EP0353370B1 - Building substructure - Google Patents

Building substructure Download PDFInfo

- Publication number

- EP0353370B1 EP0353370B1 EP88402026A EP88402026A EP0353370B1 EP 0353370 B1 EP0353370 B1 EP 0353370B1 EP 88402026 A EP88402026 A EP 88402026A EP 88402026 A EP88402026 A EP 88402026A EP 0353370 B1 EP0353370 B1 EP 0353370B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- floor

- members

- slab

- building

- fact

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/0007—Base structures; Cellars

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D27/00—Foundations as substructures

- E02D27/10—Deep foundations

- E02D27/12—Pile foundations

- E02D27/14—Pile framings, i.e. piles assembled to form the substructure

Definitions

- the present invention relates to the bases of buildings, in particular for apartment buildings or for industrial use.

- Reinforced concrete footings are then poured into these trenches, on which the supporting walls are then erected up to a certain height. On these walls is then poured a slab, also reinforced, leaving or not leaving a free space between it and the surface of the ground, depending on whether one wishes to obtain a crawl space or not.

- the purpose of the present invention is to produce basements of buildings according to a single technique which can very easily adapt to all types of soil and basement and using a majority of elements which can be prefabricated.

- the present invention is characterized in that the lower edge of the lateral wings of the floor elements is located in the plane corresponding to said level determined so as to constitute protective volumes and that the floor elements comprise sheaths, conduits and pipes necessary for the servicing of the building incorporated into the floor elements and extending inside the protection volumes.

- foundation elements will preferably be those used for deep or semi-deep foundations, such as wells, piles or micropiles which will not be described more fully here, being elements well known to man art.

- the surface 3 of the floor 2 can be arranged to have a generally planar appearance. Then, holes 4, 5, 6 ... are made, to a depth and with a diameter allowing to receive piles dimensioned to support constructions such as important buildings.

- each element comprises a slab 18 of planar shape and lateral wings 19, 20, 21, ... bordering this slab 18 in planes substantially perpendicular to that of the slab, so as to form a recessed housing 22 whose bottom is constituted by the slab itself and the edges by the side wings.

- the thickness of the wings is advantageously equal to or less than the radius of these piles.

- the distance separating the axis of the piles for example 8 and 9, is slightly greater than the length of the floor elements, for example 15, taken at the level of the slabs, so that these elements can rest by the edge of the wings on the heads 11, 12, 13 of the stakes.

- several floor elements do they rest by their corners, for example 23, 24, 25, 26, on the head of a pile, leaving a space between two facing wings .

- the floor elements may also be supported by intermediate piles, such as for example the pile 10 shown in Figure 2, arranged over the length and / or width of said elements.

- connection of the floor elements to each other may be carried out by concrete keyings but will preferably be carried out by means of metal plates 30 or other equivalent means (see FIG. 2) which will be sealed, for example at the angles 23, 24, 25 and 26 of said floor elements, after adjustment of the latter.

- a joint connection made of a material of the same nature as that which composes the upper part of the final floor will then be put in place between each floor element.

- the floor elements rest on the pile heads by the edges of the wings, so that the slabs are in the upper position and that the recessed housings 22 have their opening 40 turned downward, thus constituting for the buildings a crawl space whose importance is well known for the quality of constructions.

- the wings of the floor elements come flush with the surface of the ground 2. But it is quite obvious that, depending on the height of the piles, these elements can be at a certain distance from the surface of the ground, which is useful when the construction is erected in particular on a sloping ground and which makes it possible in certain cases to avoid developing the ground surface located under the construction, and therefore further limit the total cost price of the realization of the base.

- these hollow housings have the advantage of constituting protected volumes, in particular during their transport from the factory to the installation site.

- these volumes can thus receive all the sheaths and all the conduits 50 necessary for the servicing of a building, such as the water, electricity, telephone, etc. pipelines, and allow even to protect larger pipelines 51 such as those for discharging waste water.

- the sheaths of electricity, heating, etc. and all the pipes can be incorporated into the floor elements, and more particularly into their slab 18, during their manufacture in the factory. This is made possible by the application of the law of distribution of foundation elements, which has been stated above, and which is based on the division of the area of the proposed construction.

