EP0370280B1 - Device for demolishing chimneys - Google Patents

Device for demolishing chimneys Download PDFInfo

- Publication number

- EP0370280B1 EP0370280B1 EP89120240A EP89120240A EP0370280B1 EP 0370280 B1 EP0370280 B1 EP 0370280B1 EP 89120240 A EP89120240 A EP 89120240A EP 89120240 A EP89120240 A EP 89120240A EP 0370280 B1 EP0370280 B1 EP 0370280B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- equipment according

- suspension

- chimney

- demolition

- lowering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000725 suspension Substances 0.000 claims abstract description 56

- 210000003128 head Anatomy 0.000 claims description 9

- 239000004567 concrete Substances 0.000 claims description 4

- 239000011150 reinforced concrete Substances 0.000 claims description 4

- 229910000831 Steel Inorganic materials 0.000 claims 1

- 238000010276 construction Methods 0.000 claims 1

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 239000010959 steel Substances 0.000 claims 1

- 230000006978 adaptation Effects 0.000 description 3

- 230000000284 resting effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G23/00—Working measures on existing buildings

- E04G23/08—Wrecking of buildings

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G23/00—Working measures on existing buildings

- E04G23/08—Wrecking of buildings

- E04G2023/087—Wrecking of buildings of chimneys, smoke stacks or the like

Definitions

- the invention relates to a device for breaking off chimneys made of masonry, concrete or reinforced concrete, in particular of high chimneys, by means of a demolition tool which gradually removes the chimney shaft from the chimney head to the chimney foot, e.g. is already known from patent application EP-A-0133630.

- the invention has for its object to provide a device which allows chimneys and in particular tall chimneys to be broken off by machine with optimum safety and in a rational or economical manner.

- the generic device is characterized by a work platform that can be attached to the mouth end of the chimney shaft and suspension devices distributed over the circumference of the stage, each with at least one vertically guided lowering piston that can be locked in different height positions, in that the work platform is suspended in the interior of the chimney shaft and that a suspension arm is pivotally mounted on the upper piston end of the lowering piston, which engages over the chimney wall in the pivoted-out position.

- the invention further teaches that the work platform has supporting devices distributed over the circumference of the stage with support arms which can be adjusted against the inside of the chimney.

- the invention is based on the knowledge that an excavator with a demolition tool can then be used with sufficient freedom of movement and optimal safety for demolition of chimneys if a work platform is installed for this excavator, which is gradually lowered from the chimney head to the chimney base in accordance with the progress of demolition can be.

- a work platform can be lifted to the level of the chimney mouth in the same way as the excavator by means of an approved conveyor scaffold and hung there in the chimney shaft.

- the work platform is suspended from the chimney wall using the all-round suspension devices. Then the lowering pistons are extended, so to speak, ie the work platform hangs at the lower end the lowering piston and the suspension arms overlap the chimney wall.

- the suspension arms are swiveled in or back in individually and one after the other, so that the chimney wall can be demolished shortly above the level of the work platform.

- the lowering piston in question is then moved down or retracted by the extent of the demolition progress and the relevant suspension arm is pivoted out again, so it then overlaps the chimney wall at the demolition point that has migrated downward.

- the work platform which regularly has a polygon-like circumference, is moved on each suspension arm or lowering piston, so that finally all working pistons with their suspension arms are retracted by the degree of progress of the dismantling or moved down.

- the extent of the demolition progress corresponds to the maximum piston stroke.

- the invention provides that the support devices are connected in a radial extension to the suspension devices and the suspension devices with the support devices with the interposition of cantilever arms in the radial direction can be moved forward or can be seized.

- the cantilever arms can be designed as profile supports, rack and pinion drives or cylinder piston arrangements with screwable connecting flanges.

- profile beams can be successively connected to one another via their connecting flanges and inserted between the suspension devices and the working platform.

- the suspension devices each have a guide tube flanged directly to the working platform or to an intermediate cantilever arm in a vertical orientation for the lowering piston which is height-adjustable and lockable in the guide tube, and that the guide tube and the lowering piston are in predetermined height distances aligned cross holes to the have locking bolts. In this way, the extent of the demolition progress can vary over the height of the piston stroke, so that the working platform only has to be lowered after several demolition steps that have taken place over the chimney circumference.

- the guide tube is designed as a rectangular tube and the lowering piston as an I-profile and longitudinal guides, for example ball guides or roller guides, are arranged as ladder-shaped flat cages or roller carriages for the lowering piston.

- the lowering piston expediently has a footplate at its lower end as a stop for the guide tube and consequently the work platform, as well as suspension eyes at its upper end.

- the work platform can be attached to a conveyor frame in the chimney mouth.

- the vertically guided lowering piston carries two horizontal bearing cheeks at its upper end and the suspension arm is pivotally mounted on a horizontal bearing pin between these bearing cheeks and can be locked in a horizontal position by means of locking pins which can be inserted into aligned cross holes on one or both sides of the bearing pin.

- the bearing cheeks and the suspension arm can consist of U-profiles. Each suspension arm can at its resting end have a height-adjustable support plate in order to achieve perfect support on the demolition surface of the chimney shaft.

- the inner ends of the suspension arms and the guide tubes are connected to one another in the region of their inner connecting flanges via chain or cable pulls and thereby the working platform by means of Chain or cable pulling devices can be lowered on the suspended lowering pistons. Lowering the platform in this way is necessary before each demolition cycle. The lowered working platform then rests on the base plates of the lowering pistons and is supported against the inner wall of the shaft.

- each guide tube is surrounded by a double collar with a connecting flange for the working platform or the intermediate cantilever arm and one or two support arms are pivotably mounted in a horizontal plane between the two collars and can be fixed in a position against the inner chimney wall, e.g. by means of a chain hoist or linkage connecting both support arms, so that the support arms cannot swing out independently and the support is thereby lost.

- the support arms can have support plates which can be pivoted or articulated at the end.

- the figures show a device for breaking off chimneys made of masonry, concrete or reinforced concrete, in particular free-standing chimneys of great height.

- the chimney is broken off by means of a successive removal of the chimney shaft 1 from the chimney head to the chimney foot Demolition tool 2, which is attached to the cantilever arm 3 of an excavator 4 according to the embodiment.

- a work platform 5 is suspended in the chimney shaft 1 at its mouth end, specifically with suspension devices 6 distributed over the circumference of the stage, each with at least one vertically guided lowering piston 7, which can be locked in different height positions, and a suspension arm 8 pivotably mounted at the upper piston end, which in the pivoted-out position Spread over chimney wall.

