EP0098231B1 - Robinet à gaz couplé à un système piézo-électrique et appareils à gaz incorporant un tel robinet - Google Patents

Robinet à gaz couplé à un système piézo-électrique et appareils à gaz incorporant un tel robinet Download PDFInfo

- Publication number

- EP0098231B1 EP0098231B1 EP83420101A EP83420101A EP0098231B1 EP 0098231 B1 EP0098231 B1 EP 0098231B1 EP 83420101 A EP83420101 A EP 83420101A EP 83420101 A EP83420101 A EP 83420101A EP 0098231 B1 EP0098231 B1 EP 0098231B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cock

- piezoelectric system

- piezoelectric

- axis

- striker

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 230000000694 effects Effects 0.000 claims description 6

- 238000006073 displacement reaction Methods 0.000 claims description 5

- 230000009471 action Effects 0.000 claims description 2

- 230000000284 resting effect Effects 0.000 claims description 2

- 230000000630 rising effect Effects 0.000 claims 2

- 230000003213 activating effect Effects 0.000 claims 1

- 230000001105 regulatory effect Effects 0.000 claims 1

- 238000006243 chemical reaction Methods 0.000 description 5

- 239000002775 capsule Substances 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 230000007935 neutral effect Effects 0.000 description 3

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 241001080024 Telles Species 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000010891 electric arc Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23Q—IGNITION; EXTINGUISHING-DEVICES

- F23Q3/00—Igniters using electrically-produced sparks

- F23Q3/002—Igniters using electrically-produced sparks using piezoelectric elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23Q—IGNITION; EXTINGUISHING-DEVICES

- F23Q7/00—Incandescent ignition; Igniters using electrically-produced heat, e.g. lighters for cigarettes; Electrically-heated glowing plugs

Definitions

- the present invention relates to gas taps coupled to piezoelectric ignition systems of a gas burner, for which the rotation of the operating button in the direction of opening of the valve actuates and triggers the piezoelectric system.

- valve comprising a body, a rotary control axis, comprising at its free end an operating button

- this system itself comprises a rectangular housing, a piezoelectric element contained in the latter, a striker movable in the housing relative to the piezoelectric element, a lug for actuating the movable striker, a spring or elastic means disposed in the housing; this system is actuated from its rest position, by means of the lug, by charging the spring, then by projecting the striker against the piezoelectric element, under the effect of the loaded spring;

- an intermediate part for actuating the piezoelectric system consisting of a toothed wheel; this intermediate piece is mounted coaxially with respect to the rotary control axis, and more precisely around a hub belonging to the operating button, between the valve body and said button; each tooth on the periphery of the wheel is capable of actuating the striker of the piezoelectric system;

- the toothed wheel is locked in rotation on the hub of the operating button, both in the closing direction and in the opening direction of the valve;

- the toothed wheel is free in translation relative to the control axis, and it is pushed against a stop axially fixed relative to the valve body, by a spring disposed between said wheel and the operating button;

- each tooth of the wheel is pushed back by the lug of the piezoelectric system, and the wheel moves backwards against the spring, with each passage of a tooth against the 'pin, while returning against the stop between two teeth; in this way, the piezoelectric system remains in the rest position, when the tap is closed.

- the present invention proposes to improve the technical solution proposed by French patent FR-A-2 330 960, in two aspects: on the one hand, a connection is sought between the tap and the piezoelectric system independent of the gas appliance in which the tap is integrated, and in particular its frame,

- the rotary control axis consists of an axial adjustment screw

- a means which makes it possible to actuate the piezoelectric system, whatever the axial position of the axis, during operation of the tap or over time, for example due to wear of the adjusting screw.

- a separate and independent connection of the valve body and the operating button completely free to rotate relative to the rotary control axis; this connection is mounted at least in part between the valve body and the operating button, and is linked to the piezoelectric system.

- the link supports the entire piezoelectric system and at least one means is provided to stop the rotation of the link, at least in the direction of opening of the valve, under the effect of the intermediate actuating part of the piezoelectric system.

- the rotary axis is an axial adjustment screw

- an axial stop is provided on the rotary control axis, and the link is mounted. at least in part between this stop and the start button.

- the piezoelectric system is permanently subjected in translation to the axial movement of the control axis. If, moreover, the intermediate actuating part is itself fixed in translation relative to the adjusting screw, this completely frees itself from the axial displacements of the rotary control axis, in order to actuate the piezoelectric system with from the tap rotation.

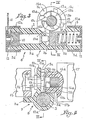

- the piezoelectric system 8 illustrated in fig. 1 comprises in known manner an elongated housing 1 at the end of which is fixed a piezoelectric element 2, against which a striker 3 is projected displaced by a pushing member 4 against the reaction in the opposite direction of an elastic means 5.

