EP0258549A2 - Casier à bouteilles empilable - Google Patents

Casier à bouteilles empilable Download PDFInfo

- Publication number

- EP0258549A2 EP0258549A2 EP87108402A EP87108402A EP0258549A2 EP 0258549 A2 EP0258549 A2 EP 0258549A2 EP 87108402 A EP87108402 A EP 87108402A EP 87108402 A EP87108402 A EP 87108402A EP 0258549 A2 EP0258549 A2 EP 0258549A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- handle

- box according

- compartments

- box

- compartment

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D1/00—Containers having bodies formed in one piece, e.g. by casting metallic material, by moulding plastics, by blowing vitreous material, by throwing ceramic material, by moulding pulped fibrous material, by deep-drawing operations performed on sheet material

- B65D1/22—Boxes or like containers with side walls of substantial depth for enclosing contents

- B65D1/24—Boxes or like containers with side walls of substantial depth for enclosing contents with moulded compartments or partitions

- B65D1/243—Crates for bottles or like containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24012—Materials

- B65D2501/24019—Mainly plastics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/2405—Construction

- B65D2501/24063—Construction of the walls

- B65D2501/24089—Height of the side walls

- B65D2501/24095—Height of the side walls corresponding to the full height of the bottles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/2405—Construction

- B65D2501/24121—Construction of the bottom

- B65D2501/24133—Grid, mesh

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/2405—Construction

- B65D2501/24146—Connection between walls or of walls with bottom

- B65D2501/24152—Integral

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24197—Arrangements for locating the bottles

- B65D2501/24203—Construction of locating arrangements

- B65D2501/2421—Partitions

- B65D2501/24216—Partitions forming square or rectangular cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24197—Arrangements for locating the bottles

- B65D2501/24203—Construction of locating arrangements

- B65D2501/24261—Ribs on the side walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24197—Arrangements for locating the bottles

- B65D2501/24343—Position pattern

- B65D2501/2435—Columns and rows

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24197—Arrangements for locating the bottles

- B65D2501/24343—Position pattern

- B65D2501/24356—Staggered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24363—Handles

- B65D2501/24509—Integral handles

- B65D2501/24528—Integral handles centrally located in open container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24363—Handles

- B65D2501/24541—Hand holes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24554—Stacking means

- B65D2501/24585—Stacking means for stacking or joining the crates together one upon the other, in the upright or upside-down position

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2501/00—Containers having bodies formed in one piece

- B65D2501/24—Boxes or like containers with moulded compartments or partitions

- B65D2501/24006—Details relating to bottle crates

- B65D2501/24554—Stacking means

- B65D2501/24585—Stacking means for stacking or joining the crates together one upon the other, in the upright or upside-down position

- B65D2501/24605—Crates with stacking feet or corner elements

Definitions

- the invention relates to a stackable bottle crate according to the preamble of claim 1.

- Conventional bottle crates are made of plastic and have a compartment division for accommodating the bottles to be transported between the side walls encompassing the crate interior. These boxes usually have external dimensions of 400 x 300 mm and accommodate a total of twenty bottles. The bottle crate is transported via the handle openings provided in the side walls. The dimensions of such a box are comparatively bulky and can only be transported with difficulty through the handle openings in the side walls. The stacking is only vertical, an offset stacking is not possible. Overall, such boxes are unfavorably designed for the purpose of transport, because they are too bulky and too heavy and because gripping the box through the recessed handle openings is cumbersome and can only be done by strong people.

- the object of the invention is therefore to create a bottle crate which ensures consumer-friendly transport and at the same time permits stable and universal stacking.

- the invention is characterized by a targeted interaction of the arrangement of a center handle and the formation of a box bottom, which allows a design of the center handle that is favorable for gripping and transporting the box to be obtained and nevertheless ensures stable stacking.

- this immersion of the central handle enables the handle bar to be pulled up in order to provide sufficient space below the handle bar for gripping the box.