- the work platform 5 also has support devices 9 distributed over the circumference of the stage, with support arms 10 which can be adjusted against the inside of the chimney.

- the support devices 9 adjoin the suspension devices 6 in a radial extension.

- the suspension devices 6 can be advanced or pre-attached with the support devices 9 with the interposition of cantilever arms 11 in the radial direction in order to always allow adaptation to the chimney diameter which increases from the chimney head to the chimney foot.

- the working platform 5 has a polygon-like circumference, consists essentially of cross-beam-shaped profile beams 12 and a platform 13 carried by them.

- the cantilever arms 11 are designed as profile beams with screwable connecting flanges 14.

- the working platform 5 and the suspension devices 6 have such connecting flanges 14.

- Catwalks 15 can be fastened on the cantilever arms 11.

- Safety nets 16 can be suspended between the cantilever arms 11, which is only indicated.

- the suspension devices 6 each have a directly on the work platform 5 or on an intermediate cantilever 11 in a vertical orientation flanged guide tube 17 for the lowering piston 7 which is height-adjustable in the guide tube and lockable at different heights.

- the guide tube 17 and the lowering piston 7 have aligned cross bores 18 for inserting locking bolts at predetermined height intervals.

- the guide tube 17 is designed as a rectangular tube and the lowering piston 7 as an I-profile. Roller guides 19 for the lowering piston 7 are arranged in the guide tube 17.

- the lowering piston 7 has a base plate 20 at its lower end and suspension eyes at its upper end. In the lowered position, the working platform 5 rests on the base plates 20 of the lowering piston 7.

- Each of the distributed lowering pistons 7 carries two horizontal bearing cheeks 21 at its upper end. Between the bearing cheeks 21, the suspension arm 8 is pivotably mounted on a horizontal bearing pin 22 and can be locked in a horizontal position by means of locking pins which can be inserted into aligned cross bores 23 on one or both sides of the bearing pin 22, when the suspension arm 8 overlaps the chimney wall and the working platform 5 is suspended with the lowering piston 7 interposed.

- the bearing cheeks 21 and the suspension arm 8 consist of U-profiles.

- Each suspension arm 8 has a height-adjustable support plate 24 at its resting end for adaptation to the respective demolition surface.

- each Guide tube 17 is surrounded by a double collar 26 with a connecting flange 14.

- one or two support arms 10 are pivotally mounted in the horizontal plane and can be fixed in the position against the chimney inner wall, for example by means of a chain hoist 27 or linkage connecting the two support arms.

- the support arms 10 are pivoted apart.

- the support arms 10 have pivotable or articulated support plates 28 in order to achieve perfect support against the chimney inner wall.

- a chimney is demolished as follows:

- the excavator 4 begins its demolition work in the region of a suspension arm 8 which is pivoted back or in. After the demolition has taken place Over a predetermined height, which must not exceed the maximum piston stroke of the lowering piston 7, the suspension arm 8 in question is pivoted back into its starting position spanning the chimney wall. The lowering piston 7 in question is then automatically in the retracted position.

- the lowering pistons 7 touch the ground. Ultimately, this also applies to the work platform.

- cantilever arms 11 are increasingly used between the working platform 5 and the guide tubes 17 for the lowering pistons 7 with the support arms 10, so that the support arms 10 can always be positioned properly against the increasing chimney inner wall and for centering and movement-free support of the work platform 5.

- substructures 31 which can be covered with carriages 30 can be connected to the cantilever arms 11 in order to achieve an expansion of the work platform 5 into the region of the chimney wall, so that the excavator 4 moves forward from the center of the chimney and can carry out demolition work from the outside with demolition tool 2 spanning the chimney wall.

- use is on the catwalks 15 and safety nets 16 are dispensed with. This is only indicated in some areas in FIG. 6.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Working Measures On Existing Buildindgs (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zum Abbrechen von Schornsteinen aus Mauerwerk, Beton oder Stahlbeton, insbes. von hohen Schornsteinen, mittels eines den Schornsteinschaft von dem Schornsteinkopf bis zum Schornsteinfuß sukzessive abtragenden Abbruchwerkzeuges, wie z.B. aus der Patentanmeldung EP-A-0133630 vorbekannt ist.The invention relates to a device for breaking off chimneys made of masonry, concrete or reinforced concrete, in particular of high chimneys, by means of a demolition tool which gradually removes the chimney shaft from the chimney head to the chimney foot, e.g. is already known from patent application EP-A-0133630.

Ein ständiges Problem bereitet der Abbruch von Schornsteinen, insbes. freistehenden Industrieschornsteinen großer Höhe. Häufig muß schon aus Sicherheitsgründen ein manueller Abbruch erfolgen, nämlich mittels manuell bedienbarer Abbruchgeräte wie Drucklufthämmer o.dgl. Man hat auch schon maschinellen Abbruch versucht. Dazu wird mit Hilfe eines zunächst am Schornsteinkopf zu installierenden Fördergerüstes ein Bagger mit Auslegerbeinen auf den Schornsteinschaft aufgesetzt. Der Baggerarm ist mit einem Abbruchwerkzeug bestückt. Mit Hilfe des Abbruchwerkzeuges können Mauerwerk und Beton sukzessive abgetragen werden, während bei Stahlbetonkonstruktionen außerdem die Bewehrung von einem Konsolgerüst aus mittels Schneidbrenner o.dgl. zerlegt wird. Der Bagger wandert mit dem Abbruchfortschritt von dem Schornsteinkopf zum Schornsteinfuß. Dazu folgen die Auslegerbeine dem Abbruchfortschritt auf der Schornsteinwand. Wegen erheblicher Absturzgefahr muß der Bagger zusätzlich an einem Kran aufgehängt werden. Der Einsatz eines solchen Krans ist kostenaufwendig. Häufig stehen Krane mit ausreichender Auslegerhöhe gar nicht zur Verfügung. Im ganzen ist diese Abbruchmethode unbefriedigend. ― Hier will die Erfindung Abhilfe schaffen.Demolition of chimneys, especially free-standing industrial chimneys of great height, is a constant problem. Often a manual demolition must take place for safety reasons, namely by means of manually operated demolition devices such as pneumatic hammers or the like. There has also been an attempt to abort the machine. For this purpose, an excavator with outrigger legs is placed on the chimney shaft with the aid of a conveyor scaffold that is initially to be installed on the chimney head. The excavator arm is equipped with a demolition tool. With the help of the demolition tool, masonry and concrete can be gradually removed, while in the case of reinforced concrete structures, the reinforcement from a bracket frame using a cutting torch or the like. is disassembled. As the demolition progresses, the excavator moves from the chimney head to the chimney foot. To do this, the boom legs follow the demolition progress on the chimney wall. Because of the considerable risk of falling, the excavator must also be hung on a crane. The use of such a crane is expensive. Often there are no cranes with sufficient boom height available. Overall, this termination method is unsatisfactory. - The invention seeks to remedy this.

