EP0337922B1 - Heating plant - Google Patents

Heating plant Download PDFInfo

- Publication number

- EP0337922B1 EP0337922B1 EP89710027A EP89710027A EP0337922B1 EP 0337922 B1 EP0337922 B1 EP 0337922B1 EP 89710027 A EP89710027 A EP 89710027A EP 89710027 A EP89710027 A EP 89710027A EP 0337922 B1 EP0337922 B1 EP 0337922B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- temperature

- heat exchanger

- heating

- burner

- temperature sensor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010438 heat treatment Methods 0.000 title claims abstract description 11

- 239000008236 heating water Substances 0.000 claims abstract description 10

- 239000000446 fuel Substances 0.000 claims abstract description 6

- 238000010079 rubber tapping Methods 0.000 claims description 3

- 239000008399 tap water Substances 0.000 claims 5

- 235000020679 tap water Nutrition 0.000 claims 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract description 39

- 230000001105 regulatory effect Effects 0.000 description 6

- 238000000034 method Methods 0.000 description 5

- 239000007789 gas Substances 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000002737 fuel gas Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24D—DOMESTIC- OR SPACE-HEATING SYSTEMS, e.g. CENTRAL HEATING SYSTEMS; DOMESTIC HOT-WATER SUPPLY SYSTEMS; ELEMENTS OR COMPONENTS THEREFOR

- F24D19/00—Details

- F24D19/10—Arrangement or mounting of control or safety devices

- F24D19/1006—Arrangement or mounting of control or safety devices for water heating systems

- F24D19/1066—Arrangement or mounting of control or safety devices for water heating systems for the combination of central heating and domestic hot water

- F24D19/1069—Arrangement or mounting of control or safety devices for water heating systems for the combination of central heating and domestic hot water regulation in function of the temperature of the domestic hot water

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H15/00—Control of fluid heaters

- F24H15/20—Control of fluid heaters characterised by control inputs

- F24H15/212—Temperature of the water

- F24H15/223—Temperature of the water in the water storage tank

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H15/00—Control of fluid heaters

- F24H15/30—Control of fluid heaters characterised by control outputs; characterised by the components to be controlled

- F24H15/305—Control of valves

Definitions

- the invention relates to a method for controlling a heating system with a primary heat exchanger that can be heated by a burner and to the flow of the primary heat exchanger via a three-way valve connected to the heating water circulation lines for heating a secondary heat exchanger arranged in a domestic hot water tank and at least one radiator, with a first temperature sensor in one for the secondary heat exchanger of the hot water tank leading branch of the flow line of the primary heat exchanger and a second temperature sensor are arranged in or on the hot water tank or its tap line and to control the three-way valve and a valve regulating the fuel supply to the burner, the two temperature sensors via signal lines to a common, via control lines with which the fuel supply to The burner regulating valve and the regulator connected to the three-way valve are connected.

- this process water temperature is also dependent on the respective draw-off quantity and on the temperature of the cold water flowing from the supply line to the storage tank.

- the object of the invention is therefore to provide a method in which there is a guarantee of a constant, arbitrarily selectable hot water temperature which is independent of the respective cold water temperature and the respective tap quantity, in particular when the system is operated by means of a single-stage burner.

- the object is achieved in that, in the case of hot water tapping or recharging, the output of the burner is regulated as a function of the temperature detected by the first temperature sensor and its deviation from a target value, this target value depending on the difference between a set hot water temperature and the temperature measured by the second temperature sensor.

- a preselectable outlet temperature of the domestic water at the tap can be guaranteed regardless of the temperature of the incoming cold water and regardless of the respective tap quantity.

- a flow switch can be arranged in its cold water supply line or in its tap line, which starts the burner regardless of the instantaneous temperature of the storage water. If the burner is equipped with a combustion air or exhaust gas blower, the blower is operated continuously from the first burner cycle until the end of the tap cycle in order to achieve a delay-free cycle of the burner and thus to limit the fluctuations in the flow temperature to a minimum.

- the water heating system comprises a burner that heats a water-carrying heat exchanger 1, preferably a gas burner 2 Fuel gas is supplied via a gas supply line 3 and a valve 4 regulating the gas supply.

- This primary heat exchanger 1 emits heating water via a supply line 5 and is connected to a return line 6, which returns the cooled heating water.

- a three-way valve 7 is arranged, which either opens the way to a heating circuit 8 in which there is at least one heating element 9, or - during the continuous or recharging operation - the flow flowing from the primary heat exchanger the way to a secondary heat exchanger 11 of a hot water tank 12 via the circulation line 10 opens.

- a tap line 13 with at least one tap valve 14 and a tap point 15 starts from the hot water tank 12.

- the hot water tank 12 is supplied with cold water from the supply line 16.

- the flow switch 17 can be arranged, which is connected to the controller 22 via a signal line 25 and starts the continuous operation of the domestic hot water tank 12 as soon as a tap is taken.

- the system comprises at least two temperature sensors, namely a temperature sensor 18 in the flow line 10 of the heating water heating the hot water tank 12 and a temperature sensor 19 arranged in or on this hot water tank 12 itself or on the tap line 13.

- temperature sensors 18 and 19 are connected via signal lines 20 and 21 to a common controller 22 which controls the valve 4 regulating the fuel supply to the burner 2 via the control line 23 and the three-way valve 7 via the control line 24, depending on the two of them measured values transmitted by the temperature sensors 18 and 19.

- the controller 22 is assigned a preselection device 26 for the desired hot water temperature and connected to it via a control line 27.

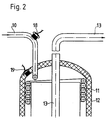

- Figure 2 shows the head area of the domestic hot water tank 12 on a larger scale, together with the connection of the hot water circulating line 10 and the outlet of the tap line 13 and with part of the coil forming the secondary heat exchanger 11.

- the output of the burner 2 is regulated as a function of the temperature detected by the temperature sensor 18 in the flow line 10 and its deviation from a predetermined target value.

- This target value is formed by the controller 22 as a function of the difference between the hot water temperature set on the preselection device 26 and the temperature measured on the sensor 19.

- the target value for the flow temperature is reduced, thus ensuring a hot water temperature that is independent of the cold water temperature and the flow rate (draw-off volume).

- this temperature sensor 19 also takes over the function of a mechanical thermostat that regulates the temperature of the storage water and starts or ends a recharging of the domestic water storage.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Thermal Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Steam Or Hot-Water Central Heating Systems (AREA)

- Sorption Type Refrigeration Machines (AREA)

- Investigating Or Analyzing Materials By The Use Of Fluid Adsorption Or Reactions (AREA)

- Display Devices Of Pinball Game Machines (AREA)

- Air-Conditioning For Vehicles (AREA)

- General Preparation And Processing Of Foods (AREA)

- Domestic Hot-Water Supply Systems And Details Of Heating Systems (AREA)

- General Induction Heating (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zur Regelung einer Heizungsanlage mit einem durch einen Brenner beheizbaren, heizwasserführenden Primärwärmetauscher sowie an den Vorlauf des Primärwärmetauschers über ein Dreiwegeventil angeschlossene Heizwasserumlaufleitungen zur Erwärmung eines in einem Brauchwasserspeicher angeordneten Sekundärwärmetauschers und mindestens eines Heizkörpers, wobei ein erster Temperaturfühler in einem zum Sekundärwärmetauscher des Brauchwasserspeichers führenden Zweig der Vorlaufleitung des Primärwärmetauschers und ein zweiter Temperaturfühler im oder am Brauchwasserspeicher oder dessen Zapfleitung angeordnet sind und zur Steuerung des Dreiwegeventiles und eines die Brennstoffzufuhr zum Brenner regelnden Ventiles die beiden Temperaturfühler über Signalleitungen an einen gemeinsamen, über Steuerleitungen mit dem die Brennstoffzufuhr zum Brenner regelnden Ventil und mit dem Dreiwegeventil verbundenen Regler angeschlossen sind.The invention relates to a method for controlling a heating system with a primary heat exchanger that can be heated by a burner and to the flow of the primary heat exchanger via a three-way valve connected to the heating water circulation lines for heating a secondary heat exchanger arranged in a domestic hot water tank and at least one radiator, with a first temperature sensor in one for the secondary heat exchanger of the hot water tank leading branch of the flow line of the primary heat exchanger and a second temperature sensor are arranged in or on the hot water tank or its tap line and to control the three-way valve and a valve regulating the fuel supply to the burner, the two temperature sensors via signal lines to a common, via control lines with which the fuel supply to The burner regulating valve and the regulator connected to the three-way valve are connected.

