EP0210187B1 - Method and device for scattering grains - Google Patents

Method and device for scattering grains Download PDFInfo

- Publication number

- EP0210187B1 EP0210187B1 EP19860900229 EP86900229A EP0210187B1 EP 0210187 B1 EP0210187 B1 EP 0210187B1 EP 19860900229 EP19860900229 EP 19860900229 EP 86900229 A EP86900229 A EP 86900229A EP 0210187 B1 EP0210187 B1 EP 0210187B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- blasting

- sand

- container

- pipe

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title abstract description 4

- 238000005422 blasting Methods 0.000 claims description 14

- 239000000428 dust Substances 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 2

- 239000004576 sand Substances 0.000 abstract description 24

- 238000005266 casting Methods 0.000 abstract description 2

- 229910000805 Pig iron Inorganic materials 0.000 abstract 1

- 239000013013 elastic material Substances 0.000 abstract 1

- 235000013339 cereals Nutrition 0.000 description 10

- 235000013312 flour Nutrition 0.000 description 3

- 238000005488 sandblasting Methods 0.000 description 3

- 206010010774 Constipation Diseases 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 206010013457 Dissociation Diseases 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical class C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C7/00—Equipment for feeding abrasive material; Controlling the flowability, constitution, or other physical characteristics of abrasive blasts

- B24C7/0046—Equipment for feeding abrasive material; Controlling the flowability, constitution, or other physical characteristics of abrasive blasts the abrasive material being fed in a gaseous carrier

- B24C7/0069—Equipment for feeding abrasive material; Controlling the flowability, constitution, or other physical characteristics of abrasive blasts the abrasive material being fed in a gaseous carrier with means for preventing clogging of the equipment or for preventing abrasive entering the airway

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C9/00—Appurtenances of abrasive blasting machines or devices, e.g. working chambers, arrangements for handling used abrasive material

Definitions

- the invention relates generally to a device for blasting a granular abrasive, in particular a sandblasting device, which is suitable for cleaning castings or compacts and for making their surface shiny.

- sandblasting devices with the aid of compressed air, which is supplied by means of a compressor, a sandblast is blown onto the work piece. To make this possible, a controllable amount of sand is entrained by the air flow in a tap and hurled onto the work piece.

- the blasting device according to the invention has the features of claim 1.

- Preferred embodiments of the invention are specified in claims 2 and 3.

- the sand is therefore regulated by means of an elastic, compressible (constricted) piece of pipe which allows the grains to pass through. If there is a blockage due to any cause, you just have to widen the constriction of the mentioned rubber pipe piece, in other words its full (original) cross section has to be adjusted again (which is possible in a few seconds) and then the compressed air will blow through the sand Constipation is removed.

- the air conveyed by the air compressor 1 passes through a line 2 (FIG. 1) to a distributor 3, from which a part of the air is passed through the branch 4 into the blasting agent container 14, where this amount of air comes from above the sand (or a other granular material) puts the sand under pressure.

- a distributor 3 from which a part of the air is passed through the branch 4 into the blasting agent container 14, where this amount of air comes from above the sand (or a other granular material) puts the sand under pressure.

- most of the air flows through line 5 to the feed tap 12. Since the air compressor 1 is near the feed tap 12 because the lines 2 and 5 are short, the amount of air supplied by the air compressor 1 has no time to cool down, but comes warmly to the tap, where moisture cannot form in this way.

- the sand falling from the container 14 is driven by the warm air through the lines 5 and 13 to the blowpipe 18.

- the person working at the jet blow box 22 puts his one hand through a hole 6 into the inside of the box and holds the blow pipe 18, while his other hand, which is passed through the opening 7, holds the work piece.

- the work can be observed through a window 8.

- the through the. Air-driven sand falls from the work piece into the funnel 9 arranged below.

- a container 10 which, due to the work of a suction fan (not shown), sucks air through the suction nozzle 21 and flows through openings 23 in the jet box 22.

- the air flow thus produced, shown in dashed lines in FIG. 2, protects the operator of the device from dust and takes the light (small) grains with it.

- the air stream flows around a baffle 20 and is then passed through a sieve 19 into the container 10.

- the still usable grains fall into the funnel 9 and the fine powder enters the container 10. From this, the material falls into a dust bag and can be easily and cleanly removed with it, without the formation of harmful dust.

