EP0081443B1 - Procédé de préréglage d'une machine offset à sec - Google Patents

Procédé de préréglage d'une machine offset à sec Download PDFInfo

- Publication number

- EP0081443B1 EP0081443B1 EP82420171A EP82420171A EP0081443B1 EP 0081443 B1 EP0081443 B1 EP 0081443B1 EP 82420171 A EP82420171 A EP 82420171A EP 82420171 A EP82420171 A EP 82420171A EP 0081443 B1 EP0081443 B1 EP 0081443B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- template

- blanket

- sector

- axis

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/08—Cylinders

- B41F13/10—Forme cylinders

- B41F13/12—Registering devices

- B41F13/16—Registering devices with means for displacing the printing formes on the cylinders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F27/00—Devices for attaching printing elements or formes to supports

- B41F27/005—Attaching and registering printing formes to supports

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S101/00—Printing

- Y10S101/36—Means for registering or alignment of print plates on print press structure

Definitions

- the present invention relates to a method for presetting a dry offset machine intended for printing cylindrical or conical parts.

- Many products are presented in cylindrical or conical containers, so for example in the field of cosmetics, aerosol tubes and jars are used. Glue tubes, yogurt jars and spray paints are other examples.

- the decoration or the indications which appear on these containers are printed by means of dry offset machines. These machines are quite expensive, so it is advisable to use them almost continuously to amortize them. This is even more imperative when the printing is carried out by a machine integrated into a complete production line in which the parts are shaped, printed, dried, undergo a final machining and are even sometimes filled and packaged. In such production lines, any downtime presents a considerable loss.

- the margins of the printed area of the transparent proof piece corresponding to a printing plate or working plate are aligned with reference lines drawn on a template and central coordinate lines are drawn on this transparent test piece as an extension of the central coordinate lines also written on the template. Then, the transparent test piece is positioned on a perforation device using these central coordinate lines and two holes of location determined with respect to these lines are perforated there, which makes it possible to position the test piece on the cylindrical device for fixing the printing plate using two lugs carried by this device, then adjusting the position of the printing plate, placed on the device below the transparent test piece, by moving this printing plate to make its printed image coincide with that of the proof piece.

- the precision of the adjustment in machine depends on the precision with which the perforations were practiced as well as on the exact adjustment of the pins or claws to the shape of the perforations. This precision is limited by the necessary characteristics of the material used to make the plates, as well as by the difficulty of making claws which are both mobile and which however have no play. In practice, these systems are little used because they do not give not full satisfaction.

- the machine shots are therefore adjusted most of the time by trial and error, the duration of the operation then depending on the skill or luck of the machine operator. For a four-color machine, therefore having four sectors on which four plates are mounted, the setting time is approximately two hours. It is with the intention of reducing this adjustment time to approximately fifteen minutes that the present invention was made.

- the method of the invention uses, analogously to the prior art, reference axes and reference crosses.

- two reference axes and reference crosses are reproduced on all the templates and clichés which are taken from a basic matrix film on which these axes and these crosses have been engraved.

- the transfer of the reference axes of each template to the corresponding sector, once the position of this template has been set, will then allow quick and precise adjustment of the position of the pictures.

- the layout of the reference axes on the sectors and the adjustment of the photographs are made by means of perforations of the templates and photographs, not used in themselves as a means of positioning as is known from the prior art, but as windows .

- the method of the invention differs from the prior art by the use of printing tests for the precise adjustment of the master template and the other templates on the corresponding sectors.

- the adjustment of the position of the master template on the corresponding plate holder sector is thus carried out using printing tests with the blanket and with a test piece: alignment bars carried by the master template then deposit images on the blanket, these images are the source of images deposited on the proof-piece then redeposited by it on the blanket, and the misalignment of these redeposited images with respect to the images deposited on the blanket by the bars of the master jig allow the position of this master jig to be adjusted.

- the positions of the other templates on their respective sectors are then adjusted more simply by means of printing tests with the blanket without proof-piece, by comparing the positions of the images of the reference crosses deposited on the blanket by the template to set and by the master template already set.

- the tracing of the axes on each sector follows the adjustment of the corresponding template by tracing portions of axes through the perforations of the template as already indicated, then by tracing the axes connecting these portions after removing the template.