- a striker 3 is projected displaced by a pushing member 4 against the reaction in the opposite direction of an elastic means 5.

- the striker brought to the bottom of the travel by the thrust member is released, so that under the reaction of the spring 5 it strikes the piezoelectric element causing it to produce a electric tension.

- Fig. 2 a more sophisticated system 8 has been illustrated, the piezoelectric element 2 of which is always retained at one of the ends of the casing or housing 1, but the striker 3 is associated with a pushing member 6 which can be moved telescopic relative to the envelope 1. This member is returned to its rest position by a spring 7. We will not return to the operation of such a piezoelectric system which is well known in practice.

- a piezoelectric system such as that shown in fig.1 is used.

- the housing of the piezoelectric system produced in one-piece form with the support or link 9, itself comprising an elongated body 9a and two side cheeks 9b determining between them a certain space below which the side wall of the body 9a is cut to form a slot 9c.

- the piezoelectric element 2 held in place by a threaded metal plug referenced 10 with which cooperates an output conductor 11 kept applied against the plug 10 by means of an insulating capsule 12.

- a inner groove 12a of the capsule 12 engages with a cord 9d formed for this purpose at the periphery of the body 9a.

- a second capsule 12 is secured to the other end of said body in order to serve as a stop at one of the ends of the spring 5 for actuating the striker 3, the opposite end of which bears on the latter or more precisely at the bottom of a depression 3a thereof.

- An intermediate actuating part 13 placed between the cheeks 9b is mounted for rotation about the rotary axis 14 of a gas tap 15 with an axial adjustment screw; this part is fixed in translation relative to the axis 14.

- the periphery of the intermediate actuating part 13 is provided with teeth 13a intended to come to cooperate with the front face 3b of the striker 3 in order to make it move back to against the reaction of the spring 5.

- the intermediate actuation part is integral with the rotary axis 14 in the direction of opening of the valve 15.

- the face of the part 13 which is oriented opposite the tap 15 is provided with four ramps 13b (fig.5) ending in steps 13c.

- the face in question of the part 13 comes to carry an open washer 16 surrounding the axis 14 and one of the ends 16a of which is suitably arched cooperates with the ramps 13b as will be better explained below.

- the opposite end of the washer 16 is deformed in order to form a tab 16b perpendicular to its general plane.

- This tab 16b enters a slot 17a (FIG. 5) of the operating button 17 of the axis 14, so that the rotation of this button in the direction of opening causes that of the actuating part 13, by abutment of the end 16a of the washer 16 against the steps 13c.

- the washer 16 rubs against the ramps 13b without driving them.

- the operating button 17 is force fitted or overmolded on the grooved end 14a of the axis 14.

- the connection 9 being placed transversely relative to and on the axis 14, the rotation of the intermediate piece 13 could l 'Drive if it had a heel 9th which cooperates with the valve 15 to wedge it angularly.

- the axis 14 includes a flange 14b against which bears the outer face of one of the cheeks 9b of the support 9, the inner face of this cheek constituting a stop for the actuating part 13, against which bears with operating clearance the end of the hub 17b formed on the operating button 17, itself crossing the other cheek 9b of the support 9.

- the latter is linked longitudinally with respect to the axis 14.

- valve 15 is of the plug or needle type, that is to say that its rotary axis may or may not be subjected to a longitudinal translation, without influencing its operation.

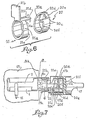

- the intermediate actuating part 20 comprises a ramp 20a which develops from a low point to a high point located on either side of a tongue 20d.

- a control element 21 which is provided with a ramp 21c whose top and bottom points are located on either side of a stop 21d.

- the tongue 20d is blocked during the rotation of the part 20 on the side of the low point F of the ramp 21c in the position of closing the valve, and on the side of the point O of the same ramp 21c in its open position.

- the ramps 20a and 21c of the piece 20 and of the element 21 each comprise a neutral zone 20e respectively 21e placed at the low point of each ramp and another neutral zone 20f, 21f disposed at the top of each ramp.

- the areas in question are actually flat areas, the role of which will be better explained below.

- the housing 1 of the piezoelectric system is contained, parallel to the axis 14, in a support produced in the form of a carcass 19 resting against a face of the valve 15.

- This carcass is extended by a lateral tab 19a through which the 'rotary axis 14, the end branch of said tab being folded back to cooperate with a second face of the valve 15 oriented parallel to the first.

- the side tab 19a is trapped between the flange 14b of the rotary axis 14, the control element 21, and an intermediate actuating part 20 on which acts, as will be described better below, the operating button 17 of the tap 15.

