EP0211136A2 - Method and winding machine with two supporting rollers for inserting a bobbin adapted for receiving web material - Google Patents

Method and winding machine with two supporting rollers for inserting a bobbin adapted for receiving web material Download PDFInfo

- Publication number

- EP0211136A2 EP0211136A2 EP86103136A EP86103136A EP0211136A2 EP 0211136 A2 EP0211136 A2 EP 0211136A2 EP 86103136 A EP86103136 A EP 86103136A EP 86103136 A EP86103136 A EP 86103136A EP 0211136 A2 EP0211136 A2 EP 0211136A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- winding

- winding tube

- transfer position

- carrier roller

- winding machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H19/00—Changing the web roll

- B65H19/22—Changing the web roll in winding mechanisms or in connection with winding operations

- B65H19/30—Lifting, transporting, or removing the web roll; Inserting core

- B65H19/305—Inserting core

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H19/00—Changing the web roll

- B65H19/22—Changing the web roll in winding mechanisms or in connection with winding operations

- B65H19/28—Attaching the leading end of the web to the replacement web-roll core or spindle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/41—Winding, unwinding

- B65H2301/417—Handling or changing web rolls

- B65H2301/418—Changing web roll

- B65H2301/4182—Core or mandrel insertion, e.g. means for loading core or mandrel in winding position

- B65H2301/41826—Core or mandrel insertion, e.g. means for loading core or mandrel in winding position by gripping or pushing means, mechanical or suction gripper

Definitions

- the invention relates to a method for automatically inserting a winding tube suitable for receiving a web into double carrier roller winding machines, the web being severed and the resulting web start being fastened to the winding tube provided with an adhesive after ejection of a finished winding roll, which is initially in defined position from a waiting position to a transfer position located above the roller bed formed by the support rollers and then released until it rests on the support rollers in a winding position.

- the winding sleeve provided with adhesive is placed with the aid of a collet from the waiting position into the transfer position above the roller bed.

- the winding tube can be brought into the transfer position in a precisely defined position, for example with a glue track pointing downwards or an adhesive strip.

- the collet is simply opened so that the winding tube gets into the roller bed in free fall.

- the glue track or the adhesive strip should fall between the support rollers so that the glue track or the adhesive strip does not touch the support rollers or, when new wrapping, the glue track first sticks the material web adhering to the support roller designed as a suction roller and with takes.

- the collet When processing winding cores with large outside diameter differences, the collet must necessarily be arranged higher, i.e. the transfer position is at a greater distance from the winding position located in the roller bed. As a result, the drop height becomes very large when processing small winding cores. This in turn leads to the fact that the small winding tubes twist during the fall and their position changes again due to the impact on the support rollers. This leads to undesirable malfunctions during winding and to contamination of the support rollers and any pressure roller that may be present due to the adhesive applied to the winding tube.

- the invention is based on the object of proposing a method in which the aforementioned disturbances are avoided, which is rather characterized by an exact insertion of the winding tubes from the waiting position into the transfer and winding position in a precisely defined position.

- Another task is to create a double carrier roll winding machine with an insertion device which is suitable for an exact insertion of the winding tubes.

- the procedural object is achieved in that the winding tube is held non-rotatably during its movement from the transfer position into the winding position. In this way it is ensured that the winding tube can no longer twist in an uncontrolled manner, but is delivered in exactly the same position as it came from the waiting position into the transfer position until it reaches the winding position. This prevents contamination of the carrier rollers and ensures that the beginning of the web is wound up correctly.

- the method according to the invention is particularly suitable when it concerns the processing of a number of adjacent ones Winding sleeves or sleeve pieces is involved, ie in cases where other means, such as hooks or the like acting on the sleeve ends. cannot be used.

- the non-rotatable holding of the winding tube already begins due to negative pressure, while in the transfer position it is still in a defined position, e.g. is held by a clamping device. This ensures in any case that the position once taken up of the winding tube is exactly maintained from the waiting position to the winding position.

- the method according to the invention can be carried out on a double carrier roller winding machine with a device for the automatic introduction of a winding tube provided with an adhesive such as adhesive tape, glue trace or the like along a surface line for adhering the beginning of the web from a waiting position to a position above that of the Carrier rollers formed roller bed lying transfer position and a winding position lying in the roller bed and with a device for ejecting a finished winding roll, in which, according to the invention, the device for inserting the winding tube has an effective holding device at least in the area between the transfer position and the winding position. Using the holding device, different winding cores can be brought in a precisely defined position from the transfer position into the winding position in the outer diameter. An uncontrolled twisting of the winding tubes with an impairment of the winding process is therefore excluded.