Anlagen dieser Art - bekannt aus der EP-A-146 264, der DE-A-21 32 745 oder der DE-A-21 42 545 - arbeiten bisher in einem weiten Umfang ihres Arbeitsbereiches zur Bereitstellung warmen Brauchwassers im Taktbetrieb, wobei es zwangsläufig zu Schwankungen der Temperatur des das Brauchwasser beheizenden Heizwassers kommt, die sich negativ auf die wünschenswerte Konstanthaltung der Brauchwassertemperatur auswirken.Systems of this type - known from EP-A-146 264, DE-A-21 32 745 or DE-A-21 42 545 - have so far been working in a wide range of their work area for providing hot water in cyclical operation, whereby it is inevitable there are fluctuations in the temperature of the heating water that heats the process water, which have a negative effect on the desirable constant maintenance of the process water temperature.

Außerdem ist diese Brauchwassertemperatur auch bei gleichbleibender Temperatur des beheizenden Wassers, zum Beispiel bei Einsatz eines modulierbaren Brenners, auch noch von der jeweiligen Zapfmenge und von der Temperatur des dem Speicher aus der Versorgungsleitung zuströmenden Kaltwassers abhängig.In addition, this process water temperature, even when the temperature of the heating water remains the same, for example when using a modular burner, is also dependent on the respective draw-off quantity and on the temperature of the cold water flowing from the supply line to the storage tank.

Aufgabe der Erfindung ist es deshalb, ein Verfahren anzugeben, bei dem eine von der jeweiligen Kaltwassertemperatur und von der jeweiligen Zapfmenge unabhängige Gewährleistung einer konstanten, beliebig wählbaren Brauchwassertemperatur, insbesondere bei einem Betrieb der Anlage mittels eines einstufigen Brenners, gegeben ist.The object of the invention is therefore to provide a method in which there is a guarantee of a constant, arbitrarily selectable hot water temperature which is independent of the respective cold water temperature and the respective tap quantity, in particular when the system is operated by means of a single-stage burner.

Erfindungsgemäß wird die Aufgabe dadurch gelöst, daß bei Brauchwasserzapfung bzw. -nachladung die Leistungsabgabe des Brenners in Abhängigkeit von der durch den ersten Temperaturfühler erfaßten Temperatur und deren Abweichung von einem Soll-Wert geregelt wird, wobei dieser Soll-Wert in Abhängigkeit von der Differenz zwischen einer eingestellten Brauchwassertemperatur und der durch den zweiten Temperaturfühler gemessenen Temperatur gebildet wird.According to the invention the object is achieved in that, in the case of hot water tapping or recharging, the output of the burner is regulated as a function of the temperature detected by the first temperature sensor and its deviation from a target value, this target value depending on the difference between a set hot water temperature and the temperature measured by the second temperature sensor.

Durch die Rückwirkung der beiden Temperaturfühler auf die Stellung des Dreiwegeventils und die Brennerfunktion kann eine vorwählbare Auslauftemperatur des Brauchwassers an der Zapfstelle unabhängig von der Temperatur des zuströmenden Kaltwassers und unabhängig von der jeweiligen Zapfmenge gewährleistet werden.Due to the reaction of the two temperature sensors to the position of the three-way valve and the burner function, a preselectable outlet temperature of the domestic water at the tap can be guaranteed regardless of the temperature of the incoming cold water and regardless of the respective tap quantity.

Zur Auslösung des Durchlaufbetriebes des Brauchwasserspeichers kann in dessen Kaltwasserversorgungsleitung oder in dessen Zapfleitung ein Strömungsschalter angeordnet sein, der den Brenner unabhängig von der augenblicklichen Temperatur des Speicherwassers startet. Ist der Brenner mit einem Verbrennungsluft- oder Abgasgebläse ausgerüstet, wird ab dem ersten Brennertakt bis zum Ende des Zapfzyklus das Gebläse im Dauerlauf betrieben, um ein verzögerungsfreies Takten des Brenners zu erreichen und damit die Schwankungen der Vorlauftemperatur auf ein Minimum zu begrenzen.To trigger the continuous operation of the hot water storage tank, a flow switch can be arranged in its cold water supply line or in its tap line, which starts the burner regardless of the instantaneous temperature of the storage water. If the burner is equipped with a combustion air or exhaust gas blower, the blower is operated continuously from the first burner cycle until the end of the tap cycle in order to achieve a delay-free cycle of the burner and thus to limit the fluctuations in the flow temperature to a minimum.

Ein Ausführungsbeispiel des Erfindungsgegenstandes ist in den Zeichnungen veranschaulicht.An embodiment of the subject matter of the invention is illustrated in the drawings.

Im einzelnen zeigen:

- Figur 1

- das Schaltschema der Anlage und

- Figur 2

- den Kopf des Brauchwasserspeichers.