- the intermediate actuating part no longer acts directly on the thrust member 6 of the piezoelectric system, but it is engaged with the control element 21, intended to act on the thrust member 6 of the piezoelectric system.

- This control element 21 comprises the ring 21a provided with the ramp 21e and the finger 21 b, the end of which enters the carcass 19, with a view to acting on the thrust member 6.

- the length of the finger 21 b is calculated so that its curved end remains constantly inside the carcass 19, even when the valve is fully open.

- the control button 17 is advantageously extended by a tubular sleeve .17d at least partially surrounding said periphery.

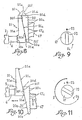

- Fig. 8 is a developed view of the two ramps 20a and 21c. When the tap is closed, these two ramps are in contact with each other, except for the neutral zones 20f and 21f of each of them. It is observed that the end of the finger 21 b is in abutment against that of the pushing element 6 of the piezoelectric system, in such a way that the depression of this member inside the carcass 19 in no way causes case the triggering of the piezoelectric system. As illustrated in fig. 9, a mark 22 placed on the operating button 17 is located opposite a sign 23 indicating the closing of the valve.

- the end of the tongue 20d pushes the control element 21 towards the tap, so that the finger 21 b of this element actuates the member 6 of the piezoelectric system, so as to cause a spark to burst, for example when the mark 22 is at the level of an index 24 (cf. Figs. 10 and 11).

- the end of the tongue 20d arrives just at the start of the flat area 21f of the ramp 21c.

- the displacement of the intermediate piece 20 in the closing direction causes the teeth 17c of the operating button to be released relative to the teeth 20c of the piece 20, the latter and the element 21 moving alternately from axially against the reaction of the return means of the thrust member 6.

- the support or connection of the piezoelectric system is also independent of the frame of the appliance.

- the carcass 19 constitutes both the support of the piezoelectric system 8 and the connection between the latter and the rotary control axis 14 (thanks to the stop 14b), to subject in displacement the movement of said system to that of the axis 14 (adjusting screw).

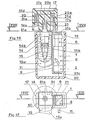

- the support of the piezoelectric system is dissociated and the connection in translation between the latter and the control axis. More precisely, according to FIG. 16 (top view, with partial section along the section plane XVI / XVI of FIG. 17) and according to FIG. 17 (front view, with partial section along the section plane XVII / XVII of Figure 16), the piezoelectric system 8 is disposed in a housing 50 of plastic material, made integral with the valve body 15, by screwing a part (not shown) on the thread 15v, which blocks the housing 50 against the 15w tap barrel. The piezoelectric system 8 can move in translation in the housing 50.

- connection between the system 8 and the axis 14 consists of a lug 51 comprising a part 51a in abutment against the part 14b of the axis, another part 51 b at right angles entering the housing 50, along the mechanism 8, and a last 51c at right angles and in the opposite direction from the part 51a, bearing against the rear of the system 8; this support is obtained permanently thanks to the reaction of the pushing member 6 against the finger 21b, provided that the length of the part 51b is correctly dimensioned relative to the stroke of the pushing member 6. In this way , the piezoelectric system 8 continuously follows the axial movement of the axis 14.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Electrically Driven Valve-Operating Means (AREA)

- Lighters Containing Fuel (AREA)

- Mechanically-Actuated Valves (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8211034A FR2528939A1 (fr) | 1982-06-17 | 1982-06-17 | Robinet a gaz couple a un systeme piezo-electrique et appareils a gaz incorporant un tel robinet |

| FR8211034 | 1982-06-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0098231A1 EP0098231A1 (fr) | 1984-01-11 |

| EP0098231B1 true EP0098231B1 (fr) | 1985-10-09 |

Family

ID=9275333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83420101A Expired EP0098231B1 (fr) | 1982-06-17 | 1983-06-14 | Robinet à gaz couplé à un système piézo-électrique et appareils à gaz incorporant un tel robinet |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0098231B1 (es) |

| JP (1) | JPS597827A (es) |

| KR (1) | KR840005201A (es) |

| DE (1) | DE3360977D1 (es) |

| ES (1) | ES272956Y (es) |

| FR (1) | FR2528939A1 (es) |

| PT (1) | PT76838B (es) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6163769A (ja) * | 1984-09-03 | 1986-04-01 | 東レ株式会社 | 汚れの目立ちにくい布帛およびその製造方法 |

| GB2181826B (en) * | 1985-10-09 | 1989-09-27 | Valor Newhome Ltd | Improvements relating to spark igniters for gas appliances |

| JP6789109B2 (ja) | 2016-12-28 | 2020-11-25 | 富士フイルム株式会社 | 血液分析方法及び血液検査キット |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1914214A1 (de) * | 1969-03-20 | 1970-10-01 | Junkers & Co | Piezoelektrische Zuendvorrichtung fuer einen Brenner eines gasbeheizten Geraetes |

| DE1962005A1 (de) * | 1969-12-11 | 1971-06-16 | Junkers & Co | Piezoelektrische Zuendvorrichtung |

| US3768959A (en) * | 1972-10-18 | 1973-10-30 | Olin Corp | Auto-ignition stove |