- the recesses for the center handle are arranged in the bottom of the box so that they match or are aligned with the possible positions of the handle in the various stacking positions

- the advantage according to claim 1 also results in different stacking positions of the boxes.

- the training according to claim 12 is advantageous because a box module from 400 x 200 mm also permits an offset stacking of the boxes and in particular also stacking in connection with boxes of the so-called Euro standard, i.e. a module of 400 mm x 300 mm.

- the stable stacking is further favored by the fact that the bottom of the recess is formed as a contact surface for the handle. As a result, the handle is also used for support.

- the depth of the recess can be added to the grip area.

- the grip strip it is expedient for the grip strip to be curved in a substantially shell-like manner in longitudinal section, resulting in an ergonomically favorable grip.

- This advantage is only possible in that a corresponding pulling up of the handle is made possible due to the immersion of the handle in the recess.

- the grip behavior is further favored by the fact that the grip strip is essentially U-shaped in cross-section transversely to the longitudinal direction of the handle, the U-web being formed by a rounding.

- the openings in the bottom grille are designed in particular also in the recesses in such a way that the crown cork or the bottle neck cannot pass through.

- the stability of the box is further enhanced by the fact that the side walls are double-walled. In particular, this enables the boxes to be stacked horizontally.

- knobs, notches or webs on the outer surface of the web walls is favorable, as a result of which the wear on the side walls is reduced.

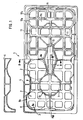

- the compartment division has a total of three compartment rows, of which the two outer compartment rows each limit four compartments 2 for holding bottles, whereas two compartments are present in the inner compartment row.

- the inner compartment row is aligned with a center handle 5, which is shown in detail in FIGS. 2 and 3.

- the bottle crate according to FIGS. 1 to 3 holds ten bottles, namely four each in the outer compartment rows and two in the inner compartment row, the two bottles in the inner compartment row being arranged offset to the adjacent bottles of the outer compartment row.

- the bottle crate 1 comprises four side walls 4, which are preferably double-walled. Especially in the narrower side walls are only in the drawings schematically shown handle openings 3 are provided, which can optionally be provided in addition to the center handle 5.

- the individual compartments 2, as far as the subjects of the outer rows of compartments are concerned, are delimited by the side walls 4 and compartment walls 6 formed in the interior of the box.

- the two compartments of the inner compartment row are limited solely by compartment walls 6, which form a column 7 with an octagonal floor plan.

- FIGS. 1 to 3 enables the bottles to be accommodated in the compartments by means of three-point storage. For example, the bottle 8 shown at the top left in FIG.

- the box bottom according to FIG. 1 has a series of recesses 11, as can be seen from the right-hand illustration in FIG. 1.

- the box is characterized by a length and width module of 400 x 200 mm, in contrast to the Euro standard with 300 x 400 mm, there is a large number of different stacking options also in connection with boxes of the Euronorm.

- the recesses 11 are designed so that even with a staggered stacking in the direction of length or width, the center handle or a recess comes to lie below or above a recess 11 or the center handle 5 and thus ensures stacking is.

- the middle handle 5 immersed in the corresponding recess 11 comes into contact with the bottom surface of the recess 11, so that there is an additional effective support of the load when stacking columns, that is to say vertically stacking the bottle crates. In this respect, there is an additional support surface due to the design of the recess 11 and the central handle 5.

- the upper handle bar 12 is curved downward in the manner of a shell, the lowest position being in the central region of the handle bar 12.

- the grip strip 12 Towards the two ends of the grip strip 12, it is pulled upwards and merges into a vertical support strut 14 on both sides via a curve 13.

- the grip strip 12 has the shape of a large U in a section transverse to the section according to FIG. 2, the two U legs 15 being connected to one another via a rounding 16, so that the U web is rounded is trained.

- the Curvature of the handle bar 12 in the longitudinal direction of the central handle 5 and the rounding on the underside of the handle bar 12 results overall in a handle bar 12 which is easy to grasp, in particular the curvature in the longitudinal direction of the central handle being possible due to the free space which results from the immersion of the central handle 5 in the recesses 11 of the box bottom is made possible.