- an adhesive such as adhesive tape, glue trace or the like along a surface line for adhering the beginning of the web from a waiting position to a position above that of the Carrier rollers formed roller bed lying

- the holding device is formed by a suction device, which consists of a strip with suction cups attached to it at a distance and connected to a vacuum source.

- the suction cups can be lowered down to the winding tube, the winding tube held by negative pressure and then the entire holding device can be lowered into the winding position of the winding tube.

- the adjusting element can be formed by telescopic cylinders.

- the telescopic cylinders are attached to an ejection bar of the ejection device which can be pivoted about the axis of the one supporting roller from a position corresponding to the waiting position of the winding tube up to its transfer position. This results in a very compact design.

- the ejection bar is at the same time designed as a carrier of a collet holding the winding tube between the waiting position and the transfer position in a defined position, to the clamping jaws of which the telescopic cylinders are arranged centrally.

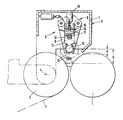

- a preferred embodiment of the invention is shown schematically in the drawing .

- a double carrier roller winding machine has two rotatably driven carrier rollers 1 and 2, between which a web 3 runs in from below.

- an ejection device 5 and an insertion device 6 integrated therein are shown from a waiting position indicated by dash-dotted lines into the transfer position shown in the drawing for winding cores suitable for winding the material web.

- a finished winding roll lying on the support rollers 1, 2 can be delivered to a transfer table (not shown).

- the insertion device 6 has a collet 8, with the clamping jaws 9, 11 of which winding sleeves of different diameters can be placed from the waiting position into the transfer position.

- a winding sleeve with a smaller diameter is 12 and one with a diameter larger winding tube is designated 13.

- the winding sleeves 12, 13 have a glue track 14 at a certain point, namely on their underside. With the aid of this, the beginning of a web 3 can be glued in a manner described in more detail below.

- a holding device 15 is arranged centrally to the clamping jaws 9, 11 of the collet 8, which essentially consists of a bar 16 which can be displaced in the vertical direction in the guides (not shown) and suction cups 17 attached to it at intervals and telescopic cylinders 18 which act as an adjusting element.

- the suction cups 17 are connected to a vacuum source, not shown.

- the double carrier roll winding machine works as follows:

- a finished winding roll lying on the support rollers 1, 2 is discharged onto a transfer table (not shown) with the aid of the ejection bar 7 of the ejection device 5.

- the ejection device 7 is moved from the waiting position into the transfer position shown. Since the insertion device 6 is coupled to the ejection device 5, a winding sleeve 12 or 13 entered in the waiting position is taken along with the movement in a precisely defined position by the collet 8 and brought into the transfer position shown. In the transfer position, the glue track 14 points downwards.

- the clamping jaws 9, 11 of the collet 8 are moved outwards.

- the holding device 15 takes effect.

- the suction cups 17 are lowered onto the winding tube 12 or 13, so that the winding tube 12 or 13 is held non-rotatably by the then effective suction air.

- the suction cups 17 or the strip 16 are then lowered by the telescopic cylinder 18 to such an extent that the winding tube 12 or 13 is brought into its winding position lying in the roller bed.

- the trace of glue 14 lies further exactly in the desired position.

Abstract

Description

Die Erfindung bezieht sich auf ein Verfahren zum automatischen Einbringen einer zur Aufnahme einer Warenbahn geeigneten Wickelhülse in Doppeltragwalzen-Wickelmasc hinen, wobei die Warenbahn durchtrennt und der dabei entstehende Warenbahnanfang nach Ausstoß einer fertigen Wickelrolle an der mit einem Klebemittel versehenen Wickelhülse befestigt wird, die zunächst in definierter Lage von einer Wartestellung in eine oberhalb des von den Tragwalzen gebildeten Walzenbetts liegende Übergabestellung gebracht und danach bis zur Auflage auf den Tragwalzen in einer Anwickelstellung abgegeben wird.The invention relates to a method for automatically inserting a winding tube suitable for receiving a web into double carrier roller winding machines, the web being severed and the resulting web start being fastened to the winding tube provided with an adhesive after ejection of a finished winding roll, which is initially in defined position from a waiting position to a transfer position located above the roller bed formed by the support rollers and then released until it rests on the support rollers in a winding position.

