EP0363808B1 - Device to form a leno weave selvedge - Google Patents

Device to form a leno weave selvedge Download PDFInfo

- Publication number

- EP0363808B1 EP0363808B1 EP89118431A EP89118431A EP0363808B1 EP 0363808 B1 EP0363808 B1 EP 0363808B1 EP 89118431 A EP89118431 A EP 89118431A EP 89118431 A EP89118431 A EP 89118431A EP 0363808 B1 EP0363808 B1 EP 0363808B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- rail

- rails

- thread guide

- guide element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03C—SHEDDING MECHANISMS; PATTERN CARDS OR CHAINS; PUNCHING OF CARDS; DESIGNING PATTERNS

- D03C7/00—Leno or similar shedding mechanisms

Definitions

- the invention relates to a device for forming a leno selvedge consisting of mutually moving heald frames, a thread guide device being attached to one heald frame and a needle holder having two parallel, essentially U-shaped frame rails, which holding a thread guide element, is arranged on the other heald frame.

- a device of the type mentioned is known for example from German utility model 79 31 872. It has been shown that these frame rails are subject to high wear, especially when the magnets arranged in the thread guide element come into direct contact with the frame rail. If the frame rails of a needle holder are worn out to such an extent that the thread guide element is no longer properly guided, so that there is a risk of binding errors, the entire needle holder must be replaced, which is expensive.

- a leno device is known with a guide frame which guides a warp thread holder in the frame rails, a thread guide device being guided in the parallel frame rails.

- a guide frame which guides a warp thread holder in the frame rails

- a thread guide device being guided in the parallel frame rails.

- needle bearing strips are provided in the end faces of the rails. The wear problem is solved by the arrangement of needle bearing strips, which have low friction.

- the invention has for its object to provide a needle holder in which the wear problem is solved with simpler means.

- a groove is arranged in each leg base of one leg of the U-shaped frame rail, which is used to receive and guide the metal rail.

- frame rails made of plastic could not be used.

- a frame rail made of plastic can now also be used; the magnetic braking of the thread guide element now takes place in cooperation with the metal rail.

- Frame rails made of plastic have the advantage of lower weight, which opens up the possibility of increasing the number of strokes of a weaving machine.

- Metal rails which according to the prior art are only nickel-plated for protection against rust, also have the disadvantage that they quickly become rusty when used in wet weaving. This is impossible with plastic frame rails.

- the metal rail itself is made of rustproof but magnetic steel.

- a device for forming a leno selvedge consists of reciprocating heald frames, a needle holder being arranged on one heald frame and the other heald frame having a thread guiding device.

- the second heald frame with the thread guide device arranged thereon has been omitted in FIG. 1.

- the needle holder designated as a whole by 1, is arranged on the heald frame 2.

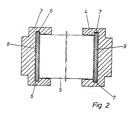

- the needle holder 1 consists of the two parallel frame rails 3 and 4, which serve to guide the thread guide element 5 (FIG. 2).

- the substantially U-shaped frame rail 3, 4 has a groove 6 and 7 in the leg base of each leg.

- the metal rails 8 and 9 are located in the grooves 6 and 7 respectively.

- the thread guide element 5 guided in the two frame rails 3, 4 is therefore not in direct contact with the frame rails, but is in contact with the metal rails 8, 9 on both sides. If the metal rails are worn, they can easily be replaced with new ones.

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zum Bilden einer Dreherkante, bestehend aus wechselseitig bewegten Webschäften, wobei an einem Webschaft eine Fadenführungseinrichtung angebracht ist und wobei an dem anderen Webschaft ein zwei parallele im wesentlichen U-förmig ausgebildete Gestellschienen aufweisender Nadelhalter angeordnet ist, der ein Fadenführungselement hält.The invention relates to a device for forming a leno selvedge consisting of mutually moving heald frames, a thread guide device being attached to one heald frame and a needle holder having two parallel, essentially U-shaped frame rails, which holding a thread guide element, is arranged on the other heald frame.

