EP0228347B2 - Process for controlling the application of colours in a printing machine, printing device equipped therewith and measuring device for such a printing device - Google Patents

Process for controlling the application of colours in a printing machine, printing device equipped therewith and measuring device for such a printing device Download PDFInfo

- Publication number

- EP0228347B2 EP0228347B2 EP86810562A EP86810562A EP0228347B2 EP 0228347 B2 EP0228347 B2 EP 0228347B2 EP 86810562 A EP86810562 A EP 86810562A EP 86810562 A EP86810562 A EP 86810562A EP 0228347 B2 EP0228347 B2 EP 0228347B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- colour

- printing

- color

- printing machine

- deviation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F33/00—Indicating, counting, warning, control or safety devices

- B41F33/0036—Devices for scanning or checking the printed matter for quality control

- B41F33/0045—Devices for scanning or checking the printed matter for quality control for automatically regulating the ink supply

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2233/00—Arrangements for the operation of printing presses

- B41P2233/50—Marks on printed material

- B41P2233/51—Marks on printed material for colour quality control

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S101/00—Printing

- Y10S101/45—Sensor for ink or dampening fluid thickness or density

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S101/00—Printing

- Y10S101/46—Printing operation controlled by code indicia on printing plate or substate

Definitions

- the invention relates to a method for regulating the ink application of a printing press according to the preamble of independent claim 1, a printing system suitable for carrying out the method according to the preamble of claim 15 and a measuring device intended for generating control data for such a printing system according to the preamble of the independent claim 18th

- control of the color guide is the most important way to influence the image impression. It takes place after visual assessment or on the basis of densitometric analyzes of color measuring fields that are also printed. An example of the latter control is described in DE-A-2 728 738.

- a method for ink application control of a printing press in which a printed sheet is measured in areas by colorimetry, the standard color values being determined according to CIE for each measuring area.

- the surface coverage in the printing inks involved is determined from the standard color values using the Neugebauer equations. These are compared with target values of a test print, and on the basis of the comparison result, zone screws and ink ducts of the printing press are automatically adjusted by means of a control circuit.

- this known method requires a special test print with full-tone fields of all possible ink combinations produced under identical conditions and an additional colorimetric measurement of the print sheet after the first printing unit. It therefore requires a double measurement effort and, above all, cannot guarantee a perfect print result with regard to the color impression achieved, if the printing conditions change e.g. B. unnoticed by rubber blanket contamination or by wear-related changes to the printing plates or by other influences. Colorimetry is only used indirectly to determine the area coverage, but the essence of colorimetry is not relevant.

- the present invention is now intended to improve the control of the ink flow in printing machines to the effect that a higher degree of agreement in the image impression between the proof or proof set and the production run is achieved and the production run remains stable in the color impression or color changes are recognized.

- the essence of the present invention thus lies in the fact that the principle of densitometric color density measurement is present and is replaced by spectral color measurement, the spectral remissions of the measured test areas being determined and the control of the color guidance (at least during the set-up phase of the printing press) based on these spectral remissions or the one from it derived colorimetric parameters and not based on density measurements.

- the image impressions of sensitive, image-important points in the production run can be optimally matched to those of the proof or replacement, whereby to a certain extent color deviations due to different tonal value increases and other material and process influences are compensated for.

- the color measurement itself can be carried out on printed color test fields or also at suitably selected points (test areas) in the image.

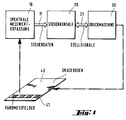

- the printing system shown in FIG. 1 essentially corresponds to the known systems of this type, for example the system according to DE-A-2 728 738, which is still to be explained, in accordance with the invention in the measured value acquisition part.

- printing sheets 40 generated by the printing press 30 are photoelectrically measured in a number of test areas, for example in selected locations of the printed image or in the area of color measurement fields 41 that are also printed, and control data 11 are determined from the measurement data obtained in this way, which are the color deviations of the Corresponding printing inks in the individual printing zones and printing units correspond and are supplied as input variables to the control console 20.

- the control console 20 generates control signals 21 from the control data 11, which adjust the ink guide elements of the printing press 30 in such a way that the color deviations are minimal.

- the device 10 comprises a measuring head 101 which, for. B. is movable by means of a stepper motor 102 relative to the printed sheet to be measured.

- a handheld measuring head 103 is also provided, which can be positioned manually on the desired test area of the printed sheet.

- the two measuring heads 101 and 103 contain a measurement arrangement, not shown, which the test area to be measured z. B. illuminated according to the usual standard at 45 ° and the light reflected from the test area at 90 ° and couples it into an optical fiber 104, which feeds it to a spectrometer 105. (Of course, the remitted light can also be supplied to the spectrometer by other means.) There the remitted light is spectrally broken down and measured.

- the measurement data obtained in this way are fed to a computer 106, which determines the control data 11 for the control console 20 from them in a manner to be explained.

- the computer 106 operates or controls a driver electronics 107 for the stepper motor 102 and the supply of the light sources in the measuring heads 101 and 103 and a data display device 108, a printer 109 and a keyboard 110. All essentially as in the known one Device.

- the primarily relevant difference for the invention of the measured value acquisition device 10 shown compared to the known device mentioned is that it is set up for spectral color analysis of the test areas to be specifically measured and thus for colorimetric analysis, while the known device is only able to measure densitometric color densities , so no color measurement / colorimetry allowed.

- the second essential difference is the evaluation of the photoelectric measurement data with regard to the control of the color guidance.

- FIG. 3 shows the basic structure (known per se) of spectrometer 105.

- the measuring light supplied via one of the measuring heads 101 and 103 via the fiber-optic light guide 104 (or directly) acts on a holographic grating 151 via an entry slit and is spatially split by the latter according to wavelengths.

- the spectrally decomposed light falls on a line-shaped arrangement of z. B.

- 35 photodiodes 152 that each photodiode is exposed to light of an individual, relatively narrow wavelength range.

- the measurement signals generated by the 35 photodiodes thus correspond to the spectral intensity distribution of the measurement light at 35 discrete support points (wavelength ranges).

- an interface (interface) 153 is provided which amplifies and digitizes the measurement signals and thus brings them into a form which the computer 106 can understand.

- the interface could of course also be spatially arranged in the computer.

- the measured value acquisition device 10, the control console 20 and the actual printing press 30 form a closed control loop.

- the ink guidance is regulated on the basis of densitometric density measurements of the printing inks involved. There are deviations from the corresponding target density values. so these are from the control console by appropriate adjustment of the color guide elements corrected, ie made zero or brought into the permissible tolerance range.

- the color guide control is therefore color density controlled.

- the principle of color density-controlled color guidance is abandoned and is substantially supplemented by a control based on spectral color measurement and colorimetry.

- the spectral remissions are determined by spectral measurement and, if necessary, the color values of a selected color coordinate system are determined by conversion and compared with corresponding target remissions or target color values.

- the color guidance is then controlled on the basis of the deviations in the spectral remissions or the color values from the target values (“color distances”) and no longer on the basis of the deviations in the densitometric color densities.

- the control is preferably carried out with the proviso that the total distance of a printing zone resulting from the sum of the color distances of different test areas should be minimal, wherein each test area and, accordingly, its color distance can, if desired, be taken into account with an individual weight.

- control according to color coordinates is described below. In principle, the same applies to the control according to spectral remissions.

- the color coordinate system on which the color measurement is based is in itself arbitrary. However, the L * a * b * system or the L * u * v * system of the CIE (Commission Internationale de l'Eclairage) is preferably used.

- the color locus is understood to mean the coordinate triple (L *, a *, b *) or (L *, u *, v *), the color distance corresponds to the vector ⁇ E Lab or ⁇ E Luv or the individual vectors ( ⁇ L * , ⁇ a *, ⁇ b *) or ( ⁇ L *, ⁇ u *, ⁇ v *).

- the target values of the color coordinates (target color locations) for the individual test areas can be used for the measured value acquisition device 10 e.g.

- the entire control system is, as shown, divided into the two components of the measured value recording device 10 and control console 20 and are those of Measured value acquisition device 10 generates control signals 11 of exactly the same type as in the known color density measuring systems, so that the measured value acquisition device 10 according to the invention can therefore be connected directly with the known control console 20 mentioned and only the measured value acquisition device has to be replaced in order to convert a corresponding pressure system to the method according to the invention.

- the computer 110 forms the color distance vector ⁇ E n for each test area.

- Each of these vectors ⁇ E n is now weighted with a weight factor g n , so that each test area can be considered individually. Typical test areas will be given greater weight, less important ones a lesser one.

- weighting factors can be done via the keyboard e.g. B. can also be entered interactively or preprogrammed.