- each floor element is advantageously made of poured reinforced concrete and may even include, in its thickness, a layer of insulating material 53 thus contributing to the total thermal insulation of the building by avoiding maximum heat leakage by floor.

- This layer of insulating material may, depending on the circumstances, be placed or poured on the upper or lower surfaces of the slab 18.

- the prefabrication of the floor elements makes it possible to incorporate in the slab the reservations and the layout of the works as well as the constituent elements in particular of the superstructure of the building. It will thus be possible to provide, on the upper surface of the slab, the layout of the various partitions, to even have, before the final installation, certain coverings such as that of the bathrooms or to open in the body of the slab passages necessary for the various pipes or ducts or to open an access hatch to the crawl space.

- the upper part of the building can thus be constructed by mounting the walls 54 in a conventional manner with other intermediate floors, partitions, etc., up to the roof 55.

- This technique is classic and known in itself and will therefore not be further developed here.

- reservations may be provided in the floor elements for the passage of reinforced concrete posts allowing the direct transfer of loads to the foundation elements.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Architecture (AREA)

- Structural Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- General Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Physics & Mathematics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Electromagnetism (AREA)

- Foundations (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Abstract

Description

La présente invention concerne les soubassements d'immeubles, notamment pour les immeubles d'habitation ou à usage industriel.The present invention relates to the bases of buildings, in particular for apartment buildings or for industrial use.

Lorsque des immeubles, de quelque type qu'ils soient, doivent être construits, on doit commencer par réaliser des fondations sur lesquelles vont ensuite être montés les murs pour définir le volume d'utilisation nécessaire.When buildings, of whatever type, are to be built, we must start by making foundations on which the walls will then be mounted to define the volume of use necessary.

Pour réaliser ces fondations, on commerce par creuser des tranchées dont les dimensions sont généralement calculées en fonction d'un certain nombre de paramètres, en particulier, de définition de la qualité du sol et du sous-sol sur lequel doit être élevé l'immeuble.To make these foundations, we trade by digging trenches whose dimensions are generally calculated according to a number of parameters, in particular, the definition of the quality of the soil and the subsoil on which the building is to be built. .

Dans ces tranchées, sont ensuite coulées des semelles en béton armé sur lesquelles sont alors érigés les murs de soutien jusqu'à une certaine hauteur. Sur ces murs est alors coulée une dalle, elle aussi armée, en laissant ou en ne laissant par un espace libre entre celle-ci et la surface du sol, selon que l'on désire obtenir un vide sanitaire ou non.Reinforced concrete footings are then poured into these trenches, on which the supporting walls are then erected up to a certain height. On these walls is then poured a slab, also reinforced, leaving or not leaving a free space between it and the surface of the ground, depending on whether one wishes to obtain a crawl space or not.

C'est ensuite, à partir de cette dalle, que sont montés les murs et les différentes parois définissant le volume utilisable de l'immeuble, et ce jusqu'à la toiture.It is then, from this slab, that the walls and the various walls defining the usable volume of the building are mounted, up to the roof.

Bien entendu, cette technique donne le résultat recherché. Cependant, elle présente un inconvénient non négligeable qui est son coût de revient. En effet, elle nécessite de longs calculs et études préliminaires, relatifs notamment à l'adaptation au sol de l'immeuble, des quantités de matériaux et une main d'oeuvre diversifiée importantes. La réalisation d'un soubassement d'immeuble selon la technique rappelée ci-dessus est donc relativement onéreuse. Il est connu également du brevet FR-A-1 547 666 un soubassement d'immeuble comportant les caractèristiqu mentionnées en préambule de la revendication 1 annexèe.Of course, this technique gives the desired result. However, it has a non-negligible drawback which is its cost price. Indeed, it requires long calculations and preliminary studies, relating in particular to the adaptation to the ground of the building, quantities of materials and a large diversified workforce. The realization of a building base according to the technique recalled above is therefore relatively expensive. It is also known from patent FR-A-1,547,666 a building base comprising the characteristics mentioned in the preamble of

La présente invention a pour but de réaliser des soubassements d'immeubles suivant une seule et même technique pouvant très facilement s'adapter à tous les types de sol et de sous-sol et utilisant une majorité d'éléments qui peuvent être préfabriqués.The purpose of the present invention is to produce basements of buildings according to a single technique which can very easily adapt to all types of soil and basement and using a majority of elements which can be prefabricated.