Eine Vorrichtung der eingangs genannten Art ist beispielsweise aus dem deutschen Gebrauchsmuster 79 31 872 bekannt. Es hat sich gezeigt, daß diese Gestellschienen einem hohen Verschleiß unterworfen sind, und zwar insbesondere dann, wenn die in dem Fadenführungselement angeordneten Magnete unmittelbar mit der Gestellschiene in Berührung kommen. Sind die Gestellschienen eines Nadelhalters soweit verschlissen, daß das Fadenführungselement nicht mehr ordnungsgemäß geführt wird, so daß die Gefahr von Bindefehlern entsteht, muß der komplette Nadelhalter ausgetauscht werden, was teuer ist.A device of the type mentioned is known for example from German utility model 79 31 872. It has been shown that these frame rails are subject to high wear, especially when the magnets arranged in the thread guide element come into direct contact with the frame rail. If the frame rails of a needle holder are worn out to such an extent that the thread guide element is no longer properly guided, so that there is a risk of binding errors, the entire needle holder must be replaced, which is expensive.

Aus der Gebrauchsmusterschrift 88 04 913 ist eine Dreherkantenvorrichtung bekannt mit einem Führungsgestell, das einen Kettfadenhalter in den Gestellschienen führt, wobei in den parallelen Gestellschienen eine Fadenführungsvorrichtung geführt wird. Dabei sind zur Verminderung der Reibung der bewegten Teile in den Schienen jeweils in den Stirnseiten der Schienen Nadellagerleisten vorgesehen. Das Verschleißproblem wird dabei durch die Anordnung von Nadellagerleisten gelöst, die eine geringe Reibung aufweisen.From the utility model 88 04 913 a leno device is known with a guide frame which guides a warp thread holder in the frame rails, a thread guide device being guided in the parallel frame rails. In order to reduce the friction of the moving parts in the rails, needle bearing strips are provided in the end faces of the rails. The wear problem is solved by the arrangement of needle bearing strips, which have low friction.

Der Erfindung liegt die Aufgabe zugrunde, einen Nadelhalter zu schaffen, bei dem das Verschleißproblem mit einfacheren Mitteln gelöst wird. Das wird erfindungsgemäß dadurch erreicht, daß die Gestellschiene auf ihrer dem Fadenführungselement zugewandten Seite eine Einlage in Form einer Metallschiene aufweist, die austauschbar ist, wobei die Gestellschiene aus Kunststoff besteht.The invention has for its object to provide a needle holder in which the wear problem is solved with simpler means. This is achieved according to the invention in that the frame rail has an insert in the form of a metal rail on its side facing the thread guide element, which insert is replaceable, the frame rail being made of plastic.

Durch diese Maßnahme wird ein Verschleiß an den Gestellschienen selbst vermieden; ist die Metallschiene verschlissen, so kann diese problemlos ausgetauscht werden. Zur Fixierung der Metallschiene in den Gestellschienen, ist jeweils in Schenkelgrund eines Schenkels der U-förmig ausgebildeten Gestellschiene eine Nut angeordnet, die der Aufnahme und Führung der Metallschiene dient.This measure prevents wear on the rack rails themselves; if the metal rail is worn, it can be replaced without any problems. To fix the metal rail in the frame rails, a groove is arranged in each leg base of one leg of the U-shaped frame rail, which is used to receive and guide the metal rail.

Da zur magnetischen Abbremsung des Fadenführungselementes die Gestellschiene immer metallisch ausgebildet sein muß, konnten Gestellschienen aus Kunststoff nicht zum Einsatz kommen. Durch den Einsatz der Metallschiene in die Gestellschiene kann nunmehr auch eine Gestellschiene aus Kunststoff zum Einsatz kommen; die magnetische Abbremsung des Fadenführungselementes erfolgt nunmehr in Zusammenarbeit mit der Metallschiene. Gestellschienen aus Kunststoff haben den Vorteil des geringeren Gewichts, wodurch sich die Möglichkeit eröffnet, die Hubzahl einer Webmaschine zu erhöhen.Since the frame rail must always be made of metal for magnetic braking of the thread guide element, frame rails made of plastic could not be used. By using the metal rail in the frame rail, a frame rail made of plastic can now also be used; the magnetic braking of the thread guide element now takes place in cooperation with the metal rail. Frame rails made of plastic have the advantage of lower weight, which opens up the possibility of increasing the number of strokes of a weaving machine.