- the weighted or, if necessary, also unweighted color distance vectors of individual measuring fields are mathematically each with a z. B. multiplied empirically determined transformation matrix, and if certain quality criteria are observed, this results in a color density change vector, the components of which are the density changes or the layer thickness changes of the printing inks involved in the printing, and thus the control data for the printing zone in question and such changes in the setting of the color guide elements causes the total color difference - determined as the sum of the amounts or the sum of the color difference squares of the individual color differences - to be minimal. This total color difference can also serve as a quality measure for the print.

- the elements of the transformation matrices essentially contain the partial derivatives of the color coordinates according to the color densities of the printing inks involved. They can be determined empirically by measurements on appropriate test prints or synthetically by modeling.

- the density change vector has three components, and the calculation from the color distance vectors, which also have three components, is therefore relatively free of complications.

- the contributions of the individual test areas must be logically assigned to the individual components of the density change vector in a suitable manner in such a way that a correspondingly multidimensional vector results.

- control signals for the color guide elements can also be determined directly from the color differences. Again, the criterion that the total color difference must be minimized is expediently used as a basis.

- the different weighting of the individual test areas can also be used here.

- the printing process usually runs in three phases. First there is the more or less rough presetting of the printing press, for. B. on the basis of measured values of the printing plates, then the so-called set-up phase (coordination. Registering), in which the ink guide is fine-tuned in one way or the other until the printed product is satisfied, and finally the production run, where the regulation focuses on maintaining the result achieved at the facility as constant as possible. Usually you do not use the proof or the like as a reference. but rather the print sheet found to be good, the so-called "O.K. sheet", and regulates in the production process to constant densitometric color densities.

- phase of density control in continuous printing can also be implemented very easily with the printing system according to the invention. All that is required is to convert the spectral reflectances into filter color densities (according to densitometry) and to compare them with the target color density values determined by an O.K. sheet. The differences in color densities then directly represent the control data 11 for the control console 20.

- the setting up of the printing press can be carried out in a color-gap-controlled manner as described further above and the production run can then be stabilized in a conventional manner in a color-density-controlled manner.

- the color density determination can be based on any filter characteristics, which achieves a high degree of flexibility in such a system.

- the two control principles can also be superimposed on one another.

- the total color difference should be for some reason, e.g. B. due to changes in the printing process such as rubber blanket pollution, etc., exceed a predetermined limit, it can be reacted in a suitable manner.

- a new color distance controlled Correction of the printing press can be initiated, in which case the color density setpoints would then be adapted (updated) for further production stabilization, or a corresponding error message can only or additionally be output.

- the total color difference can be viewed as a quality measure and, if desired, displayed or printed out.

- the screen tones should appear in different color and tonal value combinations or particularly critical tones. It is also possible to include critical tones from the subject in the measuring strips.

- subjects can be divided into groups, e.g. B. Furniture catalogs - shades of brown determining quality -, cosmetic brochures and portraits - skin tones dominant.

- groups e.g. B. Gray or green tones prevail.

- special color-oriented color measuring strips can be built up and used in a targeted manner. The areas determining the image can thus be taken into account in a simple manner.

- the inking is not always controlled zonally. In this case, it is sufficient to print a measuring field for each measuring field type and to adopt it as the target value for the entire printing sheet width or parts thereof.

- Each zone can be monitored individually on the production sheet with zonal ink feed. Measuring fields that are important for color control, such as single-color measuring fields for density-controlled regulation of the color guidance or multicolor raster fields for colorimetric control, must therefore be repeated at the smallest possible distance. Control fields for color acceptance, tonal value increase etc. can be mounted at a slightly greater distance.

- the printable color space is limited by the color loci of paper white, the single-color solid tones and the 2 and 3-color solid tone overlays (white, cyan, magenta, yellow, red, green, blue, black). All grid tones are within this color space.

- color deviations cannot be compensated for in all color tones at the same time, but the mean color difference can be optimized. It is therefore expedient to use, in addition to the fields for the color density-controlled regulation for the color distance-controlled color guidance, also suitable 2 and / or 3 color grid fields such as gray balance fields or sensitive tones depending on the subject.

- the blackening is created by 3 chromatic colors and / or black.

- Grid fields with black and 2 or 3 chromatic colors can therefore also be of interest as measuring fields for color location-controlled control.

- the color tones are advantageously chosen from critical areas of the color space.

- 4-color grid fields a color must be predetermined as a free parameter or additionally measured on a separate color measuring field.

- suitable color measuring fields can be determined for special colors according to analogous criteria.

Abstract

Description

Verfahren zur Farbauftragsregelung bei einer Druckmaschine, entsprechend ausgerüstete Druckanlage und Messvorrichtung für eine solche Druckanlage.Process for ink application control in a printing press, suitably equipped printing system and measuring device for such a printing system.

Die Erfindung betrifft ein Verfahren zur Regelung des Farbauftrags einer Druckmaschine gemäss dem Oberbegriff des unabhängigen Anspruchs 1, eine zur Durchführung des Verfahrens geeignete Druckanlage nach dem Oberbegriff des Anspruchs 15 und eine zur Erzeugung von Steuerdaten für eine solche Druckanlage bestimmte Messvorrichtung gemäss dem Oberbegriff des unabhängigen Anspruchs 18.The invention relates to a method for regulating the ink application of a printing press according to the preamble of independent claim 1, a printing system suitable for carrying out the method according to the preamble of claim 15 and a measuring device intended for generating control data for such a printing system according to the preamble of the independent claim 18th

Im laufenden Druckprozess ist die Steuerung der Farbführung die wichtigste Möglichkeit zur Beeinflussung des Bildeindrucks. Sie erfolgt nach visueller Beurteilung oder aufgrund von densitometrischen Analysen von mitgedruckten Farbmessfeldern. Ein Beispiel für letztgenannte Steuerung ist in DE-A-2 728 738 beschrieben.In the ongoing printing process, the control of the color guide is the most important way to influence the image impression. It takes place after visual assessment or on the basis of densitometric analyzes of color measuring fields that are also printed. An example of the latter control is described in DE-A-2 728 738.

In der Praxis hat es sich gezeigt, dass die Steuerung der Farbführung allein aufgrund von densitometrischen Dichtemessungen vielfach ungenügend ist. So kommt es u.a. häufig vor, dass bei Regelung auf gleiche Volltondichten erhebliche Farbunterschiede zwischen Andruck bzw. Andruckersatz und Fortdruck auftreten. Diese Farbunterschiede (Bildeindrücke) müssen dann noch manuell durch interaktive Anpassung der Farbführung korrigiert werden. Die Ursachen für diese Farbunterschiede liegen in den im allgemeinen unterschiedlichen Herstellungsprozessen für Andruck/Andruckersatz und Fortdruck und in den farblichen Unterschieden der dabei verwendeten Materialien. Ebenfalls ist bei konstanter Farb- insbesondere Volltondichte die Konstanz des Farbeindrucks aufgrund von Aenderungen des Tonwerts durch Gummituchverschmutzung oder andere Einflüsse nicht gewahrleistet.In practice, it has been shown that the control of the color control is often insufficient due to densitometric density measurements alone. So it often happens, among other things, that, when regulating to the same solid ink densities, significant color differences occur between the proof or proof set and the production run. These color differences (image impressions) must then be corrected manually by interactive adjustment of the color guide. The reasons for these color differences lie in the generally different manufacturing processes for proofing / proofing and production and in the color differences of the materials used. Likewise, with a constant color density, in particular solid color density, the constancy of the color impression due to changes in the tonal value due to rubber blanket contamination or other influences is not ensured.

Aus der DD 227 094 ist ein Verfahren zur Farbauftragsregelung einer Druckmaschine bekannt, bei dem ein Druckbogen bereichsweise farbmetrisch ausgemessen wird, wobei für jeden Messbereich die Normfarbwerte nach CIE bestimmt werden. Aus den Normfarbwerten werden mit Hilfe der Neugebauer-Gleichungen die Flächendeckungsgrade in den beteiligten Druckfarben ermittelt. Diese werden mit Sollwerten eines Probedrucks verglichen, und anhand des Vergleichsergebnisses werden Zonenschrauben und Farbduktoren der Druckmaschine mittels eines Steuerkreises automatisch verstellt.From DD 227 094 a method for ink application control of a printing press is known, in which a printed sheet is measured in areas by colorimetry, the standard color values being determined according to CIE for each measuring area. The surface coverage in the printing inks involved is determined from the standard color values using the Neugebauer equations. These are compared with target values of a test print, and on the basis of the comparison result, zone screws and ink ducts of the printing press are automatically adjusted by means of a control circuit.