- the funnel 9 After a long and experience-free undisturbed working period, the funnel 9 is full. Then the work should be stopped, whereupon the grains, again without disturbing the environment, are conveyed back into the sand container 14 as follows: the negative pressure of a suction compressor 16 (FIG. 2) conveys the grains into the pipeline 15 because this suction compressor is included A vacuum 17 is brought about above the grains. In this way, the grains are quickly returned to the container 14 on a closed path, whereby the funnel 9 is emptied and the work can be resumed.

- a suction compressor 16 FIG. 2

- the feed valve 12 consists essentially of a tube made of rubber or plastic 12A with elastic walls which are compressible in the middle and thus narrow.

- the pressure bars 12B shown in FIG. 4 are used for the narrowing.

- the pipe section 12A connects the lower pipe socket of the sand container 14 to the line 13, which conducts the air-sand mixture to the blow pipe 18.

- the best method of narrowing and widening, i.e. H. Regulation consists in arranging the strips 12B in a V-shape, whereby they enclose the tube 12A like scissors. In this way, the pipe section 12A is compressed into a pear-shaped or triangular cross-section.

- the advantage of this solution is, among other things, that the pipe cannot be completely blocked.

- a remote control In order to ensure that the operator of the device can easily move and adjust the strips 12B from his work place, with the aid of push buttons or with a lever, these strips are moved via a remote control.

- a remote control a compressed air or electrical or other control device known per se is used, which preferably enables a stepless (continuous) control.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cleaning In General (AREA)

- Air Transport Of Granular Materials (AREA)

Abstract

Description

Die Erfindung betrifft im Allgemeinen eine Vorrichtung zum Aufstrahlen eines körnigen Strahlmittels, insbesondere eine Sandstrahlvorrichtung, die geeignet ist Gußformstücke oder Preßlinge zu reinigen und deren Fläche glänzend zu machen.The invention relates generally to a device for blasting a granular abrasive, in particular a sandblasting device, which is suitable for cleaning castings or compacts and for making their surface shiny.

Der Grundgedanke bekannter Sandstrahlvorrichtungen besteht darin, daß mit Hilfe von Preßluft, die mittels eines Kompressors geliefert wird, ein Sandstrahl auf das Arbeitsstück geblasen wird. Um dies zu ermöglichen, wird durch den Luftstrom in einem Speisehahn eine regelbare Menge Sand mitgerissen und auf das Arbeitstück geschleudert.The basic idea of known sandblasting devices is that with the aid of compressed air, which is supplied by means of a compressor, a sandblast is blown onto the work piece. To make this possible, a controllable amount of sand is entrained by the air flow in a tap and hurled onto the work piece.

Ein Nachteil der bekannten Vorrichtungen besteht darin, daß der Speisehahn und die Rohrleitung oft verstopfen, wodurch die .Arbeit ausgesetzt und der Speisehahn mit langwieriger Handarbeit gereinigt werden muß. Um diesen Nachteil vermeiden zu können, weist die Strahlvorrichtung gemäß der Erfindung die Merkmale aus dem Patentanspruch 1 auf. Bevorzugte Ausgestaltungen der Erfindung sind in den Patentansprüchen 2 und 3 angegeben. Im Sinne der Erfindung wird daher der Sand vermittels eines elastischen, zusammendrückbaren (verengten) Rohrstückes geregelt, welches die Körner durchläßt. Falls infolge irgendeiner Ursache eine Verstopfung zustandekommt, muß man einfach nur die Verengung des erwähnten Gummirohrstückes aufweiten, mit anderen Worten dessen voller (ursprüriglicher) Querschnitt muß wieder eingestellt werden (was in einigen Sekunden möglich ist) und dann wird die Preßluft den Sand durchblasen, die Verstopfung wird beseitigt.A disadvantage of the known devices is that the feed tap and the pipeline often become blocked, which means that work must be suspended and the feed tap cleaned with lengthy manual work. In order to avoid this disadvantage, the blasting device according to the invention has the features of

Es ist bekannt, daß nach dem Strahlen die kleinen mehl- oder staubartigen Körner abgesondert werden müssen, der restliche Teil des Sandes kann aber erneuert, mehrmals benutzt werden. Diese Absonderung und die Zurückführung des Sandes nach dem Strahlen in den Sandbehälter wurde bisher mit Hüfe von Zyklonen durchgeführt. Im Sinne des Anspruchs 3 jedoch wird der Mehlsand mit Hilfe eines Luftstromes durch ein Metallsieb, im geschlossenen Weg, d. h. ohne Umweltverschmutzung in einen besonderen Behälter gefördert, der sich neben dem Strahlkasten befindet. Von diesem gelangt das Sandmehl in einen Staubsack, mit welchem es leicht und rein entfernt werden kann. Die brauchbaren Körner werden mittels eines Saugkompressors - ebenfalls umweltfreundlich - in den Sandbehälter zurückgeführt.It is known that after blasting, the small flour or dust-like grains must be separated, but the rest of the sand can be renewed, used several times. This separation and the return of the sand after blasting into the sand container has been carried out with the help of cyclones. In the sense of

Die Einzelheiten der Erfindung werden in verbindung mit der beiliegenden Zeichung erläutert, in der ein Ausführungsbeispiel der Erfindung Schematisch dargestellt ist.

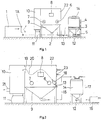

- Fig. 1 veranschaulicht die ganze Vorrichtung ; jedoch sind zwecks leichter Verständlichkeit einige Teile in dieser Figur nicht dargestellt. Diese Figur ist in erster Linie zur Erklärung der Sandstrahlarbeit geeignet.

- Fig. 2 zeigt ebenfalls die ganze Vorrichtung ; jedoch wurden auch hier einige Teile weggelassen und diejenigen dargestellt, die in Fig. 1 fehlen. Die Fig. 2 veranschaulicht das Zurückführen des bereits benutzten Sandes in den Sandbehälter und die Absonderung der kleinen (staubartigen) Körner.

- In Fig. 3 ist der Sandbehälter (Strahlmittelbehälter) und der dazu gehörende Speisehahn in größerem Maßstab dargestellt und

- Fig. 4 ist ein Schnitt gemäß der Linie IV-IV in Fig. 3 in noch größerem Maßstab.

- Fig. 1 illustrates the whole device; however, some parts are not shown in this figure for ease of understanding. This figure is primarily suitable for explaining sandblasting work.

- Fig. 2 also shows the whole device; however, some parts have also been omitted here and those which are missing in FIG. 1 have been shown. Fig. 2 illustrates the return of the sand already used in the sand container and the separation of the small (dust-like) grains.

- In Fig. 3 the sand container (blasting agent container) and the associated tap are shown on a larger scale and

- Fig. 4 is a section along the line IV-IV in Fig. 3 on an even larger scale.

Die durch den Luftverdichter 1 geförderte Luft gelangt durch eine Leitung 2 (Fig. 1) zu einem Verteiler 3, von welchem ein Teil der Luft durch die Abzweigung 4 in den Strahlmittelbehälter 14 geleitet wird, wo diese Luftmenge von oberhalb des Sandes her (oder ein anderes körniges Material) den Sand unter Druck stellt. Der größte Teil der Luft strömt jedoch durch die Leitung 5 zum Speisehahn 12. Da der Luftverdichter 1 sich in der Nähe des Speisehahns 12 befindet, weil die Leitungen 2 und 5 kurz sind, hat die durch den Luftverdichter 1 gelieferte Luftmenge keine Zeit zum Abkühlen, sondern gelangt warm zum Speisehahn, wo in dieser Weise ein Feuchtigkeitsniederschlag nicht zustandekommen kann.The air conveyed by the

Der vom Behälter 14 herabfallende Sand wird durch die warme Luft durch die Leitungen 5 und 13 zum Blasrohr 18 getrieben. Die bei dem Strahlblaskasten 22 arbeitende Person steckt ihre eine Hand durch ein Loch 6 in das Innere des Kastens und hält das Blasrohr 18, wobei ihre andere Hand, die durch die Öffnung 7 hindurchgeführt wird, das Arbeitsstück hält. Die Arbeit kann durch ein Fenster 8 beobachtet werden. Der durch den. Luftstrom getriebene Sand fällt vom Arbeitsstück herunter in den unten angeordneten Trichter 9.The sand falling from the

Neben dem Strahlblaskasten 22 befindet sich ein Behälter 10, welcher infolge der Arbeit eines nicht dargestellten Saugventilators durch den Saugstutzen 21 Luft saugt, welche durch Öffnungen 23 in den Strahlblaskasten 22 strömt. Der so hergestellt, in Fig. 2 gestrichelt dargestellte Luftstrom schützt den Bediener der Vorrichtung vor Staub und reißt die leichten (kleinen) Kömer mit sich. Der Luftstrom strömt um eine Ablenkplatte 20 und wird sodann durch ein Sieb 19 in den Behälter 10 geleitet. Infolge der abscheidenden Wirkung des Siebes 19 fallen die noch brauchbaren Körner in den Trichter 9 und das feine Pulver gelangt in den Behälter 10. Von diesem fällt das Material in einen Staubsack und kann mit diesem leicht und rein, ohne gesundheitsschädliche Staubbildung, entfernt werden.Next to the