Metallschienen, die nach dem Stand der Technik zum Schutz gegen Rost lediglich vernickelt sind, haben darüber hinaus den Nachteil, daß sie beim Einsatz in der Naßweberei schnell Rost ansetzen. Das ist bei Gestellschienen aus Kunststoff ausgeschlossen. Die Metallschiene selbst besteht aus rostfreiem aber magnetischem Stahl.Metal rails, which according to the prior art are only nickel-plated for protection against rust, also have the disadvantage that they quickly become rusty when used in wet weaving. This is impossible with plastic frame rails. The metal rail itself is made of rustproof but magnetic steel.

In der Zeichnung ist eine beispielsweise Ausführungsform dargestellt.

- Fig. 1

- zeigt die Vorrichtung zum Bilden einer Dreherkante in einer Seitenansicht;

- Fig. 2

- zeigt die zwei parallelen Gestellschienen eines Nadelhalters im Schnitt, wobei die Nadeln weggelassen sind.

- Fig. 1

- shows the device for forming a leno edge in a side view;

- Fig. 2

- shows the two parallel frame rails of a needle holder in section, with the needles omitted.

Gemäß Fig. 1 besteht eine Vorrichtung zum Bilden einer Dreherkante aus wechselseitig bewegten Webschäften, wobei an dem einen Webschaft ein Nadelhalter angeordnet ist, und der andere Webschaft eine Fadenführungseinrichtung aufweist. Zur besseren Übersicht ist in Fig. 1 der zweite Webschaft mit der daran angeordneten Fadenführungseinrichtung weggelassen worden.1, a device for forming a leno selvedge consists of reciprocating heald frames, a needle holder being arranged on one heald frame and the other heald frame having a thread guiding device. For a better overview, the second heald frame with the thread guide device arranged thereon has been omitted in FIG. 1.

Gemäß Fig. 1 ist der insgesamt mit 1 bezeichnete Nadelhalter an den Webschaft 2 angeordnet. Der Nadelhalter 1 besteht aus den zwei parallelen Gestellschienen 3 und 4, die der Führung des Fadenführungselementes 5 dienen (Fig. 2). Die im wesentlichen U-förmig ausgebildete Gestellschiene 3, 4 weist im Schenkelgrund eines jeden Schenkels eine Nut 6 bzw. 7 auf. In den Nuten 6 bzw. 7 befindet sich die Metallschiene 8 bzw. 9. Das in den beiden Gestellschienen 3, 4 geführte Fadenführungselement 5 steht somit nicht unmittelbar mit den Gestellschienen in Berührung, sondern liegt beidseitig an den Metallschienen 8, 9 an. Sind die Metallschienen verschlissen, so können diese in einfacher Weise durch neue ersetzt werden.1, the needle holder, designated as a whole by 1, is arranged on the

Claims (4)

- Device for the formation of a leno edge, consisting of alternately moved healds, wherein a thread guide device is mounted on one heald and wherein a needle holder (1), which comprises two parallel frame rails (3, 4) constructed substantially in U-shape, is arranged at the other heald (2) and holds a thread guide element (5), characterised thereby that the frame rail (3, 4) has an insert, which is in the form of a metal rail (8, 9) and is exchangeable, on its side facing the thread guide element (5), wherein the frame rail (3, 4) consists of plastics material.

- Device according to claim 1, characterised thereby that the frame rail (3, 4) comprises means for the fixing of the metal rail (8, 9).