- a process as described in the preamble of claim 1 is known from the specification FR-A-2312373.

- the method of adjusting the machine and adjusting the working plates on such a machine comprises, according to the invention, operations or steps for preparing the films, templates and plates used (steps a) to f)), then adjustment steps g) to i).

- the operations or stages of preparation are:

- Figure 3 does not show the image printed on the blanket as it actually appears, in fact, the templates being engraved in positive, they are "readable”, which has the consequence that the blanket is "unreadable” since the image is reversed. In the drawing, this inversion has been deliberately ignored so that the reader finds the various elements in the same arrangement in all the figures.

- the preset template is a thin plate, identical to those usually used in dry offset.

- the template 1 is produced according to the same process as a working plate.

- the various elements that appear on the template in the figures are first arranged on a lithorthochromatic film allowing copying on photopolymer plates, the plates then being immersed in a washing bath creating the relief.

- Usual locating crosses 2 in photoengraving are placed on a film.

- Two axes AA 'and BB' are added.

- the axis AA ′ is arranged parallel to the axis of rotation of the plate-holding sector on which the template will be fixed in a subsequent step.

- the axis AA ' is located near the right hooking margin 3 of the template. Its position more or less close to said margin does not play a role.

- the second axis BB ' is then arranged perpendicular to the axis AA' in the variant presented.

- the direction of the axis BB ' is not, however, necessarily perpendicular to the axis AA', but it is preferable that the two axes form an angle between 80 and 100 ° between them.

- the film carrying the locating crosses 2 and the axes AA 'and BB' constitutes a basic matrix.

- the two right bars 9 and 11 are placed at a distance from the right edge 12 of the plate which varies according to the machine on which the plates will have to work. For a machine of the W1FAG type, the distance which separates the right edge 12 of the plate from the right edge 13 of the bars 9 and 11 is fixed at 40 mm.

- the top 14 of the bar 9 is arranged 25 mm from the top of the plate 15.

- the base 16 of the bar 11 is located 25 mm from the bottom of the plate 17.

- the two left bars 8 and 10 have the same dimensions as the two bars on the right. Their positioning on the photograph takes into account two factors. First, their position is determined by two perpendicular to the axis AA '. One of them is raised by the vertex 14 of the right upper bar 9. The vertex 18 of the bar 8 is aligned on this perpendicular. In the same way, the base 16 of the bar 11 and the base 19 of the bar 10 are aligned on the same perpendicular to the axis AA '.

- the distance which separates the right side 13 of the two right bars 9 and 11 from the left side 20 of the two left bars 8 and 10 is determined by the development of the parts on which the printing will finally take place.

- the usual diameters of the parts which are printed by means of plates of the format shown are 35, 40 and 45 mm.

- the developments of these parts are therefore respectively 109.2 mm, 124.8 mm and 140.4 mm.

- the distance is 124.8 mm and thus corresponds to a part 40 mm in diameter.

- the number of templates that must be engraved depends on the number of color groups in the machine. For a dry offset press with four color groups, four templates are produced.

- the first of these four templates includes all the elements described so far, namely the cross marks 2, the positioning axes AA 'and BB' and the alignment bars. 8,9,10 and 11 (fig. 2).

- the other three templates are identical to each other, but only have crosses 2 and axes AA 'and BB' (fig. 1).

- the presetting begins with the positioning of the master template on the first color group of the machine.

- the master jig 100 is the one which has the alignment bars 8, 9, 10 and 11 in addition to the crosses 2 and the axes AA 'and BB'.

- the master template is fixed on the sector corresponding to the first group.

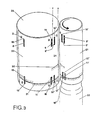

- a test piece 21 is then placed on the workpiece mandrel 22 (fig. 3).

- a passage is made with the blanket 23.

- the ink is transferred from the template to the blanket 23 then, from the latter, to the test piece 21.

- the end of the blanket 23 is not not yet adjusted and an additional part 24 protrudes. Therefore, the blanket 23 is in contact with the test piece 21 over a developed length greater than the development of the piece.

- the ink that the blancher 23 deposited on the proof piece 21 is redeposited, after the piece has completed a full turn, on the additional part of the blanket.

