | |

| US4909974A (en) | Process for the preparation of multilayer blocks suitable for the production of slabs without the use of a sawing machine | |

| US3209057A (en) | Pressure molding of dry material | |

| US3720738A (en) | Method for producing compression-molded articles | |

| EP0569070B1 (fr) | Moule pour la fabrication d'éléments en céramiques, en particulier de carreaux pressés émaillés et moyens d'alimentation de ce moule | |

| US4450127A (en) | Method for compacting powder material with adjustable die and punch assembly | |

| US3709646A (en) | Apparatus for producing compression-molded articles | |

| JP3341447B2 (ja) | 粉末圧縮成形装置 | |

| JPS5850870Y2 (ja) | 高粘度粒状物供給装置 | |

| US4158691A (en) | Method for pressing articles such as plates from pulverulent porcelain composition | |

| JPS6139361B2 (fr) | ||

| CH668032A5 (en) | Unevenly-pressed ceramic item detection method - measures pressure distribution over surface and compares with desired value | |

| CN113453879A (zh) | 用于对至少两个压制件进行粉末压制的方法以及粉末压制设备 | |

| EP0566171B1 (fr) | Dispositif d'asservissement d'un moule pour matière céramique | |

| EP0468577B1 (fr) | Installation à productivité élevée pour la fabrication de carreaux en céramique en général | |

| RU2021109C1 (ru) | Пресс полусухого прессования |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19911016 |

|

| 17Q | First examination report despatched |

Effective date: 19921201 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: IBERDITAN, S.L. |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940831 Ref country code: LI Effective date: 19940831 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19940831 Ref country code: FR Effective date: 19940831 Ref country code: DK Effective date: 19940831 Ref country code: CH Effective date: 19940831 Ref country code: BE Effective date: 19940831 Ref country code: AT Effective date: 19940831 |

|

| REF | Corresponds to: |

Ref document number: 110618 Country of ref document: AT Date of ref document: 19940915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 69011924 Country of ref document: DE Date of ref document: 19941006 |

|

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EN | Fr: translation not filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950403 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970222 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050403 |