Der Erfindung liegt die Aufgabe zugrunde, eine Vorrichtung zu schaffen, welche das Abbrechen von Schornsteinen und insbesondere hohen Schornsteinen auf maschinellem Wege mit optimaler Sicherheit und in rationeller bzw. wirtschaftlicher Weise ermöglicht.The invention has for its object to provide a device which allows chimneys and in particular tall chimneys to be broken off by machine with optimum safety and in a rational or economical manner.

Zur Lösung dieser Aufgabe ist die gattungsgemäße Vorrichtung mit einer an dem Mündungsende des Schornsteinschaftes einhängbaren Arbeitsbühne mit über den Bühnenumfang verteilten Abhängeeinrichtungen mit jeweils zumindest einem vertikal geführten sowie in verschiedenen Höhenstellungen arretierbaren Absenkkolben dadurch gekennzeichnet, daß die Arbeitsbühne in dem Inneren des Schornsteinschaftes eingehängt ist und, daß am oberen Kolbenende der Absenkkolben jeweils ein Abhängearm einschwenkbar gelagert ist, welcher in ausgeschwenkter Stellung die Schornsteinwand übergreift. Weiter lehrt die Erfindung, daß die Arbeitsbühne über den Bühnenumfang verteilte Abstützeinrichtungen mit gegen die Schornsteininnenwand anstellbaren Stützarmen aufweist. ― Die Erfindung geht von der Erkenntnis aus, daß sich ein Bagger mit einem Abbruchwerkzeug dann mit ausreichender Bewegungsfreiheit und optimaler Sicherheit zum Abbruch von Schornsteinen einsetzen läßt, wenn für diesen Bagger eine Arbeitsbühne installiert wird, die nach Maßgabe des Abbruchfortschrittes vom Schornsteinkopf zum Schornsteinfuß schrittweise abgesenkt werden kann. Eine solche Arbeitsbühne läßt sich in gleicher Weise wie der Bagger mittels eines zugelassenen Fördergerüstes auf das Niveau der Schornsteinmündung einheben und dort in den Schornsteinschaft einhängen. Die Arbeitsbühne wird mit Hilfe der rundum vorgesehenen Abhängeeinrichtungen an der Schornsteinwand abgehängt. Dann sind die Absenkkolben gleichsam ausgefahren, d.h. die Arbeitsbühne hängt am unteren Ende der Absenkkolben, und die Abhängearme übergreifen die Schornsteinwand. Im Zuge der Abbrucharbeiten werden die Abhängearme einzeln und nacheinander ein- bzw. zurückgeschwenkt, so daß dort Abbruch der Schornsteinwand bis kurz über das Niveau der Arbeitsbühne erfolgen kann. Anschließend wird der betreffende Absenkkolben um das Maß des Abbruchfortschrittes nach unten gefahren bzw. eingefahren und der betreffende Abhängearm wieder ausgeschwenkt, übergreift dann also die Schornsteinwand an der nach unten gewanderten Abbruchstelle. Auf diese Weise wird rundum der Arbeitsbühne, die regelmäßig einen polygonartigen Umfang aufweist, an jedem Abhängearm bzw. Absenkkolben verfahren, so daß schließlich sämtliche Arbeitskolben mit ihren Abhängearmen um das Maß des Abbaufortschrittes eingefahren bzw. nach unten gefahren sind. Dabei entspricht das Maß des Abbruchfortschrittes dem maximalen Kolbenhub. Nach einem Abbruchzyklus befinden sich sämtliche Absenkkolben in eingefahrener Stellung, die Arbeitsbühne also im Bereich des oberen Endes der Absenkkolben. Nunmehr wird die Arbeitsbühne nach Maßgabe des Kolbenhubs abgesenkt und befindet sich in abgesenkter Position wiederum am unteren Ende der Absenkkolben, so daß ein neuer Abbruchzyklus erfolgen und die Schornsteinwand rundum um das Maß des Kolbenhubs weiter abgebrochen werden kann undsofort. Die gegen die Schornsteininnenwand anstellbaren Abstützeinrichtungen dienen dazu, die Arbeitsbühne in dem Schornsteinschaft zu zentrieren und gegen Ausschwenkbewegungen zu sichern. Im Zuge des Absenkens der Arbeitsbühne werden die Abstützeinrichtungen vorübergehend gelöst und folglich von der Schornsteininnenwand zurückgenommen. Stets steht für den Bagger eine einwandfrei gesicherte Arbeitsplattform zur Verfügung, so daß die Abbrucharbeiten unter Verzicht auf eine zusätzliche Kranaufhängung in maschineller und rationeller Weise erfolgen können.To achieve this object, the generic device is characterized by a work platform that can be attached to the mouth end of the chimney shaft and suspension devices distributed over the circumference of the stage, each with at least one vertically guided lowering piston that can be locked in different height positions, in that the work platform is suspended in the interior of the chimney shaft and that a suspension arm is pivotally mounted on the upper piston end of the lowering piston, which engages over the chimney wall in the pivoted-out position. The invention further teaches that the work platform has supporting devices distributed over the circumference of the stage with support arms which can be adjusted against the inside of the chimney. - The invention is based on the knowledge that an excavator with a demolition tool can then be used with sufficient freedom of movement and optimal safety for demolition of chimneys if a work platform is installed for this excavator, which is gradually lowered from the chimney head to the chimney base in accordance with the progress of demolition can be. Such a work platform can be lifted to the level of the chimney mouth in the same way as the excavator by means of an approved conveyor scaffold and hung there in the chimney shaft. The work platform is suspended from the chimney wall using the all-round suspension devices. Then the lowering pistons are extended, so to speak, ie the work platform hangs at the lower end the lowering piston and the suspension arms overlap the chimney wall. In the course of the demolition work, the suspension arms are swiveled in or back in individually and one after the other, so that the chimney wall can be demolished shortly above the level of the work platform. The lowering piston in question is then moved down or retracted by the extent of the demolition progress and the relevant suspension arm is pivoted out again, so it then overlaps the chimney wall at the demolition point that has migrated downward. In this way, the work platform, which regularly has a polygon-like circumference, is moved on each suspension arm or lowering piston, so that finally all working pistons with their suspension arms are retracted by the degree of progress of the dismantling or moved down. The extent of the demolition progress corresponds to the maximum piston stroke. After a demolition cycle, all of the lowering pistons are in the retracted position, i.e. the working platform is in the area of the upper end of the lowering piston. Now the working platform is lowered according to the piston stroke and is again in the lowered position at the lower end of the lowering piston, so that a new demolition cycle can take place and the chimney wall can be broken off all the way around the extent of the piston stroke and immediately. The support devices that can be adjusted against the inside of the chimney serve to center the working platform in the chimney shaft and to secure it against swiveling out movements. In the course of lowering the working platform, the support devices are temporarily released and consequently withdrawn from the inside of the chimney. The excavator always has a perfectly secured one Work platform available so that the demolition work can be done mechanically and rationally without an additional crane suspension.

