EP0347582A2 - Pompe d'injection pour moteurs à combustion interne - Google Patents

Pompe d'injection pour moteurs à combustion interne Download PDFInfo

- Publication number

- EP0347582A2 EP0347582A2 EP19890108891 EP89108891A EP0347582A2 EP 0347582 A2 EP0347582 A2 EP 0347582A2 EP 19890108891 EP19890108891 EP 19890108891 EP 89108891 A EP89108891 A EP 89108891A EP 0347582 A2 EP0347582 A2 EP 0347582A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- chamber

- pump

- connection

- control

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/44—Details, components parts, or accessories not provided for in, or of interest apart from, the apparatus of groups F02M59/02 - F02M59/42; Pumps having transducers, e.g. to measure displacement of pump rack or piston

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

- F02M55/001—Pumps with means for preventing erosion on fuel discharge

Definitions

- the invention relates to an injection pump for internal combustion engines, with a pump piston in a pump piston liner to which a suction chamber is connected, the connection to the working chamber of the pump from which the pump piston is ground at the start of delivery, and in which the control of the pump pressure at the end of delivery by renewed release the connection to the suction chamber.

- an injection pump has become known, in which the connection between the working chamber and the suction chamber is first released to control the pump pressure at the end of delivery and then further overflow openings are released by the pump piston.

- the pump pressure is turned off at the end of the injection process, the fuel under high pressure passes through a recess in the pump piston to a space on the outside of the pump piston which is delimited by a control edge, and this space is relieved when the bores are smoothed over to the suction chamber.

- the fuel flows back under high pressure into the suction space, which is usually under relatively low pressure, namely the backing pump pressure.

- excessive wear which could be attributed to cavitation, was found due to the rapid pressure relief.

- the rapid reduction in pressure always loads all wear parts and thus limits the service life of the injection pump.

- the invention now aims to reduce the wear that occurs due to rapid pressure reduction at the injection end in an injection pump of the type mentioned.

- the solution to this problem essentially consists in the fact that at least one of a pressure-maintaining valve is attached to the working space and / or a throttle limited separate control chamber is connected via a connection that can also be opened and closed by the pump piston, this connection to the work space being opened earlier at the end of pump delivery than the controllable connection to the suction chamber.

- a separate control chamber which is initially connected to the working chamber of the pump piston during the compression stroke and is ground by the pump piston, this separate control chamber is filled with fuel under pressure in the course of the compression stroke, the pressure built up in the separate control chamber by a Pressure maintaining valve and / or a throttle is maintained. If the pressure is relieved at the end of the injection in this already pressurized space, a first pressure relief is achieved to a pressure level that lies between the backing pump pressure and the injection pump pressure, so that the pressure reduction is less violent and the risk of gas bubbles or Cavities due to expansion and negative pressure in the vicinity of liquid jets with a subsequent implosion with the resulting cavitation are substantially reduced or completely avoided.

- the design according to the invention is such that the connection to the control chamber with its upper edge in the direction of the compression stroke is higher than the upper edge of the further connection to the suction chamber.

- This configuration of the edge of the connection which can be formed in a simple manner by a bore, with the control chamber ensures that the control chamber is connected to one before pump delivery Relatively high pressure is biased, since fuel is pressed into the control chamber in the region of the stroke between the control of the bore to the suction chamber and the control of the bore to the control chamber. In this way, the first pressure level, against which the pressure relief occurs during the shutdown, is raised, whereby the risk of cavitation phenomena is further reduced.

- a structurally particularly simple embodiment of the separate control chamber can be achieved by screwing a wall part having a throttle and / or a pressure control valve to the separate control chamber.

- a wall part having the pressure holding valve or the throttle can be designed, for example, as a screw plug, as a result of which the arrangement of a pressure holding valve and the required sealing in the separate wall part can be achieved more easily.

- the assembly of the elements for the separate control room is also made considerably easier by such a separate wall part.

- the filling process of the injection pump for the compression stroke can be carried out in a conventional manner via the bores or connections to the suction space, i.e. to the room which is under backing pressure.

- the filling can also be carried out via the separate control chamber, for which the design is advantageously made such that the wall part having the throttle and / or the pressure control valve additionally has a suction valve that opens to the control chamber.

- the design according to a preferred development of the injection pump according to the invention is such that several connecting channels with the suction space and are distributed over the piston sleeve circumference the control chamber are arranged, which are opened and closed by corresponding control edges on the piston.

