EP0341993A1 - Matériau en feuille utilisé pour la formation de l'élément à boucles d'une fermeture du type à crochets et à boucles - Google Patents

Matériau en feuille utilisé pour la formation de l'élément à boucles d'une fermeture du type à crochets et à boucles Download PDFInfo

- Publication number

- EP0341993A1 EP0341993A1 EP89304709A EP89304709A EP0341993A1 EP 0341993 A1 EP0341993 A1 EP 0341993A1 EP 89304709 A EP89304709 A EP 89304709A EP 89304709 A EP89304709 A EP 89304709A EP 0341993 A1 EP0341993 A1 EP 0341993A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fibers

- backing

- portions

- sheet

- ridges

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000463 material Substances 0.000 title claims abstract description 125

- 239000000835 fiber Substances 0.000 claims abstract description 234

- 238000000034 method Methods 0.000 claims description 36

- 239000010410 layer Substances 0.000 claims description 20

- 239000012815 thermoplastic material Substances 0.000 claims description 9

- 239000013047 polymeric layer Substances 0.000 claims 4

- 239000003082 abrasive agent Substances 0.000 claims 1

- -1 polypropylene Polymers 0.000 description 21

- 239000004743 Polypropylene Substances 0.000 description 16

- 229920001155 polypropylene Polymers 0.000 description 16

- 229920005989 resin Polymers 0.000 description 16

- 239000011347 resin Substances 0.000 description 16

- 239000000203 mixture Substances 0.000 description 12

- 229920003345 Elvax® Polymers 0.000 description 7

- 238000012360 testing method Methods 0.000 description 7

- 238000005984 hydrogenation reaction Methods 0.000 description 6

- 238000006116 polymerization reaction Methods 0.000 description 6

- 229920000728 polyester Polymers 0.000 description 5

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 4

- 235000001674 Agaricus brunnescens Nutrition 0.000 description 4

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 4

- 239000005977 Ethylene Substances 0.000 description 4

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 4

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 4

- 239000011162 core material Substances 0.000 description 4

- 229920000098 polyolefin Polymers 0.000 description 4

- 150000003097 polyterpenes Chemical class 0.000 description 4

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- 229920006271 aliphatic hydrocarbon resin Polymers 0.000 description 3

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 239000005038 ethylene vinyl acetate Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 230000000717 retained effect Effects 0.000 description 3

- 238000005096 rolling process Methods 0.000 description 3

- 229920001169 thermoplastic Polymers 0.000 description 3

- 239000004416 thermosoftening plastic Substances 0.000 description 3

- HECLRDQVFMWTQS-RGOKHQFPSA-N 1755-01-7 Chemical compound C1[C@H]2[C@@H]3CC=C[C@@H]3[C@@H]1C=C2 HECLRDQVFMWTQS-RGOKHQFPSA-N 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 2

- 239000004831 Hot glue Substances 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- 229920003351 Ultrathene® Polymers 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 150000007513 acids Chemical class 0.000 description 2

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 2

- 230000001143 conditioned effect Effects 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 150000002148 esters Chemical class 0.000 description 2

- BFMKFCLXZSUVPI-UHFFFAOYSA-N ethyl but-3-enoate Chemical compound CCOC(=O)CC=C BFMKFCLXZSUVPI-UHFFFAOYSA-N 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 238000005065 mining Methods 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920006149 polyester-amide block copolymer Polymers 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- HJWLCRVIBGQPNF-UHFFFAOYSA-N prop-2-enylbenzene Chemical compound C=CCC1=CC=CC=C1 HJWLCRVIBGQPNF-UHFFFAOYSA-N 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 239000004716 Ethylene/acrylic acid copolymer Substances 0.000 description 1

- 229920002544 Olefin fiber Polymers 0.000 description 1

- 241000845082 Panama Species 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 229920006272 aromatic hydrocarbon resin Polymers 0.000 description 1

- 238000009960 carding Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 229920006242 ethylene acrylic acid copolymer Polymers 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000012760 heat stabilizer Substances 0.000 description 1

- 238000009940 knitting Methods 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- UEGPKNKPLBYCNK-UHFFFAOYSA-L magnesium acetate Chemical compound [Mg+2].CC([O-])=O.CC([O-])=O UEGPKNKPLBYCNK-UHFFFAOYSA-L 0.000 description 1

- 229940069446 magnesium acetate Drugs 0.000 description 1

- 235000011285 magnesium acetate Nutrition 0.000 description 1

- 239000011654 magnesium acetate Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 229920003145 methacrylic acid copolymer Polymers 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 239000004767 olefin fiber Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 1

- 125000004805 propylene group Chemical group [H]C([H])([H])C([H])([*:1])C([H])([H])[*:2] 0.000 description 1

- 239000012047 saturated solution Substances 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 229920006352 transparent thermoplastic Polymers 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B18/00—Fasteners of the touch-and-close type; Making such fasteners

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H11/00—Non-woven pile fabrics

- D04H11/04—Non-woven pile fabrics formed by zig-zag folding of a fleece or layer of staple fibres, filaments, or yarns, strengthened or consolidated at the folds

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B18/00—Fasteners of the touch-and-close type; Making such fasteners

- A44B18/0003—Fastener constructions

- A44B18/0011—Female or loop elements

Definitions

- loop fastener portions made from many such loop materials work well with many different hook fastener portions, many of the processes by which they are made are more expensive than may be desired, particularly when the loop fastener portions are intended for a limited amount of use, such as to attach a disposable diaper to an infant, or to attach an abrasive disk to a backing pad by which it is driven.

- a sheet material adapted to be cut into pieces to form loop portions for fasteners, which sheet material comprises a backing, and a multiplicity of fibers having portions bonded to the backing along a front surface at spaced bonding locations to form arcuate portions of the fibers projecting from the front surface of the backing between the bonding locations.

- the arcuate portions have a height from the backing of less than about 0.64 centimeters (0.250 inch) and preferably less than about 0.318 centimeters (0.125 inch).

- the width of the bonding locations should be between about 0.005 and 0.075 inch, and the width of the arcuate portions of the fibers should be between about 0.06 and 0.35 inch.