Weitere erfindungswesentliche Merkmale sind im folgenden aufgeführt. So sieht die Erfindung vor, daß sich die Abstützeinrichtungen in radialer Verlängerung an die Abhängeeinrichtungen anschließen und die Abhängeeinrichtungen mit den Abstützeinrichtungen unter Zwischenschaltung von Kragarmen in Radialrichtung vorfahrbar bzw. vorpfändbar sind. Dadurch wird eine Anpassung an unterschiedliche Schornsteindurchmesser möglich, zumal sich der Schornsteindurchmesser regelmäßig vom Schornsteinkopf zum Schornsteinfuß vergrößert. Die Kragarme können als Profilträger, Zahnstangentriebe oder Zylinderkolbenanordnungen mit verschraubbaren Anschlußflanschen ausgebildet sein. Beispielsweise lassen sich sukzessive mehrere Profilträger über ihre Anschlußflansche miteinander verbinden und zwischen die Abhängeeinrichtungen und der Arbeitsbühne einsetzen. Ferner können auf den Kragarmen Laufstege befestigt und zwischen den Kragarmen Fangnetze aufgehängt werden, so daß eine zusätzliche Sicherheit für das Abbruchpersonal erreicht wird. ― Nach einem Vorschlag der Erfindung mit selbständiger Bedeutung ist vorgesehen, daß die Abhängeeinrichtungen jeweils ein unmittelbar an der Arbeitsbühne oder an einem zwischengeschalteten Kragarm in vertikaler Ausrichtung angeflanschtes Führungsrohr für den in dem Führungsrohr höhenverstellbaren und arretierbaren Absenkkolben aufweist, und daß das Führungsrohr und der Absenkkolben in vorgegebenen Höhenabständen fluchtende Querbohrungen zum Ein stecken von Arretierungsbolzen aufweisen. Auf diese Weise läßt sich das Maß des Abbruchfortschrittes über die Höhe des Kolbenhubes variieren, so daß die Arbeitsbühne erst nach mehreren über den Schornsteinumfang erfolgenden Abbruchschritten abgesenkt werden muß. Ferner ist eine derartige Ausbildung der Abhängeeinrichtungen in fertigungs- und bedienungstechnischer Hinsicht besonders einfach, stabil und funktionsgerecht. Das gilt auch unter Berücksichtigung der weiteren Empfehlung der Erfindung, wonach das Führungsrohr als Rechteckrohr und der Absenkkolben als I-Profil ausgebildet sind und in dem Führungsrohr Längsführungen, z.B. Kugelführungen oder Rollenführungen als leiterförmige Flachkäfige oder Wälzwagen für den Absenkkolben angeordnet sind. Auf diese Weise wird Leichtgängigkeit für den bzw. die Absenkkolben in ihren Führungsrohren erreicht, werden insbes. Verkantungen vermieden. Der Absenkkolben weist an seinem unteren Ende zweckmäßigerweise eine Fußplatte als gleichsam Anschlag für das Führungsrohr und folglich die Arbeitsbühne sowie an seinem oberen Ende Aufhängeösen auf. Aufgrund dieser Aufhängeösen, die sich auch an der Arbeitsbühne befinden, läßt sich die Arbeitsbühne an einem Fördergerüst in die Schornsteinmündung einhängen. Vorzugsweise trägt der vertikal geführte Absenkkolben an seinem oberen Ende zwei horizontale Lagerwangen und ist zwischen diesen Lagerwangen der Abhängearm auf einem horizontalen Lagerbolzen schwenkbar gelagert und mittels ein- oder beidseitig des Lagerbolzens in fluchtende Querbohrungen einsteckbaren Arretierungsbolzen in horizontaler Position feststellbar. Die Lagerwangen und der Abhängearm können aus U-Profilen bestehen. Jeder Abhängearm kann an seinem aufliegenden Ende eine höhenjustierbare Auflagerplatte aufweisen, um eine einwandfreie Abstützung auf der Abbruchfläche des Schornsteinschaftes zu erreichen.Further features essential to the invention are listed below. Thus, the invention provides that the support devices are connected in a radial extension to the suspension devices and the suspension devices with the support devices with the interposition of cantilever arms in the radial direction can be moved forward or can be seized. This makes it possible to adapt to different chimney diameters, especially since the chimney diameter increases regularly from the chimney head to the chimney base. The cantilever arms can be designed as profile supports, rack and pinion drives or cylinder piston arrangements with screwable connecting flanges. For example, several profile beams can be successively connected to one another via their connecting flanges and inserted between the suspension devices and the working platform. Furthermore, catwalks can be attached to the cantilever arms and safety nets can be hung between the cantilever arms, so that additional safety for demolition personnel is achieved. - According to a proposal of the invention with independent meaning, it is provided that the suspension devices each have a guide tube flanged directly to the working platform or to an intermediate cantilever arm in a vertical orientation for the lowering piston which is height-adjustable and lockable in the guide tube, and that the guide tube and the lowering piston are in predetermined height distances aligned cross holes to the have locking bolts. In this way, the extent of the demolition progress can vary over the height of the piston stroke, so that the working platform only has to be lowered after several demolition steps that have taken place over the chimney circumference. Furthermore, such a design of the suspension devices is particularly simple, stable and functional in terms of production and operating technology. This also applies taking into account the further recommendation of the invention, according to which the guide tube is designed as a rectangular tube and the lowering piston as an I-profile and longitudinal guides, for example ball guides or roller guides, are arranged as ladder-shaped flat cages or roller carriages for the lowering piston. In this way, ease of movement for the lowering piston or pistons in their guide tubes is achieved, in particular tilting is avoided. The lowering piston expediently has a footplate at its lower end as a stop for the guide tube and consequently the work platform, as well as suspension eyes at its upper end. Due to these suspension eyes, which are also located on the work platform, the work platform can be attached to a conveyor frame in the chimney mouth. Preferably, the vertically guided lowering piston carries two horizontal bearing cheeks at its upper end and the suspension arm is pivotally mounted on a horizontal bearing pin between these bearing cheeks and can be locked in a horizontal position by means of locking pins which can be inserted into aligned cross holes on one or both sides of the bearing pin. The bearing cheeks and the suspension arm can consist of U-profiles. Each suspension arm can at its resting end have a height-adjustable support plate in order to achieve perfect support on the demolition surface of the chimney shaft.