- the first patterns deposited by the blanket are the bars 8 and 20, these are printed 8 'and 10' on the piece 21 then redeposited on the blanket 8 "and 10". It is then checked that the top 18 "of the bar 8" is aligned at the same height as the top 14 of the bar 9 which marks the end of the blanket. We also check the alignment of the base 19 "of the bar 10" with the base 16 of the bar 11. If the vertices 18 "and 14 and the bases 19" and 16 are not aligned, we adjust the master template 100 on the sector by the set of fixing bars 34 (fig. 6) until said alignment is obtained. When the alignment is obtained, we have the demonstration that the axis AA 'as well as the alignment bars 8, 9, 10 and 11 are well oriented parallel to the axis of rotation of the sector.

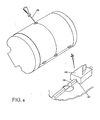

- the master template 100 being correctly positioned on the first sector, the sector is marked (fig. 4) by means of a stylus by tracing two marks aligned on the axis AA 'by the perforations 4 and 6 and two others marks aligned on the axis BB 'by the perforations 5 and 7.

- the guide has a countersink 28 which follows the relief of the axis 28 and drives the stylus by sliding on the rail formed by the relief of the axis.

- one of the three identical templates shown in fig. 1. We then pass over the blanket, but without using a proof piece this time.

- the master template 100 which is mounted on the first sector deposits its patterns, in particular the locating crosses 2 on the blanket as in FIG. 3.

- the second template 1 in turn deposits its patterns, as shown in FIG. 1 on the blanket.

- the second template is then adjusted on the second sector until its locating crosses 2 exactly coincide on the blanket with the crosses 2 left by the master template 100.

- the marking of the second is practiced sector in the same way as for the first.

- the templates receive, in addition to the elements already described, gauges 29 making it possible to control the pressure on the blanket as well as the lining and millimeter scales 30, 31 and 32.

- the gauges 29 are arranged differently on each of the four output templates that the gauges of each template leave a distinct imprint on the blanket.

- the millimeter scales each have their own function.

- Ladders 30 and 31 are arranged on the master template (fig. 7).

- the origin of the scale 30 is placed on the blanket end line which is determined by the straight edge 13 of the alignment bars 9 and 11. As mentioned above, the blanket is longer than the development of the proof piece.

- the scale 30 is printed from the master template on the additional part 24 of the blanket (fig. 3). Reading the reported scale 30 gives the exact indication of the length of the additional part 24 which will have to be deleted. This indication makes it possible to adjust the blanket holder sector 33 so that the real end X of the blanket coincides with the ideal end Y determined by the straight edge 13 of the alignment bars 9 and 11.

- the second millimeter scale 31 (fig.

- a millimeter scale 32 is arranged (fig. 8). It was originally carried over from scale 31; its axis is parallel to the axis AA '.

- the ladder 31 extends over the entire length of the master template, because it often happens that the sectors of a machine are in a totally desynchronized phase.

- the scale 32 printed by the second template for example can be found both on the far left and on the far right of the imprint left by the master template on the blanket.

- the measurement of the correction to be made can be read directly at the point of intersection between the scale 31 and the scale 32.

- the correction in development, ie the synchronization of the sectors, can be read on the scale 31; the correction affecting the height positioning of the template on the sector can be read on the scale 32.

- the assembly formed by the scales 31 of the master template and 32 of each of the three other templates has the same function as the locating crosses 2 , but occurs when the amplitude of the corrections is greater.

- the machine When the machine is preset, that is to say when the axes AA 'and BB' have been traced on the four sectors, the machine is ready to receive the working shots and to start the serial printing of the parts.

- the setting in machine of the sets of stereotypes is summarized for the operator to check the coincidence of the axes AA 'and BB' traced on the sector with the axes AA 'and BB' engraved on the stereotype (fig. 6e).

- the operator just has to adjust the picture by the play of the fixing bars 34 (fig. 6) by bringing the axes in superposition.

- the machine preset allows different formats to be used; in fact, the axis AA 'being close to the attachment margin 3, whatever the size of the plate, it is possible to punch two holes revealing the axis AA'. Regarding the axis BB ', it will be halfway up if the picture is large, it will be at the top of the picture if it is small.

- the advantage of the present invention compared to already known solutions is that it succeeds in moving the adjustment moment to a certain extent, or more precisely in dividing the adjustment into two distinct stages.

- the first step is to preset the machine. This is a little longer than the setting as it is usually practical, but it has the merit of deploying a permanent effect, and therefore does not have to be repeated.

- the second step closely dependent on the first, consists in shifting the timing of the adjustment of the plate on the sector or, more precisely, in presetting it so that the adjustment in machine is limited to a simple control, thus eliminating the groping which immobilizes the machine too much.

- the already known systems also try to shift the timing of the adjustment, but, in addition to their uncertain functioning, they have the handicap of asking for total precision in an operation (the perforation of the pictures) which is precisely that which is least suitable for it.

- the present invention requires the same precision of an operation which lends itself perfectly to it (copying the matrix film) whereas the perforations used are made with relative precision without any resulting disadvantage.

Landscapes

- Mechanical Engineering (AREA)

- Engineering & Computer Science (AREA)

- Printing Methods (AREA)

- Control Of Motors That Do Not Use Commutators (AREA)

- Amplifiers (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Diaphragms For Electromechanical Transducers (AREA)

- Apparatuses And Processes For Manufacturing Resistors (AREA)

- Surgical Instruments (AREA)

- Transition And Organic Metals Composition Catalysts For Addition Polymerization (AREA)

- Pens And Brushes (AREA)

- Bidet-Like Cleaning Device And Other Flush Toilet Accessories (AREA)

- Drying Of Solid Materials (AREA)

- Superconductors And Manufacturing Methods Therefor (AREA)

- Washing And Drying Of Tableware (AREA)

- Oscillators With Electromechanical Resonators (AREA)

- Vehicle Body Suspensions (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Ceramic Products (AREA)

- Printing Plates And Materials Therefor (AREA)

- Pinball Game Machines (AREA)

- Soil Working Implements (AREA)

- Steering Control In Accordance With Driving Conditions (AREA)

- Looms (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Ultra Sonic Daignosis Equipment (AREA)

- Discharging, Photosensitive Material Shape In Electrophotography (AREA)

- Manufacture Or Reproduction Of Printing Formes (AREA)

- Optical Recording Or Reproduction (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Treating Waste Gases (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82420171T ATE17681T1 (de) | 1981-12-08 | 1982-12-06 | Verfahren zur voreinstellung einer trockenoffsetmachine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH7831/81A CH648237A5 (fr) | 1981-12-08 | 1981-12-08 | Procede de fabrication de gabarits et de cliches et leur utilisation pour le reglage d'une machine offset a sec destinee a l'impression de pieces cylindriques ou coniques. |

| CH7831/81 | 1981-12-08 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0081443A1 EP0081443A1 (fr) | 1983-06-15 |

| EP0081443B1 true EP0081443B1 (fr) | 1986-01-29 |

Family

ID=4331110

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82420171A Expired EP0081443B1 (fr) | 1981-12-08 | 1982-12-06 | Procédé de préréglage d'une machine offset à sec |

Country Status (18)

| Country | Link |

|---|---|

| US (1) | US4520730A (es) |

| EP (1) | EP0081443B1 (es) |

| JP (1) | JPS58104748A (es) |

| AT (1) | ATE17681T1 (es) |

| BE (1) | BE895274A (es) |

| CA (1) | CA1191393A (es) |

| CH (1) | CH648237A5 (es) |

| DE (1) | DE3268902D1 (es) |

| ES (1) | ES8404913A1 (es) |

| FI (1) | FI73628C (es) |

| FR (1) | FR2517593B1 (es) |

| GR (1) | GR77851B (es) |

| IT (1) | IT1154386B (es) |

| MX (1) | MX157654A (es) |

| NO (1) | NO159984C (es) |

| OA (1) | OA07266A (es) |

| PT (1) | PT75943B (es) |

| ZA (1) | ZA828948B (es) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3903806C1 (es) * | 1989-02-09 | 1990-02-01 | Dieter Dr. 4005 Meerbusch De Hoell | |

| US5363564A (en) * | 1993-04-22 | 1994-11-15 | E. L. Harley Inc. | Printing plate mounting and proofing machine and method for using same |

| US5722178A (en) * | 1995-05-10 | 1998-03-03 | Wells; Harold T. | Method for setting and regulating the position of webbing in a printing press using premarked makeready tape |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR438296A (fr) * | 1911-12-27 | 1912-05-13 | Karl Marie Schlueter | Gabarits servant au réglage des clichés |

| US1151461A (en) * | 1912-01-17 | 1915-08-24 | Hugo Knudsen | Process for making printing-plates. |

| US2236000A (en) * | 1938-09-07 | 1941-03-25 | John A Koessler | Method for registering printing plates |

| US2580576A (en) * | 1948-11-15 | 1952-01-01 | Jr Robert R Myers | Method of registering multicolor printing plates |

| US2630755A (en) * | 1949-08-15 | 1953-03-10 | Inez L Herrin | Method of cutting stencils |

| US2711031A (en) * | 1952-05-06 | 1955-06-21 | Jr Harry C Kessler | Lithographic step and repeat system |

| US2793442A (en) * | 1955-03-11 | 1957-05-28 | Intercompany Corp | Procedure and apparatus for registering photographic sheets and the like |

| US2894454A (en) * | 1957-08-01 | 1959-07-14 | Hall Printing Co W F | Method of preregistering printing plates in multicolor printing |

| US3361060A (en) * | 1965-03-15 | 1968-01-02 | Mosstype Corp | Machine for mounting and proofing rubber printing plates |

| DE2045953C3 (de) * | 1970-09-17 | 1981-10-22 | Heinz 5653 Leichlingen Metje | Paßsystem zum Einpassen von Druckplatten in Offset-Rollen-Rotationsmachinen |

| US3908546A (en) * | 1972-10-16 | 1975-09-30 | Motter Printing Press Co | Plate clamping mechanism for printing cylinder |

| FR2312373A1 (fr) * | 1975-05-28 | 1976-12-24 | Liege Ste Francaise | Machine a imprimer en continu une empreinte sur des bouchons |

| DE2526446A1 (de) * | 1975-06-13 | 1976-12-23 | Roland Offsetmaschf | Vorrichtung zum justieren von druckplatten auf dem plattenzylinder von druckmaschinen mit hilfe einer ablesevorrichtung und auf den druckplatten einkopierten passkreuzen |

| US4191106A (en) * | 1975-12-01 | 1980-03-04 | K and Manufacturing Company, Inc. | Printing plate clamping assembly |

| DE3025060A1 (de) * | 1979-07-30 | 1981-02-19 | Riso Kagaku Corp | Anordnung und vorrichtung zum anbringen bzw. anheften einer folie, eines folienartigen bogens oder eines flachmaterials an einen anheftvorsprung eines formkoerpers |

-

1981

- 1981-12-08 CH CH7831/81A patent/CH648237A5/fr not_active IP Right Cessation

-

1982

- 1982-11-10 US US06/440,549 patent/US4520730A/en not_active Expired - Fee Related

- 1982-12-01 IT IT24546/82A patent/IT1154386B/it active

- 1982-12-02 GR GR69968A patent/GR77851B/el unknown

- 1982-12-02 MX MX195412A patent/MX157654A/es unknown

- 1982-12-03 OA OA57860A patent/OA07266A/xx unknown

- 1982-12-03 ES ES517897A patent/ES8404913A1/es not_active Expired

- 1982-12-06 ZA ZA828948A patent/ZA828948B/xx unknown

- 1982-12-06 DE DE8282420171T patent/DE3268902D1/de not_active Expired

- 1982-12-06 AT AT82420171T patent/ATE17681T1/de active

- 1982-12-06 EP EP82420171A patent/EP0081443B1/fr not_active Expired

- 1982-12-06 FR FR8220610A patent/FR2517593B1/fr not_active Expired

- 1982-12-06 PT PT75943A patent/PT75943B/pt not_active IP Right Cessation

- 1982-12-07 JP JP57214592A patent/JPS58104748A/ja active Pending

- 1982-12-07 BE BE0/209673A patent/BE895274A/fr not_active IP Right Cessation

- 1982-12-07 FI FI824195A patent/FI73628C/fi not_active IP Right Cessation

- 1982-12-07 NO NO824106A patent/NO159984C/no unknown

- 1982-12-07 CA CA000417126A patent/CA1191393A/fr not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| FI824195L (fi) | 1983-06-09 |

| EP0081443A1 (fr) | 1983-06-15 |

| CA1191393A (fr) | 1985-08-06 |

| FI73628C (fi) | 1987-11-09 |

| FI73628B (fi) | 1987-07-31 |

| ES517897A0 (es) | 1984-05-16 |

| NO159984B (no) | 1988-11-21 |

| FR2517593A1 (fr) | 1983-06-10 |

| GR77851B (es) | 1984-09-25 |

| PT75943B (fr) | 1985-02-27 |

| PT75943A (fr) | 1983-01-01 |

| IT1154386B (it) | 1987-01-21 |

| NO159984C (no) | 1989-03-01 |

| JPS58104748A (ja) | 1983-06-22 |

| IT8224546A0 (it) | 1982-12-01 |

| ZA828948B (en) | 1983-10-26 |

| BE895274A (fr) | 1983-06-07 |

| MX157654A (es) | 1988-12-08 |

| FI824195A0 (fi) | 1982-12-07 |

| ES8404913A1 (es) | 1984-05-16 |

| DE3268902D1 (en) | 1986-03-13 |

| US4520730A (en) | 1985-06-04 |

| CH648237A5 (fr) | 1985-03-15 |

| FR2517593B1 (fr) | 1986-02-14 |

| OA07266A (fr) | 1984-08-31 |

| ATE17681T1 (de) | 1986-02-15 |

| NO824106L (no) | 1983-06-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4019436A (en) | Technique for producing a pre-distorted design format for use in transfer printing | |

| US4380956A (en) | Mounting of flexible printing plates | |

| JPH0242070B2 (es) | ||

| US4611539A (en) | Device and method for the precision mounting of flexible printing plates | |

| CA2268624A1 (en) | Method and apparatus for use in offset printing | |

| US3948171A (en) | Method for printing multicolor halftone images on cylindrical objects | |

| FR2491833A1 (fr) | Support d'elements d'information comportant un motif figuratif surmonte d'un dessin lineaire, et procede de fabrication d'un tel support | |

| EP0081443B1 (fr) | Procédé de préréglage d'une machine offset à sec | |

| US4860650A (en) | Method for attaining longitudinal registry of rolls in printing presses | |

| WO2006000683A1 (fr) | Procede et dispositif de marquage d'une lentille ophtalmique | |

| US4179990A (en) | Method for making lithographic printing plates | |

| EP1593502B1 (fr) | Procede et dispositif de reglage initial de la coincidence des cylindres graves d'une presse rotative polychrome | |

| GB2083411A (en) | Improvements in or relating to the mounting of flexible printing plates | |

| EP1947511A1 (en) | Process for the manufacture of printing support for rollers for the printing of laminar materials, machine for implementing the process and the printing support for printing rollers | |

| GB2179890A (en) | Pin register system in production of printing plates | |

| BE1005060A6 (fr) | Methode de fabrication de plaques d'impression pour presses rotatives. | |

| US4043815A (en) | Method of making printing plates for offset printing | |

| US979890A (en) | Method of producing letterpress planographic-printing plates. | |

| US2322540A (en) | Method of making printing members | |

| US2969728A (en) | Method of embossing | |

| FR2504062A1 (fr) | Duplicateur d'impression offset en couleurs tramees | |

| Hentschel | 3rd Meeting:-" Process Engraving" | |

| FR2819318A1 (fr) | Procede et dispositif pour ameliorer la precision du reperage d'une image d'une forme d'impression | |

| US543040A (en) | Jules michaud | |

| SU391396A1 (ru) | Способ изготовления матриц |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT DE GB LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19830625 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT DE GB LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 17681 Country of ref document: AT Date of ref document: 19860215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3268902 Country of ref document: DE Date of ref document: 19860313 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921111 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19921112 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19921116 Year of fee payment: 11 Ref country code: AT Payment date: 19921116 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19921202 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19921231 Year of fee payment: 11 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19931206 Ref country code: GB Effective date: 19931206 Ref country code: AT Effective date: 19931206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19931207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931206 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940901 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82420171.9 Effective date: 19940710 |