- the ridges can be elongate and generally parallel so that the bonding locations are also elongate and generally parallel and are continuous in one direction across the front surface of the backing so that continuous rows of the arcuate portions extend across the backing of the sheet material; or alternately the ridges can be elongate, generally parallel, and in a regular pattern of discontinuous lengths so that the parallel bonding locations are also in a regular pattern of discontinuous lengths to to form a regular pattern of discontinuous rows of the arcuate portions along the front surface of the backing.

- the backing could be a woven, knitted, random woven, nonwoven or other layer of intertwined fibers, but preferably is a continuous polymeric film in the range of about 0.0025 to 0.013 centimeters (0.001 to 0.005 inch) thick which is generally less expensive than a backing of entwined fibers and allows the backing to be printed by conventional methods along one of its surfaces with graphics (such as advertising, instructions or locating marks) which will be visible through the loop portions of the fibers due to their large percentage of open area.

- graphics such as advertising, instructions or locating marks

- the film may be a single layer of a polymeric material such as polypropylene, polyester, or polyamide; or may have a plurality of layers such as a central layer of a relatively high strength material such as polyester, a layer defining the first surface of a material more easily bonded to the fiber such as ethylene vinyl acetate or polyethylene, and a layer defining its second surface adapted to adhere the backing to a substrate such as polyethylene or a bonding layer of room-temperature non-tacky thermoplastic material adapted to adhere a fastener portion to a polyolefin layer (such as may be found on a disposable diaper) that can be bonded to the polyolefin layer under heat and pressure that leaves the polyolefin layer substantially undeformed and will hold the fastener portion to the polyolefin layer with greater force than that which is required to separate an engaged fastener, which bonding layer of room-temperature non-tacky thermoplastic material is described in U.S.

- Patent application No. 126,746 filed November 30, 1987 can include from about 40% to about 100% of a thermoplastic material having a softening point of generally below 120 degrees Centigrade and preferably below 100 degrees Centigrade, and from about 60% to about 0% of a tackifying resin that has a softening point below about 105 degrees Centigrade and preferably below 95 degrees Centigrade.

- Suitable thermoplastic materials include ethylene and propylene based copolymers such as ethylene/vinyl acetate copolymers, ethylene/acrylic acid copolymers, and ethylene/methacrylic acid copolymers.

- thermoplastic materials include ethylene/vinyl acetate copolymers, especially those with a melt flow index from about 40 to about 2500, and preferably with a melt flow index between about 50 and about 1000.

- Such materials are available commercially as Elvax 40W, Elvax 150, Elvax 210W, Elvax 220W, Elvax 310, Elvax 410, and Elvax 4980W from E. I. DuPont de Nemours and Co. of Wilmington, Delaware; Escorene UL7710 and Escorene UL7720 from Exxon Chemical Co., Houston, Texas; and Ultrathene 639-35 and Ultrathene 649-04, available from USI Chemical Co. of Cincinnati, Ohio.

- Suitable tackifying resins are preferably solid or semisolid, however liquid tackifying resins can also be used.

- the tackifying resin when used, should be compatible with the thermoplastic material and may include rosin esters, rosin acids, and derivatives of these; hydrogenated rosin esters and rosin acids and derivatives of these; aliphatic hydrocarbon resins; mixed aliphatic/aromatic hydrocarbon resins, polyterpene resins; resins made from the polymerization and hydrogenation of a dicyclopentadiene feed stream; polyterpene resins and aromatic-modified polyterpene resins; resins made from the polymerization and hydrogenation of a C9 hydrocarbon stream; and resins made from the polymerization and hydrogenation of a mixture of alphamethyl styrene, styrene, and vinyl toluene.

- Preferred tackifying resins include aliphatic hydrocarbon resins such as Escorez 1580 and Escorez 1310, available from Exxon Chemical of Houston, Texas; Hercotac 95, available from Hercules Chemical Co. of Wilmington, Delaware; and Wingtack Plus and Wingtack 95, available from the Goodyear Tire and Rubber Company of Akron, Ohio. Additional preferred solid tackifying resins include the aromatic-modified polyterpene resins such as Wingtack 86, available from Goodyear; Zonatac 105, available from Arizona Chemical Co.

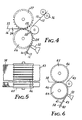

- the corrugating members 26 and 27 are mounted in axially parallel relationship with portions of the ridges 28 of the corrugating members 26 and 27 meshing generally in the manner of gear teeth; at least one of the corrugating members 26 or 27 is rotated; and the sheet of fibers is fed between the meshed portions of the ridges 28 of the corrugating members 26 and 27 to generally conform the sheet of fibers to the periphery of the first corrugating member 26 and form the arcuate portions of the fibers 16 in the spaces between the ridges 28 of the first corrugating member 26 and the generally parallel anchor portions 24 of the sheet of fibers along the outer surfaces of the ridges 28 on the first corrugating member 26.

- the formed sheet of fibers is retained along the periphery of the first corrugating member 26 after it has moved past the meshed portions of the ridges 28; the backing 12 is bonded to the parallel anchor portions 24 of the sheet of fibers on the end surfaces of the ridges 28 on the first corrugating member 26 as by the action of a sonic welder 30 or by other sources of heat and pressure such as heat from within the first corrugating member 26; and the bonded backing 12 and fibers 16 or sheet material 10 is separated from the first corrugating member 26.

- the sheet of fibers fed between the meshed portions of the ridges 28 of the corrugating members 26 and 27 can be in the form of a non woven web or sheet, or, as illustrated in Figure 4, in the form of yarns 33 distributed to provide a sheet of uniformly distributed fibers by passing the yarns 33 through a comb 34 and fed between the meshed portion of the ridges 28 of the corrugating members 26 and 27 with all of the fibers 16 extending generally perpendicular to the axes of the corrugating members 26 and 27.

- Corrugating members 26 and 27 adapted to have such a sheet of fibers 32 fed into them can have their ridges 28 oriented generally in the range of 0 to 45 degrees with respect to their axes, but preferably have their ridges 28 oriented at about 5 degrees with respect to their axes so that the sonic welder 30 will always be adjacent and heating the parallel portions 24 of the sheet of fibers along a portion of at least one of the ridges 28 to help even out the energy output of the sonic welder 30 and so that the fibers 16 in the sheet material 10 all extend in directions at about right angles (i.e., 85 degrees) to the parallel bonding locations 18.

- the method can further include printing the backing along one of its surfaces prior to the bonding step, as along its rear surface 14 with a printer 36, which may preferably be done at a location remote from the corrugating members 26 and 27.