A cet effet, la présente invention se caractérise en ce que la tranche inférieure des ailes latérales des éléments de plancher est située dans le plan correspondant audit niveau déterminé de façon à constituer des volumes de protection et que les éléments de plancher comprennent des gaines, conduits et canalisations nécessaires à la viabilisation de l'immeuble incorporés aux éléments de plancher et s'étendant à l'intérieur des volumes de protection.To this end, the present invention is characterized in that the lower edge of the lateral wings of the floor elements is located in the plane corresponding to said level determined so as to constitute protective volumes and that the floor elements comprise sheaths, conduits and pipes necessary for the servicing of the building incorporated into the floor elements and extending inside the protection volumes.

Les éléments de fondation seront de préférence ceux qui sont employés pour les fondations profondes ou semi-profondes, tels que les puits, les pieux ou micropieux qui ne seront pas plus amplement décrits ici, s'agissant d'éléments bien connus de l'Homme de l'Art.The foundation elements will preferably be those used for deep or semi-deep foundations, such as wells, piles or micropiles which will not be described more fully here, being elements well known to man art.

La répartition de ces éléments au sol, pour une construction donnée, résultera de l'application d'une loi consistant en un découpage rationnel de superficie de ladite construction en plusieurs éléments de plancher présentant des caractéristiques struturelles identiques, ce découpage étant opéré en tenant compte notamment :

- du poids et de l'encombrement des éléments de plancher ;

- du positionnement éventuel d'une ou de plusieurs pièces de la future construction sur un même élément de plancher ;

- des points d'arrivée et de départ et aussi de la circulation des fluides dans les différents lieux de la construction.

- the weight and size of the floor elements;

- the possible positioning of one or more parts of the future construction on the same floor element;

- arrival and departure points and also the circulation of fluids in the various places of construction.

Les caractéristiques et avantages de la présente invention apparaîtront au cours de la description suivante donnée en regard des dessins annexés à titre illustratif mais nullement limitatif, dans lesquels :

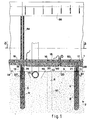

- la Figure 1 représente, vu en coupe verticale transversale référencée b-b sur la Figure 2, un exemple de réalisation d'un soubassement selon l'invention réalisé avec la technique dite des pieux forés, et

- la Figure 2 représente, vu en coupe de dessus référencée a-a sur la Figure 1, l'exemple de réalisation du soubassement selon la Figure 1.

- FIG. 1 represents, seen in vertical transverse section referenced bb in FIG. 2, an example of an embodiment of a base according to the invention produced with the technique known as bored piles, and

- FIG. 2 represents, seen in section from above referenced aa in FIG. 1, the embodiment of the base according to FIG. 1.

La description suivante est celle d'un exemple de réalisation d'une partie d'un soubassement 1 sur un sol 2. Les deux Figures représentant un même mode de réalisation, les mêmes références y désignent les mêmes éléments, quelle que soit la Figure sur laquelle elles apparaissent.The following description is that of an exemplary embodiment of part of a

Dans une première étape, bien qu'elle ne soit pas indispensable, la surface 3 du sol 2 peut être aménagée pour avoir une allure générale sensiblement plane. Ensuite, des forages 4, 5, 6... sont réalisés, sur une profondeur et avec un diamètre permettant de recevoir des pieux dimensionnés pour soutenir des constructions telles que des immeubles importants.In a first step, although it is not essential, the

Bien entendu, la répartition de ces forages sur la surface du terrain devant recevoir une construction, sera déterminée par application de la loi ci-dessus définie en fonction notamment de la nature et de la qualité du sol et du sous-sol de ce terrain.Of course, the distribution of these boreholes on the surface of the land to receive a construction, will be determined by application of the law above defined in particular according to the nature and the quality of the soil and the subsoil of this land.