Bei einem aus der DE-PS 29 20 707 bekanntgewordenen Verfahren zum automatischen Trennen und Anwickeln einer Materialbahn wird die mit Klebemittel versehene Wickelhülse mit Hilfe einer Spannzange von der Wartestellung aus in die oberhalb des Walzenbetts liegende Übergabestellung plaziert. Auf diese Weise kann die Wickelhülse in genau definierter Lage, zum Beispiel mit nach unten weisender Leimspur oder einem Klebestreifen in die Übergabestellung gebracht werden. Zum Einbringen der Wickelhülse in die im Walzenbett befindliche Anwickelstellung wird die Spannzange einfach geöffnet, so daß die Wickelhülse im freien Fall in das Walzenbett gelangt. Dabei soll die Leimspur bzw. der Klebestreifen so zwischen die Tragwalzen fallen, daß die Leimspur oder der Klebestreifen die Tragwalzen nicht berührt bzw. beim neuen Wickeln die Leimspur zuerst die an der als Saugwalze ausgebildeten Tragwalze haftende Materialbahn anklebt und mit nimmt.In a method for the automatic cutting and winding of a material web which has become known from DE-PS 29 20 707, the winding sleeve provided with adhesive is placed with the aid of a collet from the waiting position into the transfer position above the roller bed. In this way, the winding tube can be brought into the transfer position in a precisely defined position, for example with a glue track pointing downwards or an adhesive strip. To insert the winding tube into the winding position in the roller bed, the collet is simply opened so that the winding tube gets into the roller bed in free fall. The glue track or the adhesive strip should fall between the support rollers so that the glue track or the adhesive strip does not touch the support rollers or, when new wrapping, the glue track first sticks the material web adhering to the support roller designed as a suction roller and with takes.

Bei der Verarbeitung von Wickelhülsen mit großen Außendurchmesser-Unterschieden muß die Spannzange zwangsläufig höher angeordnet werden, d.h. die Übergabestellung besitzt einen größeren Abstand von der im Walzenbett befindlichen Anwickelstellung. Das hat zur Folge, daß die Fallhöhe bei der Verarbeitung von kleinen Wickelhülsen sehr groß wird. Dies führt wiederum dazu, daß sich die kleinen Wickelhülsen während des Fallens verdrehen und ihre Lage durch den Aufprall auf die Tragwalzen nochmals verändern. Hierdurch kommt es zu unerwünschten Störungen beim Anwickeln sowie zu einer Verschmutzung der Tragwalzen und einer gegebenenfalls vorhandenen Druckwalze durch das auf die Wickelhülse aufgetragene Klebemittel.When processing winding cores with large outside diameter differences, the collet must necessarily be arranged higher, i.e. the transfer position is at a greater distance from the winding position located in the roller bed. As a result, the drop height becomes very large when processing small winding cores. This in turn leads to the fact that the small winding tubes twist during the fall and their position changes again due to the impact on the support rollers. This leads to undesirable malfunctions during winding and to contamination of the support rollers and any pressure roller that may be present due to the adhesive applied to the winding tube.

Der Erfindung liegt nun die Aufgabe zugrunde, ein Verfahren vorzuschlagen, bei dem die vorgenannten Störungen vermieden werden, das sich vielmehr durch ein exaktes Einbringen der Wickelhülsen von der Wartestellung bis in die Übergabe- und Anwickelstellung in genau definierter Lage auszeichnet. Eine weitere Aufgabe besteht in der Schaffung einer Doppeltragwalzen-Wickelmaschine mit einer ein exaktes Einlegen der Wickelhülsen geeigneten Einlegeeinrichtung.The invention is based on the object of proposing a method in which the aforementioned disturbances are avoided, which is rather characterized by an exact insertion of the winding tubes from the waiting position into the transfer and winding position in a precisely defined position. Another task is to create a double carrier roll winding machine with an insertion device which is suitable for an exact insertion of the winding tubes.