- Figures 5 and 6 schematically illustrate a first alternate way to perform the method according to the present invention for forming a sheet material 40 according to the present invention, which method generally comprises forming fibers 38 into a sheet having arcuate portions 41 projecting in the same direction from spaced generally parallel anchor portions of the sheet, and bonding the spaced anchor portions of the sheet of fibers with the fibers along a front surface of a backing 43 with the arcuate portions 41 projecting from the front surface of the backing 43.

- a sheet material according to the present invention was made as described in Example 1 except that the individual fibers used were 6.2 denier polypropylene fibers commercially available as 420/68 yarn from Phillips Fibers Incorporated, Greenville, SC., and the ridges and spaces between the ridges of the corrugating rollers were shaped to cause projecting arcuate portions of the fibers roughly semicircular in shape with heights of about 0.318 centimeter (0.125 inch) between the parallel bonding locations. It was noted that the printing on the backing could be easily seen through the arcuate portions of the fibers.

- the sheet material was tested as in Example 1, and the average results obtained are tabulated in table 1 below.

- a sheet material according to the present invention was made generally as described in Example 1 except that no comb was used and the multiplicity of fibers used to form the sheet of fibers were those commercially available from Hercules as 9d T-101 fibers.

- the fibers were used in an amount to provide a basis weight of 45 grams per square meter for the sheet of fibers, and the orientation of the fibers in the sheet was estimated to be in a ratio of about seven in the longitudinal direction to one in the cross direction.

- a strip of the appropriate hook or mushroom material at least 7" (178 mm) long by width and an equal length of the loop to which it will be mated. If the samples are removed from a roll of material remove the outer lap of material before selecting the required number of strips. On each strip the end closest to the center of the roll must be marked. These markings are used to mark the directionality of the specimens.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Slide Fasteners, Snap Fasteners, And Hook Fasteners (AREA)

- Laminated Bodies (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Food-Manufacturing Devices (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US19383288A | 1988-05-13 | 1988-05-13 | |

| US193832 | 1988-05-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0341993A1 true EP0341993A1 (fr) | 1989-11-15 |

| EP0341993B1 EP0341993B1 (fr) | 1993-08-18 |

Family

ID=22715199

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89304709A Expired - Lifetime EP0341993B1 (fr) | 1988-05-13 | 1989-05-10 | Matériau en feuille utilisé pour la formation de l'élément à boucles d'une fermeture du type à crochets et à boucles |

Country Status (11)

| Country | Link |

|---|---|

| EP (1) | EP0341993B1 (fr) |

| JP (1) | JP2896159B2 (fr) |

| KR (1) | KR960013457B1 (fr) |

| AU (1) | AU622171B2 (fr) |

| BR (1) | BR8902225A (fr) |

| CA (1) | CA1333952C (fr) |

| DE (1) | DE68908468T2 (fr) |

| ES (1) | ES2043010T3 (fr) |

| IL (1) | IL90159A (fr) |

| MX (1) | MX173200B (fr) |

| ZA (1) | ZA893577B (fr) |

Cited By (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1995019242A1 (fr) * | 1994-01-13 | 1995-07-20 | Minnesota Mining And Manufacturing Company | Article abrasif, son procede de fabrication et machine a abraser |

| TR27991A (tr) * | 1991-05-20 | 1995-11-16 | Procter & Gamble | Yeniden baglanabilir baglama araci icin dokunmamis disi bilesen ve bunu yapmaya mahsus yöntem. |

| EP0712590A3 (fr) * | 1994-11-18 | 1997-01-15 | Acushnet Co | Gant possédant une inscription sur les boucles et crochets |

| US5607345A (en) * | 1994-01-13 | 1997-03-04 | Minnesota Mining And Manufacturing Company | Abrading apparatus |

| WO1997024482A1 (fr) * | 1995-12-29 | 1997-07-10 | Kimberly-Clark Worldwide, Inc. | Bande de non-tisse non lie a motif et son procede de fabrication |

| EP0800808A1 (fr) * | 1995-10-27 | 1997-10-15 | Kao Corporation | Article absorbant |

| WO1998006290A1 (fr) * | 1996-08-14 | 1998-02-19 | Minnesota Mining And Manufacturing Company | Procede et installation servant a fabriquer rapidement un materiau a boucles |

| DE19722748A1 (de) * | 1997-05-30 | 1998-12-03 | Corovin Gmbh | Schlaufenmaterial |

| EP0913104A3 (fr) * | 1997-10-31 | 1999-09-29 | Uni-Charm Corporation | Elément femelle d'une fermeture à crochets et à boucles |

| US6039911A (en) * | 1997-01-09 | 2000-03-21 | 3M Innovative Properties Company | Method for capping stem fasteners |

| WO2000073063A1 (fr) * | 1999-05-28 | 2000-12-07 | Velcro Industries B.V. | Presentoirs et decorations utilisant des fixations detachables |

| EP1048236A3 (fr) * | 1999-03-26 | 2001-09-05 | Uni-Charm Corporation | Fixation mécanique |

| WO2002077349A1 (fr) * | 2001-03-23 | 2002-10-03 | 3M Innovative Properties Company | Tissu composite pour le controle de fluides |

| USRE38652E1 (en) | 1992-08-20 | 2004-11-16 | Velcro Industries B.V. | Hook for hook and loop fasteners |

| US6849142B1 (en) | 1991-05-20 | 2005-02-01 | The Procter & Gamble Company | Method of making multi-layer female component for refastenable fastening device |

| US7282251B2 (en) | 2001-06-12 | 2007-10-16 | Vekro Industries B.V. | Loop materials for touch fastening |

| WO2008003438A1 (fr) * | 2006-07-05 | 2008-01-10 | Nuova Pansac S.P.A. | Dispositif d'attache mécanique libérable |

| US7468114B2 (en) | 2002-11-13 | 2008-12-23 | Kao Corporation | Composite sheet and process and apparatus for producing the same |

| US7785095B2 (en) | 2001-03-14 | 2010-08-31 | Velcro Industries B.V. | Molding apparatus and related methods |

| US7790264B2 (en) | 2007-04-17 | 2010-09-07 | Aplix, Inc. | Loop material for loop and hook type fastener used in a disposable article or garment |