Dieses bekannte Verfahren erfordert zur Bestimmung der in die Neugebauer-Gleichungen eingehenden Grössen zwingend einen unter identischen Bedingungen hergestellten speziellen Probedruck mit Volltonfeldern sämtlicher möglicher Druckfarbenkombinationen sowie eine zusätzliche farbmetrische Ausmessung des Druckbogens bereits nach dem ersten Druckwerk. Es erfordert deshalb einen doppelten Messaufwand und kann vor allem zumindest dann kein bezüglich des erzielten Farbeindrucks einwandfreies Druckergebnis gewährleisten, wenn sich die Druckbedingungen z. B. durch Gummituchverschmutzung oder durch abnutzungsbedingte Veränderungen der Druckplatten oder durch sonstige Einflüsse unbemerkt verändern. Die Farbmetrik wird nur indirekt zur Bestimmung der Flächendeckungsgrade verwendet, das Wesen der Farbmetrik kommt jedoch nicht zum Tragen.In order to determine the quantities included in the Neugebauer equations, this known method requires a special test print with full-tone fields of all possible ink combinations produced under identical conditions and an additional colorimetric measurement of the print sheet after the first printing unit. It therefore requires a double measurement effort and, above all, cannot guarantee a perfect print result with regard to the color impression achieved, if the printing conditions change e.g. B. unnoticed by rubber blanket contamination or by wear-related changes to the printing plates or by other influences. Colorimetry is only used indirectly to determine the area coverage, but the essence of colorimetry is not relevant.

Durch die vorliegende Erfindung soll nun die Steuerung der Farbführung bei Druckmaschinen dahingehend verbessert werden, dass ein höherer Übereinstimmungsgrad im Bildeindruck zwischen Andruck bzw. Andruckersatz und Fortdruck erzielt wird und der Fortdruck im Farbeindruck stabil bleibt oder Farbveränderungen erkannt werden.The present invention is now intended to improve the control of the ink flow in printing machines to the effect that a higher degree of agreement in the image impression between the proof or proof set and the production run is achieved and the production run remains stable in the color impression or color changes are recognized.

Dieses Ziel wird durch das im Anspruch 1 beschriebene erfindungsgemässe Verfahren, die entsprechend ausgerüstete Druckanlage gemäss Anspruch 15 und die erfindungsgemässe Messvorrichtung nach Anspruch 18 erreicht.This goal is achieved by the method according to the invention described in claim 1, the correspondingly equipped pressure system according to claim 15 and the measuring device according to the invention according to claim 18.

Der Kern der vorliegenden Erfindung liegt also darin, dass das Prinzip der densitometrischen Farbdichtemessung vorlassen und durch spektrale Farbmessung ersetzt wird, wobei die spektralen Remissionen der ausgemessenen Testbereiche bestimmt werden und die Steuerung der Farbführung (zumindest während der Einrichtphase der Druckmaschine) aufgrund dieser spektralen Remissionen oder der daraus abgeleiteten farbmetrischen Kenngrössen und nicht aufgrund von Dichtemessungen erfolgt. Auf diese Weise können die Bildeindrücke auch heikler, bildwichtiger Stellen im Fortdruck optimal mit denjenigen des Andrucks bzw. Andruckersatzes in Übereinstimmung gebracht werden, wobei bis zu einem gewissen Grad auch Farbabweichungen aufgrund unterschiedlicher Tonwertzunahmen und anderer Material- und Prozesseinflüsse ausgeglichen werden. Die Farbmessung selbst kann auf mitgedruckten Farbtestfeldern oder auch auf geeignet gewählten Stellen (Testbereichen) im Bild erfolgen.The essence of the present invention thus lies in the fact that the principle of densitometric color density measurement is present and is replaced by spectral color measurement, the spectral remissions of the measured test areas being determined and the control of the color guidance (at least during the set-up phase of the printing press) based on these spectral remissions or the one from it derived colorimetric parameters and not based on density measurements. In this way, the image impressions of sensitive, image-important points in the production run can be optimally matched to those of the proof or replacement, whereby to a certain extent color deviations due to different tonal value increases and other material and process influences are compensated for. The color measurement itself can be carried out on printed color test fields or also at suitably selected points (test areas) in the image.

Im folgenden wird die Erfindung anhand der Zeichnung naher erläutert. Es zeigen:

- Fig. 1

- ein stark vereinfachtes Blockschema einer erfindungsgemässen Druckanlage

- Fig. 2

- ein Blockschema des Messwerterfassungs-Teiles der Anlage nach Fig. 1 und

- Fig. 3

- eine schematische Skizze eines Details aus Fig. 2.

- Fig. 1

- a greatly simplified block diagram of a printing system according to the invention

- Fig. 2

- a block diagram of the measured value acquisition part of the system of FIG. 1 and

- Fig. 3

- 3 shows a schematic sketch of a detail from FIG. 2.

Die in Fig. 1 dargestellte Druckanlage entspricht bis auf die noch zu erläuternden erfindungsgemässen Unterschiede im Messwerterfassungsteil im wesentlichen den bekannten Anlagen dieser Art, beispielsweise etwa der schon erwähnten Anlage gemäss DE-A-2 728 738. Dementsprechend umfasst die dargestellte Druckanlage ein Messwerterfassungsgerät 10, eine Steuerkonsole 20 und eine mit einer fernsteuerbaren Farbführung ausgestattete Druckmaschine 30.The printing system shown in FIG. 1 essentially corresponds to the known systems of this type, for example the system according to DE-A-2 728 738, which is still to be explained, in accordance with the invention in the measured value acquisition part. a

Mit dem Messwerterfassungsgerät 10 werden von der Druckmaschine 30 erzeugte Druckbogen 40 in einer Reihe von Testbereichen, beispielsweise etwa in ausgewählten Stellen des Druckbilds oder im Bereich von mitgedruckten Farbmessfeldern 41 fotoelektrisch ausgemessen, und aus den dabei gewonnenen Messdaten werden Steuerdaten 11 ermittelt, welche den Farbabweichungen der am Druck beteiligten Druckfarben in den einzelnen Druckzonen und Druckwerken entsprechen und als Eingangsgrössen der Steuerkonsole 20 zugeführt werden Die Steuerkonsole 20 erzeugt aus den Steuerdaten 11 Stellsignale 21, welche die Farbführungsorgane der Druckmaschine 30 in der Weise verstellen, dass die Farbabweichungen minimal werden.With the measured

In Fig. 2 ist der prinzipielle Aufbau des Messwerterfassungsgeräts 10 dargestellt. Er entspricht in weiten Teilen demjenigen des in US-A-4 505 589 beschriebenen Gerätes. so dass sich die folgende Beschreibung im wesentlichen auf die erfindungsgemässen Unterschiede gegenüber diesem bekannten Gerät konzentriert.2 shows the basic structure of the measured

Das Gerät 10 umfasst einen Messkopf 101, der z. B. mittels eines Schrittmotors 102 relativ zum auszumessenden Druckbogen bewegbar ist. Zusätzlich ist noch ein Handmesskopf 103 vorgesehen, der manuell auf dem gewünschten Testbereich des Druckbogens positioniert werden kann. Die beiden Messköpfe 101 und 103 enthalten eine nicht dargestellte Messanordnung, welche den auszumessenden Testbereich z. B. gemäss dem üblichen Standard unter 45° beleuchtet und das vom Testbereich unter 90° remittierte Licht auffängt und in einen Lichtleiter 104 einkoppelt, der es einem Spektrometer 105 zuführt. (Selbstverständlich kann das remittierte Licht dem Spektrometer auch über andere Mittel zugeführt werden.) Dort wird das remittierte Licht spektral zerlegt und gemessen. Die dabei gewonnenen Messdaten werden einem Rechner 106 zugeführt, der aus ihnen in noch zu erläuternder Weise die Steuerdaten 11 für die Steuerkonsole 20 ermittelt. Daneben bedient bzw. steuert der Rechner 106 eine Treiber-Elektronik 107 für den Schrittmotor 102 und die Speisung der Lichtquellen in den Messköpfen 101 und 103 und ein Datensichtgerät 108, einen Drucker 109, und eine Tastatur 110. alles im wesentlichen so wie beim genannten bekannten Gerät.The

Der für die Erfindung primär relevante Unterschied des dargestellten Messwerterfassungsgeräts 10 gegenüber dem erwähnten bekannten Gerät besteht in erster Linie darin, dass es zur spektralen Farbanalyse der speziell auszumessenden Testbereiche und somit zur farbmetrischen Analyse eingerichtet ist, während das bekannte Gerät lediglich densitometrische Farbdichten zu messen imstande ist, also keine Farbmessung/Farbmetrik erlaubt. Der zweite wesentliche Unterschied besteht in der Auswertung der fotoelektrischen Messdaten im Hinblick auf die Steuerung der Farbführung.The primarily relevant difference for the invention of the measured