- Fig. 1 shows that the box floor is like a floor grid, that is, with a number of openings 17a, 17b and 17c ..., these floor openings are also provided in the region of the recesses 11. These bottom openings 17a ... are dimensioned so that the bottles of a lower crate layer cannot dip through the crate bottom of the top layer.

- knobs, notches and webs in the manner of ribs which are formed or molded on the outer surface of the side walls 4 and provide stiffening of the side walls and wear protection when the box is arranged horizontally when the box is on one of the side walls is arranged standing.

- the webs extend in particular essentially over the entire depth or height of the bottle crate.

- the double-wall structure of the side wall 4 can be closed on the inner surface, as can be seen from a comparison with the side wall at the top left in FIG. 4.

- the closed structure of the side wall 4 has the advantage that dirt cannot build up on the side wall or in the region of openings in the side wall.

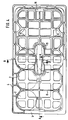

- FIGS. 4 to 6 differs from the embodiment according to FIGS. 1 to 3 in that the compartment division consists of two parallel rows of compartments, each with five compartments.

- the structure of the center handle is similar to the embodiment according to FIGS. 1 to 3, so that an additional explanation appears to be unnecessary.

- recesses 11 are formed at those points at which the center handle 5 can come to rest in different stacking positions in order to ensure that the center handle 5 is immersed in the bottom of the box and thus ensures vertical stacking.

- the center handle has both in the region of the handle bar 12 and in the region of the essentially vertical ones Handle struts 14 in cross section on an open profile, which is essentially U-shaped or shell-shaped in the illustrated embodiment.

- the open profile of the center handle has, in particular in the central section, a region 16a set back from the profile ends 15a and 15b. In the exemplary embodiment shown, this recessed area is equal to the U-web between the two U-legs 15.

- This design of the center handle has the advantage that the burr that arises during the shaping of the box as a result of the separating edges of the tool can be shifted into this area, so that when the box is gripped the hand does not come into contact with the possibly sharp-edged ridge and thus risk of injury excluded are. Furthermore, an increase in the stiffness of the handle is achieved due to the curved profile of the center handle. A special adaptation of the handle to the load handling function is achieved when stacking several boxes on top of each other. The stiffening of the handle as a result of the profile of the central handle also brings about a stable connection of the handle to the box, which in turn is advantageous when carrying the box.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87108402T ATE89795T1 (de) | 1986-09-05 | 1987-06-10 | Stapelbarer flaschenkasten. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3630383 | 1986-09-05 | ||

| DE3630383 | 1986-09-05 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0258549A2 true EP0258549A2 (fr) | 1988-03-09 |

| EP0258549A3 EP0258549A3 (en) | 1989-03-22 |

| EP0258549B1 EP0258549B1 (fr) | 1993-05-26 |

| EP0258549B2 EP0258549B2 (fr) | 1996-05-01 |

Family

ID=6309048

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87108402A Expired - Lifetime EP0258549B2 (fr) | 1986-09-05 | 1987-06-10 | Casier à bouteilles empilable |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0258549B2 (fr) |

| JP (1) | JP2557067B2 (fr) |

| AT (1) | ATE89795T1 (fr) |

| DE (1) | DE3785981D1 (fr) |

| ES (1) | ES2040225T5 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1990005676A2 (fr) * | 1988-11-08 | 1990-05-31 | Schoeller International Engineering Kg | Casier a bouteilles en matiere plastique |

| EP0388720A2 (fr) * | 1989-03-22 | 1990-09-26 | Schoeller-Plast AG | Dispositif pour la finition de casiers à bouteilles en matière plastique |

| DE4027813A1 (de) * | 1990-09-01 | 1992-03-05 | Wilhelm Goetz | Transport und aufbewahrungsbehaelter |

| GR900100306A (en) * | 1990-04-23 | 1992-07-30 | Schoeller International Engin | Synthetic packing cases for bottles |