| US7805818B2 (en) | 2001-09-05 | 2010-10-05 | The Procter & Gamble Company | Nonwoven loop member for a mechanical fastener |

| CN102454050A (zh) * | 2010-10-26 | 2012-05-16 | 台湾百和工业股份有限公司 | 粘扣带用毛面的制造方法,制造设备及粘扣带用毛面 |

| WO2012112768A1 (fr) | 2011-02-16 | 2012-08-23 | 3M Innovative Properties Company | Procédé de fabrication d'une bande de fixation mécanique et bande de fixation mécanique réticulée ainsi obtenue |

| WO2012121875A1 (fr) | 2011-03-09 | 2012-09-13 | 3M Innovative Properties Company | Matériau de boucles pour éléments de fixation à crochets et boucles |

| EP2545798A1 (fr) | 2011-07-13 | 2013-01-16 | 3M Innovative Properties Company | Système de produit sanitaire |

| WO2013040156A1 (fr) | 2011-09-16 | 2013-03-21 | 3M Innovative Properties Company | Fermeture mécanique, système de fermeture et article absorbant jetable |

| EP2447048A3 (fr) * | 2010-10-26 | 2013-12-04 | Taiwan Paiho Limited | Procédé de formation d'un élément de boucle pour dispositif de fixation à crochets et boucles, appareil pour réaliser le procédé et article fabriqué selon le procédé |

| US8673097B2 (en) | 2007-06-07 | 2014-03-18 | Velcro Industries B.V. | Anchoring loops of fibers needled into a carrier sheet |

| CN103653555A (zh) * | 2012-09-14 | 2014-03-26 | 台湾百和工业股份有限公司 | 黏扣带制造方法及黏扣带 |

| US8753459B2 (en) | 2002-12-03 | 2014-06-17 | Velcro Industries B.V. | Needling loops into carrier sheets |

| US8777919B2 (en) | 2010-12-07 | 2014-07-15 | 3M Innovative Properties Company | Fastening tab and method of making the same |

| US8784972B2 (en) | 2007-11-26 | 2014-07-22 | Kao Corporation | Composite sheet |

| US8790475B2 (en) | 2010-10-26 | 2014-07-29 | Taiwan Paiho Limited | Method for forming loop member of hook-and-loop fastener, apparatus for performing the method, and article manufactured by the method |

| KR20150081306A (ko) * | 2012-10-31 | 2015-07-13 | 킴벌리-클라크 월드와이드, 인크. | 흡수 용품 |

| KR20150081307A (ko) * | 2012-10-31 | 2015-07-13 | 킴벌리-클라크 월드와이드, 인크. | 흡수 용품 |

| US9138031B2 (en) | 2011-02-16 | 2015-09-22 | 3M Innovative Properties Company | Method of making a mechanical fastening strip and reticulated mechanical fastening strip therefrom |

| WO2016065134A1 (fr) | 2014-10-22 | 2016-04-28 | 3M Innovative Properties Company | Composants imprimés et leurs procédés de fabrication |

| US9327473B2 (en) | 2012-10-31 | 2016-05-03 | Kimberly-Clark Worldwide, Inc. | Fluid-entangled laminate webs having hollow projections and a process and apparatus for making the same |

| WO2016081438A1 (fr) | 2014-11-17 | 2016-05-26 | 3M Innovative Properties Company | Article absorbant et stratifié de fixation |

| US9480608B2 (en) | 2012-10-31 | 2016-11-01 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| WO2017030856A1 (fr) | 2015-08-14 | 2017-02-23 | 3M Innovative Properties Company | Tissu composite comprenant un film structuré, et son procédé de formation |

| WO2017112601A1 (fr) | 2015-12-21 | 2017-06-29 | 3M Innovative Properties Company | Procédé de fabrication d'un stratifié avec une couche thermoplastique étirée |

| US9713558B2 (en) | 2012-11-16 | 2017-07-25 | 3M Innovative Properties Company | Absorbent article including laminate and method of making the same |

| US9872542B2 (en) | 2011-08-25 | 2018-01-23 | Velcro BVBA | Loop-engageable fasteners and related systems and methods |

| US10070999B2 (en) | 2012-10-31 | 2018-09-11 | Kimberly-Clark Worldwide, Inc. | Absorbent article |

| WO2019005729A1 (fr) | 2017-06-29 | 2019-01-03 | 3M Innovative Properties Company | Procédé de fabrication d'un stratifié avec une couche thermoplastique étirée |

| WO2019005769A1 (fr) | 2017-06-29 | 2019-01-03 | 3M Innovative Properties Company | Procédé de fabrication de bandes multiples d'élément de fixation mécanique |

| US10376420B2 (en) | 2013-06-13 | 2019-08-13 | 3M Innovative Properties Company | Personal hygiene article and container for the same |

| US10704172B2 (en) | 2014-04-10 | 2020-07-07 | 3M Innovative Properties Company | Fibers and articles including them |

| WO2020142433A1 (fr) | 2018-12-31 | 2020-07-09 | 3M Innovative Properties Company | Article comportant un film microporeux et son procédé de fabrication |

| US10709619B2 (en) | 2013-06-13 | 2020-07-14 | 3M Innovative Properties Company | Fastening tape and mechanical fastener including microporous film |

| US10779618B2 (en) | 2016-08-08 | 2020-09-22 | 3M Innovative Properties Company | Sheet of loop material, method and apparatus for forming same |

| US11007093B2 (en) | 2017-03-30 | 2021-05-18 | Kimberly-Clark Worldwide, Inc. | Incorporation of apertured area into an absorbent article |

| WO2022112946A1 (fr) | 2020-11-28 | 2022-06-02 | 3M Innovative Properties Company | Article comprenant un film microporeux et adhésif coloré et procédé pour le fabriquer |

| US11365495B2 (en) | 2017-02-28 | 2022-06-21 | Kimberly-Clark Worldwide, Inc. | Process for making fluid-entangled laminate webs with hollow projections and apertures |

| EP3863580B1 (fr) | 2018-10-08 | 2022-08-31 | LK Mahnke GmbH & Co., KG | Couche jetable |

| WO2024079720A1 (fr) | 2022-10-14 | 2024-04-18 | 3M Innovative Properties Company | Fixation mécanique à nombre élevé d'éléments de fixation, stratifié de fixation et article absorbant |