- Figure 1

- the circuit diagram of the system and

- Figure 2

- the head of the domestic hot water tank.

Die erfindungsgemäße Wasserbeheizungsanlage umfaßt gemäß Figur 1 einen einen wasserführenden Wärmetauscher 1 beheizenden Brenner, vorzugsweise einen Gasbrenner 2, dem über eine Gaszufuhrleitung 3 und ein die Gaszufuhr regelndes Ventil 4 Brenngas zugeführt wird.According to FIG. 1, the water heating system according to the invention comprises a burner that heats a water-carrying heat exchanger 1, preferably a gas burner 2 Fuel gas is supplied via a

Dieser Primärwärmetauscher 1 gibt über eine Vorlaufleitung 5 Heizwasser ab und ist an eine Rücklaufleitung 6 angeschlossen, die das abgekühlte Heizwasser rückführt.This primary heat exchanger 1 emits heating water via a supply line 5 and is connected to a return line 6, which returns the cooled heating water.

In der Vorlaufleitung 5 ist ein Dreiwegeventil 7 angeordnet, das dem Vorlauf entweder den Weg in einen Heizkreis 8 freigibt, in dem sich zumindest ein Heizkörper 9 befindet, oder - während des Durchlauf- oder Nachladebetriebes - dem vom Primärwärmetauscher zuströmenden Vorlauf den Weg zu einem Sekundärwärmetauscher 11 eines Warmwasserspeichers 12 über die Umlaufleitung 10 öffnet. Vom Warmwasserspeicher 12 geht eine Zapfleitung 13 mit zumindest einem Zapfventil 14 und einer Zapfstelle 15 aus.In the flow line 5, a three-

Der Brauchwasserspeicher 12 wird aus der Versorgungsleitung 16 mit Kaltwasser versorgt. In dieser Versorgungsleitung 16 (oder in der Zapfleitung 13) kann der Strömungsschalter 17 angeordnet sein, der über eine Signalleitung 25 mit dem Regler 22 verbunden ist und den Durchlaufbetrieb des Brauchwasserspeichers 12 startet, sobald eine Zapfung erfolgt.The

Die Anlage umfaßt zumindest zwei Temperaturfühler, nämlich einen Temperaturfühler 18 im Vorlauf der Umlaufleitung 10 des den Brauchwasserspeicher 12 beheizenden Heizwassers und einen in oder an diesem Brauchwasserspeicher 12 selbst oder an der Zapfleitung 13 angeordneten Temperaturfühler 19.The system comprises at least two temperature sensors, namely a

Diese Temperaturfühler 18 und 19 sind über Signalleitungen 20 beziehungsweise 21 mit einem gemeinsamen Regler 22 verbunden, der über die Steuerleitung 23 das die Brennstoffzufuhr zum Brenner 2 regelnde Ventil 4 und über die Steuerleitung 24 das Dreiwegeventil 7 steuert, und zwar in Abhängigkeit von den beiden ihm seitens der Temperaturfühler 18 und 19 übermittelten Meßwerte.These

Dem Regler 22 ist eine Vorwahleinrichtung 26 für die gewünschte Brauchwassertemperatur zugeordnet und über eine Steuerleitung 27 mit diesem verbunden.The

Figur 2 zeigt den Kopfbereich des Brauchwasserspeichers 12 in einem größeren Maßstab, samt dem Anschluß der heizwasserführenden Umlaufleitung 10 und dem Ausgang der Zapfleitung 13 sowie mit einem Teil der den Sekundärwärmetauscher 11 bildenden Rohrschlange.Figure 2 shows the head area of the domestic

Die Leistungsabgabe des Brenners 2 wird in Abhängigkeit von der durch den Temperaturfühler 18 in der Vorlaufleitung 10 erfaßten Temperatur und deren Abweichung von einem vorgegebenen Soll-Wert geregelt. Dieser Soll-Wert wird durch den Regler 22 in Abhängigkeit von der Differenz zwischen der an der Vorwahleinrichtung 26 eingestellten Brauchwassertemperatur und der am Fühler 19 gemessenen Temperatur gebildet.The output of the burner 2 is regulated as a function of the temperature detected by the

Mit steigender Brauchwassertemperatur wird der Soll-Wert für die Vorlauftemperatur zurückgenommen und somit eine von der Kaltwassertemperatur und der Durchflußmenge (Zapfmenge) unabhängige Brauchwassertemperatur gewährleistet.As the hot water temperature increases, the target value for the flow temperature is reduced, thus ensuring a hot water temperature that is independent of the cold water temperature and the flow rate (draw-off volume).