- the in um In the case of four bores, bores arranged offset with respect to the longitudinal direction of the piston can be offset by 90 °, two bores each leading to separate control chambers. Overall, this results in a symmetrical loading of the piston even with the gradual expansion of the pump chamber at the end of the injection process.

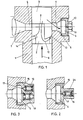

- FIG. 1 shows an axial section through the working space of an injection pump

- Figure 2 is an enlarged view of a modified training for the completion of the separate control room

- 3 shows a further section analogous to the section according to FIG. 2 through a modified design of the detachable wall part of the separate control chamber

- 4 shows the pressure in the pump chamber or working chamber of the injection pump

- 5 shows the pressure in the control chamber when using a throttle

- 6 shows the pressure in the control chamber in an embodiment with a pressure-maintaining valve

- 1 denotes the pump piston liner and 2 denotes the pump piston.

- the working space of the pump piston within the pump piston liner 1 is denoted by 3, and a connecting bore 4 to an exhaust chamber 5 connects to this working space 3.

- the working space 3 is reduced, whereby compression of the fuel can be achieved.

- the upper edge 9 of the pump piston 2 first grinds the connection 6 to the suction chamber 7 and subsequently also the connection 4 to the control chamber 5. After the connection bore 6 has been closed, fuel is still pressed out under high pressure via the connection bore 4 into the control chamber 5, for which purpose Advantage of the 4 hole Control chamber 5 is made larger in diameter than the diameter of bore 6.

- the control chamber 5 is delimited by a detachable wall part 10 which carries a throttle 11.

- fuel is first pressed out into the control chamber 5 under pressure in the direction of the arrow 12 when the control edge 13 grinds the connecting bore 4 earlier than the opposite control edge 14 the correspondingly assigned connecting bore 6. This can in turn be achieved on the one hand that the bore 4 has a larger diameter than the bore 6.

- the shape of the control edges 13 and 14 can be chosen accordingly that actually first a pressure relief to the pressure level in the control chamber 5 and only then a further pressure relief in the suction chamber he follows.

- control chamber 5 can also be closed off by a wall part 15 with a pressure holding valve 16.

- a pressure holding valve 16 has the advantage that a defined pressure is specified in the control chamber 5 and, in order to reduce dynamic pressure peaks, a throttle 17 can be connected upstream of the pressure holding valve.

- a suction valve 18 is also installed in this releasable wall element 15 according to FIG. 2 in addition to the pressure holding valve 16. Via this suction valve, the working space of the pump piston 2 can also be filled via the control chamber 5, so that a faster and more uniform filling than with the exclusive aid of the bore 6, which is connected to the suction chamber 7, is possible.

- the pressure ratios in the pump chamber and in the control chamber are entered in FIGS. 4, 5 and 6 in an assigned manner.

- the pump pressure rises rapidly at point FB1, this point corresponding to the position of the pump piston 2 at which the upper edge 9 bores the bore 6 Suction chamber 7 blended.

- fuel is still pumped into the control chamber 5, but the pressure continues to rise to point FB2, at which the upper edge 9 of the pump piston 2 also drags over the bore 4.

- the injection end FE2 is reached when the pump pressure can be reduced again by grinding the control edge 13, and a first partial area of the pressure relief takes place from FE2 to point FE1 by pressure compensation against the pressure in the control chamber 5.

- the pressure curve differs primarily at the point FB2 from the pressure curve as shown in FIG. While using a throttle, as shown in Fig. 5, a sharp maximum is achieved in FB2, which goes into a phase of pressure relief by the throttle, but this pressure relief takes place largely continuously up to point FE2, the pressure curve goes when using a Pressure maintaining valve according to Figure 6 after the pressure peak is reduced by the Pressure holding valve in the holding pressure of the pressure holding valve.

- a special pressure holding valve 16 is provided, to the closing member 19 of which a bore 20 is connected in the flow direction after the control chamber 5, which can be connected to the fuel return from the pump.

- a pressure maintaining valve 16 can be screwed directly into the wall of the pump piston liner.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

- Output Control And Ontrol Of Special Type Engine (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3820706A DE3820706A1 (de) | 1988-06-18 | 1988-06-18 | Einspritzpumpe fuer brennkraftmaschinen |

| DE3820706 | 1988-06-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0347582A2 true EP0347582A2 (fr) | 1989-12-27 |

| EP0347582A3 EP0347582A3 (fr) | 1990-08-08 |

Family

ID=6356794

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89108891A Ceased EP0347582A3 (fr) | 1988-06-18 | 1989-05-18 | Pompe d'injection pour moteurs à combustion interne |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4957418A (fr) |

| EP (1) | EP0347582A3 (fr) |

| JP (1) | JPH0240076A (fr) |

| DE (1) | DE3820706A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0877163A1 (fr) * | 1997-05-06 | 1998-11-11 | Man B&W Diesel Aktiengesellschaft | Pompe d'injection de combustible |

| EP2351929A2 (fr) * | 2008-10-27 | 2011-08-03 | Hyundai Heavy Industries Co., Ltd. | Appareil empêchant l'érosion par cavitation dans une pompe d'injection de carburant d'un moteur diesel |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3926166A1 (de) * | 1989-08-08 | 1991-02-14 | Bosch Gmbh Robert | Kraftstoffeinspritzpumpe fuer dieselbrennkraftmaschinen |

| DE4106813A1 (de) * | 1991-03-04 | 1992-09-10 | Bosch Gmbh Robert | Kraftstoffeinspritzpumpe fuer brennkraftmaschinen |

| DE4206883A1 (de) * | 1992-03-05 | 1993-09-09 | Bosch Gmbh Robert | Kraftstoffeinspritzpumpe fuer brennkraftmaschinen |

| GB9225585D0 (en) * | 1992-12-08 | 1993-01-27 | Lucas Ind Plc | Fuel injection pump |

| DK176162B1 (da) * | 1997-04-21 | 2006-10-23 | Man B & W Diesel As | Brændstofpumpe til forbrændingsmotorer, især store langsomtgående marinedieselmotorer |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB434788A (en) * | 1933-12-04 | 1935-09-09 | Georges Grauce | Improvements in or relating to fuel pumps |

| US2305308A (en) * | 1939-02-17 | 1942-12-15 | Fischlmayr Hans | Automatic timing mechanism for fuel injection pumps |

| DE822453C (de) * | 1948-10-02 | 1951-11-26 | Bosch Gmbh Robert | Einspritzpumpe, insbesondere fuer leicht siedenden Kraftstoff |

| FR2318320A1 (fr) * | 1975-07-15 | 1977-02-11 | Sulzer Ag | Dispositif d'injection de carburant d'un moteur diesel |

| JPS59192841A (ja) * | 1983-04-14 | 1984-11-01 | Nippon Denso Co Ltd | 燃料噴射装置 |

| DE3539760A1 (de) * | 1985-11-09 | 1987-05-14 | Man B & W Diesel Gmbh | Kraftstoffeinspritzvorrichtung fuer eine brennkraftmaschine |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB530945A (en) * | 1938-07-12 | 1940-12-24 | Daimler Benz Ag | Improvements in and connected with fuel-injection pumps for internal combustion engines |

| US3368491A (en) * | 1966-06-22 | 1968-02-13 | Murphy Diesel Company | Fuel injection pump |

| DE2537344C2 (de) * | 1975-08-21 | 1986-05-15 | CKD Praha O.P., Prag/Praha | Kraftstoff-Einspritzpumpe für Brennkraftmaschinen |

| DE2730091C2 (de) * | 1977-07-02 | 1986-12-04 | Robert Bosch Gmbh, 7000 Stuttgart | Schrägkantengesteuerte Kraftstoffeinspritzpumpe für Brennkraftmaschinen |

| EP0269610A1 (fr) * | 1986-11-21 | 1988-06-01 | Robert Bosch Ag | Elément de pompe d'une pompe à injection de combustible pour moteur à injection |

-

1988

- 1988-06-18 DE DE3820706A patent/DE3820706A1/de not_active Withdrawn

-

1989

- 1989-03-29 US US07/330,389 patent/US4957418A/en not_active Expired - Fee Related