Nach einem Vorschlag der Erfindung, dem in Kombination mit den beanspruchten Maßnahmen aber auch selbständig besondere Bedeutung zukommt, ist vorgesehen, daß die innenliegenden Enden der Abhängearme und die Führungsrohre im Bereich ihrer innenliegenden Anschlußflansche über Ketten- oder Seilzüge miteinander verbunden sind und dadurch die Arbeitsbühne mittels Ketten- oder Seilzuggeräten an den abgehängten Absenkkolben absenkbar sind. Ein derartiges Absenken der Arbeitsbühne ist vor jedem Abbruchzyklus erforderlich. Die abgesenkte Arbeitsbühne liegt dann auf den Fußplatten der Absenkkolben auf und ist im übrigen gegen die Schachtinnenwand abgestützt. Erfindungsgemäß ist jedes Führungsrohr von einem Doppelkragen mit Anschlußflansch für die Arbeitsbühne bzw. den zwischengeschalteten Kragarm umgeben und sind zwischen beiden Kragen ein oder zwei Stützarme in horizontaler Ebene schwenkbar gelagert und in gegen die Schornsteininnenwand angestellter Position fixierbar, z.B. mittels eines beide Stützarme verbindenden Kettenzuges oder Gestänges, damit die Stützarme nicht selbständig ausschwenken können und dadurch die Abstützung verlorengeht. Um eine einwandfreie Abstützung bzw. Anpassung an die Schornsteininnenwand zu erreichen, können die Stützarme endseitig schwenkbar oder gelenkig gelagerte Abstützteller aufweisen.According to a proposal of the invention, which in combination with the claimed measures is also of particular importance independently, it is provided that the inner ends of the suspension arms and the guide tubes are connected to one another in the region of their inner connecting flanges via chain or cable pulls and thereby the working platform by means of Chain or cable pulling devices can be lowered on the suspended lowering pistons. Lowering the platform in this way is necessary before each demolition cycle. The lowered working platform then rests on the base plates of the lowering pistons and is supported against the inner wall of the shaft. According to the invention, each guide tube is surrounded by a double collar with a connecting flange for the working platform or the intermediate cantilever arm and one or two support arms are pivotably mounted in a horizontal plane between the two collars and can be fixed in a position against the inner chimney wall, e.g. by means of a chain hoist or linkage connecting both support arms, so that the support arms cannot swing out independently and the support is thereby lost. In order to achieve proper support or adaptation to the inside of the chimney, the support arms can have support plates which can be pivoted or articulated at the end.

Im folgenden wird die Erfindung anhand einer lediglich ein Ausführungsbeispiel darstellenden Zeichnung näher erläutert; es zeigen:

- Fig. 1

- einen Vertikalschnitt durch eine Schornsteinmündung mit angedeutetem Fördergerüst nach dem Einhängen einer Arbeitsbühne,

- Fig. 2

- eine schematische Aufsicht auf den Gegenstand nach Fig. 1, jedoch mit horizontal geschnittenem Fördergerüst und lediglich angedeuteter Arbeitsbühne und fortgelassenem Bagger,

- Fig. 3

- den Gegenstand nach Fig. 1 nach erfolgtem Abbruch der Schornsteinwand im Bereich eines wieder ausgeschwenkten Abhängearmes mit für die Abbrucharbeiten angedeuteter Einschwenkstellung,

- Fig. 4

- den Gegenstand nach Fig. 3 nach einem Abbruchzyklus,

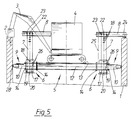

- Fig. 5

- den Gegenstand nach Fig. 4 nach erfolgtem Absenken der Arbeitsbühne zu Beginn eines neuen Abbruchzyklus und

- Fig. 6

- eine schematische Aufsicht auf einen Schornstein mit teilweisem Horizontalschnitt in einem oberen und einem unteren Schornsteinbereich und eingesetzter Arbeitsbühne ohne die Schornsteinwand übergreifende Abhängearme.

In the following the invention is explained in more detail with reference to a drawing showing only one embodiment; show it:

- Fig. 1

- a vertical section through a chimney mouth with an indicated conveyor frame after hanging in a working platform,

- Fig. 2

- 1 shows a schematic plan view of the object according to FIG. 1, but with a horizontally cut conveyor frame and only an indicated working platform and omitted excavator,

- Fig. 3

- 1 after the chimney wall has been demolished in the region of a pivoted out suspension arm with the pivoted-in position indicated for the demolition work,

- Fig. 4

- 3 after an abort cycle,

- Fig. 5

- 4 after the working platform has been lowered at the beginning of a new demolition cycle and

- Fig. 6

- is a schematic plan view of a chimney with a partial horizontal section in an upper and a lower chimney area and inserted work platform without suspension arms spanning the chimney wall.