In Fig. 3 ist der prinzipielle (an sich bekannte) Aufbau des Spektrometers 105 gezeigt. Das über den faseroptischen Lichtleiter 104 (oder direkt) von einem der Messköpfe 101 und 103 zugeführte Messlicht beaufschlagt über einen Eintrittsspalt ein holografisches Gitter 151 und wird von diesem nach Wellenlängen geordnet räumlich aufgespaltet. Das so spektral zerlegte Licht fällt derart auf eine zeilenförmige Anordnung von z. B. 35 Fotodioden 152, dass jede Fotodiode mit Licht eines individuellen, relativ engen Wellenlängenbereichs beaufschlagt wird. Die von den 35 Fotodioden erzeugten Meßsignale entsprechen also der spektralen Intensitätsverteilung des Messlichts an 35 diskreten Stützpunkten (Wellenlängenbereichen). Zur Abfrage der Fotodioden 152 ist ein Interface (Schnittstelle) 153 vorgesehen, welches die Meßsignale verstärkt und digitalisiert und so in eine für den Rechner 106 verständliche Form bringt. Das Interface könnte räumlich natürlich auch im Rechner angeordnet sein.3 shows the basic structure (known per se) of

Das Messwerterfassungsgerät 10, die Steuerkonsole 20 und die eigentliche Druckmaschine 30 bilden einen geschlossenen Regelkreis. Bei den bisher bekannten Systemen dieser Art erfolgt die Regelung der Farbführung aufgrund von densitometrischen Dichtemessungen der beteiligten Druckfarben. Ergeben sich Abweichungen gegenüber entsprechenden Soll-Dichtewerten. so werden diese von der Steuerkonsole durch entsprechende Verstellung der Farbführungsorgane ausgeregelt, d.h. zu Null gemacht bzw. in den zulässigen Toleranzbereich gebracht. Die Farbführungssregelung erfolgt also farbdichtengesteuert.The measured

Aus den einleitend erwähnten Gründen ist diese bekannte Art der Farbführungssteuerung nicht in allen Fällen vollauf befriedigend.For the reasons mentioned in the introduction, this known type of color guide control is not completely satisfactory in all cases.

Gemäss dem grundlegenden Gedanken der Erfindung wird das Prinzip der alleinigen farbdichtengesteuerten Farbführung verlassen und durch eine auf spektraler Farbmessung und Farbmetrik beruhende Steuerung wesentlich ergänzt. Mit anderen Worten, für jeden Testbereich (z. B. Farbmessfeld) werden durch spektrale Messung die spektralen Remissionen ermittelt und gegebenenfalls durch Umrechnung die Farbwerte eines ausgewählten Farbkoordinatensystems bestimmt und mit entsprechenden Soll-Remissionen respektive Soll-Farbwerten verglichen. Die Steuerung der Farbführung erfolgt dann aufgrund der Abweichungen der spektralen Remissionen oder der Farbwerte von den Soll-Werten ("Farbabstände") und nicht mehr aufgrund der Abweichungen der densitometrischen Farbdichten. Vorzugsweise erfolgt die Regelung mit der Massgabe, dass der sich aus der Summe der Farbabstände verschiedener Testbereiche ergebende Gesamtabstand einer Druckzone minimal werden soll, wobei jeder Testbereich und entsprechend sein Farbabstand erwünschtenfalls mit einem individuellen Gewicht berücksichtigt werden kann.In accordance with the basic concept of the invention, the principle of color density-controlled color guidance is abandoned and is substantially supplemented by a control based on spectral color measurement and colorimetry. In other words, for each test area (e.g. color measuring field), the spectral remissions are determined by spectral measurement and, if necessary, the color values of a selected color coordinate system are determined by conversion and compared with corresponding target remissions or target color values. The color guidance is then controlled on the basis of the deviations in the spectral remissions or the color values from the target values (“color distances”) and no longer on the basis of the deviations in the densitometric color densities. The control is preferably carried out with the proviso that the total distance of a printing zone resulting from the sum of the color distances of different test areas should be minimal, wherein each test area and, accordingly, its color distance can, if desired, be taken into account with an individual weight.

Im folgenden wird die Steuerung nach Farbkoordinaten beschrieben. Für die Steuerung nach spektralen Remissionen gilt prinzipiell das gleiche.The control according to color coordinates is described below. In principle, the same applies to the control according to spectral remissions.

Das der Farbmessung zugrunde liegende Farbkoordinatensystem ist an sich beliebig. Vorzugsweise wird jedoch das L*a*b*-System oder das L*u*v*-System der CIE (Commission Internationale de l'Eclairage) verwendet. Unter Farbort wird im folgenden das Koordinaten-Tripel (L*, a*, b*) bzw. (L*, u*, v*) verstanden, unter Farbabstand entsprechend der Vektor ΔELab bzw. ΔELuv oder die Einzelvektoren (ΔL*, Δa*, Δb*) bzw. (ΔL*, Δu*, Δv*). Die Sollwerte der Farbkoordinaten (Soll-Farborte) für die einzelnen Testbereiche können dem Messwerterfassungsgerät 10 z. B. von Hand über die Tastatur 110 eingegeben werden. Viel einfacher und zweckmässiger ist es jedoch, den Andruck bzw. Andruckersatz, oder was sonst als Referenz dienen soll, mit dem Gerät selbst auszumessen und die Messwerte bzw. die daraus errechneten Daten als entsprechende Sollwerte abzuspeichern. Dasselbe gilt auch für die im Zusammenhang mit der noch zu beschreibenden, überlagerten dichteabhängigen Steuerung benötigen Farbdichte-Sollwerte.The color coordinate system on which the color measurement is based is in itself arbitrary. However, the L * a * b * system or the L * u * v * system of the CIE (Commission Internationale de l'Eclairage) is preferably used. In the following, the color locus is understood to mean the coordinate triple (L *, a *, b *) or (L *, u *, v *), the color distance corresponds to the vector ΔE Lab or ΔE Luv or the individual vectors (ΔL * , Δa *, Δb *) or (ΔL *, Δu *, Δv *). The target values of the color coordinates (target color locations) for the individual test areas can be used for the measured

Aus Gründen der leichteren Verständlichkeit einerseits und Kompatibilität mit bestehenden Geräten andererseits ist das gesamte Regelsystem darstellungsgemäss auf die beiden Komponenten Messwerterfassungsgerät 10 und Steuerkonsole 20 aufgeteilt und sind die vom Messwerterfassungsgerät 10 erzeugten Steuersignale 11 genau von derselben Art wie bei den bekannten Farbdichtemessanlagen, so dass das erfindungsgemässe Messwerterfassungserät 10 also direkt mit der genannten bekannten Steuerkonsole 20 zusammengeschlossen werden kann und zur Umrüstung einer entsprechenden Druckanlage auf das erfindungsgemässe Verfahren nur das Messwerterfassungsgerät ersetzt werden muss. Selbstverständlich ist es aber auch ohne weiteres möglich, die zur Ausregelung der Farbabweichungen erforderlichen Stellsignale ohne den Umweg über die kompatiblen Steuersignale unmittelbar aus den vom Messwerterfassungsgerät berechneten Farbabständen zu erzeugen und die dafür notwendigen elektrischen Schaltungen anders zusammenzufassen oder auch in ein einziges Gerät zu integrieren. Die dargestellte Zweiteilung ist daher, wenngleich auch sehr praxisnahe, rein beispielsweise zu verstehen.For reasons of easier comprehensibility on the one hand and compatibility with existing devices on the other hand, the entire control system is, as shown, divided into the two components of the measured

Der Rechner 110 bildet, wie schon erläutert, für jeden Testbereich den Farbabstandsvektor ΔEn. Jeder dieser Vektoren ΔEn wird nun mit einem Gewichtsfaktor gn gewichtet, sodass also jeder Testbereich individuell berücksichtigt werden kann. Bildtypische Testbereiche werden dabei ein grösseres Gewicht erhalten, weniger bildwichtige ein geringeres.As already explained, the

Selbstverständlich ist es auch möglich, auf die Gewichtung zu verzichten, und alle Testbereiche gleich zu behandeln oder aber von vorneherein nur bestimmte Testbereiche zur Steuerung heranzuziehen. Die Gewichtsfaktoren können über die Tastatur z. B. auch interaktiv eingegeben oder vorprogrammiert sein.Of course, it is also possible to forego weighting and to treat all test areas equally, or to use only certain test areas for control from the outset. The weighting factors can be done via the keyboard e.g. B. can also be entered interactively or preprogrammed.