| EP1110875A2 (fr) * | 1999-12-20 | 2001-06-27 | Schoeller Wavin Systems GmbH | Système de transport avec porte-bouteilles |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1383878A (en) * | 1973-10-04 | 1974-02-12 | Dale Ltd John | Crate |

| FR2227183A1 (fr) * | 1973-04-24 | 1974-11-22 | Spumalit Anstalt | |

| CA1018942A (fr) * | 1975-12-11 | 1977-10-11 | Scepter Manufacturing Company Limited | Caisses empilables |

| FR2387849A1 (fr) * | 1977-04-22 | 1978-11-17 | Schoeller & Co Ag A | Casier a bouteilles empilable en matiere plastique |

| DE2828395A1 (de) * | 1978-06-28 | 1980-01-17 | Schoeller & Co Ag A | 10er-minikasten |

| DE2945112A1 (de) * | 1979-11-08 | 1981-05-21 | Stucki Kunststoffwerk Und Werkzeugbau Gmbh, 4902 Bad Salzuflen | Flaschenkasten aus kunststoff |

| DE8513674U1 (de) * | 1985-05-09 | 1985-08-29 | Seidel, Walter, 6526 Alsheim | Flaschenträger |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS52155125U (fr) * | 1976-05-20 | 1977-11-25 |

-

1987

- 1987-06-10 ES ES87108402T patent/ES2040225T5/es not_active Expired - Lifetime

- 1987-06-10 EP EP87108402A patent/EP0258549B2/fr not_active Expired - Lifetime

- 1987-06-10 DE DE8787108402T patent/DE3785981D1/de not_active Expired - Lifetime

- 1987-06-10 AT AT87108402T patent/ATE89795T1/de not_active IP Right Cessation

- 1987-08-18 JP JP20360887A patent/JP2557067B2/ja not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2227183A1 (fr) * | 1973-04-24 | 1974-11-22 | Spumalit Anstalt | |

| GB1383878A (en) * | 1973-10-04 | 1974-02-12 | Dale Ltd John | Crate |

| CA1018942A (fr) * | 1975-12-11 | 1977-10-11 | Scepter Manufacturing Company Limited | Caisses empilables |

| FR2387849A1 (fr) * | 1977-04-22 | 1978-11-17 | Schoeller & Co Ag A | Casier a bouteilles empilable en matiere plastique |

| DE2828395A1 (de) * | 1978-06-28 | 1980-01-17 | Schoeller & Co Ag A | 10er-minikasten |

| DE2945112A1 (de) * | 1979-11-08 | 1981-05-21 | Stucki Kunststoffwerk Und Werkzeugbau Gmbh, 4902 Bad Salzuflen | Flaschenkasten aus kunststoff |

| DE8513674U1 (de) * | 1985-05-09 | 1985-08-29 | Seidel, Walter, 6526 Alsheim | Flaschenträger |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1990005676A2 (fr) * | 1988-11-08 | 1990-05-31 | Schoeller International Engineering Kg | Casier a bouteilles en matiere plastique |

| WO1990005676A3 (fr) * | 1988-11-08 | 1990-06-28 | Schoeller Int Eng | Casier a bouteilles en matiere plastique |

| EP0388720A2 (fr) * | 1989-03-22 | 1990-09-26 | Schoeller-Plast AG | Dispositif pour la finition de casiers à bouteilles en matière plastique |

| EP0388720A3 (fr) * | 1989-03-22 | 1992-04-01 | Schoeller-Plast AG | Dispositif pour la finition de casiers à bouteilles en matière plastique |

| GR900100306A (en) * | 1990-04-23 | 1992-07-30 | Schoeller International Engin | Synthetic packing cases for bottles |

| DE4027813A1 (de) * | 1990-09-01 | 1992-03-05 | Wilhelm Goetz | Transport und aufbewahrungsbehaelter |

| EP1110875A2 (fr) * | 1999-12-20 | 2001-06-27 | Schoeller Wavin Systems GmbH | Système de transport avec porte-bouteilles |

| EP1110875A3 (fr) * | 1999-12-20 | 2002-06-26 | Schoeller Wavin Systems GmbH | Système de transport avec porte-bouteilles |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS6367255A (ja) | 1988-03-26 |

| ATE89795T1 (de) | 1993-06-15 |

| EP0258549B1 (fr) | 1993-05-26 |

| ES2040225T3 (es) | 1993-10-16 |

| ES2040225T5 (es) | 1996-06-16 |

| JP2557067B2 (ja) | 1996-11-27 |

| DE3785981D1 (de) | 1993-07-01 |

| EP0258549A3 (en) | 1989-03-22 |

| EP0258549B2 (fr) | 1996-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1586815C3 (de) | Flaschenträger | |

| DE3121243A1 (de) | Zwischenlagekorb | |

| EP3636559B1 (fr) | Boîte empilable | |

| DE19641686C2 (de) | Stapelbarer Behälter, insbesondere Lager- und Transportbehälter sowie Behältersystem | |

| EP0258549B2 (fr) | Casier à bouteilles empilable | |

| EP0512289B1 (fr) | Casier à bouteilles en matière plastique avec saillies de guidage | |

| DE102005021170A1 (de) | Transport- und Lagerbehälter | |

| DE102017124267A1 (de) | Flaschenkasten für die Einstellung von sowohl Einzelflaschen wie auch Mehrflaschenpacks und dergleichen Flaschengebinden | |

| EP0275919B1 (fr) | Casier en matière plastique, destiné à contenir des récipients, notamment des bouteilles | |

| DE4442836A1 (de) | Flaschenkasten | |

| EP0585535B1 (fr) | Casier empilable en plastique | |

| WO1987007577A1 (fr) | Casier a bouteilles gerbable | |

| DE8113717U1 (de) | Quaderfoermiger Flaschenkasten aus Kunststoff | |

| DE3419910C2 (fr) | ||

| DE3014239C2 (de) | Flaschenkasten | |

| EP0487824B1 (fr) | Casier à bouteilles en matière plastique | |

| DE3232732A1 (de) | Einsatzbehaeltnis fuer einkaufswagen | |

| EP3626646A1 (fr) | Boîte empilable | |

| EP0835817A2 (fr) | Récipient empilable, en particulier récipient de stockage et de transport ainsi que système à récipients | |

| DE202004007452U1 (de) | Vorrichtung zum Transport und zur Aufbewahrung von Kunststoffflaschen | |

| DE4411647A1 (de) | Im Kreuzstapelverbund stapelbarer Transportbehälter | |

| DE102017124272A1 (de) | Mehrflaschengebinde, wie Sixpacks und dergleichen | |

| EP0073954A2 (fr) | Panier à bouteilles avec parois inclinées | |

| EP3428084A1 (fr) | Multi-packs de bouteilles, comme six-packs et analogues | |

| DE3004673A1 (de) | Transport- und/oder lagerkasten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT CH DE ES LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES LI NL |

|

| 17P | Request for examination filed |

Effective date: 19890913 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SCHOELLER-PLAST AG |

|

| 17Q | First examination report despatched |

Effective date: 19910326 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES LI NL |

|

| REF | Corresponds to: |

Ref document number: 89795 Country of ref document: AT Date of ref document: 19930615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3785981 Country of ref document: DE Date of ref document: 19930701 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: OBERLAND PLASTIC GMBH Effective date: 19931129 |

|

| 26 | Opposition filed |

Opponent name: STUCKI KUNSTSTOFFWERK UND WERKZEUGBAU GMBH Effective date: 19931218 Opponent name: OBERLAND PLASTIC GMBH Effective date: 19931129 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: OBERLAND PLASTIC GMBH. |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: STUCKI KUNSTSTOFFWERK UND WERKZEUGBAU GMBH |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19950630 Year of fee payment: 9 |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19960501 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT CH DE ES LI NL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Kind code of ref document: T5 Effective date: 19960616 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19960621 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960625 Year of fee payment: 10 |

|

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19970610 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 19970611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19980625 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20000101 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20000201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060828 Year of fee payment: 20 |