Families Citing this family (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5032122A (en) * | 1987-04-24 | 1991-07-16 | The Procter & Gamble Company | Loop fastening material for fastening device and method of making same |

| US5380313A (en) * | 1987-06-19 | 1995-01-10 | The Proctor & Gamble Company | Loop fastening material for fastening device and method of making same |

| US5643397A (en) * | 1988-05-13 | 1997-07-01 | Minnesota Mining And Manufacturing Company | Equipment for forming a sheet of loop material |

| US5616394A (en) * | 1988-05-13 | 1997-04-01 | Minnesota Mining And Manufacturing Company | Sheet of loop material, and garments having such loop material incorporated therein |

| US5256231A (en) * | 1988-05-13 | 1993-10-26 | Minnesota Mining And Manufacturing Company | Method for making a sheet of loop material |

| US5149573A (en) * | 1990-06-01 | 1992-09-22 | Minnesota Mining And Manufacturing Company | Highly transparent strip material used for forming fasteners |

| TW317223U (en) | 1994-01-13 | 1997-10-01 | Minnesota Mining & Mfg | Abrasive article |

| US5517737A (en) * | 1994-06-06 | 1996-05-21 | The Procter & Gamble Company | Apparatus for continuously stretching or continuously releasing stretching forces from a web using two pairs of opposing non-planar belts |

| US5547531A (en) * | 1994-06-06 | 1996-08-20 | The Proctor & Gamble Company | Nonwoven female component for refastenable fastening device and method of making the same |

| US5762645A (en) * | 1994-06-06 | 1998-06-09 | The Procter & Gamble Company | Fastening device and method of use |

| US5595567A (en) * | 1994-08-09 | 1997-01-21 | The Procter & Gamble Company | Nonwoven female component for refastenable fastening device |

| US5476702A (en) * | 1994-12-28 | 1995-12-19 | Kimberly-Clark Corporation | Fastening system for absorbent article and method of manufacture |

| US5624427A (en) * | 1995-01-18 | 1997-04-29 | The Procter & Gamble Company | Female component for refastenable fastening device |

| US5763041A (en) * | 1995-12-21 | 1998-06-09 | Kimberly-Clark Worldwide, Inc. | Laminate material |

| US5699593A (en) * | 1996-08-30 | 1997-12-23 | Minnesota Mining & Manufacturing Company | Loop fastening material |

| US5931823A (en) | 1997-03-31 | 1999-08-03 | Kimberly-Clark Worldwide, Inc. | High permeability liner with improved intake and distribution |

| US5868987A (en) * | 1997-06-19 | 1999-02-09 | Minnesotamining And Manufacturing | Superimposed embossing of capped stem mechanical fastener structures |

| US5888607A (en) * | 1997-07-03 | 1999-03-30 | Minnesota Mining And Manufacturing Co. | Soft loop laminate and method of making |

| US6329016B1 (en) | 1997-09-03 | 2001-12-11 | Velcro Industries B.V. | Loop material for touch fastening |

| US6342285B1 (en) | 1997-09-03 | 2002-01-29 | Velcro Industries B.V. | Fastener loop material, its manufacture, and products incorporating the material |

| US6162522A (en) * | 1998-06-19 | 2000-12-19 | Kimberly-Clark Worldwide, Inc. | Loop substrate for releasably attachable abrasive sheet material |

| US6586066B1 (en) | 2000-03-21 | 2003-07-01 | Awi Licensing Company | Preglued underlayment composite and associated flooring installation system |

| US8678807B2 (en) | 2000-10-24 | 2014-03-25 | Velcro Industries B.V. | Molding apparatus and related methods |

| US20030171051A1 (en) | 2002-03-08 | 2003-09-11 | 3M Innovative Properties Company | Wipe |

| US7052565B2 (en) | 2003-01-27 | 2006-05-30 | 3M Innovative Properties Company | Web constructions with severed elongate strands |

| US7932196B2 (en) | 2003-08-22 | 2011-04-26 | Kimberly-Clark Worldwide, Inc. | Microporous stretch thinned film/nonwoven laminates and limited use or disposable product applications |

| US7303805B2 (en) | 2003-12-22 | 2007-12-04 | 3M Innovative Properties Company | Loop fabric |

| FR2870436B1 (fr) * | 2004-05-21 | 2006-07-14 | Aplix Sa | Film a filaments individuels ancres |

| MX2007003695A (es) | 2004-08-31 | 2007-05-18 | Henry K Obermeyer | Sistema de union de alta resistencia para compuestos reforzados con fibras. |

| US8734931B2 (en) | 2007-07-23 | 2014-05-27 | 3M Innovative Properties Company | Aerogel composites |

| CA2747385A1 (fr) | 2008-12-18 | 2010-07-15 | 3M Innovative Properties Company | Aerogels telecheliques hybrides |

| JP4823326B2 (ja) * | 2009-02-27 | 2011-11-24 | 大王製紙株式会社 | 止着用フロントシートを有する紙おむつ |

| US9138957B2 (en) | 2010-06-21 | 2015-09-22 | 3M Innovative Properties Company | Slit hook strips and laminates and articles containing the same |

| US9078793B2 (en) | 2011-08-25 | 2015-07-14 | Velcro Industries B.V. | Hook-engageable loop fasteners and related systems and methods |

| WO2014097634A1 (fr) * | 2012-12-21 | 2014-06-26 | 株式会社瑞光 | Procédé pour produire un article à porter jetable et dispositif d'adhésion utilisé dans celui-ci |

| WO2015178706A1 (fr) * | 2014-05-21 | 2015-11-26 | 백창원 | Velcro unidirectionnel ayant une aiguille à crochet et une boucle utilisant le principe du moment de force, le principe de frottement et d'élasticité dans un plan incliné, et analogue, et procédé de fabrication de boucle |

| EP3746293A4 (fr) * | 2018-01-31 | 2021-10-13 | 3M Innovative Properties Company | Article comprenant une couche composite et son procédé de fabrication |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3533871A (en) * | 1968-04-10 | 1970-10-13 | Armstrong Cork Co | Nonwoven tufted fabric by crimping |

| US3869764A (en) * | 1972-02-29 | 1975-03-11 | Int Fastener Ets | Press-on and split-off type fastener and manufacturing device therefor |

| GB2056332A (en) * | 1979-08-17 | 1981-03-18 | Siaco Ltd | Improvements in abrasive and polishing sheets |

| GB2168653A (en) * | 1984-12-12 | 1986-06-25 | Yoshida Kogyo Kk | Surface-type fastener with a mark thereon and method of providing such mark |

| EP0289198A1 (fr) * | 1987-04-24 | 1988-11-02 | The Procter & Gamble Company | Pièce femelle à boucles pour fermeture textile et procédé de fabrication |