Die gewichteten oder gegebenenfalls auch ungewichteten Farbabstandvektoren einzelner Messfelder werden mathematisch je mit einer z. B. empirisch ermittelten Transformationsmatrix multipliziert, und bei Beachtung gewisser Gütekriterien ergibt sich daraus ein Farb-Dichteänderungsvektor, dessen Komponenten die Dichteänderungen bzw. die Schichtdickenänderungen der am Druck beteiligten Druckfarben sind, und der damit die Steuerdaten für die betreffende Druckzone darstellt und solche Änderungen der Einstellung der Farbführungsorgane hervorruft, dass der Gesamtfarbabstand - ermittelt als die Summe der Beträge oder Summe der Farbabstandquadrate der einzelnen Farbabstände - minimal wird. Dieser Gesamtfarbabstand kann auch als Qualitätsmass für den Druck dienen.The weighted or, if necessary, also unweighted color distance vectors of individual measuring fields are mathematically each with a z. B. multiplied empirically determined transformation matrix, and if certain quality criteria are observed, this results in a color density change vector, the components of which are the density changes or the layer thickness changes of the printing inks involved in the printing, and thus the control data for the printing zone in question and such changes in the setting of the color guide elements causes the total color difference - determined as the sum of the amounts or the sum of the color difference squares of the individual color differences - to be minimal. This total color difference can also serve as a quality measure for the print.

Die Elemente der Transformationsmatrizen enthalten im wesentlichen die partiellen Ableitungen der Farbkoordinaten nach den Farbdichten der beteiligten Druckfarben. Sie können empirisch durch Messungen an entsprechenden Testdrucken oder synthetisch durch Modellierung ermittelt werden.The elements of the transformation matrices essentially contain the partial derivatives of the color coordinates according to the color densities of the printing inks involved. They can be determined empirically by measurements on appropriate test prints or synthetically by modeling.

Für den Dreifarbendruck hat der Dichteänderungsvektor drei Komponenten, und die Berechnung aus den ebenfalls drei Komponenten aufweisenden Farbabstandsvektoren ist daher relativ komplikationsfrei. Bei mehr als drei Druckfarben müssen jedoch die Beiträge der einzelnen Testbereiche in geeigneter Weise logisch den einzelnen Komponenten des Dichteänderungsvektors in der Weise zugeordnet werden, dass sich ein entsprechend mehrdimensionaler Vektor ergibt.For three-color printing, the density change vector has three components, and the calculation from the color distance vectors, which also have three components, is therefore relatively free of complications. With more than three inks However, the contributions of the individual test areas must be logically assigned to the individual components of the density change vector in a suitable manner in such a way that a correspondingly multidimensional vector results.

Wie schon erwähnt, können die Stellsignale für die Farbführungsorgane aber ohne weiteres auch direkt aus den Farbabständen ermittelt werden. Auch hier wird man zweckmässigerweise wieder das Kriterium zugrundelegen, dass der Gesamtfarbabstand minimalisiert werden muss. Die unterschiedliche Gewichtung der einzelnen Testhereiche kann auch dabei angewandt werden.As already mentioned, the control signals for the color guide elements can also be determined directly from the color differences. Again, the criterion that the total color difference must be minimized is expediently used as a basis. The different weighting of the individual test areas can also be used here.

Der Druckprozess verläuft üblicherweise in drei Phasen. Da ist zunächst die mehr oder weniger grobe Voreinstellung ("Presetting") der Druckmaschine z. B. aufgrund von Messwerten der Druckplatten, dann die sogenannte Einrichtephase (Abstimmen. Registermachen), in der die Farbführung anhand des Andruckes bzw. Andruckersatzes auf die eine oder die andere Weise solange fein eingestellt wird, bis das Druckerzeugnis befriedigt, und schliesslich der Fortdruck, bei dem sich die Regelung darauf konzentriert, das bei der Einrichtung erreichte Ergebnis möglichst konstant beizubehalten. Üblicherweise benützt man hierbei als Referenz nicht den Andruck oder dergleichen. sondern den für gut befundenen Druckbogen, den sogenannten "O.K.-Bogen", und regelt im Fortdruck auf konstante densitometrische Farbdichten.The printing process usually runs in three phases. First there is the more or less rough presetting of the printing press, for. B. on the basis of measured values of the printing plates, then the so-called set-up phase (coordination. Registering), in which the ink guide is fine-tuned in one way or the other until the printed product is satisfied, and finally the production run, where the regulation focuses on maintaining the result achieved at the facility as constant as possible. Usually you do not use the proof or the like as a reference. but rather the print sheet found to be good, the so-called "O.K. sheet", and regulates in the production process to constant densitometric color densities.

Die Phase der Dichteregelung im Fortdruck lässt sich sehr einfach auch mit der erfindungsgemässen Druckanlage realisieren. Es brauchen dazu lediglich die spektralen Remissionen in Filter-Farbdichten (entsprechend der Densitometrie) umgerechnet und mit den von einem O.K.-Bogen ermittelten Sollfarbdichtewerten verglichen zu werden. Die Differenzen der Farbdichten stellen dann unmittelbar die Steuerdaten 11 für die Steuerkonsole 20 dar.The phase of density control in continuous printing can also be implemented very easily with the printing system according to the invention. All that is required is to convert the spectral reflectances into filter color densities (according to densitometry) and to compare them with the target color density values determined by an O.K. sheet. The differences in color densities then directly represent the

Gemäss einer vorteilhaften Ausführungsform des erfindungsgemässen Verfahrens kann also das Einrichten der Druckmaschine wie weiter vorne beschrieben farbabstandgesteuert erfolgen und der Fortdruck dann in an sich herkömmlicher Weise farbdichtengesteuert stabilisiert werden. Ein besonderer Vorteil dabei ist ferner, dass der Farbdichte-Ermittlung beliebige Filtercharakteristiken zugrunde gelegt werden können, wodurch hohe Flexibilität einer solchen Anlage erreicht wird.According to an advantageous embodiment of the method according to the invention, the setting up of the printing press can be carried out in a color-gap-controlled manner as described further above and the production run can then be stabilized in a conventional manner in a color-density-controlled manner. Another particular advantage is that the color density determination can be based on any filter characteristics, which achieves a high degree of flexibility in such a system.

Gemäss einer weiteren vorteilhaften Variante können die beiden Steuerungsprinzipien einander auch überlagert werden. Das heisst, während der farbdichtegesteuerten Fortdruckstabilisierung wird zusätzlich der Gesamtfarbabstand bestimmt und überwacht. Solle der Gesamtfarbabstand aus irgendwelchen Gründen, z. B. aufgrund von Veränderungen im Druckprozess wie etwa Gummituchverschmutzung etc., einen vorgegebenen Grenzwert überschreiten, so kann in geeigneter Weise reagiert werden. Beispielsweise kann eine neue farbabstandgesteuerte Korrektur der Druckmaschine veranlasst werden, wobei dann gleichzeitig die Farbdichte-Sollwerte für die weitere Fortdruckstabilisierung angepasst (aktualisiert) würden, oder es kann nur oder zusätzlich eine entsprechende Fehlermeldung ausgegeben werden.According to a further advantageous variant, the two control principles can also be superimposed on one another. This means that the total color distance is also determined and monitored during the color density-controlled production stabilization. The total color difference should be for some reason, e.g. B. due to changes in the printing process such as rubber blanket pollution, etc., exceed a predetermined limit, it can be reacted in a suitable manner. For example, a new color distance controlled Correction of the printing press can be initiated, in which case the color density setpoints would then be adapted (updated) for further production stabilization, or a corresponding error message can only or additionally be output.

Der Gesamtfarbabstand kann als Qualitätsmass betrachtet und erwünschtenfalls angezeigt oder ausgedruckt werden.The total color difference can be viewed as a quality measure and, if desired, displayed or printed out.

Ein wichtiges Element zur standardisierten Drucküberwachung ist der Farbmeßstreifen. Die Rastertone sollen dabei in verschiedenen Farb- und Tonwertkombinationen bzw. besonders kritischen Tönen angepasst vorkommen. Es ist auch möglich, kritische Töne aus dem Sujet in den Meßstreifen aufzunehmen.An important element for standardized pressure monitoring is the color measuring strip. The screen tones should appear in different color and tonal value combinations or particularly critical tones. It is also possible to include critical tones from the subject in the measuring strips.

Sujets lassen sich farbabhängig erfahrungsgemäss in Gruppen einteilen, z. B. Möbelkataloge - Brauntöne qualitätsbestimmend -, Kosmetikprospekte und Porträts - Hauttone dominant. So gibt es auch Gruppen, in denen z. B. Grau- oder Grüntone vorherrschen. Dementsprechend lassen sich spezielle farborientierte Farbmeßstreifen aufbauen und gezielt anwenden. Damit kann in einfacher Weise den bildbestimmenden Bereichen Rechnung getragen werden.According to experience, subjects can be divided into groups, e.g. B. Furniture catalogs - shades of brown determining quality -, cosmetic brochures and portraits - skin tones dominant. There are also groups in which e.g. B. Gray or green tones prevail. Accordingly, special color-oriented color measuring strips can be built up and used in a targeted manner. The areas determining the image can thus be taken into account in a simple manner.

Beim Andruck/Andruckersatz ist die Farbführung nicht immer zonal gesteuert. Es reicht in diesem Fall aus, von jedem Messfeldtyp ein Messfeld mitzudrucken und für die ganze Druckbogenbreite oder Teile davon als Sollwert zu übernehmen.With the proofing / proofing set, the inking is not always controlled zonally. In this case, it is sufficient to print a measuring field for each measuring field type and to adopt it as the target value for the entire printing sheet width or parts thereof.

Auf dem Fortdruckbogen mit zonaler Farbzuführung kann jede Zone einzeln überwacht werden. Zur Farbsteuerung wichtige Messfelder wie Einfarbenmessfelder zur dichtegesteuerten Regelung der Farbführung oder Mehrfarben-Raster-Felder zur colorimetrischen Steuerung müssen sich daher in möglichst kleinem Abstand wiederholen. Kontrollfelder für Farbannahme, Tonwertzunahme usw. können mit etwas grösserem Abstand montiert sein.Each zone can be monitored individually on the production sheet with zonal ink feed. Measuring fields that are important for color control, such as single-color measuring fields for density-controlled regulation of the color guidance or multicolor raster fields for colorimetric control, must therefore be repeated at the smallest possible distance. Control fields for color acceptance, tonal value increase etc. can be mounted at a slightly greater distance.

Im Dreifarbendruck wird der druckbare Farbraum durch die Farborte von Papierweiss, der Einfarben-Volltone sowie der 2- und 3-Farben-Volltonübereinanderdrucke (Weiss, Cyan, Magenta, Yellow, Rot, Grün, Blau, Schwarz) begrenzt. Sämtliche Rastertöne liegen innerhalb dieses Farbraumes. Beim Druck können Farbabweichungen zwar nicht in allen Farbtönen gleichzeitig ausgeglichen werden, jedoch ist eine Optimierung des mittleren Farbabstandes möglich. Es ist daher zweckmässig, nebst den Feldern für die farbdichtegesteuerte Regelung für die farbabstandgesteuerte Farbführung zusätzlich geeignete 2-und/oder 3-Farben-Rasterfelder wie Graubalance-Felder oder sujetabhängig heikle Töne heranzuziehen.In three-color printing, the printable color space is limited by the color loci of paper white, the single-color solid tones and the 2 and 3-color solid tone overlays (white, cyan, magenta, yellow, red, green, blue, black). All grid tones are within this color space. When printing, color deviations cannot be compensated for in all color tones at the same time, but the mean color difference can be optimized. It is therefore expedient to use, in addition to the fields for the color density-controlled regulation for the color distance-controlled color guidance, also suitable 2 and / or 3 color grid fields such as gray balance fields or sensitive tones depending on the subject.

Im Vierfarbendruck wird die Verschwärzlichung durch 3 Buntfarben und/oder durch Schwarz erzeugt. Als Messfelder zur farbortgesteuerten Regelung können daher auch Rasterfelder mit Schwarz und 2 oder 3 Buntfarben von Interesse sein. Die Farbtöne werden mit Vorteil aus kritischen Bereichen des Farbraums gewählt. Bei Verwendung von 4-Farben-Rasterfeldern muss eine Farbe als freier Parameter vorbestimmt oder auf einem separaten Farbmessfeld zusätzlich gemessen werden.In four-color printing, the blackening is created by 3 chromatic colors and / or black. Grid fields with black and 2 or 3 chromatic colors can therefore also be of interest as measuring fields for color location-controlled control. The color tones are advantageously chosen from critical areas of the color space. When using 4-color grid fields, a color must be predetermined as a free parameter or additionally measured on a separate color measuring field.

Für Sonderfarben können je nach Sujet nach analogen Gesichtspunkten geeignete Farbmessfelder bestimmt werden.Depending on the subject, suitable color measuring fields can be determined for special colors according to analogous criteria.

Claims (23)

- A process for controlling the application of ink by a printing machine in which a printed sheet, printed by the printing machine, is measured colorimetrically in a number of test areas with reference to a selected colour coordinate system, the resulting colour location coordinates are processed in conjunction with reference values to produce control data for the inking process elements of the printing machine, and the inking process of the printing machine is controlled automatically using those control data, wherein there are used as reference values reference colour location coordinates based on the same selected colour coordinate system, wherein starting from the colour location coordinates for the measured test areas the colour deviation vectors to those reference colour location coordinates are determined, wherein the colour deviation vectors are converted into the control data necessary for controlling the inking process of the printing machine, for example into changes in layer thickness, and wherein the inking process of the printing machine is controlled on the basis of the control data converted from the colour deviation vectors.

- A process according to claim 1, wherein the inking process is so controlled that individual colour deviations of given test areas are minimal.

- A process according to claim 1, wherein the inking process is so controlled that the total colour deviation resulting from the individual colour deviations is minimal.

- A process according to any one of claims 1 to 3, wherein the individual colour deviations are given different weights when calculating the total colour deviation.

- A process according to any one of claims 1 to 4, wherein the control data are calculated for printing zones from the colour deviations of the test areas belonging to the printing zones involved.

- A process according to any one of claims 1 to 5, wherein the zonal control data are calculated from the colour deviations of zone-overlapping test areas.

- A process according to any one of claims 1 to 6, wherein the weighting of the individual colour deviations varies by area over the print width.

- A process according to any one of claims 1 to 7, wherein the control data are calculated from the standard colour values obtained by digital filtering (weighting) of the spectral reflections using CIE-standard spectral value curves and from their conversion into a selected colour coordinate system suitable for colour deviation evaluation, especially the CIELAB or CIELUV system.

- A process according to any one of claims 1 to 7, wherein in addition the control data are calculated from the colour densities obtained by digital filtering (weighting) of the spectral reflections using selected colour filter curves.

- A process according to any one of claims 1 to 9, wherein the setting-up of the printing machine, that is to say the matching of the print to the master, is effected with colour deviation control and subsequently the printing run is carried out based on colour densities in such a manner that those colour densities are maintained essentially at constant reference values.

- A process according to any one of claims 1 to 10, wherein there are used as test areas simultaneously printed colour measuring fields and, in particular, also multi-colour halftone fields are provided as colour measuring fields.

- A process according to claim 10, wherein the colour-density-controlled printing run stabilisation is superposed on the colour deviation-controlled regulation of the inking process so that a new colour deviation-controlled correction is made, with simultaneous updating of the reference values for the colour densities, if the colorimetric colour deviations exceed a threshold value.

- A process according to claim 10, wherein the total colour deviation or deviations is or are also formed and monitored during the printing run and a warning is issued, or a new colour deviation-controlled correction of the printing machine is carried out, if the colour deviation tolerance is exceeded.

- A process according to claim 11, wherein colour measuring fields are used having colour tones taken from selected critical image areas of the printed sheet.

- A printing installation for carrying out the process according to any one of the preceding claims, comprising a printing machine, a data acquisition device for colorimetric measurement of a printed sheet by area with reference to a selected colour coordinate system, and a control means for processing the colour location coordinates produced by the data acquisition device and for producing adjustment signals for the inking process elements of the printing machine from those colour location coordinates and reference values, wherein the control means is designed to determine colour deviation vectors from the colour location coordinates produced by the data acquisition device by comparison with reference colour location coordinates and to produce the adjustment signals on the basis of those colour deviation vectors.

- A printing installation according to claim 15, wherein the data acquisition device is arranged for spectral photometric measurement of the printed sheet at a number of different wavelengths and for the production of corresponding spectral photometric measured data.

- A printing installation according to claim 16, wherein the control means is designed to convert the spectral photometric measured data produced by the data acquisition device also into colour densities and to produce the adjustment signals for the inking process elements also from the result of a comparison of those colour densities with corresponding reference colour densities.

- A measuring device for producing control data for the inking process elements of a printing machine comprising a data acquisition device for colorimetric measurement of a printed sheet by area with reference to a selected colour coordinate system, and a processing means that from the colour location coordinates produced by the data acquisition device produces the control data that represent the deviation of colour of the measured areas of the printed sheet from corresponding reference values, wherein the processing means is designed to determine from the colour location coordinates produced by the data acquisition device, by comparison with reference colour location coordinates, colour deviation vectors thereto, and to produce the control data for the inking process elements of the printing machine from those colour deviation vectors.

- A measuring device according to claim 18, wherein the data acquisition device is arranged for spectral photometric measurement of the printed sheet at a number of different wavelengths and for production of corresponding spectral photometric measured data.

- A measuring device according to claim 19, wherein the processing means is additionally arranged to convert the spectral photometric measured data produced by the data acquisition device into colour densities, compare them with reference colour densities, and produce the control data for the printing machine from the result of that comparison.

- A measuring device according to any one of claims 18 to 20, wherein it is arranged to perform the process steps according to one or more of claims 1 to 15.

- A measuring device according to claim 18, wherein, in addition to photoelectric colour measurement with a controlledly movable measuring head, a freely movable measuring head is connected with which colour measurement may be effected at any location and on any samples.

- A measuring device according to claim 22, wherein the freely movable measuring head acts on the same spectrometer module as the controlledly movable measuring head.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT86810562T ATE47564T1 (en) | 1985-12-10 | 1986-12-04 | PROCEDURE FOR INK ORDER CONTROL IN A PRINTING PRESS, APPROPRIATELY EQUIPPED PRINTING SYSTEM AND MEASURING DEVICE FOR SUCH PRINTING SYSTEM. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH526285 | 1985-12-10 | ||

| CH5262/85 | 1985-12-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0228347A1 EP0228347A1 (en) | 1987-07-08 |

| EP0228347B1 EP0228347B1 (en) | 1989-10-25 |

| EP0228347B2 true EP0228347B2 (en) | 1996-11-13 |

Family

ID=4290661

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86810562A Expired - Lifetime EP0228347B2 (en) | 1985-12-10 | 1986-12-04 | Process for controlling the application of colours in a printing machine, printing device equipped therewith and measuring device for such a printing device |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6041708A (en) |

| EP (1) | EP0228347B2 (en) |

| JP (1) | JP2505434B2 (en) |

| AT (1) | ATE47564T1 (en) |

| DE (1) | DE3666554D1 (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19749066A1 (en) * | 1997-11-06 | 1999-05-12 | Heidelberger Druckmasch Ag | Process for regulating the color application in a printing press |

| DE19749063A1 (en) * | 1997-11-06 | 1999-05-12 | Heidelberger Druckmasch Ag | Process for achieving color measurements for ink printers |

| DE19749064A1 (en) * | 1997-11-06 | 1999-05-12 | Heidelberger Druckmasch Ag | Method for determining color value gradients |

| DE102007028327A1 (en) | 2007-06-15 | 2008-12-18 | Flexicon Ag | Printing system for printing plastic container, has support printing unit dimensioned and arranged such that support printing unit provides support for measuring strip printing unit opposite undesired local printing pressure increase |

| DE102007032944A1 (en) | 2007-07-14 | 2009-01-15 | Nelissen, Christian, Dipl.-Ing. | Method for establishing target parameters for standardized printing comprises choosing main printing ink, spot ink and substrate from databases, profile generated from choices being input and target parameters for process calculated from it |

| DE102009013174A1 (en) | 2008-03-31 | 2009-10-01 | Heidelberger Druckmaschinen Ag | Method for process control of printing process in printing machine, involves converting set of standard values into another set of standard values with polynomial of degree n greater than one |

| DE19830487B4 (en) * | 1997-11-06 | 2010-12-16 | Heidelberger Druckmaschinen Ag | Method for determining area coverage in a printed image |

| US11458724B2 (en) | 2016-09-13 | 2022-10-04 | Advanced Vision Technology (A.V.T.) Ltd. | System and method for controlling color characteristics of a printed image |

Families Citing this family (82)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4967379A (en) * | 1987-12-16 | 1990-10-30 | Gretag Aktiengesellschaft | Process for the ink control or regulation of a printing machine by comparing desired color to obtainable color data |

| US4975862A (en) * | 1988-01-14 | 1990-12-04 | Gretag Aktiengesellschaft | Process and apparatus for the ink control of a printing machine |

| AU615020B2 (en) * | 1988-01-14 | 1991-09-19 | Gretag Aktiengesellschaft | Process and apparatus for the ink control of a printing machine |

| DE3812099C2 (en) * | 1988-04-12 | 1995-01-26 | Heidelberger Druckmasch Ag | Process for color control of an offset printing press |

| DE3829341A1 (en) * | 1988-08-30 | 1990-03-08 | Roland Man Druckmasch | DATA COLLECTION FOR COLOR CONTROL SYSTEMS |

| DE3830731A1 (en) * | 1988-09-09 | 1990-03-22 | Heidelberger Druckmasch Ag | DEVICE FOR COLOR MEASUREMENT |

| DE3903981C2 (en) * | 1989-02-10 | 1998-04-09 | Heidelberger Druckmasch Ag | Process for controlling ink filling in a printing press |

| DE3913382C2 (en) * | 1989-04-24 | 1995-12-14 | Heidelberger Druckmasch Ag | Process for controlling the ink flow of a printing press |

| EP0421003B1 (en) * | 1989-10-02 | 1994-12-07 | grapho metronic Mess- und Regeltechnik GmbH & Co. | Method of controlling the ink supply in a printing machine |

| DE4013286C2 (en) * | 1990-04-26 | 2001-04-12 | Roland Man Druckmasch | Control for multiple presses in a press room |

| DE4038574C2 (en) * | 1990-12-04 | 1999-05-27 | Roland Man Druckmasch | Process for controlling the printing ink order in the production of multicolored printed products |

| DE4104537C2 (en) * | 1991-02-14 | 1999-05-12 | Roland Man Druckmasch | Method for controlling a color guide of an offset printing machine |

| DE4122794A1 (en) * | 1991-07-10 | 1993-01-14 | Roland Man Druckmasch | METHOD FOR MONITORING AND REGULATING THE PRINTING PROCESS, ESPECIALLY ON OFFSET PRINTING MACHINES |

| EP0736381B1 (en) * | 1991-09-19 | 1999-01-27 | LINTEC Corporation | Die cutting device for a printing device |

| US5540148A (en) * | 1991-09-19 | 1996-07-30 | Lintec Co., Ltd. | Printing device and die-cutting device |

| US5224421A (en) * | 1992-04-28 | 1993-07-06 | Heidelberg Harris, Inc. | Method for color adjustment and control in a printing press |

| DE4229267A1 (en) * | 1992-09-02 | 1994-03-03 | Roland Man Druckmasch | Method for controlling the printing process on an autotypically operating printing machine, in particular sheet-fed offset printing machine |

| DE4240077C2 (en) * | 1992-11-28 | 1997-01-16 | Heidelberger Druckmasch Ag | Process for zonal control / regulation of the ink flow in a printing press |

| DE4321179A1 (en) * | 1993-06-25 | 1995-01-05 | Heidelberger Druckmasch Ag | Method and device for controlling or regulating the operations of a printing machine |

| DE4431270C2 (en) * | 1993-10-21 | 1997-01-16 | Roland Man Druckmasch | Process for controlling the ink flow of an autotypically working printing machine |

| DE4343905C2 (en) * | 1993-12-22 | 1996-02-15 | Roland Man Druckmasch | Process for controlling the ink flow in a printing press |

| DE4403861C2 (en) * | 1994-02-08 | 1998-08-20 | Heidelberger Druckmasch Ag | Method for producing a multicolored print with a printing press in at least two different runs |

| DE4415486C2 (en) * | 1994-05-03 | 1998-06-04 | Heidelberger Druckmasch Ag | Process for determining the permissible tolerances for the control or regulation of the coloring on a printing press |

| DE19511076C1 (en) * | 1995-03-25 | 1996-05-23 | Roland Man Druckmasch | Colour impurity detection in multicolour print esp. on offset machine |

| DE19515499C2 (en) * | 1995-04-27 | 1997-03-06 | Heidelberger Druckmasch Ag | Process for simultaneous multi-color control during printing |

| US6459425B1 (en) * | 1997-08-25 | 2002-10-01 | Richard A. Holub | System for automatic color calibration |

| DE19627459B4 (en) * | 1996-07-08 | 2010-01-07 | Heidelberger Druckmaschinen Ag | Method for controlling a printing machine |

| EP0860276B1 (en) * | 1997-02-19 | 2002-10-16 | Baldwin Germany GmbH | Device and method for quality control |

| DE19722073C2 (en) * | 1997-05-27 | 1999-12-16 | Techkon Elektronik Gmbh | Process and line printer for digital output and colorimetric measurement of colored images |

| DE29721199U1 (en) * | 1997-11-29 | 1998-01-29 | Roland Man Druckmasch | Measuring system |

| JP3384769B2 (en) * | 1999-04-19 | 2003-03-10 | リョービ株式会社 | Ink supply amount adjustment device and ink supply amount adjustment method |

| ATE274184T1 (en) * | 1999-10-11 | 2004-09-15 | Gretag Macbeth Ag | DEVICE FOR AUTOMATIC MEASUREMENT OF MEASURING FIELDS |

| DE10105990A1 (en) | 2000-03-03 | 2001-09-06 | Heidelberger Druckmasch Ag | Method for controlling ink layer parameters for selected print zones in printer output to ensure there is a more homogenous ink distribution with sharper definition between print zones |