Außerhalb der Zapfzeiten übernimmt dieser Temperaturfühler 19 auch die Funktion eines die Temperatur des Speicherwassers regelnden mechanischen Thermostaten und startet beziehungsweise beendet eine Nachladung des Brauchwasserspeichers.Outside the tapping times, this

Claims (1)

- A heating system that comprises a primary heat exchanger (1), which conducts room-heating water and is heatable by a burner (2), and room-heating water circulating lines (10 and 8), which are connected to the flow line (5) from the primary heat exchanger (1) by a three-way valve (7) and serve to heat a secondary heat exchanger (11), which is disposed in a tap water accumulator (12), and to heat at least one radiator (9), wherein a first temperature sensor (18) is provided in a branch line (5), which from the flow line (5) leading from the primary heat exchanger (1) extends to the secondary heat exchanger (11) of the tap water accumulator (12), and a second temperature sensor (19) is provided in or at the tap water accumulator (12) or its tap line (13), and for a control of the three-way valve (7) and of a valve (4) controlling the fuel supply to the ourner (2) the two temperature sensors (18 and 19) are connected by signal lines (20 and 21) to a common controller (22), which is connected by control lines (23and 24) to the valve (4) by which the fuel supply to the burner (2) is controlled to the three-way valve (7), characterized in that during a tapping or heating of tap water the output power of the burner (2) is automatically controlled in dependence on the temperature that is detected by the first temperature sensor (18) and on the deviation of said temperature from a setpoint is determined in dependence on the difference between a preset tap water temperature and the temperature that is detected by the second temperature sensor (19).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT978/88 | 1988-04-15 | ||

| AT0097888A AT389584B (en) | 1988-04-15 | 1988-04-15 | HEATING SYSTEM |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0337922A2 EP0337922A2 (en) | 1989-10-18 |

| EP0337922A3 EP0337922A3 (en) | 1990-10-31 |

| EP0337922B1 true EP0337922B1 (en) | 1994-02-02 |

Family

ID=3504143

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89710027A Expired - Lifetime EP0337922B1 (en) | 1988-04-15 | 1989-04-17 | Heating plant |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0337922B1 (en) |

| AT (2) | AT389584B (en) |

| DE (2) | DE58906857D1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE1004890A6 (en) * | 1990-05-07 | 1993-02-16 | Vaillant Sa | Water heating system. |

| IT1254266B (en) * | 1992-03-12 | 1995-09-14 | HYDRAULIC GROUP PERFECTED FOR COMBINED HEATING AND DOMESTIC WATER SYSTEMS | |

| AT402764B (en) * | 1992-04-07 | 1997-08-25 | Vaillant Gmbh | WATER HEATER FOR DOMESTIC AND HEATING WATER |

| AT405465B (en) * | 1996-01-15 | 1999-08-25 | Vaillant Gmbh | WATER HEATING SYSTEM |

| SE9601181D0 (en) * | 1996-03-27 | 1996-03-27 | Alf Ottosson | Methods and apparatus for temperature control of tap hot water |

| DE19850714A1 (en) * | 1998-11-03 | 2000-05-04 | Gaswaerme Inst Ev | Process and arrangement for heating and hot water preparation |

| DE102009034556A1 (en) * | 2009-07-23 | 2011-02-03 | Viessmann Werke Gmbh & Co Kg | Method for monitoring the state of soiling of a heat exchanger for hot water preparation on a heater |

| IT201600068864A1 (en) * | 2016-07-01 | 2018-01-01 | Eti S N C Di Fogale Maria Elisa & Bortolato Luciano | KIT OR SYSTEM OF DISTRIBUTION OF THERMAL ENERGY FOR THE PRODUCTION OF DOMESTIC HOT WATER AND FOR HEATING AND USING THE KIT |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT306305B (en) * | 1970-12-14 | 1973-04-10 | Vaillant Joh Kg | Circulation heating system with utility water heater |

| DE2142545B1 (en) * | 1971-08-25 | 1973-02-08 | Joh. Vaillant Kg, 5630 Remscheid | |

| DE2307109A1 (en) * | 1973-02-14 | 1974-08-29 | Junkers & Co | HEATING UNIT FOR HOT WATER AND HOT WATER |

| GB2151816B (en) * | 1983-12-19 | 1986-10-08 | British Gas Corp | Control of a central heating system |

-

1988

- 1988-04-15 AT AT0097888A patent/AT389584B/en not_active IP Right Cessation

-

1989

- 1989-04-17 EP EP89710027A patent/EP0337922B1/en not_active Expired - Lifetime

- 1989-04-17 DE DE89710027T patent/DE58906857D1/en not_active Expired - Fee Related

- 1989-04-17 AT AT89710027T patent/ATE101255T1/en not_active IP Right Cessation

- 1989-04-17 DE DE3912593A patent/DE3912593A1/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| EP0337922A3 (en) | 1990-10-31 |

| AT389584B (en) | 1989-12-27 |

| ATA97888A (en) | 1989-05-15 |

| DE58906857D1 (en) | 1994-03-17 |

| ATE101255T1 (en) | 1994-02-15 |

| DE3912593A1 (en) | 1989-10-26 |

| EP0337922A2 (en) | 1989-10-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0337922B1 (en) | Heating plant | |

| EP0308848B1 (en) | Method and device for temperature control of the heating medium of a closed loop heating system with minimum temperature limitation | |

| DE69709928T2 (en) | Combined control system for gas and air for controlling the combustion of a gas boiler | |

| AT394771B (en) | METHOD AND DEVICE FOR CARRYING OUT THE METHOD FOR IMMEDIATELY TAPING WARM HOT WATER | |

| DE19530000A1 (en) | Domestic hot water supply system | |

| EP1310746B1 (en) | Device and method for control of fluid heater | |

| DE102005040792B3 (en) | Control device for a combination heating device comprises a control unit formed as a self-learning pilot control unit | |

| EP0229319B1 (en) | Hot water heating installation with a heat consumption meter | |

| DE4303579A1 (en) | Fuel fired heater for hot water heating system - has monitor for mean temperature of heat exchanger to allow for condensation effects | |

| DE2931024C2 (en) | Device for controlling the fuel supply and the air supply to a burner | |

| DE4004392A1 (en) | Domestic hot water system | |

| EP0642069B1 (en) | Regulation device | |

| CH688491A5 (en) | Method for operating a burner having a condensing boiler. | |

| EP1508751A1 (en) | Method and device for adapting the supply temperature of a heat generator to the respective heat circuit load of a downstream heating system | |

| EP0049328A1 (en) | Device for the heat recovery of waste gases of some plants | |

| DE19511366B4 (en) | Method for controlling a heating system | |

| DE2529858A1 (en) | Control of hot water central heating system - is operated by temp. difference between flow and return | |

| DE3832495A1 (en) | Method and apparatus for controlling the temperature of the heating medium of a closed-circuit heating system with minimum-temperature limitation | |

| AT397854B (en) | Method for controlling a boiler | |

| DE3515658C2 (en) | ||

| DE3503738A1 (en) | Circuit for controlling the heat delivery of a fuel-heated heat source | |

| DE19645135A1 (en) | Method of controlling heating assembly | |

| EP0711960A1 (en) | Method and device for heating water for domestic use | |

| EP1450111B1 (en) | Method for determining a heat requirement and heating apparatus for carrying out this method | |

| EP0916903A2 (en) | Space heating system and method for its operatoin |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19901212 |

|

| 17Q | First examination report despatched |

Effective date: 19910814 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VAILLANT S.A.R.L Owner name: VAILLANT GES.M.B.H Owner name: VAILLANT B.V. Owner name: VAILLANT GMBH Owner name: VAILLANT LTD. Owner name: JOH. VAILLANT GMBH U. CO. Owner name: N.V. VAILLANT S.A. |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: N.V. VAILLANT S.A. Owner name: JOH. VAILLANT GMBH U. CO. Owner name: VAILLANT GMBH Owner name: VAILLANT S.A.R.L Owner name: VAILLANT GES.M.B.H Owner name: VAILLANT B.V. Owner name: VAILLANT LTD. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19940202 Ref country code: GB Effective date: 19940202 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19940202 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940202 Ref country code: SE Effective date: 19940202 Ref country code: NL Effective date: 19940202 |

|

| REF | Corresponds to: |

Ref document number: 101255 Country of ref document: AT Date of ref document: 19940215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58906857 Country of ref document: DE Date of ref document: 19940317 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940430 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19940202 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19950308 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950322 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950323 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950327 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19960417 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19960430 Ref country code: LI Effective date: 19960430 Ref country code: BE Effective date: 19960430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960430 Year of fee payment: 8 |

|

| BERE | Be: lapsed |

Owner name: N.V. VAILLANT S.A. Effective date: 19960430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19961227 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980101 |