-

1989

- 1989-04-27 AU AU33783/89A patent/AU622171B2/en not_active Ceased

- 1989-05-02 IL IL90159A patent/IL90159A/xx unknown

- 1989-05-04 MX MX015930A patent/MX173200B/es unknown

- 1989-05-09 CA CA000599067A patent/CA1333952C/fr not_active Expired - Fee Related

- 1989-05-10 DE DE89304709T patent/DE68908468T2/de not_active Expired - Lifetime

- 1989-05-10 ES ES89304709T patent/ES2043010T3/es not_active Expired - Lifetime

- 1989-05-10 EP EP89304709A patent/EP0341993B1/fr not_active Expired - Lifetime

- 1989-05-12 ZA ZA893577A patent/ZA893577B/xx unknown

- 1989-05-12 BR BR898902225A patent/BR8902225A/pt not_active IP Right Cessation

- 1989-05-12 JP JP1120214A patent/JP2896159B2/ja not_active Expired - Lifetime

- 1989-05-13 KR KR1019890006448A patent/KR960013457B1/ko not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3533871A (en) * | 1968-04-10 | 1970-10-13 | Armstrong Cork Co | Nonwoven tufted fabric by crimping |

| US3869764A (en) * | 1972-02-29 | 1975-03-11 | Int Fastener Ets | Press-on and split-off type fastener and manufacturing device therefor |

| GB2056332A (en) * | 1979-08-17 | 1981-03-18 | Siaco Ltd | Improvements in abrasive and polishing sheets |

| GB2168653A (en) * | 1984-12-12 | 1986-06-25 | Yoshida Kogyo Kk | Surface-type fastener with a mark thereon and method of providing such mark |

| EP0289198A1 (fr) * | 1987-04-24 | 1988-11-02 | The Procter & Gamble Company | Pièce femelle à boucles pour fermeture textile et procédé de fabrication |

Cited By (86)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6849142B1 (en) | 1991-05-20 | 2005-02-01 | The Procter & Gamble Company | Method of making multi-layer female component for refastenable fastening device |

| TR27991A (tr) * | 1991-05-20 | 1995-11-16 | Procter & Gamble | Yeniden baglanabilir baglama araci icin dokunmamis disi bilesen ve bunu yapmaya mahsus yöntem. |

| USRE38652E1 (en) | 1992-08-20 | 2004-11-16 | Velcro Industries B.V. | Hook for hook and loop fasteners |

| US5607345A (en) * | 1994-01-13 | 1997-03-04 | Minnesota Mining And Manufacturing Company | Abrading apparatus |

| WO1995019242A1 (fr) * | 1994-01-13 | 1995-07-20 | Minnesota Mining And Manufacturing Company | Article abrasif, son procede de fabrication et machine a abraser |

| EP0712590A3 (fr) * | 1994-11-18 | 1997-01-15 | Acushnet Co | Gant possédant une inscription sur les boucles et crochets |

| EP0800808A1 (fr) * | 1995-10-27 | 1997-10-15 | Kao Corporation | Article absorbant |

| EP0800808A4 (fr) * | 1995-10-27 | 2004-03-10 | Kao Corp | Article absorbant |

| WO1997024482A1 (fr) * | 1995-12-29 | 1997-07-10 | Kimberly-Clark Worldwide, Inc. | Bande de non-tisse non lie a motif et son procede de fabrication |

| WO1998006290A1 (fr) * | 1996-08-14 | 1998-02-19 | Minnesota Mining And Manufacturing Company | Procede et installation servant a fabriquer rapidement un materiau a boucles |

| US6039911A (en) * | 1997-01-09 | 2000-03-21 | 3M Innovative Properties Company | Method for capping stem fasteners |

| DE19722748C2 (de) * | 1997-05-30 | 2002-04-18 | Corovin Gmbh | Schlaufenmaterial |

| DE19722748A1 (de) * | 1997-05-30 | 1998-12-03 | Corovin Gmbh | Schlaufenmaterial |

| KR100478761B1 (ko) * | 1997-10-31 | 2005-07-25 | 유니챰 가부시키가이샤 | 메카니칼파스너의암부재 |

| EP0913104A3 (fr) * | 1997-10-31 | 1999-09-29 | Uni-Charm Corporation | Elément femelle d'une fermeture à crochets et à boucles |

| EP1048236A3 (fr) * | 1999-03-26 | 2001-09-05 | Uni-Charm Corporation | Fixation mécanique |

| US7160600B2 (en) | 1999-05-28 | 2007-01-09 | Velcro Industries B.V. | Hook-engageable fastener sheets, and methods and articles of manufacture |

| US8500940B2 (en) | 1999-05-28 | 2013-08-06 | Velcro Industries B.V. | Hook-engageable fastener sheets, and methods and articles of manufacture |

| WO2000073063A1 (fr) * | 1999-05-28 | 2000-12-07 | Velcro Industries B.V. | Presentoirs et decorations utilisant des fixations detachables |

| US7785095B2 (en) | 2001-03-14 | 2010-08-31 | Velcro Industries B.V. | Molding apparatus and related methods |

| WO2002077349A1 (fr) * | 2001-03-23 | 2002-10-03 | 3M Innovative Properties Company | Tissu composite pour le controle de fluides |

| US7282251B2 (en) | 2001-06-12 | 2007-10-16 | Vekro Industries B.V. | Loop materials for touch fastening |

| US7805818B2 (en) | 2001-09-05 | 2010-10-05 | The Procter & Gamble Company | Nonwoven loop member for a mechanical fastener |

| USD640064S1 (en) | 2002-09-05 | 2011-06-21 | The Procter & Gamble Company | Nonwoven material with pattern element |

| US9259059B2 (en) | 2002-09-05 | 2016-02-16 | The Procter & Gamble Company | Nonwoven loop member for a mechanical fastener |