Dans ces forages 4, 5, 6... sont ainsi coulés des pieux circulaires 8, 9, 10,... réalisés en béton éventuellement armé, et arasés et recépés de façon que leurs têtes 11, 12, 13,... soient à un niveau donné, au moins celui de la surface 3 du sol 2. Avantageusement, toutes les têtes seront dans un même plan horizontal 14. De plus, par application de la loi de répartition exposée plus haut, les pieux sont répartis dans le sol en des points localisés, c'est-à-dire en nombre et à des distances les uns des autres tels qu'ils soient en relation avec des éléments de plancher 15, 16, 17,... de dimensions déterminées, étant donné que ces derniers sont avantageusement préfabriqués en usine.In these

En effet, pour la mise en oeuvre du procédé, il est réalisé des éléments de plancher identiques bien que pouvant présenter des superficies différentes. Chaque élément comprend une dalle 18 de forme plane et des ailes latérales 19, 20, 21,... bordant cette dalle 18 dans des plans sensiblement perpendiculaires à celui de la dalle, de façon à former un logement en creux 22 dont le fond est constitué par la dalle elle-même et les bords par les ailes latérales. L'épaisseur des ailes est avantageusement égale ou inférieure au rayon de ces pieux. Par contre, la distance séparant l'axe des pieux, par exemple 8 et 9, est légèrement supérieure à la longueur des éléments de plancher, par exemple 15, prise au niveau des dalles, de façon que ces éléments puissent reposer par la tranche des ailes sur les têtes 11, 12, 13 des pieux. Ainsi, dans le cas de réalisation d'un plancher total, plusieurs éléments de plancher reposent-ils par leurs coins, par exemple 23, 24, 25, 26, sur la tête d'un pieux en laissant un espace entre deux ailes en regard.Indeed, for the implementation of the method, identical floor elements are produced, although they may have different surfaces. Each element comprises a

Toutefois, en fonction notamment de leur charge, les éléments de plancher pourront être également supportés par des pieux intermédiaires, comme par exemple le pieux 10 représenté à la figure 2, disposés sur la longueur et/ou la largeur desdits éléments.However, depending in particular on their load, the floor elements may also be supported by intermediate piles, such as for example the

La liaison des éléments de plancher entre eux pourra être effectuée par des clavetages en béton mais sera de préférence réalisée au moyen de plaques métalliques 30 ou autres moyens équivalents (voir figure 2) qui seront scellées, par exemple au niveau des angles 23, 24, 25 et 26 desdits éléments de plancher, après réglage de ces derniers. Un raccord de joint en un matériau de la même nature que celui qui compose la partie supérieure du plancher définitif sera alors mis en place entre chaque élément de plancher.The connection of the floor elements to each other may be carried out by concrete keyings but will preferably be carried out by means of

L'association de ces éléments de plancher aux éléments de fondation, et donc dans l'exemple illustré aux pieux, pourra être, de manière classique, réalisée au moyen de fers 28, 29 émergeant de la tête des pieux mais, de préférence, et selon une caractéristique avantageuse de l'invention, la tête desdits éléments de fondation sera munie d'appuis glissants 31 afin d'autoriser, dans certaines limites, des déplacements des éléments de plancher dans le plan horizontal. Ceci permettra d'assurer à la construction une meilleure efficacité anti-sismique. En outre, afin de limiter de tels déplacements latéraux, quelques pieux seront munis de barres de liaison 27 enveloppées de joints souples.The association of these floor elements with the foundation elements, and therefore in the example illustrated with the piles, can be, in a conventional manner, carried out by means of

Comme mentionné ci-avant, les éléments de plancher reposent sur la tête des pieux par les tranches des ailes, de façon que les dalles soient en position supérieure et que les logements en creux 22 aient leur ouverture 40 tournée vers le dessous, constituant ainsi pour les immeubles un vide sanitaire dont l'importance est bien connue pour la qualité des constructions.As mentioned above, the floor elements rest on the pile heads by the edges of the wings, so that the slabs are in the upper position and that the recessed housings 22 have their

Dans l'exemple illustré, les ailes des éléments de plancher viennent affleurer la surface du sol 2. Mais il est bien évident que, selon la hauteur des pieux, ces éléments peuvent être à une certaine distance de la surface du sol, ce qui est utile lorsque la construction est érigée notamment sur un sol en déclivité et ce qui permet d'éviter dans certains cas d'aménager la surface du sol située sous la construction, et donc de limiter encore le coût de revient total de la réalisation du soubassement.In the example illustrated, the wings of the floor elements come flush with the surface of the

De plus, ces logements en creux présentent l'avantage de constituer des volumes protégés, notamment pendant leur transport de l'usine vers le site d'installation.In addition, these hollow housings have the advantage of constituting protected volumes, in particular during their transport from the factory to the installation site.