- 1989-05-18 EP EP89108891A patent/EP0347582A3/fr not_active Ceased

- 1989-06-19 JP JP1154799A patent/JPH0240076A/ja active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB434788A (en) * | 1933-12-04 | 1935-09-09 | Georges Grauce | Improvements in or relating to fuel pumps |

| US2305308A (en) * | 1939-02-17 | 1942-12-15 | Fischlmayr Hans | Automatic timing mechanism for fuel injection pumps |

| DE822453C (de) * | 1948-10-02 | 1951-11-26 | Bosch Gmbh Robert | Einspritzpumpe, insbesondere fuer leicht siedenden Kraftstoff |

| FR2318320A1 (fr) * | 1975-07-15 | 1977-02-11 | Sulzer Ag | Dispositif d'injection de carburant d'un moteur diesel |

| JPS59192841A (ja) * | 1983-04-14 | 1984-11-01 | Nippon Denso Co Ltd | 燃料噴射装置 |

| DE3539760A1 (de) * | 1985-11-09 | 1987-05-14 | Man B & W Diesel Gmbh | Kraftstoffeinspritzvorrichtung fuer eine brennkraftmaschine |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 9, no. 57 (M-363)(1780) 13 März 1985, & JP-A-59 192841 (NIPPON DENSO K.K.) 1 November 1984, * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0877163A1 (fr) * | 1997-05-06 | 1998-11-11 | Man B&W Diesel Aktiengesellschaft | Pompe d'injection de combustible |

| EP2351929A2 (fr) * | 2008-10-27 | 2011-08-03 | Hyundai Heavy Industries Co., Ltd. | Appareil empêchant l'érosion par cavitation dans une pompe d'injection de carburant d'un moteur diesel |

| EP2351929A4 (fr) * | 2008-10-27 | 2013-12-18 | Hyun Dai Heavy Ind Co Ltd | Appareil empêchant l'érosion par cavitation dans une pompe d'injection de carburant d'un moteur diesel |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0240076A (ja) | 1990-02-08 |

| EP0347582A3 (fr) | 1990-08-08 |

| US4957418A (en) | 1990-09-18 |

| DE3820706A1 (de) | 1989-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3876971T2 (de) | Kraftstoffeinspritzventil fuer einen motor. | |

| WO1991010062A1 (fr) | Pompe d'injection de carburant a commande electrique pour moteurs a combustion interne, en particulier pompe d'injection combinee avec l'injecteur | |

| DE69814990T2 (de) | Einspritzventil | |

| DE2332666A1 (de) | Kraftstoff-einspritzeinrichtung | |

| DE69915946T2 (de) | Dichtung | |

| DE10117600C1 (de) | Hochdruck-Kraftstoffpumpe für ein Kraftstoffsystem einer direkteinspritzenden Brennkraftmaschine, Kraftstoffsystem sowie Brennkraftmaschine | |

| EP0347582A2 (fr) | Pompe d'injection pour moteurs à combustion interne | |

| EP0267177A1 (fr) | Buse d'injection de combustible | |

| DE2258309C2 (de) | Kraftstoffverteilereinspritzpumpe für Brennkraftmaschinen | |

| DE2043914C3 (de) | Brennstoffeinspritzdüse für Brennkraftmaschinen | |

| DE3440574A1 (de) | Kraftstoffeinspritzduese | |

| DE3508170C2 (de) | Brennstoffeinspritzpumpenanordnung zur Versorgung der Brennkraftmaschine | |

| DE2303824A1 (de) | Einspritzpumpe | |

| EP0418800B1 (fr) | Dispositif d'injection de combustible pour un moteur à combustion interne | |

| DE10352024A1 (de) | Elektromagnetventil | |

| DE19717922A1 (de) | Zweistufenregelventil | |

| DE1258220B (de) | Kolben fuer Kompressoren und Pumpen | |

| DE102014218488A1 (de) | Verfahren zum Nitrieren eines Bauteils eines Kraftstoffeinspritzsystems | |

| DE2445696A1 (de) | Hochdruckplungerpumpe | |

| DE2044572A1 (de) | Einspritzvorrichtung einer Dieselbrennkraftmaschine | |

| WO2018072933A1 (fr) | Pompe haute pression pour système d'injection de carburant | |

| WO1998014704A1 (fr) | Pompe a piston radial | |

| DE3914582A1 (de) | Brennstoffeinspritzvorrichtung | |

| DE10116635A1 (de) | Verfahren zum Betreiben einer Pumpe-Düse-Einheit sowie Pumpe-Düse-Einheit | |

| DE3225131A1 (de) | Kraftstoffeinspritzduese |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19901212 |

|

| 17Q | First examination report despatched |

Effective date: 19910507 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ROBERT BOSCH GMBH |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19920227 |