Die verfahrensmäßige Aufgabe wird dadurch gelöst, daß die Wickelhülse während ihrer Bewegung von der Übergabestellung in die Anwickelstellung unverdrehbar gehalten wird. Auf diese Weise wird sichergestellt, daß sich die Wickelhülse nicht mehr in unkontrollierter Weise verdrehen kann, sondern in genau der gleichen Lage, wie sie von der Wartestellung in die Übergabestellung gelangt ist, bis in die Anwickelstellung abgegeben wird. Dadurch wird eine Verschmutzung der Tragwalzen vermieden und ein einwandfreies Anwickeln des Anfangs der Warenbahn gewährleistet.The procedural object is achieved in that the winding tube is held non-rotatably during its movement from the transfer position into the winding position. In this way it is ensured that the winding tube can no longer twist in an uncontrolled manner, but is delivered in exactly the same position as it came from the waiting position into the transfer position until it reaches the winding position. This prevents contamination of the carrier rollers and ensures that the beginning of the web is wound up correctly.

Das erfindungsgemäße Verfahren eignet sich insbesondere dann, wenn es sich um die Verarbeitung von mehreren nebeneinanderliegenden Wickelhülsen bzw. Hülsenstücken handelt, d.h. in solchen Fällen, wo andere Mittel, wie z.B. an den Hülsenenden angreifende Haken od.dgl. nicht verwendet werden können.The method according to the invention is particularly suitable when it concerns the processing of a number of adjacent ones Winding sleeves or sleeve pieces is involved, ie in cases where other means, such as hooks or the like acting on the sleeve ends. cannot be used.

In zweckmäßiger Weise ist vorgesehen, daß die unverdrehbare Halterung der Wickelhülse durch Unterdruck bereits beginnt, während sie in der Übergabestellung noch in definierter Lage, z.B. durch eine Spanneinrichtung gehalten wird. Hierdurch ist in jedem Fall sichergestellt, daß die einmal eingenommene Lage der Wickelhülse von der Wartestellung aus bis in die Anwickelstellung genau eingehalten wird.It is expediently provided that the non-rotatable holding of the winding tube already begins due to negative pressure, while in the transfer position it is still in a defined position, e.g. is held by a clamping device. This ensures in any case that the position once taken up of the winding tube is exactly maintained from the waiting position to the winding position.

Das erfindungsgemäße Verfahren läßt sich auf einer Doppeltragwalzen-Wickelmaschine mit einer Einrichtung zum automatischen Einbringen einer mit einem Klebemittel, wie Klebestreifen, Leimspur od.dgl., längs einer Mantellinie zum Ankleben des Anfangs der Warenbahn versehenen Wickelhülse aus einer Wartestellung in eine oberhalb des von den Tragwalzen gebildeten Walzenbetts liegende Übergabestellung und eine im Walzenbett liegende Anwickelstellung und mit einer Einrichtung zum Ausstoßen einer fertigen Wickelrolle durchführen, bei der erfindungsgemäß die Einrichtung zum Einlegen der Wickelhülse eine zumindest im Bereich zwischen der Übergabestellung und der Anwickelstellung wirksame Haltevorrichtung aufweist. Mittels der Haltevorrichtung lassen sich im Außendurchmesser unterschiedliche Wickelhülsen in genau definierter Lage von der Übergabestellung in die Anwickelstellung bringen. Ein unkontrolliertes Verdrehen der Wickelhülsen mit einer Beeinträchtigung des Anwickelvorgangs ist damit ausgeschlossen.The method according to the invention can be carried out on a double carrier roller winding machine with a device for the automatic introduction of a winding tube provided with an adhesive such as adhesive tape, glue trace or the like along a surface line for adhering the beginning of the web from a waiting position to a position above that of the Carrier rollers formed roller bed lying transfer position and a winding position lying in the roller bed and with a device for ejecting a finished winding roll, in which, according to the invention, the device for inserting the winding tube has an effective holding device at least in the area between the transfer position and the winding position. Using the holding device, different winding cores can be brought in a precisely defined position from the transfer position into the winding position in the outer diameter. An uncontrolled twisting of the winding tubes with an impairment of the winding process is therefore excluded.

In zweckmäßiger Ausgestaltung der Erfindung ist die Haltevorrichtung von einer Saugvorrichtung gebildet, die aus einer Leiste mit daran mit Abstand befestigten Saugnäpfen besteht, die an eine Unterdruckquelle angeschlossen sind. In der Übergabestellung können die Saugnäpfe bis auf die Wickelhülse abgesenkt werden, dabei durch Unterdruck die Wickelhülse gehalten und dann die gesamte Haltevorrichtung bis in die Anwickelstellung der Wickelhülse abgesenkt werden. Zu diesen Zweck hat es sich als vorteilhaft erwiesen, wenn die Leiste in Führungen verschiebbar gelagert und durch ein Verstellelement beaufschlagbar ist. Das Verstellelement kann dabei von Teleskopzylindern gebildet sein.In an advantageous embodiment of the invention, the holding device is formed by a suction device, which consists of a strip with suction cups attached to it at a distance and connected to a vacuum source. In the transfer position, the suction cups can be lowered down to the winding tube, the winding tube held by negative pressure and then the entire holding device can be lowered into the winding position of the winding tube. For this purpose, it has proven to be advantageous if the bar is mounted displaceably in guides and can be acted upon by an adjusting element. The adjusting element can be formed by telescopic cylinders.

Von besonderer Bedeutung ist, daß die Teleskopzylinder an einem um die Achse der einen Tragwalze von einer der Wartestellung der Wickelhülse bis in deren Übergabestellung entsprechenden Stellung verschwenkbaren Ausstoßbalken der Ausstoßeinrichtung befestigt sind. Hierdurch ergibt sich eine sehr gedrängte Bauweise.It is of particular importance that the telescopic cylinders are attached to an ejection bar of the ejection device which can be pivoted about the axis of the one supporting roller from a position corresponding to the waiting position of the winding tube up to its transfer position. This results in a very compact design.

Dazu trägt auch bei, wenn der Ausstoßbalken zugleich als Träger einer die Wickelhülse zwischen der Wartestellung und der Übergabestellung in definierter Lage haltenden Spannzange ausgebildet ist, zu deren Spannbacken die Teleskopzylinder zentrisch angeordnet sind.This also contributes if the ejection bar is at the same time designed as a carrier of a collet holding the winding tube between the waiting position and the transfer position in a defined position, to the clamping jaws of which the telescopic cylinders are arranged centrally.

Ein bevorzugtes Ausführungsbeispiel der Erfindung ist in der Zeichnung schematisch dargestellt.A preferred embodiment of the invention is shown schematically in the drawing .

Eine im einzelnen nicht dargestellte Doppeltragwalzen-Wickelmaschine besitzt zwei drehbar angetriebene Tragwalzen 1 und 2, zwischen denen von unten her eine Warenbahn 3 einläuft. Um die Drehachse 4 der Tragwalze 2 sind eine Ausstoßeinrichtung 5 und eine darin integrierte Einlegevorrichtung 6 aus einer mit strichpunktierten Linien angedeuteten Wartestellung in die in der Zeichnung dargestellte Übergabestellung für zum Aufwickeln der Warenbahn geeignete Wickelhülsen gezeigt. Mit Hilfe eines Ausstoßbalkens 7 der Ausstoßeinrichtung 5 kann eine auf den Tragwalzen 1,2 liegende fertige Wickelrolle an eine nicht dargestellten Übergabetisch abgegeben werden.A double carrier roller winding machine, not shown in detail, has two rotatably driven

Die Einlegeeinrichtung 6 besitzt eine Spannzange 8, mit deren Spannbacken 9,11 Wickelhülsen unterschiedlichen Durchmessers von der Wartestellung in die Übergabestellung plaziert werden können. Eine im Durchmesser kleinere Wickelhülse ist mit 12 und eine im Durchmesser größere Wickelhülse ist mit 13 bezeichnet. Die Wickelhülsen 12,13 besitzen an einer bestimmten Stelle, nämlich an ihrer Unterseite, eine Leimspur 14. Mit deren Hilfe kann in weiter unten näher beschriebener Weise der Anfang einer Warenbahn 3 angeklebt werden.The

Zentrisch zu den Spannbacken 9,11 der Spannzange 8 ist eine Haltevorrichtung 15 angeordnet, die im wesentlichen aus einer in nicht dargestellten Führungen in vertikaler Richtung verschiebbaren Leiste 16 sowie daran mit Abständen befestigten Saugnäpfen 17 und aus als Verstellelement wirkenden Teleskopzylindern 18 besteht. Die Saugnäpfe 17 sind an eine nicht dargestellte Unterdruckquelle angeschlossen.A holding device 15 is arranged centrally to the clamping

Die Doppeltragwalzen-Wickelmaschine arbeitet wie folgt:The double carrier roll winding machine works as follows:

Eine auf den Tragwalzen 1,2 liegende fertige Wickelrolle wird mit Hilfe d es Ausstoßbalkens 7 der Ausstoßeinrichtung 5 auf einen nicht dargestellten Übergabetisch abgegeben. Zu diesem Zweck wird die Ausstoßeinrichtung 7 von der Wartestellung in die dargestellte Übergabestellung bewegt. Da die Einlegevorrichtung 6 mit der Ausstoßeinrichtung 5 gekoppelt ist, wird zugleich mit dieser Bewegung ein in der Wartestellung eingegebene Wickelhülse 12 bzw. 13 durch die Spannzange 8 in genau definierter Lage mitgenommen und in die dargestellte Übergabestellung gebracht. In der Übergabestellung weist die Leimspur 14 nach unten. Zur Abgabe der Wickelhülse 12 bzw. 13 in die mit strichpunktierten Linien dargestellte Anwickelstellung im Walzenbett der Tragwalzen 1,2 werden die Spannbacken 9,11 der Spannzange 8 nach außen bewegt. Kurz vor dem Öffnen der Spannzange 8 wird jedoch die Haltevorrichtung 15 wirksam. Zu diesem Zweck werden die Saugnäpfe 17 auf die Wickelhülse 12 bzw. 13 abgesenkt, so daß durch die dann wirksame Saugluft die Wickelhülse 12 bzw. 13 unverdrehbar gehalten wird. Gleichzeitig werden dann durch die Teleskopzylinder 18 die Saugnäpfe 17 bzw. die Leiste 16 soweit abgesenkt, daß die Wickelhülse 12 bzw. 13 in ihre im Walzenbett liegende Anwickelstellung gebracht wird. Dabei liegt die Leimspur 14 weiter hin genau in der gewünschten Stellung. Somit kann die durch eine nicht dargestellte Schneideinrichtung abgeschnittene Warenbahn 3 in exakter Weise an die Wickelhülse 12 bzw. 13 angeklebt werden. In der Zeichnung ist mit a die Senkhöhe einer im Durchmesser großen Wickelhülse 13 und mit b die Senkhöhe einer im Durchmesser kleinen Wickelhülse 12 dargestellt. Die Saugnäpfe 17 sind in der Anwickelstellung mit dünnen Linien angedeutet. A finished winding roll lying on the

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT86103136T ATE39673T1 (en) | 1985-07-31 | 1986-03-08 | PROCESS AND DOUBLE ROLLER WINDING MACHINE FOR AUTOMATIC INSERTION OF A WINDING SLEEVE SUITABLE FOR TAKING A WEB. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3527377 | 1985-07-31 | ||

| DE19853527377 DE3527377A1 (en) | 1985-07-31 | 1985-07-31 | METHOD AND DOUBLE CARRIER ROLLING MACHINE FOR AUTOMATICALLY PUTTING IN A WINDING SLEEVE SUITABLE FOR RECORDING A TRACK OF GOODS |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0211136A2 true EP0211136A2 (en) | 1987-02-25 |

| EP0211136A3 EP0211136A3 (en) | 1988-03-30 |

| EP0211136B1 EP0211136B1 (en) | 1989-01-04 |

Family

ID=6277241

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86103136A Expired EP0211136B1 (en) | 1985-07-31 | 1986-03-08 | Method and winding machine with two supporting rollers for inserting a bobbin adapted for receiving web material |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US4726533A (en) |

| EP (1) | EP0211136B1 (en) |

| JP (1) | JPH06610B2 (en) |

| AT (1) | ATE39673T1 (en) |

| CA (1) | CA1275995C (en) |

| DE (1) | DE3527377A1 (en) |

| ES (1) | ES2000801A6 (en) |

| FI (1) | FI80660C (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3744961C2 (en) * | 1987-11-05 | 1995-05-18 | Beloit Corp | Roll cutting machine for making smaller rolls |

| DE3811871A1 (en) * | 1988-04-09 | 1989-10-26 | Jagenberg Ag | METHOD AND DEVICE FOR WINDING MATERIALS, IN PARTICULAR PAPER OR CARDBOARD |

| DE4029914A1 (en) * | 1990-09-21 | 1992-03-26 | Jagenberg Ag | CARRIER ROLLING MACHINE |

| DE19508207C2 (en) * | 1995-03-08 | 1998-05-14 | Kampf Gmbh & Co Maschf | Roll cutting and winding machine |

| DE29613556U1 (en) * | 1996-08-05 | 1997-12-11 | Beloit Technologies Inc | Sleeve insertion device for winding machines |

| JP2000511861A (en) * | 1996-06-13 | 2000-09-12 | ビロイト テクノロジーズ、インコーポレイテッド | Core insertion device for winding machine |

| CN112897135B (en) * | 2021-02-23 | 2022-09-30 | 重庆富美包装印务有限公司 | Conveying roller angle adjusting structure |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2920707A1 (en) * | 1979-05-22 | 1980-12-04 | Jagenberg Werke Ag | METHOD AND DEVICE FOR AUTOMATICALLY SEPARATING AND REWINDING A MATERIAL |

| GB2065081A (en) * | 1979-12-05 | 1981-06-24 | Jagenberg Werke Ag | Apparatus for accurately inserting winding cores in winding machines |

| JPS5811452A (en) * | 1981-07-15 | 1983-01-22 | Mitsubishi Heavy Ind Ltd | Web winding device |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2743616A1 (en) * | 1977-09-28 | 1979-03-29 | Jagenberg Werke Ag | DEVICE FOR WINDING RAIL-SHAPED MATERIAL |

| NO790519L (en) * | 1978-06-21 | 1979-12-27 | Ahlstroem Oy | SPIRAL WRAPPED SLEEVE, METHOD FOR MANUFACTURING THE SLEEVE, PROCEDURE FOR USING THE SLEEVE IN A WRAPPING APPLIANCE AND DEVICE FOR USING THE SLEEVE |

| JPS557160A (en) * | 1978-06-30 | 1980-01-18 | Mitsubishi Heavy Ind Ltd | Strip coiling device |

| DE2909736C3 (en) * | 1979-03-13 | 1982-02-18 | J.M. Voith Gmbh, 7920 Heidenheim | Process and double drum roller for rolling up endlessly fed webs |

| DE2930474C2 (en) * | 1979-07-27 | 1981-08-13 | J.M. Voith Gmbh, 7920 Heidenheim | Double roller developing machine |

| AT373220B (en) * | 1979-07-27 | 1983-12-27 | Voith Gmbh J M | DOUBLE CARRIER ROLLER FOR REWINDING MATERIALS |

| DE3244966C1 (en) * | 1982-12-04 | 1984-06-07 | Jagenberg AG, 4000 Düsseldorf | Process and separating device for severing web-like cellulose when winding onto winding sleeves |

| JPS59124644A (en) * | 1982-12-27 | 1984-07-18 | Ishikawajima Harima Heavy Ind Co Ltd | Method and apparatus for winding in paper machine |

| FI69819C (en) * | 1983-05-03 | 1986-05-26 | Waertsilae Oy Ab | ANORDINATION FOER BANRULLNING |

| FI69820C (en) * | 1983-05-12 | 1986-05-26 | Waertsilae Oy Ab | ANORDNING FOER RULLNING AV MATERIALBANA |

-

1985

- 1985-07-31 DE DE19853527377 patent/DE3527377A1/en active Granted

-

1986

- 1986-03-08 AT AT86103136T patent/ATE39673T1/en not_active IP Right Cessation

- 1986-03-08 EP EP86103136A patent/EP0211136B1/en not_active Expired

- 1986-04-24 FI FI861731A patent/FI80660C/en not_active IP Right Cessation

- 1986-06-03 US US06/870,003 patent/US4726533A/en not_active Expired - Fee Related

- 1986-06-09 CA CA000511128A patent/CA1275995C/en not_active Expired - Fee Related

- 1986-07-30 ES ES8600742A patent/ES2000801A6/en not_active Expired

- 1986-07-31 JP JP61179011A patent/JPH06610B2/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2920707A1 (en) * | 1979-05-22 | 1980-12-04 | Jagenberg Werke Ag | METHOD AND DEVICE FOR AUTOMATICALLY SEPARATING AND REWINDING A MATERIAL |

| GB2065081A (en) * | 1979-12-05 | 1981-06-24 | Jagenberg Werke Ag | Apparatus for accurately inserting winding cores in winding machines |

| JPS5811452A (en) * | 1981-07-15 | 1983-01-22 | Mitsubishi Heavy Ind Ltd | Web winding device |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN, Band 7, Nr. 87 (M-206)[1230], 9. April 1983; & JP - A- 58 011 452 (MITSUBISHI JUKOGYO K.K.) 22.01.1983 * |