Comme dans l'exemple illustré, ces volumes peuvent ainsi recevoir toutes les gaines et tous les conduits 50 nécessaires à la viabilisation d'un immeuble, comme les canalisations d'eau, d'électricité, de téléphone, etc..., et permettent même de protéger des canalisations plus importantes 51 comme celles d'évacuation des eaux usées.As in the example illustrated, these volumes can thus receive all the sheaths and all the

Selon une autre caractéristique de l'invention, les gaines d'électricité, de chauffage, etc... et toutes les canalisations, peuvent être incorporées aux éléments de plancher, et plus particulièrement à leur dalle 18, lors de leur fabrication en usine. Ceci est rendu possible par l'application de la loi de répartition des éléments de fondation, qui a été énoncée ci-avant, et qui repose sur le découpage de la superficie de la construction projetée.According to another characteristic of the invention, the sheaths of electricity, heating, etc. and all the pipes, can be incorporated into the floor elements, and more particularly into their

Bien entendu, chaque élément de plancher est avantageusement réalisé en béton armé coulé et peut même comprendre, dans son épaisseur, une couche de matériau isolant 53 contribuant ainsi à l'isolation thermique totale de l'immeuble en évitant un maximum de fuites de calories par le sol. Cette couche de matériau isolant pourra selon les circonstances être disposée ou coulée sur les surfaces supérieure ou inférieure de la dalle 18.Of course, each floor element is advantageously made of poured reinforced concrete and may even include, in its thickness, a layer of insulating

Selon une caractéristique avantageuse de la présente invention, la préfabrication des éléments de plancher permet d'incorporer à la dalle les réservations et le tracé des ouvrages ainsi que des éléments constitutifs notamment de la superstructure de l'immeuble. Il sera ainsi possible de prévoir, sur la superficie supérieure de la dalle, la tracé des diverses cloisons, de disposer même, avant l'installation définitive, certains revêtements comme celui des salles de bain ou d'ouvrir dans le corps de la dalle les passages nécessaires aux diverses canalisations ou gaines ou encore d'ouvrir une trappe d'accés au vide sanitaire.According to an advantageous characteristic of the present invention, the prefabrication of the floor elements makes it possible to incorporate in the slab the reservations and the layout of the works as well as the constituent elements in particular of the superstructure of the building. It will thus be possible to provide, on the upper surface of the slab, the layout of the various partitions, to even have, before the final installation, certain coverings such as that of the bathrooms or to open in the body of the slab passages necessary for the various pipes or ducts or to open an access hatch to the crawl space.

Quand l'ensemble du plancher est totalement constitué, la partie supérieure de l'immeuble peut être ainsi construite en montant les murs 54 de façon classique avec d'autres planchers intermédiaires, des cloisons, etc..., jusqu'au toit 55. Cette technique est classique et connue en elle-même et ne sera donc pas plus amplement développée ici.When the entire floor is completely formed, the upper part of the building can thus be constructed by mounting the

Dans l'hypothèse où l'immeuble ainsi construit présenterait une charge très importante, des réservations pourront être prévues dans les éléments de plancher pour le passage de poteaux en béton armé permettant le report direct des charges sur les éléments de fondation.In the event that the building thus constructed presents a very large load, reservations may be provided in the floor elements for the passage of reinforced concrete posts allowing the direct transfer of loads to the foundation elements.

Claims (7)

- Building substructure (1) comprising a plurality of foundation members (8, 9, 10) distributed on the ground (2) according to a predetermined law and in such a way that their head (11, 12, 13) is located at a predetermined level, a plurality of prefabricated floor members (15, 16, 17), each member comprising a flat slab (18) and side flanges (19, 20, 21) bordering said slab, these flanges defining with said slab a hollow recess (22), said floor members being juxtaposed one beside the other in order to form a total floor and associated with said foundation members, resting on the head of these foundation members through the intermediary of said flanges in order that the opening of said hollow recess is on the under side with respect to said slab, characterised by the fact that the lower edge of the side flanges (19, 20, 21) of the floor members is situated in the plane corresponding to said predetermined level in order to constitute protection volumes and that the floor members comprise casings, conduits and pipe lines (50, 51) necessary for making said building habitable incorporated in said floor members and extending inside protection volumes.