| JP3781941B2 (en) | 2000-03-13 | 2006-06-07 | 大日本スクリーン製造株式会社 | Printing device |

| JP3748194B2 (en) | 2000-04-26 | 2006-02-22 | 大日本スクリーン製造株式会社 | Printing color management method and prepress printing system |

| US6584372B1 (en) * | 2000-05-17 | 2003-06-24 | Abb Automation Inc. | Dye rate control for paper web color change |

| JP2002086689A (en) * | 2000-09-13 | 2002-03-26 | Komori Corp | Method and device for color administration for printing machine |

| EP1762387B1 (en) | 2000-10-13 | 2014-05-14 | Dainippon Screen Mfg., Co., Ltd. | Printing press equipped with color chart measuring apparatus |

| DE10152470B4 (en) * | 2000-11-23 | 2014-08-14 | Heidelberger Druckmaschinen Ag | Method for color presetting in multicolor printing |

| PL200158B1 (en) * | 2000-12-06 | 2008-12-31 | Avt Advanced Vision Technology | Spectral color control method |

| US6564714B2 (en) | 2000-12-06 | 2003-05-20 | Delaware Capital Formation, Inc. | Spectral color control method |

| CA2439819A1 (en) * | 2001-03-02 | 2002-09-12 | The Ackley Martinez Company Dba Mgi Studio | Printing adjustment system and method |

| ATE552974T1 (en) * | 2001-07-04 | 2012-04-15 | Dainippon Screen Mfg | APPARATUS AND METHOD FOR MEASURING COLOR METER STRIP |

| DE60227259D1 (en) * | 2001-07-30 | 2008-08-07 | Ackley Martinez Co Dba Mgi Stu | Color management method and system |

| US20030156299A1 (en) * | 2001-07-30 | 2003-08-21 | The Ackley Martinz Company Dba Mgi Studio | Color management processing system |

| JP3880831B2 (en) | 2001-10-10 | 2007-02-14 | 大日本スクリーン製造株式会社 | Ink preset method |

| JP2003118085A (en) | 2001-10-10 | 2003-04-23 | Dainippon Screen Mfg Co Ltd | Printer |

| US6792863B2 (en) | 2001-10-15 | 2004-09-21 | Dainippon Screen Mfg Co., Ltd. | Printing apparatus for automatically controlling ink supply device |

| DE10257981A1 (en) * | 2002-01-15 | 2003-07-24 | Heidelberger Druckmasch Ag | Color control of printing machine with spectral based color measurement used to determine actual vale of spectral reflectance |

| JP2003311933A (en) | 2002-04-24 | 2003-11-06 | Dainippon Screen Mfg Co Ltd | Patch measuring device and printing device incorporating the same |

| JP3934473B2 (en) * | 2002-05-09 | 2007-06-20 | 大日本スクリーン製造株式会社 | Patch measuring device and printing device incorporating the same |

| US7017492B2 (en) * | 2003-03-10 | 2006-03-28 | Quad/Tech, Inc. | Coordinating the functioning of a color control system and a defect detection system for a printing press |

| US7032508B2 (en) * | 2003-03-21 | 2006-04-25 | Quad/Tech, Inc. | Printing press |

| US7573613B2 (en) | 2003-08-07 | 2009-08-11 | Mitsubishi Heavy Industries Ltd. | Method and apparatus for controlling picture color tone of printing press |

| DE50305862D1 (en) | 2003-10-23 | 2007-01-11 | Gretag Macbeth Ag | Color quality assessment and color control in color reproduction |

| FR2861845B1 (en) * | 2003-10-29 | 2006-01-13 | Arjo Wiggins | METHOD AND DEVICE FOR CONTROLLING THE COLOR OF A SUPPORT |

| JP4280615B2 (en) | 2003-12-09 | 2009-06-17 | 富士フイルム株式会社 | Adjustment amount measuring apparatus and adjustment amount measurement program |

| JP2005246839A (en) * | 2004-03-05 | 2005-09-15 | Mitsubishi Heavy Ind Ltd | Method and equipment for controlling color tone in printing machine |

| DE102004021601B4 (en) * | 2004-05-03 | 2020-10-22 | Heidelberger Druckmaschinen Ag | Inline measurement and control for printing machines |

| JP4365754B2 (en) * | 2004-08-31 | 2009-11-18 | 三菱重工業株式会社 | Pattern color tone control method and apparatus |

| JP2006076191A (en) * | 2004-09-10 | 2006-03-23 | Mitsubishi Heavy Ind Ltd | Method and device for controlling color tone of pattern |

| DE102004061469A1 (en) | 2004-12-18 | 2006-07-13 | Man Roland Druckmaschinen Ag | Method for controlling the color in an offset printing machine |

| US7605959B2 (en) | 2005-01-05 | 2009-10-20 | The Ackley Martinez Company | System and method of color image transformation |

| US20060170996A1 (en) * | 2005-02-02 | 2006-08-03 | Steven Headley | Color control of a web printing press utilizing intra-image color measurements |

| DE102005007780A1 (en) * | 2005-02-19 | 2006-08-31 | Man Roland Druckmaschinen Ag | Apparatus and method for measuring zonal coloring |

| DE102007005018B4 (en) * | 2006-02-24 | 2020-06-04 | Heidelberger Druckmaschinen Ag | Process for the color control of copies of a printing press |

| DE102006014657B4 (en) * | 2006-03-28 | 2008-11-20 | Koenig & Bauer Aktiengesellschaft | Method for color control of a printing press |

| DE102006038200A1 (en) * | 2006-08-16 | 2008-02-21 | Man Roland Druckmaschinen Ag | Control room of a printing machine |

| US20080204771A1 (en) * | 2007-02-22 | 2008-08-28 | Albat Andreas M | Continuous calibration of proof printer |

| JP5129982B2 (en) * | 2007-05-18 | 2013-01-30 | リョービ株式会社 | Color matching method and color matching device for printing press |

| DE102007059176B4 (en) | 2007-12-06 | 2013-10-17 | Windmöller & Hölscher Kg | Method for operating a printing press and printing press for carrying out the method |

| DE102007059175A1 (en) | 2007-12-06 | 2009-06-10 | Windmöller & Hölscher Kg | Color mixture composition regulating method for sheet fed printing machine, involves producing correction color mixture due to variation of optical actual values that are obtained by continuous and even printed print substrate |

| CN101939167B (en) | 2007-12-06 | 2013-07-03 | 温德莫勒及霍尔希尔公司 | Colour-management |

| DE102007059177B4 (en) | 2007-12-06 | 2011-07-14 | Windmöller & Hölscher KG, 49525 | Apparatus and method for controlling the composition of the printing ink on a printing machine |

| DE102010009226B4 (en) * | 2009-03-13 | 2024-02-15 | Heidelberger Druckmaschinen Ag | Method for controlling the ink application in a printing press |

| DE102009046853A1 (en) * | 2009-11-19 | 2011-05-26 | Manroland Ag | Method for determining the properties of a printed substrate |

| RU2468922C2 (en) * | 2011-02-22 | 2012-12-10 | Государственное Образовательное Учреждение Высшего Профессионального Образования "Омский Государственный Технический Университет" | Method to select components of printing system for optimal colour rendition in multicolour printing |

| DE102014002509A1 (en) | 2014-02-21 | 2015-08-27 | Heidelberger Druckmaschinen Ag | Conversion of spectral characterization data |

| DE102018216442A1 (en) * | 2018-09-26 | 2020-03-26 | Heidelberger Druckmaschinen Ag | Register measurement without register marks |

| DE102019201482A1 (en) * | 2019-02-06 | 2020-08-06 | Heidelberger Druckmaschinen Ag | Machine downtime |

| DE102019122351A1 (en) * | 2019-08-20 | 2021-02-25 | Canon Production Printing Holding B.V. | Method and device for checking and / or adapting current ink transfer properties of a printing system and using a sensor arranged in a printing system |

| DE102023103467A1 (en) | 2022-03-24 | 2023-09-28 | Heidelberger Druckmaschinen Aktiengesellschaft | Method for adjusting a color in a printing press |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE99439C (en) * | ||||

| DE234257C (en) * | 1909-05-08 | |||

| FR2181213A5 (en) * | 1972-04-21 | 1973-11-30 | Renault | |

| US3958509A (en) * | 1974-06-13 | 1976-05-25 | Harris Corporation | Image scan and ink control system |

| US3995958A (en) * | 1975-07-21 | 1976-12-07 | Hallmark Cards, Incorporated | Automatic densitometer and method of color control in multi-color printing |

| US4022534A (en) * | 1976-03-23 | 1977-05-10 | Kollmorgen Corporation | Reflectometer optical system |