Nach einer langen und erfahrungsgemäß ungestörten Arbeitsperiode ist der Trichter 9 voll. Dann soll die Arbeit eingestellt werden, worauf die Körner, wiederum ohne Belästigung der Umwelt, folgendermaßen in den Sandbehälter 14 zurückbefördert werden : der Unterdruck eines Saugkompressors 16 (Fig. 2) fördert die Körner in die Rohrleitung 15, weil dieser Saugkompressor mit Hilfe einer Leitung 17 oberhalb der Körner ein Unterdruck zustandebringt. In dieser Weise werden die Körner schnell, auf geschlossenem Weg, in den Behälter 14 zurückgebracht, wodurch der Trichter 9 entleert wird und die Arbeit wieder aufgenommen werden kann.After a long and experience-free undisturbed working period, the

Wie es in Fig. dargestellt ist, besteht der Speisehahn 12 im wesen tlichen aus einem aus Gummi oder Kunststoff hergestellten Rohrstück 12A mit elastischen Wänden, welche in der Mitte zusammendrückbar und somit verengbar sind. Für das Verengen werden die in Fig. 4 dargestellten Preßleisten 12B benutzt. Das Rohrstück 12A verbindet den unteren Rohrstutzen des Sandbehälters 14 mit der Leitung 13, welche die Luft-Sandmischung zu dem Blasrohr 18 leitet. Die beste Methode der Verengung und Erweiterung, d. h. Regelung, besteht darin, die Leisten 12B in V-Form anzuordnen, wodurch sie das Rohr 12A scherenartig umschließen. In dieser Weise wird das Rohrstück 12A zu einem birnenförmigen oder dreickförmigen Querschnitt zusammengedrückt. Der Vorteil dieser Lösung besteht unter anderem darin, daß das Rohr nicht vollständig gesperrt werden kann.As shown in Fig., The

Bei der beschriebenen Art der Regelung, bei welcher der für das Strömen des Sandes vorhandene Querschnitt des den Sand leitenden Rohres geändert wird, sind im Hahn keine aufeinander gleitenden metallischen Reibflächen vorhanden, die Verstopfungen verursachen, wodurch der Sand leicht und sicher bei kleimen Reibungswiderstand durch das Rohrstück 12A gleitet. Hierdurch ist die Lebensdauer dieses Rohres groß und Betriebstörungen werden vermieden. Falls sehr selten der Speisehahn doch verstopft wird, muß man einfach nur die Leisten 12B ganz auseinanderdrehen, wodurch der ursprüngliche (größte) Querschnitt des Rohres 12A wieder hergestellt wird, sodaß der Sand infolge seines Gewichtes und des Luftdruckes in einigen Sekunden durch das Rohr 12A fließt ; die Verstopfung kann also leicht und schnell beseitigt werden.In the described type of control, in which the cross-section of the pipe guiding the sand for the flow of the sand is changed, there are no metallic friction surfaces sliding on one another in the tap, which cause blockages, as a result of which the sand can be easily and safely with small frictional resistance due to the

Um zu erreichen, daß der Bediener der Vorrichtung die Leisten 12B von seiner Arbeitsstelle aus, mit Hilfe von Druckknöpfen oder mit einem Hebel einfach bewegen und einstellen kann, werden diese Leisten über eine Femsteuerung bewegt. Zur Fernsteuerung wird eine mit Preßluft arbeitende oder elektrische, oder eine andere an sich bekannte Steuervorrichtung benutzt, die vorzugsweise eine stufenlose (kontinuierliche) Regelung ermöglicht.In order to ensure that the operator of the device can easily move and adjust the

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT86900229T ATE47068T1 (en) | 1985-01-29 | 1985-12-20 | METHOD AND DEVICE FOR SPREADING GRAIN. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| HU31785A HU191769B (en) | 1985-01-29 | 1985-01-29 | Grain-spreading apparatus and charging tap belonging to the apparatus of this kind |

| HU31785 | 1985-01-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0210187A1 EP0210187A1 (en) | 1987-02-04 |

| EP0210187B1 true EP0210187B1 (en) | 1989-10-11 |

Family

ID=10949058

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19860900229 Expired EP0210187B1 (en) | 1985-01-29 | 1985-12-20 | Method and device for scattering grains |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0210187B1 (en) |

| DE (1) | DE3573555D1 (en) |

| HU (1) | HU191769B (en) |

| WO (1) | WO1986004288A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2723020B1 (en) * | 1994-07-26 | 1996-09-27 | Kegler Maurice | REMOTE CONTROL SANDING MACHINE |

| DE19623024A1 (en) * | 1996-06-08 | 1997-12-11 | Josef Bauer | Wet jet plant |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT237959B (en) * | 1962-12-11 | 1965-01-25 | Friedrich Huemer | Water jet nozzle for garden spraying and fire departments |

| FR2067747A5 (en) * | 1969-11-14 | 1971-08-20 | Abrasive Dev | |

| DE2226909C3 (en) * | 1971-07-15 | 1974-09-12 | Badische Maschinenfabrik Gmbh, 7500 Karlsruhe | Shot blasting machine |

| DE2152782A1 (en) * | 1971-10-22 | 1973-05-10 | Johann Boxler | DEVICE FOR SAND-BLASTING THE SURFACE OF WORK PIECES |

| DE2203699A1 (en) * | 1972-01-27 | 1973-08-02 | Winkler Duennebier Kg Masch | Mogul installation mould powder cooling - in air heater inlet |

| US4300318A (en) * | 1980-01-28 | 1981-11-17 | Knox Manufacturing Co. | Cabinet for use in abrasive blasting system |

-

1985

- 1985-01-29 HU HU31785A patent/HU191769B/en not_active IP Right Cessation

- 1985-12-20 EP EP19860900229 patent/EP0210187B1/en not_active Expired

- 1985-12-20 WO PCT/HU1985/000077 patent/WO1986004288A1/en active IP Right Grant

- 1985-12-20 DE DE8686900229T patent/DE3573555D1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| EP0210187A1 (en) | 1987-02-04 |

| WO1986004288A1 (en) | 1986-07-31 |

| DE3573555D1 (en) | 1989-11-16 |

| HU191769B (en) | 1987-04-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0044310B2 (en) | Work piece powder coating installation including a cabin to temporary receive the work piece | |

| DE3933405C2 (en) | ||

| DE2214983B2 (en) | Pocket or bag filters | |

| EP0610578A1 (en) | Installation for coating by spraying powder | |

| DE2835474C2 (en) | ||

| EP0210187B1 (en) | Method and device for scattering grains | |

| DE2366276B1 (en) | Pick-up device for the grist of a mill for the house control and smaller commercial enterprises | |

| DE2303055A1 (en) | FACILITY FOR SURFACE TREATMENT | |

| DE3824710C2 (en) | ||

| DE4109452A1 (en) | METHOD AND DEVICE FOR SIGHTING SAND OR THE LIKE RIESELGUT | |

| EP1080789A1 (en) | Powder recovery unit | |

| DE3943076A1 (en) | HAND DEVICE WITH MILLING OR GRINDING WHEEL | |

| EP0594916B1 (en) | Method and device for cleaning of surfaces, in particular for masonry | |

| DE356813C (en) | Method and device for the separation and separate extraction (sifting) of dust from dusty materials such as coal and. Like., By means of air flow | |

| DE2500833A1 (en) | Separating device for tobacco waste - uses compressed air blast to separate lighter waste on vibrating conveyor | |

| DE8914626U1 (en) | Reprocessing device for solid blasting media | |

| DE10257241A1 (en) | Workshop or hobby vacuuming system for acting on surfaces has jet lance containing injector co-axial with accelerating tube | |

| DE4013584C2 (en) | Sand blasting device | |

| DE2456140A1 (en) | Granular material sizing - by adding material to horizontal air stream for gravity/aerodynamic trajectory sorting into chambers | |

| DE3805221C2 (en) | ||

| DE971464C (en) | Conveyor screw for grain and other grainy bulk goods | |

| DE950824C (en) | Device for additional cleaning of removed filter hoses | |

| DE2102928A1 (en) | Process for cleaning filters in pneumatic conveying systems | |

| DE271639C (en) | ||

| DE2025381A1 (en) | Electrostatic resin coating of articles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19861212 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT DE FR GB IT SE |

|

| 17Q | First examination report despatched |

Effective date: 19871030 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 47068 Country of ref document: AT Date of ref document: 19891015 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3573555 Country of ref document: DE Date of ref document: 19891116 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19901119 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19901122 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19901214 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19901218 Year of fee payment: 6 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910227 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19911220 Ref country code: AT Effective date: 19911220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19911221 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 86900229.5 Effective date: 19920704 |