In den Figuren ist eine Vorrichtung zum Abbrechen von Schornsteinen aus Mauerwerk, Beton oder Stahlbeton, insbes. von freistehenden Schornsteinen großer Höhe dargestellt. Das Abbrechen erfolgt mittels eines den Schornsteinschaft 1 von dem Schornsteinkopf bis zum Schornsteinfuß sukzessive abtragenden Abbruchwerkzeuges 2, welches nach dem Ausführungsbeispiel an dem Auslegerarm 3 eines Baggers 4 befestigt ist. In den Schornsteinschaft 1 ist an seinem Mündungsende eine Arbeitsbühne 5 eingehängt, und zwar mit über den Bühnenumfang verteilten Abhängeeinrichtungen 6 mit jeweils zumindest einem vertikal geführten sowie in verschiedenen Höhenstellungen arretierbaren Absenkkolben 7 und einem am oberen Kolbenende schwenkbar gelagerten Abhängearm 8, welche in ausgeschwenkter Stellung die Schornsteinwand übergreifen. Die Arbeitsbühne 5 weist außerdem über den Bühnenumfang verteilte Abstützeinrichtungen 9 mit gegen die Schornsteininnenwand anstellbaren Stützarmen 10 auf. Die Abstützeinrichtungen 9 schließen sich in radialer Verlängerung an die Abhängeeinrichtungen 6 an. Die Abhängeeinrichtungen 6 sind mit den Abstützeinrichtungen 9 unter Zwischenschaltung von Kragarmen 11 in Radialrichtung vorfahrbar bzw. vorpfändbar, um stets eine Anpassung an den sich vom Schornsteinkopf zum Schornsteinfuß hin vergrößernden Schornsteindurchmesser zu ermöglichen. Die Arbeitsbühne 5 weist im Ausführungsbeispiel einen polygonartigen Umfang auf, besteht im wesentlichen aus traversenartigen Profilträgern 12 und einer davon getragenen Plattform 13. Die Kragarme 11 sind als Profilträger mit verschraubbaren Anschlußflanschen 14 ausgebildet. Ebenso weisen die Arbeitsbühne 5 und die Abhängeeinrichtungen 6 derartige Anschlußflansche 14 auf. Auf den Kragarmen 11 lassen sich Laufstege 15 befestigen. Zwischen den Kragarmen 11 lassen sich Fangnetze 16 aufhängen, was lediglich angedeutet ist.The figures show a device for breaking off chimneys made of masonry, concrete or reinforced concrete, in particular free-standing chimneys of great height. The chimney is broken off by means of a successive removal of the

Die Abhängeeinrichtungen 6 weisen jeweils ein unmittelbar an der Arbeitsbühne 5 oder an einem zwischengeschalteten Kragarm 11 in vertikaler Ausrichtung angeflanschtes Führungsrohr 17 für den in dem Führungsrohr höhenverstellbaren und in verschiedenen Höhen arretierbaren Absenkkolben 7 auf. Das Führungsrohr 17 und der Absenkkolben 7 besitzen in vorgegebenen Höhenabständen fluchtende Querbohrungen 18 zum Einstecken von Arretierungsbolzen. Das Führungsrohr 17 ist als Rechteckrohr und der Absenkkolben 7 als I-Profil ausgebildet. In dem Führungsrohr 17 sind Rollenführungen 19 für den Absenkkolben 7 angeordnet. Der Absenkkolben 7 weist an seinem unteren Ende eine Fußplatte 20 und an seinem oberen Ende Aufhängeösen auf. In abgesenkter Position lagert die Arbeitsbühne 5 auf den Fußplatten 20 der Absenkkolben 7 auf. Jeder der verteilten Absenkkolben 7 trägt an seinem oberen Ende zwei horizontale Lagerwangen 21. Zwischen den Lagerwangen 21 ist der Abhängearm 8 auf einem horizontalen Lagerbolzen 22 schwenkbar gelagert und mittels ein- oder beidseitig des Lagerbolzens 22 in fluchtende Querbohrungen 23 einsteckbaren Arretierungsbolzen in horizontaler Position feststellbar, wenn nämlich der Abhängearm 8 die Schornsteinwand übergreift und die Arbeitsbühne 5 unter Zwischenschaltung des Absenkkolbens 7 dadurch abgehängt wird. Die Lagerwangen 21 und der Abhängearm 8 bestehen aus U-Profilen. Jeder Abhängearm 8 weist an seinem aufliegenden Ende eine höhenjustierbare Auflagerplatte 24 zur Anpassung an die jeweilige Abbruchfläche auf.The

Die innenliegenden Enden der Abhängearme 8 und die Führungsrohre 17 im Bereich ihrer innenliegenden Anschlußflansche 14 sind über Ketten- oder Seilzüge 25 miteinander verbunden. Dadurch ist die Arbeitsbühne 5 mittels Ketten- oder Seilzuggeräten an den abgehängten Absenkkolben 7 absenkbar. Jedes Führungsrohr 17 ist von einem Doppelkragen 26 mit Anschlußflansch 14 umgeben. Im Doppelkragen 26 bzw. zwischen beiden Kragen sind ein oder zwei Stützarme 10 in horizontaler Ebene schwenkbar gelagert und in gegen die Schornsteininnenwand angestellter Position fixierbar, z.B. mittels eines beide Stützarme verbindenden Kettenzuges 27 oder Gestänges. Im Zuge des Absenkens der Arbeitsbühne 5 werden die Stützarme 10 auseinandergeschwenkt. Im übrigen weisen die Stützarme 10 schwenkbar oder gelenkig gelagerte Abstützteller 28 auf, um eine einwandfreie Abstützung gegen die Schornsteininnenwand zu erreichen.The inner ends of the

Der Abbruch eines Schornsteines erfolgt wie folgt:A chimney is demolished as follows:

Nachdem die Arbeitsbühne 5 mit Hilfe eines Fördergerüstes 29 in die Schornsteinmündung eingesetzt und auf die abgehängte Arbeitsbühne 5 ein Bagger 4 mit einem Abbruchwerkzeug 2 aufgesetzt worden ist, beginnt der Bagger 4 seine Abbrucharbeit im Bereich eines zurück- bzw. eingeschwenkten Abhängearmes 8. Nach erfolgtem Abbruch über ein vorgegebenes Höhenmaß, welches den maximalen Kolbenhub der Absenkkolben 7 nicht übersteigen darf, wird der betreffende Abhängearm 8 wieder in seine die Schornsteinwand übergreifende Ausgangsstellung zurückgeschwenkt. Der betreffende Absenkkolben 7 befindet sich dann automatisch in eingefahrener Stellung. Anschließend erfolgt der weitere Abbruch der Schornsteinwand im Bereich des nächsten einzuschwenkenden Abhängearmes 8 undsofort nacheinander bei sämtlichen Abhängearmen 8,, so daß schließlich sämtliche Absenkkolben 7 eingefahren und die Abhängearme 8 wieder in die Schornsteinwand übergreifende Position eingeschwenkt sind. Dann werden die Stützarme 10 gelöst und auseinandergeschwenkt, so daß nunmehr die Arbeitsbühne 5 auf den Absenkkolben 7 bis auf deren Fußplatten 20 abgesenkt werden kann. Nun beginnt ein neuer Abbruchzyklus in der beschriebenen Weise, wobei die Möglichkeit besteht, für den Abbruchfortschritt Höhenmaße zu verwirklichen, die nicht dem maximalen Kolbenhub der Absenkkolben 7 entsprechen, sondern Bruchteile davon, weil die in die Führungsrohre 17 einfahrenden Absenkkolben 7 in durch die Querbohrungen 18 vorgegebenen Höhenabständen verstellbar und arretierbar sind. Im Bereich des Schachtfußes schließlich setzen die Absenkkolben 7 auf das Erdreich auf. Das gilt letztlich dann auch für die Arbeitsbühne. Auf dem Weg von dem Schornsteinkopf zum Schornsteingrund werden in zunehmendem Maße Kragarme 11 zwischen die Arbeitsbühne 5 und den Führungsrohren 17 für die Absenkkolben 7 mit den Stützarmen 10 eingesetzt, damit die Stützarme 10 stets einwandfrei gegen die sich im Durchmesser vergrößernde Schornsteininnenwand angestellt werden können und für eine Zentrierung sowie bewegungsfreie Abstützung der Arbeitsbühne 5 sorgen.After the

Nach einem weiteren Vorschlag der Erfindung ist vorgesehen, daß an die Kragarme 11 mit Fahrplatten 30 belegbare Unterkonstruktionen 31 anschließbar sind, um gleichsam eine Erweiterung der Arbeitsbühne 5 bis in den Bereich der Schornsteinwand zu erreichen, so daß also der Bagger 4 aus der Schornsteinmitte heraus vorfahren und Abbrucharbeiten mit die Schornsteinwand übergreifendem Abbruchwerkzeug 2 von aussen durchführen kann. In diesem Fall wird auf den Einsatz der Laufstege 15 und Fangnetze 16 verzichtet. Das ist lediglich bereichsweise in Fig. 6 angedeutet.According to a further proposal of the invention, it is provided that

Claims (16)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89120240T ATE71690T1 (en) | 1988-11-24 | 1989-11-01 | CHIMNEY BREAKDOWN DEVICE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3839677A DE3839677A1 (en) | 1988-11-24 | 1988-11-24 | DEVICE FOR BREAKING CHIMNEYS |

| DE3839677 | 1988-11-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0370280A1 EP0370280A1 (en) | 1990-05-30 |

| EP0370280B1 true EP0370280B1 (en) | 1992-01-15 |

Family

ID=6367809

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89120240A Expired - Lifetime EP0370280B1 (en) | 1988-11-24 | 1989-11-01 | Device for demolishing chimneys |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4955457A (en) |

| EP (1) | EP0370280B1 (en) |

| JP (1) | JPH06105013B2 (en) |

| AT (1) | ATE71690T1 (en) |

| DE (1) | DE3839677A1 (en) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2678311B1 (en) * | 1991-06-25 | 1993-10-29 | Morel Sa | TOOL, METHOD AND MATERIAL FOR DEMOLITION OF WALLS, ESPECIALLY CHIMNEYS. |

| DE19722185A1 (en) * | 1997-05-27 | 1998-12-10 | Michael Barnsteiner | Demolition device for structures and method for demolishing structures |

| DE29812795U1 (en) | 1998-07-17 | 1998-12-03 | Ostermeyer Anbautechnik GmbH, 88448 Attenweiler | Device for breaking off a structure having a circumferential wall, such as a chimney or a cooling tower |

| DE19928574C2 (en) * | 1999-06-23 | 2001-11-15 | Stingl Montage Und Befestigung | Working platform |

| JP3592313B2 (en) * | 2002-05-10 | 2004-11-24 | 大王製紙株式会社 | Internal wall work equipment for tower tank |

| US7607481B2 (en) * | 2007-05-16 | 2009-10-27 | Gulfstream Services, Inc. | Method and apparatus for dropping a pump down plug or ball |

| DE202008004374U1 (en) | 2008-03-28 | 2008-08-14 | Barnsteiner, Michael | Device for breaking off structures |

| DE102010006427A1 (en) | 2010-02-01 | 2011-12-15 | Tvf Altwert Gmbh | Device for dismantling inner chimney in industrial chimney in power plant, has beam hoist formed in running rails in horizontally displaceable manner over entire breadth of rails and comprising height-adjustable tools to break concrete |

| JP5974110B2 (en) | 2012-11-08 | 2016-08-23 | ベステラ株式会社 | Scattering device for collective chimney dismantling and disassembling method of collective chimney using the device |

| US9279262B2 (en) * | 2013-12-09 | 2016-03-08 | International Chimney Corporation | Chimney demolition vehicle |

| DE102016113227B3 (en) * | 2016-07-18 | 2017-12-21 | Karl Hartinger Kranbetrieb Gmbh & Co.Kg | Working device, in particular for use in the dismantling of a concrete tower |

| DE102016113224B3 (en) * | 2016-07-18 | 2017-11-16 | Karl Hartinger Kranbetrieb Gmbh & Co.Kg | Method for dismantling concrete towers |

| US10890003B2 (en) * | 2016-12-16 | 2021-01-12 | International Chimney Corporation | Liner removal apparatus |

| CN108868194B (en) * | 2018-07-30 | 2023-12-22 | 威海新特重工股份有限公司 | Chimney dismantling device and chimney dismantling method |

| CN112049462A (en) * | 2020-08-07 | 2020-12-08 | 新兴铸管股份有限公司 | Mechanical dismantling process for high-altitude building |

| DE102021000427A1 (en) | 2020-08-25 | 2022-03-03 | Wörmann Team GmbH & Co. KG | Device and method for dismantling a concrete tower, in particular a concrete segment tower, of a wind turbine |

| DE102020127750A1 (en) | 2020-10-21 | 2022-04-21 | Karl Hartinger Kranbetrieb Gmbh & Co Kg | Device and method for separating clamping elements |

| CN112482740B (en) * | 2020-10-27 | 2022-05-10 | 中国一冶集团有限公司 | Large concave curved working face construction operation device and construction operation method thereof |

| RU2753332C1 (en) * | 2021-02-19 | 2021-08-13 | Александр Васильевич Сало | Chimney dismantling machine |