-

1982

- 1982-06-17 FR FR8211034A patent/FR2528939A1/fr active Granted

-

1983

- 1983-06-08 PT PT76838A patent/PT76838B/pt unknown

- 1983-06-14 EP EP83420101A patent/EP0098231B1/fr not_active Expired

- 1983-06-14 DE DE8383420101T patent/DE3360977D1/de not_active Expired

- 1983-06-15 KR KR1019830002649A patent/KR840005201A/ko not_active Ceased

- 1983-06-16 ES ES1983272956U patent/ES272956Y/es not_active Expired

- 1983-06-17 JP JP58107999A patent/JPS597827A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JPS597827A (ja) | 1984-01-17 |

| EP0098231A1 (fr) | 1984-01-11 |

| DE3360977D1 (en) | 1985-11-14 |

| KR840005201A (ko) | 1984-11-05 |

| ES272956Y (es) | 1984-10-01 |

| FR2528939B1 (es) | 1985-01-25 |

| ES272956U (es) | 1984-03-01 |

| FR2528939A1 (fr) | 1983-12-23 |

| PT76838B (fr) | 1986-02-18 |

| PT76838A (fr) | 1983-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0978610B1 (fr) | Serrure électrique perfectionnée pour ouvrant de véhicule automobile | |

| FR2569087A1 (fr) | Chaussure de ski | |

| FR2672554A1 (fr) | Frein a main de stationnement pour vehicule automobile et procede de fabrication du levier de ce frein. | |

| EP0812972A2 (fr) | Serrure électrique pour ouvrant de véhicule automobile | |

| EP0069687A1 (fr) | Dispositif de commande assurant des positions multiples préétablies et contrôlées, applicable en particulier aux changements de vitesse pour les cycles et véhicules similaires | |

| FR2498740A1 (fr) | Allumeur piezo-electrique du type a percussion et bouton-poussoir | |

| EP0098231B1 (fr) | Robinet à gaz couplé à un système piézo-électrique et appareils à gaz incorporant un tel robinet | |

| EP0466534B1 (fr) | Levier de frein à main notamment pour véhicule automobile | |

| EP2605256B1 (fr) | Dispositif de commande de la motorisation du dispositif de rearmement du dispositif de fermeture des contacts dans un appareil de protection electrique et appareil le comportant | |

| CA2180514A1 (fr) | Briquet a gaz comportant un systeme d'allumage de securite | |

| FR2478476A1 (fr) | Fixation de securite pour ski | |

| FR2798956A1 (fr) | Dispositif d'actionnement d'un organe de debrayage pour un motoreducteur d'entrainement d'une installation de fermeture ou de protection solaire | |

| FR2480223A1 (fr) | Derailleur pour chaine de bicyclette ou similaire | |

| EP0604330B1 (fr) | Disjoncteur modulaire associé à un bloc de télécommande | |

| FR2614597A1 (fr) | Dispositif pour actionner le changement de vitesses d'une bicyclette | |

| EP0906997A1 (fr) | Dispositif de verrouillage comportant un objet de transmission commandé par came | |

| EP3697195A1 (fr) | Boitier de transmission et engin roulant equipe d'un tel boitier | |

| FR2765531A1 (fr) | Siege de vehicule | |

| FR2544894A1 (fr) | Dispositif de commande mecanique a distance avec liaison flexible | |

| EP0102263B1 (fr) | Serrure à commande électrique pour portière de véhicule automobile | |

| FR2797006A1 (fr) | Dispositif de maintien de deux joncs d'armement dans un moyeu de synchronisation pouvant etre utilise dans un ensemble synchroniseur pour une transmission d'un vehicule automobile | |

| FR2564395A1 (fr) | Enrouleur de ceinture de securite | |

| EP1615524A2 (fr) | Dispositif formant pince a epiler | |

| EP1670009B1 (fr) | Mecanisme de commande d'un interrupteur électrique multipolaire | |

| FR2548253A1 (fr) | Dispositif a loquet pour serrure, notamment pour serrure de vehicule automobile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19840517 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 3360977 Country of ref document: DE Date of ref document: 19851114 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870630 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19900101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19910328 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19910403 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19910531 Year of fee payment: 9 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910829 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19920614 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19920615 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19920614 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19930226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930302 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83420101.4 Effective date: 19930109 |