- Device according to claim 2, characterised thereby that for the fixing of the metal rail (8, 9) to the frame rail (3, 4) a respective groove (6, 7) is arranged in the limb base of each limb.

- Device according to claim 1, characterised thereby that the metal rail (8, 9) consists of stainless, but magnetic, steel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89118431T ATE91161T1 (en) | 1988-10-14 | 1989-10-04 | DEVICE FOR FORMING A TURN EDGE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8812937U | 1988-10-14 | ||

| DE8812937U DE8812937U1 (en) | 1988-10-14 | 1988-10-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0363808A1 EP0363808A1 (en) | 1990-04-18 |

| EP0363808B1 true EP0363808B1 (en) | 1993-06-30 |

Family

ID=6828875

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89118431A Expired - Lifetime EP0363808B1 (en) | 1988-10-14 | 1989-10-04 | Device to form a leno weave selvedge |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5048573A (en) |

| EP (1) | EP0363808B1 (en) |

| JP (1) | JPH02127537A (en) |

| AT (1) | ATE91161T1 (en) |

| DE (2) | DE8812937U1 (en) |

| ES (1) | ES2041929T3 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4204629C1 (en) * | 1992-02-15 | 1993-03-04 | Kloecker-Entwicklungs-Gmbh, 4280 Borken, De | |

| DE10257519B3 (en) * | 2002-12-10 | 2004-04-01 | Klöcker-Entwicklungs-Gmbh | Turned edge weaving unit, includes magnets near upper ends of reeds, with polarity arranged to cause mutual attraction |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2918945A (en) * | 1958-07-16 | 1959-12-29 | Crompton & Knowles Corp | Selvage and method and means for making same |

| US3650576A (en) * | 1970-11-20 | 1972-03-21 | Ingersoll Rand Co | Liner for aluminum drill guide feed |

| GB1400166A (en) * | 1971-06-21 | 1975-07-09 | Somet Soc Mec Tessile | Leno selvedge shedding device |

| US4324437A (en) * | 1978-05-12 | 1982-04-13 | Narang Rajendra K | Endless track |

| DE7931872U1 (en) * | 1979-11-12 | 1980-03-27 | Kloecker, Heinz, 4280 Borken | DEVICE FOR MAKING A BINDING FABRIC EDGE, ESPECIALLY IN CONTINUOUS WEAVING MACHINES |

| CH639440A5 (en) * | 1979-09-05 | 1983-11-15 | Rueti Ag Maschf | Weft insertion device for weaving machines with removal of the weft from stationary bobbins. |

| CH639439A5 (en) * | 1979-09-05 | 1983-11-15 | Rueti Ag Maschf | GRIPPER HEAD FOR WEAVING MACHINES WITH THE REMOVAL OF THE WIFE FROM FIXED REELS. |

| IT1132580B (en) * | 1980-08-29 | 1986-07-02 | Nuovo Pignone Spa | PERFECTED DEVICE FOR THE DOUBLE-ROUND ENGLISH CROSS BINDING OF THE SIDE EDGES OF A FABRIC IN A TEXTILE FRAME |

| DE3442204A1 (en) * | 1984-08-27 | 1986-03-06 | Klöcker-Entwicklungs-GmbH, 4280 Borken | DEVICE FOR FORMING A ROTARY EDGE |

| JPS61172175U (en) * | 1985-04-17 | 1986-10-25 | ||

| EP0214322B1 (en) * | 1985-09-02 | 1989-12-20 | GebràDer Sulzer Aktiengesellschaft | Leno shed in looms |

| DE8804913U1 (en) * | 1988-03-31 | 1988-08-18 | Kloecker-Entwicklungs-Gmbh, 4280 Borken, De |

-

1988

- 1988-10-14 DE DE8812937U patent/DE8812937U1/de not_active Expired

-

1989

- 1989-10-04 EP EP89118431A patent/EP0363808B1/en not_active Expired - Lifetime

- 1989-10-04 DE DE8989118431T patent/DE58904837D1/en not_active Expired - Fee Related

- 1989-10-04 ES ES198989118431T patent/ES2041929T3/en not_active Expired - Lifetime

- 1989-10-04 AT AT89118431T patent/ATE91161T1/en not_active IP Right Cessation

- 1989-10-06 JP JP1260354A patent/JPH02127537A/en active Granted

- 1989-10-11 US US07/419,889 patent/US5048573A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0375651B2 (en) | 1991-12-02 |

| JPH02127537A (en) | 1990-05-16 |

| ES2041929T3 (en) | 1993-12-01 |

| DE58904837D1 (en) | 1993-08-05 |

| DE8812937U1 (en) | 1989-01-05 |

| US5048573A (en) | 1991-09-17 |

| ATE91161T1 (en) | 1993-07-15 |

| EP0363808A1 (en) | 1990-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH477579A (en) | Floor covering material made from pile fabric | |

| DE202018107373U1 (en) | Device for forming a leno selvedge | |

| EP0363808B1 (en) | Device to form a leno weave selvedge | |

| DE2217091A1 (en) | Heald holding and drive device on weaving machines | |

| EP0214322B1 (en) | Leno shed in looms | |

| DE2803377A1 (en) | THREAD CHANGING DEVICE | |

| DE2935504C2 (en) | Heddle | |

| EP0282874B1 (en) | Heald frame device for leno selvedges | |

| DE3008987C2 (en) | ||

| DE3832622C1 (en) | ||

| DE3830107A1 (en) | TURNING DEVICE FOR WEAVING MACHINES | |

| EP0174533A2 (en) | Device for forming a leno selvage | |

| DE4000395C2 (en) | ||

| DE3414368C2 (en) | Loom, in particular terry loom | |

| EP0233141B1 (en) | Needle loom | |

| EP0980448B1 (en) | Gripper weaving machine | |

| DE2704747A1 (en) | DEVICE FOR HOLDING THE END OF THE WEFT IN WEAVING MACHINES | |

| DE1710317C3 (en) | Method and device for producing a leno weave | |

| DE2936116C2 (en) | Thread clamp of a loom | |

| EP0248364B1 (en) | Device for making a selvedge presenting a linkage | |

| EP0018430A1 (en) | Rail bearing device for the warp stop motion in a weaving loom | |

| DE8316232U1 (en) | DEVICE FOR CARRYING OUT THE TIE OF THE STICKED (FALSE) TAILS OF FABRICS OF WOVEN CHAIRS | |

| AT16450B (en) | Method and device for brushing apart, evenly distributing and roughening the warp threads on mechanical looms. | |

| DE7931872U1 (en) | DEVICE FOR MAKING A BINDING FABRIC EDGE, ESPECIALLY IN CONTINUOUS WEAVING MACHINES | |

| AT333680B (en) | HAND WEAVER |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900507 |

|

| 17Q | First examination report despatched |

Effective date: 19920226 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 91161 Country of ref document: AT Date of ref document: 19930715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58904837 Country of ref document: DE Date of ref document: 19930805 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19930818 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930906 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930922 Year of fee payment: 5 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930924 Year of fee payment: 5 |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO JAUMANN |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3008382 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19931005 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19931014 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19931031 Year of fee payment: 5 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931001 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2041929 Country of ref document: ES Kind code of ref document: T3 |

|

| EPTA | Lu: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940719 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940729 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19941004 Ref country code: GB Effective date: 19941004 Ref country code: AT Effective date: 19941004 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941005 Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 19941005 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19941017 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19941027 Year of fee payment: 6 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 89118431.9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19950430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19950501 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19941004 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3008382 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 89118431.9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19951031 Ref country code: CH Effective date: 19951031 Ref country code: BE Effective date: 19951031 |

|

| BERE | Be: lapsed |

Owner name: KLOCKER-ENTWICKLUNGS-G.M.B.H. Effective date: 19951031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960702 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051004 |