| US12044020B2 (en) | 2021-08-05 | 2024-07-23 | Veit & Company | Demolition system |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1218008A (en) * | 1916-08-28 | 1917-03-06 | Hiram A Smith | Device for use in erecting silos. |

| US1652403A (en) * | 1926-12-13 | 1927-12-13 | Nat Conveyor Company | Building derrick for bunkers |

| US2221133A (en) * | 1940-02-09 | 1940-11-12 | Glenn V Gladville | Scaffold |

| US2710418A (en) * | 1952-06-04 | 1955-06-14 | Ayers B Putnam | Power scaffolds |

| DE1280534B (en) * | 1962-12-01 | 1968-10-17 | Babcock & Wilcox Dampkessel We | Protective hood for a work scaffold for industrial chimney construction |

| US3346300A (en) * | 1966-08-08 | 1967-10-10 | Louis A Grant | Blast furnace lining removing machine |

| US3370888A (en) * | 1965-11-08 | 1968-02-27 | Skendrovic Lawrence | Furnace refractory delining apparatus |

| US4068895A (en) * | 1976-07-01 | 1978-01-17 | O. W. Reese, Inc. | Demolition machine for delining a furnace |

| US4407392A (en) * | 1981-08-31 | 1983-10-04 | Western Electric Company, Inc. | Safety scaffold for metal melting furnaces |

| GB2120308B (en) * | 1982-05-07 | 1985-12-24 | Black And Son W B | Improvements in the piecemeal demolition of chimneys |

| US4607994A (en) * | 1982-05-17 | 1986-08-26 | Tellus Maskin Ab | Transport arrangement especially for lining material |

| EP0133630A1 (en) * | 1983-08-05 | 1985-03-06 | W.B. Black & Sons (Holdings) Limited | Improvements in the piecemeal demolition of chimneys |

| DE3512212C2 (en) * | 1985-04-03 | 1997-04-24 | Michael Barnsteiner | Method and device for demolishing chimneys |

| DE3635597C2 (en) * | 1986-10-20 | 1996-08-29 | Michael Barnsteiner | Device for demolishing chimneys or the like and method for assembling the device |

| US4861112A (en) * | 1988-07-26 | 1989-08-29 | Louis A. Grant, Inc. | Apparatus for cleaning aluminum cells |

-

1988

- 1988-11-24 DE DE3839677A patent/DE3839677A1/en active Granted

-

1989

- 1989-11-01 AT AT89120240T patent/ATE71690T1/en active

- 1989-11-01 EP EP89120240A patent/EP0370280B1/en not_active Expired - Lifetime

- 1989-11-22 JP JP1302293A patent/JPH06105013B2/en not_active Expired - Lifetime

- 1989-11-22 US US07/440,900 patent/US4955457A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US4955457A (en) | 1990-09-11 |

| DE3839677A1 (en) | 1990-05-31 |

| DE3839677C2 (en) | 1992-03-05 |

| JPH06105013B2 (en) | 1994-12-21 |

| JPH02243878A (en) | 1990-09-27 |

| ATE71690T1 (en) | 1992-02-15 |

| EP0370280A1 (en) | 1990-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0370280B1 (en) | Device for demolishing chimneys | |

| DE4431503B4 (en) | Machine for preparing welding work on a track | |

| DE2947210A1 (en) | DEVICE FOR LIFTING SLIDING SHAPES ON STEEL RODS FOR THE PRODUCTION OF CONCRETE CONSTRUCTIONS AND THE LIKE | |

| EP2288770B1 (en) | Device for demolishing constructions | |

| DE3049687C2 (en) | ||

| DE3635597C2 (en) | Device for demolishing chimneys or the like and method for assembling the device | |

| DE3512212C2 (en) | Method and device for demolishing chimneys | |

| DE20304654U1 (en) | Device for demolishing buildings | |

| EP0105504B1 (en) | Method and device for dismantling floor slab forms | |

| DE10225183A1 (en) | Demolition machine for especially walls has transporting device mounted on top of wall and movable along it, and means to support transporting device on wall and which are brought into engagement with sides of wall | |

| DE69825528T2 (en) | Device for handling boring bars | |

| DE2015940B2 (en) | DEVICE FOR ADJUSTING SLIDING FORMS | |

| DE69400159T2 (en) | Scaffolding floor and assembly process for scaffolding with this floor | |

| DE102017118658B3 (en) | Apparatus and method for disassembling and shredding vertically aligned objects | |

| DE8414857U1 (en) | CONSTRUCTION DEVICE FOR PUTTING FINISHED PARTS, IN PARTICULAR FIREPLACES | |

| DE2461251C3 (en) | Device for pre-assembly, transport and installation of a route or tunnel extension | |

| EP0724669B1 (en) | Process and device for moving a travelling scaffolding around bridge piers | |

| DE3839261C1 (en) | Process and apparatus for pulling down essentially hollow-cylindrical structures, such as chimneys | |

| DE102009030741B4 (en) | Device and method for mounting and / or dismantling a crane jib and crane with such a device | |

| DE3545965C2 (en) | ||

| CH668800A5 (en) | Tall chimney demolition mechanism - has annular working platform, travelling on vertical rails on chimney outer wall and fitted with support columns | |

| EP0320855A2 (en) | Wrecking arrangement for chimneys, particularly for convergent chimneys | |

| DE4028884A1 (en) | Frame to facilitate building of vertical wall - has platform which can beraised or lowered to support building material | |

| DE2432851A1 (en) | PROCEDURE FOR REPLACING A FORMING BODY AND FORMWORK EQUIPPED FOR THE PROCESS | |

| DE2142627A1 (en) | Soaking pit demolition and scooping machine - of compact design and operating over a wide area of the pit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19900718 |

|

| 17Q | First examination report despatched |

Effective date: 19910507 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE FR GB IT NL |

|

| REF | Corresponds to: |

Ref document number: 71690 Country of ref document: AT Date of ref document: 19920215 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19941110 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19941125 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19941130 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19941205 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19951101 Ref country code: AT Effective date: 19951101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19951130 |

|

| BERE | Be: lapsed |

Owner name: ROBOTA G.M.B.H. FEUERUNGS- UND SCHORNSTEINBAU Effective date: 19951130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19951101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| NLS | Nl: assignments of ep-patents |

Owner name: WESTSCHROTT INDUSTRIE-ABBRUCH GMBH & CO. ROBOTA KG |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20011130 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030601 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20030601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051101 |