Also Published As

| Publication number | Publication date |

|---|---|

| FI80660C (en) | 1990-07-10 |

| DE3527377A1 (en) | 1987-02-12 |

| EP0211136B1 (en) | 1989-01-04 |

| JPS6231647A (en) | 1987-02-10 |

| ATE39673T1 (en) | 1989-01-15 |

| JPH06610B2 (en) | 1994-01-05 |

| DE3527377C2 (en) | 1988-07-07 |

| FI861731A (en) | 1987-02-01 |

| US4726533A (en) | 1988-02-23 |

| EP0211136A3 (en) | 1988-03-30 |

| FI80660B (en) | 1990-03-30 |

| CA1275995C (en) | 1990-11-06 |

| FI861731A0 (en) | 1986-04-24 |

| ES2000801A6 (en) | 1988-03-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3308271A1 (en) | DEVICE FOR REWINDING LENGTH-SIDED SHEETS AND METHOD FOR WINDING REELS / CASE CHANGE | |

| DE3545659A1 (en) | DEVICE FOR REMOVING BINDING WIRE FROM BALLS, ESPECIALLY ROMBIAN WASTE PAPER OR FIBER BALES | |

| DE2930474C2 (en) | Double roller developing machine | |

| EP0143960B1 (en) | Device for straightening and cutting wire into lengths | |

| DE2917601A1 (en) | DEVICE FOR TURNING UP OPTICAL FIBERS O.DGL. | |

| DE3336957C2 (en) | ||

| DE2628608A1 (en) | DEVICE FOR BINDING OBJECTS WITH A TAPE | |

| EP0211136B1 (en) | Method and winding machine with two supporting rollers for inserting a bobbin adapted for receiving web material | |

| EP1452474B1 (en) | Method and apparatus for the mechanical production of a cable coil | |

| DE3040398C2 (en) | Process for exchanging a finished lap for an empty lap core in a double-roll winder and device for carrying out the process | |

| EP0226139A2 (en) | Method and device for binding strip coils | |

| EP0000065B1 (en) | Process and apparatus for bundling rods, tubes, profiles, and other oblong objects | |

| DE3836498A1 (en) | METHOD AND DEVICE FOR REMOVING AN ADHESIVE TAPE WRAPPED A PLATE FOR PRINTED CIRCUITS | |

| EP4148749A1 (en) | Method and device for automatically applying a single-sided adhesive tape to a cable or cable end | |

| EP0406581B1 (en) | Arrangement for chopping of a web on a reversing winder | |

| AT394508B (en) | PLANT FOR PRODUCING STRAPPED WIRE ROLLS | |

| DE2513144C3 (en) | Method and device for automatically fixing the outer thread end of balls on automatic ball winding machines | |

| EP0337079B1 (en) | Process and device for winding webs of material, particularly paper- or cardboard webs | |

| DE102004000040A1 (en) | Apparatus for inserting winding spool in roller bed of double carrier roller winding machine, e.g. for winding sheets of paper, including spool tongs with tension jaws and adhesive application system | |

| DE2836480B2 (en) | Device for picking up and rotating a band | |

| EP0593410A1 (en) | Process and apparatus for stripwise laying out of tape material | |

| DE102013000808A1 (en) | Device for winding strip-shaped material on coils, has gripping device, which is movable relative to feeding lance and has two end positions, where former end position is closer to feeding lance than latter end position | |

| DE3902844C1 (en) | Apparatus for the automatic feeding of bull-block machines with drawing stock in strand form, especially tubes | |

| DE3146549A1 (en) | Reeling machine | |

| EP0644140B1 (en) | Device and method for changing a foil strip roll and foil holding clamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT FR IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT FR IT SE |

|

| 17P | Request for examination filed |

Effective date: 19880302 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: JAGENBERG AKTIENGESELLSCHAFT |

|

| 17Q | First examination report despatched |

Effective date: 19880621 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT FR IT SE |

|

| REF | Corresponds to: |

Ref document number: 39673 Country of ref document: AT Date of ref document: 19890115 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: DE DOMINICIS & MAYER S.R.L. |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930219 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930222 Year of fee payment: 8 |

|

| ITTA | It: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 86103136.7 Effective date: 19941010 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950223 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19960308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050308 |