| USD642809S1 (en) | 2002-09-05 | 2011-08-09 | The Procter & Gamble Company | Nonwoven material with pattern element |

| US7851047B2 (en) | 2002-11-13 | 2010-12-14 | Kao Corporation | Composite sheet and process and apparatus for producing the same |

| US7468114B2 (en) | 2002-11-13 | 2008-12-23 | Kao Corporation | Composite sheet and process and apparatus for producing the same |

| US8393374B2 (en) | 2002-11-13 | 2013-03-12 | Kao Corporation | Apparatus for producing a composite sheet |

| US8753459B2 (en) | 2002-12-03 | 2014-06-17 | Velcro Industries B.V. | Needling loops into carrier sheets |

| WO2008003438A1 (fr) * | 2006-07-05 | 2008-01-10 | Nuova Pansac S.P.A. | Dispositif d'attache mécanique libérable |

| US7960008B2 (en) | 2007-04-17 | 2011-06-14 | Aplix, Inc. | Loop material for loop and hook type fastener used in a disposable article or garment |

| US7790264B2 (en) | 2007-04-17 | 2010-09-07 | Aplix, Inc. | Loop material for loop and hook type fastener used in a disposable article or garment |

| USRE45946E1 (en) | 2007-04-17 | 2016-03-29 | Aplix, Inc. | Loop material for loop and hook type fastener used in a disposable article or garment |

| USRE44842E1 (en) | 2007-04-17 | 2014-04-15 | Aplix, Inc. | Loop material for loop and hook type fastener used in a disposable article or garment |

| US8673097B2 (en) | 2007-06-07 | 2014-03-18 | Velcro Industries B.V. | Anchoring loops of fibers needled into a carrier sheet |

| US8784972B2 (en) | 2007-11-26 | 2014-07-22 | Kao Corporation | Composite sheet |

| EP2447048A3 (fr) * | 2010-10-26 | 2013-12-04 | Taiwan Paiho Limited | Procédé de formation d'un élément de boucle pour dispositif de fixation à crochets et boucles, appareil pour réaliser le procédé et article fabriqué selon le procédé |

| CN102454050A (zh) * | 2010-10-26 | 2012-05-16 | 台湾百和工业股份有限公司 | 粘扣带用毛面的制造方法,制造设备及粘扣带用毛面 |

| US8790475B2 (en) | 2010-10-26 | 2014-07-29 | Taiwan Paiho Limited | Method for forming loop member of hook-and-loop fastener, apparatus for performing the method, and article manufactured by the method |

| US8777919B2 (en) | 2010-12-07 | 2014-07-15 | 3M Innovative Properties Company | Fastening tab and method of making the same |

| US9138031B2 (en) | 2011-02-16 | 2015-09-22 | 3M Innovative Properties Company | Method of making a mechanical fastening strip and reticulated mechanical fastening strip therefrom |

| US10456303B2 (en) | 2011-02-16 | 2019-10-29 | 3M Innovative Properties Company | Method of making a mechanical fastening strip and reticulated mechanical fastening strip therefrom |

| WO2012112768A1 (fr) | 2011-02-16 | 2012-08-23 | 3M Innovative Properties Company | Procédé de fabrication d'une bande de fixation mécanique et bande de fixation mécanique réticulée ainsi obtenue |

| WO2012121875A1 (fr) | 2011-03-09 | 2012-09-13 | 3M Innovative Properties Company | Matériau de boucles pour éléments de fixation à crochets et boucles |

| US9913766B2 (en) | 2011-07-13 | 2018-03-13 | 3M Innovative Properties Company | Sanitary product system |

| EP2545798A1 (fr) | 2011-07-13 | 2013-01-16 | 3M Innovative Properties Company | Système de produit sanitaire |

| WO2013009964A1 (fr) | 2011-07-13 | 2013-01-17 | 3M Innovative Properties Company | Système pour article hygiénique |

| US9872542B2 (en) | 2011-08-25 | 2018-01-23 | Velcro BVBA | Loop-engageable fasteners and related systems and methods |

| WO2013040156A1 (fr) | 2011-09-16 | 2013-03-21 | 3M Innovative Properties Company | Fermeture mécanique, système de fermeture et article absorbant jetable |

| US10165833B2 (en) | 2011-09-16 | 2019-01-01 | 3M Innovative Properties Company | Mechanical fastener, fastening system, and disposable absorbent article |

| CN103653555B (zh) * | 2012-09-14 | 2015-10-21 | 台湾百和工业股份有限公司 | 黏扣带制造方法及黏扣带 |

| CN103653555A (zh) * | 2012-09-14 | 2014-03-26 | 台湾百和工业股份有限公司 | 黏扣带制造方法及黏扣带 |

| US9474660B2 (en) | 2012-10-31 | 2016-10-25 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| KR20150081307A (ko) * | 2012-10-31 | 2015-07-13 | 킴벌리-클라크 월드와이드, 인크. | 흡수 용품 |

| US9480608B2 (en) | 2012-10-31 | 2016-11-01 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| US9480609B2 (en) | 2012-10-31 | 2016-11-01 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| US10478354B2 (en) | 2012-10-31 | 2019-11-19 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| US10470947B2 (en) | 2012-10-31 | 2019-11-12 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid-entangled body facing material including a plurality of hollow projections |

| US11491058B2 (en) | 2012-10-31 | 2022-11-08 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid entangled body facing material including a plurality of projections |

| US9327473B2 (en) | 2012-10-31 | 2016-05-03 | Kimberly-Clark Worldwide, Inc. | Fluid-entangled laminate webs having hollow projections and a process and apparatus for making the same |

| US10070999B2 (en) | 2012-10-31 | 2018-09-11 | Kimberly-Clark Worldwide, Inc. | Absorbent article |

| US12029633B2 (en) | 2012-10-31 | 2024-07-09 | Kimberly-Clark Worldwide, Inc. | Absorbent article with a fluid entangled body facing material including a plurality of projections |

| KR20150081306A (ko) * | 2012-10-31 | 2015-07-13 | 킴벌리-클라크 월드와이드, 인크. | 흡수 용품 |

| US9713558B2 (en) | 2012-11-16 | 2017-07-25 | 3M Innovative Properties Company | Absorbent article including laminate and method of making the same |