- Building substructure according to Claim 1, characterised by the fact that said foundation members are constituted by shafts, piles (8, 9, 10) or micro-piles.

- Building substructure according to Claim 1, characterized by the fact that said floor members comprise, on the upper surface of their slab, coverings ensuring the finish of the floor of the rooms.

- Building substructure according to Claim 1, characterised by the fact that said floor members comprise reserved areas and the lay-out intended for the structures and members constituting the building.

- Building substructure according to Claim 1, characterised by the fact that said floor members are connected to each other by means of metal plates (30) or other equivalent means.

- Building substructure according to Claim 1 or 2, characterised by the fact that the head of said foundation members is provided with sliding supports (31).

- Building substructure according to Claim 1 or 2, characterised by the fact that the head of said foundation members comprises a connection bar (27) in order to limit the lateral movements of said floor members.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR878701885A FR2610339B1 (en) | 1987-02-04 | 1987-02-04 | PROCESS FOR PRODUCING BASES OF BUILDINGS AND MEANS FOR CARRYING OUT SAID METHOD |

| AT88402026T ATE89046T1 (en) | 1988-08-03 | 1988-08-03 | SUBSTRUCTURE OF A BUILDING. |

| EP88402026A EP0353370B1 (en) | 1988-08-03 | 1988-08-03 | Building substructure |

| DE8888402026T DE3880831D1 (en) | 1988-08-03 | 1988-08-03 | UNDERBODY OF A BUILDING. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP88402026A EP0353370B1 (en) | 1988-08-03 | 1988-08-03 | Building substructure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0353370A1 EP0353370A1 (en) | 1990-02-07 |

| EP0353370B1 true EP0353370B1 (en) | 1993-05-05 |

Family

ID=8200413

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88402026A Expired - Lifetime EP0353370B1 (en) | 1987-02-04 | 1988-08-03 | Building substructure |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0353370B1 (en) |

| AT (1) | ATE89046T1 (en) |

| DE (1) | DE3880831D1 (en) |

| FR (1) | FR2610339B1 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5224321A (en) * | 1990-02-22 | 1993-07-06 | Fearn Richard N | Building foundation and floor assembly |

| WO1992014886A1 (en) * | 1991-02-22 | 1992-09-03 | Fearn Richard N | Building foundation and floor assembly |

| US5794393A (en) * | 1996-05-29 | 1998-08-18 | Fearn; Richard Neil | Concrete foundation wall form apparatus and method |

| GB2327688A (en) * | 1997-07-29 | 1999-02-03 | John Joseph Freeman | Floor with integral ground beams |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3040411A (en) * | 1956-05-07 | 1962-06-26 | Charles B Messenger | Process of constructing a concrete support structure |

| DE1157164B (en) * | 1957-12-14 | 1963-11-07 | Gruen & Bilfinger Ag | Underwater foundation made of prefabricated components, which are placed on ram piles with support eyes on the underside |

| FR1413829A (en) * | 1963-11-29 | 1965-10-08 | Foundation of a construction | |

| GB1086986A (en) * | 1965-03-08 | 1967-10-11 | Marley Concrete Ltd | Improvements in building foundations |

| FR1547666A (en) * | 1967-10-17 | 1968-11-29 | New prefabricated floor | |

| AU464495B2 (en) * | 1972-05-10 | 1975-08-28 | Handford Boot Patents Pty. Limited | Improvements in or relating to building construction |

| FR2505906A1 (en) * | 1981-05-14 | 1982-11-19 | Antoine Vercelletto | Reinforced concrete foundations suspended over thermal insulation - made by casting onto intermediate water-impermeable film |

| FR2539165B1 (en) * | 1983-01-10 | 1985-10-11 | Phenix Maisons | PREFABRICATED SUPPORT PART FOR INDUSTRIALIZED FLOORS AND SIDING |

| JPS6080627A (en) * | 1983-10-12 | 1985-05-08 | Taisei Corp | Pile head supporting structure of pile-type ground tank |