| US10376420B2 (en) | 2013-06-13 | 2019-08-13 | 3M Innovative Properties Company | Personal hygiene article and container for the same |

| US10709619B2 (en) | 2013-06-13 | 2020-07-14 | 3M Innovative Properties Company | Fastening tape and mechanical fastener including microporous film |

| US10704172B2 (en) | 2014-04-10 | 2020-07-07 | 3M Innovative Properties Company | Fibers and articles including them |

| US10687588B2 (en) | 2014-10-22 | 2020-06-23 | 3M Innovative Properties Company | Printed components and methods for making the same |

| WO2016065134A1 (fr) | 2014-10-22 | 2016-04-28 | 3M Innovative Properties Company | Composants imprimés et leurs procédés de fabrication |

| US10973710B2 (en) | 2014-11-17 | 2021-04-13 | 3M Innovative Properties Company | Absorbent article and fastening laminate |

| WO2016081438A1 (fr) | 2014-11-17 | 2016-05-26 | 3M Innovative Properties Company | Article absorbant et stratifié de fixation |

| WO2017030856A1 (fr) | 2015-08-14 | 2017-02-23 | 3M Innovative Properties Company | Tissu composite comprenant un film structuré, et son procédé de formation |

| US11020949B2 (en) | 2015-12-21 | 2021-06-01 | 3M Innovative Properties Company | Method of making a laminate with a stretched thermoplastic layer |

| WO2017112601A1 (fr) | 2015-12-21 | 2017-06-29 | 3M Innovative Properties Company | Procédé de fabrication d'un stratifié avec une couche thermoplastique étirée |

| US10967624B2 (en) | 2015-12-21 | 2021-04-06 | 3M Innovative Properties Company | Fastening articles and methods of making the same |

| US10779618B2 (en) | 2016-08-08 | 2020-09-22 | 3M Innovative Properties Company | Sheet of loop material, method and apparatus for forming same |

| US11365495B2 (en) | 2017-02-28 | 2022-06-21 | Kimberly-Clark Worldwide, Inc. | Process for making fluid-entangled laminate webs with hollow projections and apertures |

| US11007093B2 (en) | 2017-03-30 | 2021-05-18 | Kimberly-Clark Worldwide, Inc. | Incorporation of apertured area into an absorbent article |

| US11998430B2 (en) | 2017-03-30 | 2024-06-04 | Kimberly-Clark Worldwide, Inc. | Incorporation of apertured area into an absorbent article |

| WO2019005769A1 (fr) | 2017-06-29 | 2019-01-03 | 3M Innovative Properties Company | Procédé de fabrication de bandes multiples d'élément de fixation mécanique |

| WO2019005729A1 (fr) | 2017-06-29 | 2019-01-03 | 3M Innovative Properties Company | Procédé de fabrication d'un stratifié avec une couche thermoplastique étirée |

| EP3863580B1 (fr) | 2018-10-08 | 2022-08-31 | LK Mahnke GmbH & Co., KG | Couche jetable |

| WO2020142433A1 (fr) | 2018-12-31 | 2020-07-09 | 3M Innovative Properties Company | Article comportant un film microporeux et son procédé de fabrication |

| WO2022112946A1 (fr) | 2020-11-28 | 2022-06-02 | 3M Innovative Properties Company | Article comprenant un film microporeux et adhésif coloré et procédé pour le fabriquer |

| WO2024079720A1 (fr) | 2022-10-14 | 2024-04-18 | 3M Innovative Properties Company | Fixation mécanique à nombre élevé d'éléments de fixation, stratifié de fixation et article absorbant |

Also Published As

| Publication number | Publication date |

|---|---|

| KR960013457B1 (ko) | 1996-10-05 |

| ZA893577B (en) | 1991-01-30 |

| DE68908468D1 (de) | 1993-09-23 |

| AU3378389A (en) | 1989-11-16 |

| MX173200B (es) | 1994-02-08 |

| CA1333952C (fr) | 1995-01-17 |

| EP0341993B1 (fr) | 1993-08-18 |

| ES2043010T3 (es) | 1993-12-16 |

| IL90159A (en) | 1993-07-08 |

| AU622171B2 (en) | 1992-04-02 |

| JP2896159B2 (ja) | 1999-05-31 |

| BR8902225A (pt) | 1990-01-02 |

| JPH0218036A (ja) | 1990-01-22 |

| DE68908468T2 (de) | 1994-03-03 |

| KR890016937A (ko) | 1989-12-14 |

| IL90159A0 (en) | 1989-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0341993B1 (fr) | Matériau en feuille utilisé pour la formation de l'élément à boucles d'une fermeture du type à crochets et à boucles | |

| EP0957702B1 (fr) | Materiau de fixation a boucles | |

| EP0319249B1 (fr) | Couche à jeter avec élément de fermeture | |

| KR100263353B1 (ko) | 재고착가능한 고착 장치용 부직 암형 부재 및 그의 제조 방법 | |

| KR100195810B1 (ko) | 루프재 시트와, 루프재 시트 형성장치 및 방법과, 이 루프재 시트를 구비한 가먼트 및 기저귀 | |

| US5888607A (en) | Soft loop laminate and method of making | |

| US5354591A (en) | Coated abrasive sheet material with loop material for attachment incorporated therein | |

| US5763041A (en) | Laminate material | |

| KR100263794B1 (ko) | 재고착가능한 고착 장치용 다층 암형 부재 및 그의 제조 방법 | |

| US4761318A (en) | Loop fastener portion with thermoplastic resin attaching and anchoring layer | |

| RU2196047C2 (ru) | Слоистый материал, используемый в качестве петельчатого компонента застежки | |

| US5616394A (en) | Sheet of loop material, and garments having such loop material incorporated therein | |

| CA1122786A (fr) | Organes d'assemblage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB GR IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900301 |

|

| 17Q | First examination report despatched |

Effective date: 19910930 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB GR IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 68908468 Country of ref document: DE Date of ref document: 19930923 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3008788 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2043010 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 89304709.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950412 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19950428 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19960531 Ref country code: LI Effective date: 19960531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19961130 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3008788 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20070524 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080526 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20080529 Year of fee payment: 20 Ref country code: DE Payment date: 20080630 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080528 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080529 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081201 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20090509 |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090509 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080519 Year of fee payment: 20 |