-

1987

- 1987-02-04 FR FR878701885A patent/FR2610339B1/en not_active Expired - Lifetime

-

1988

- 1988-08-03 DE DE8888402026T patent/DE3880831D1/en not_active Expired - Lifetime

- 1988-08-03 EP EP88402026A patent/EP0353370B1/en not_active Expired - Lifetime

- 1988-08-03 AT AT88402026T patent/ATE89046T1/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| DE3880831D1 (en) | 1993-06-09 |

| FR2610339A1 (en) | 1988-08-05 |

| FR2610339B1 (en) | 1991-06-07 |

| ATE89046T1 (en) | 1993-05-15 |

| EP0353370A1 (en) | 1990-02-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0185065B1 (en) | Method for making a rigid slab able to support a building | |

| EP1941104B1 (en) | New type of building, method and means for erecting it | |

| EP0180667B1 (en) | Preassembled modules and their use in a building construction | |

| EP0081402A1 (en) | Process for obtaining hollow structures such as ducts, grain tanks or shelters. | |

| EP0244890B1 (en) | Process for producing hollow structures such as ducts, silos, or shelters, and structures obtained by this process | |

| WO1991002851A2 (en) | Cellular structures for sustaining walls | |

| US8011158B1 (en) | Footing for support of structure such as building | |

| EP0353370B1 (en) | Building substructure | |

| FR3033584B1 (en) | MODULAR CONSTRUCTION FROM PREFABRICATED ELEMENTS | |

| WO2000046458A1 (en) | Building slab, assembly of same and use for producing structures capable of supporting heavy loads | |

| EP0093030B1 (en) | Sublevel space, in particular a cellar and method of creating the same | |

| FR2464339A1 (en) | Multi-storey building frame made of precast units - uses columns between doubled rectangular floor slabs with cavity connected by ties in column ducts | |

| EP1211355A1 (en) | Base wall for construction and method for realization of such | |

| BE1004988A4 (en) | SET OF ELEMENTS FOR erect WALLS OF A HOUSE. | |

| EP0242497B1 (en) | Tunnel construction process | |

| FR2633650A1 (en) | Building block with a partial filling of mortar, facilitating the circulation of air and used for the construction of walls for buildings | |

| BE1008399A6 (en) | BLOCK CONSTRUCTION hollowed INTERNALLY, FOR RECEIVING A CURABLE GROUT. | |

| FR2558868A1 (en) | Method for constructing walls of buildings or of other structures, and shuttering unit for its implementation | |

| EP2455549B1 (en) | Concrete foundation including a ballasting assembly | |

| FR2462523A3 (en) | PREFABRICATED ELEMENT FOR THE CONSTRUCTION OF A WALL WITH HIGH THERMAL AND SOUND INSULATION | |

| FR3047262A1 (en) | MODULAR DEVICE FOR FORMING A GROUND ANCHOR POINT | |

| FR2638182A1 (en) | MODULAR PREFABRICATED CONSTRUCTION FOR HOUSEHOLD USE | |

| FR2744471A1 (en) | Prefabricated hollow brick modules for cladding, load bearing walls, acoustic insulation, low walls and other construction | |

| FR2858990A1 (en) | Prefabricated and insulated panel construction procedure uses additional reinforcing rods and metal frames on corners | |

| EP1045091B1 (en) | Construction element reinforcement method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900928 |

|

| 17Q | First examination report despatched |

Effective date: 19910607 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19930505 Ref country code: NL Effective date: 19930505 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19930505 Ref country code: SE Effective date: 19930505 Ref country code: AT Effective date: 19930505 Ref country code: DE Effective date: 19930505 Ref country code: GB Effective date: 19930505 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19930505 |

|

| REF | Corresponds to: |

Ref document number: 89046 Country of ref document: AT Date of ref document: 19930515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3880831 Country of ref document: DE Date of ref document: 19930609 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19930831 Ref country code: CH Effective date: 19930831 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19930831 Ref country code: LI Effective date: 19930831 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19930505 |

|

| BERE | Be: lapsed |

Owner name: VIRELIZIER GERMAIN NOEL LOUIS Effective date: 19930831 Owner name: CALMET RENE VINCENT AUGUSTE Effective date: 19930831 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |