EP0068734B1 - Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisé - Google Patents

Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisé Download PDFInfo

- Publication number

- EP0068734B1 EP0068734B1 EP19820303149 EP82303149A EP0068734B1 EP 0068734 B1 EP0068734 B1 EP 0068734B1 EP 19820303149 EP19820303149 EP 19820303149 EP 82303149 A EP82303149 A EP 82303149A EP 0068734 B1 EP0068734 B1 EP 0068734B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drying

- column

- particulate material

- grain

- dryer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000011236 particulate material Substances 0.000 title claims description 30

- 238000001035 drying Methods 0.000 claims description 107

- 238000001816 cooling Methods 0.000 claims description 14

- 230000005484 gravity Effects 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 2

- 235000013339 cereals Nutrition 0.000 description 156

- 239000003570 air Substances 0.000 description 97

- 240000008042 Zea mays Species 0.000 description 9

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 9

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 9

- 235000005822 corn Nutrition 0.000 description 9

- 238000009826 distribution Methods 0.000 description 9

- 238000005192 partition Methods 0.000 description 7

- 238000003860 storage Methods 0.000 description 6

- 238000005336 cracking Methods 0.000 description 5

- 241000209094 Oryza Species 0.000 description 4

- 235000007164 Oryza sativa Nutrition 0.000 description 4

- 238000007599 discharging Methods 0.000 description 4

- 238000004064 recycling Methods 0.000 description 4

- 230000000717 retained effect Effects 0.000 description 4

- 235000009566 rice Nutrition 0.000 description 4

- 239000012080 ambient air Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 238000009827 uniform distribution Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 230000000295 complement effect Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 230000003134 recirculating effect Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 210000004243 sweat Anatomy 0.000 description 2

- MFRCZYUUKMFJQJ-UHFFFAOYSA-N 1,4-dioxane-2,5-dione;1,3-dioxan-2-one Chemical compound O=C1OCCCO1.O=C1COC(=O)CO1 MFRCZYUUKMFJQJ-UHFFFAOYSA-N 0.000 description 1

- 230000003466 anti-cipated effect Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B17/00—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement

- F26B17/12—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft

- F26B17/122—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft the material moving through a cross-flow of drying gas; the drying enclosure, e.g. shaft, consisting of substantially vertical, perforated walls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B25/00—Details of general application not covered by group F26B21/00 or F26B23/00

- F26B25/001—Handling, e.g. loading or unloading arrangements

- F26B25/002—Handling, e.g. loading or unloading arrangements for bulk goods

Definitions

- This invention relates generally to gravity flow dryers for particulate material and, more particularly, to a multi-stage gravity flow dryer for particulate material wherein the discharge of the dryer is channelized.

- the need to dry grain prior to storage has long been recognized in the art and many grain drying systems have been developed to accomplish this purpose.

- the grain is .heated by air at a predetermined temperature during a first drying process and then the grain is quickly cooled to a desired storage temperature by exposing the grain to a flow of ambient air.

- One such system is the cross-flow column type grain dryer in which grain flows downwardly by gravity through a column having perforate walls and heated air is forced transversely through the perforate walls of the column to contact the grain to dry the grain or remove moisture.

- Typical of such cross-flow grain dryers are the grain dryers shown and described in US ⁇ A ⁇ 3238640 and DE-C-717052.

- Constructional details of the discharge means of a dryer according to Claim 1 are the subject- matter of divisonal application EP-A-0206069.

- a column type gravity flow dryer for particulate material for example, corn or other type grain.

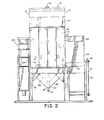

- the dryers generally designated 10, includes a generally square-shaped housing 12 comprised of a pair of solid end walls 14 and 16 and a pair of side walls 18 and 20. Each of the side walls 18 and 20 includes solid upper and lower portions 22 and 24, respectively, and a perforate intermediate portion 26.

- the housing 12 further includes a suitable roof 28 and is supported at the bottom by suitable support means or legs 30.

- At the top of the housing 12 is a means for introducing moist particulate material or grain into the top portion of the housing, in this embodiment, a suitably sized wet grain inlet 32.

- the assembly 34 On the outside of the housing 12 adjacent end wall 14, is an assembly or means 34 for providing drying air and cooling air to the housing 12.

- the assembly 34 which is supported by a suitable support frame 36, generally includes a blower section 38 and a heater section 40.

- the blower section 38 comprises a pair of blowers or fans 42 and 44 both of which are mounted for rotation on a single shaft 46.

- the fan shaft 46 extends outwardly through a generally circular cooling air inlet opening 48 in the blower section 38 and is journaled for rotation within a suitable bearing 39.

- a suitable drive pulley 50 is mounted on the outwardly extending end of the fan shaft 46.

- the drive pulley 50 is driven to rotation by means of a standard drive belt system 52 which also engages a second drive pulley 54.

- the drive pulley 54 may be driven by any suitable means, for example, an electric motor or a power takeoff mechanism on a tractor or other vehicle (not shown).

- the fan 42 which is closest to the cooling air inlet opening 48, is the cool air fan and the fan 44, which is furthest from the air inlet opening 48, is the hot air fan, the fans being separated by a vertical partition 43 to form individual chambers surrounding each fan. Cooling air is drawn in through the inlet opening 48 by the cool air fan 42 and is directed into a pair of cool air ducts 56 which in turn direct the cooling air into the dryer housing 12.

- the hot air fan 44 draws air in through a second generally rectangular air inlet opening 49 located in the other housing end wall 16 at the opposite end of the housing and the hot air fan 44 directs the flow of air upwardly into the heater section 40.

- the heater section 40 includes a burner 58 which heats the air received from the fan 44. In the preferred embodiment, the burner 58 may be a standard Maxon gas burner. The heated air from the burner 58 passes into a collector chamber 60 and thereafter is directed into the housing 12 by a pair of generally cylindrical hot air ducts 62.

- the heater section 40 and the blower section 38 are separated by a generally horizontally disposed partition 64 which contains an airflow control means, comprising in this embodiment, a plurality of adjustable dampers 66.

- the adjustable dampers 66 are provided to control the flow of air from the hot air fan 44 to the burner 58. In this manner, it is possible to effectively regulate the hot air flow into the housing 12 to efficiently dry a variety of different types of particulate material. For example, it may be desirable to provide a large hot air flow into the housing 12 for drying high moisture content corn and a much smaller hot air flow into the housing 12 for drying lower moisture content rice.

- the adjustable dampers 66 may be set in a substantially fully open position to apply a large hot air flow to dry corn or in a substantially closed position to apply a small hot air flow when drying rice.

- the dryer 10 comprises a pair of generally vertical outer drying columns 68, each column being defined by first and second substantially parallel opposed spaced perforate walls 70 and 26.

- a wet grain hopper 72 is provided at the top portion of the dryer for receiving and temporarily storing the moist grain introduced into the top of the housing 12 through the wet grain inlet 32.

- the wet grain hopper 72 is defined by the roof panels 28, the side wall upper solid portions 22 and a pair of sloping interior hopper walls 74.

- the wet grain hopper 72 also functions to distribute the moist grain into the top portions of each of the outer drying columns 68.

- the columns are tapered outwardly from top to bottom so that the width of each of the columns is greater at the bottom than at the top.

- the air flow is less restricted at the top of the columns (where the grain is wetter and provides a high air flow rate through the outer columns 68) than at the bottom of the columns (where the grain is drier), thereby providing for a more volume controlled airflow through the columns over their entire length.

- each of the outer drying columns 68 is a dividing wall means, in the present embodiment a generally vertical partition 76, for dividing the lower portion of each of the drying columns 68 into two generally parallel channels 78 and 80.

- Each of the channels 78 and 80 preferably contains separate discharge means, in the present embodiment metering rolls 82 and 84, respectively, for discharging particulate material from the channels 78 and 80 at predetermined rates.

- Both of the metering rolls 82 and 84 are driven by a system of drive belts and pulleys generally designated 85. As shown, the drive pulley for the metering roll 84 is of a smaller diameter than the drive pulley for metering roll 82.

- metering roll 84 rotates faster than metering roll 82 to thereby discharge grain from the innermost channel 80 at a faster rate than the grain is discharged from the outermost channel 78.

- the grain from both channels 78 and 80 is discharged by the respective metering rolls 82 and 84 into a receiving hopper 86.

- heated air from the hot air ducts 62 passes outwardly through the outer drying columns 68 to contact and dry the grain in the columns. Since the heated air enters each of the columns 68 through the inner perforated walls 70, the hottest driest air impinges upon the grain on the side of the drying columns adjacent the inner perforated walls 70. As the heated air continues on its path across the columns, a certain amount of heat is lost to the grain in the columns and the air picks up and retains moisture from the grain. By the time the air reaches the grain adjacent the outermost perforate walls 26, a significant portion of the heat has been lost to the grain and the same flow of air is also somewhat moisture laden and not able to dry the grain as effectively.

- the drying of the grain is somewhat uneven across the column, the grain adjacent the inner perforate walls 70 becoming drier as it flows down the columns than the grain flowing down the columns adjacent the outer perforate walls 26.

- the faster drying grain adjacent wall 70 is more quickly removed from the columns and the slower drying grain adjacent wall 26 is retained in the columns for a longer period of time and is exposed to the drying air for a longer period of time to promote more uniform drying across the column.

- each of the partitions 78 is provided with an adjustable or pivotable section or divider 79.

- the adjustable or pivotable sections 79 may be adjusted depending upon the initial moisture content and type of grain being dried to change the relative proportions of the grain entering the channels 78 and 80 in order to further improve the uniformity of the drying across the columns. For example, when drying corn with a very high initial moisture content, it may be desirable to adjust the pivotable sections 79 to provide for a smaller portion of the grain flowing into channels 80 than is flowing into channels 78. In this manner, more of the corn is retained in the drying columns 68 for a longer time period.

- the uniformly dried grain discharged from each of the channels 78 and 80 of the outer drying columns 68 is received and collected in the receiving hopper 86.

- a tube member 88 which extends vertically upwardly into the dryer housing 12.

- a conveyor means for example, a grain carrying auger 90 which is driven to rotation by means of a suitable drive pulley 92 extending outwardly from the bottom of the receiving hopper 86.

- the drive pulley 92 may be driven by any suitable means, for example, an electric motor or the power takeoff from a tractor or other vehicle (not shown).

- the lower end of the tube member 88 contains a plurality of openings 94 which allow the partially dried grain from the outer columns 68 which has accumulated within the receiving hopper 86 to pass into the tube member 88.

- the grain passing into the tube member 88 is conveyed or transported upwardly by the rotating grain auger 90 and is discharged from the tube member 88 into a substantially enclosed inner chamber 96.

- the rotation of the grain auger 90 is sufficient to evenly distribute the grain discharged from the tube member 88 over the inner chamber 96.

- cross- augers or other suitable means may be employed to provide an even distribution of the grain across the length and width of the inner chamber 96.

- the inner chamber 96 serves as a steeping or tempering chamber for the grain.

- the sloping lower walls 98 of the steeping chamber 96 are at an angle of not less than 45° in order to provide for an acceptable flow of the moist grain downwardly through the steeping chamber.

- the sloping lower walls 98 of the steeping chamber include suitable insulation 102 to prevent the grain flowing through the steeping chamber adjacent the lower walls 98 from becoming overheated due to its proximity to the incoming heated air passing through the hot air ducts 62.

- the upper walls 74 of the steeping chamber 96 are also sloped at an angle of not less than 45° to assure an acceptable flow of the incoming moist grain from the wet grain inlet 32 into the outer drying columns 68.

- the upper steeping chamber walls 74 include means, for example, a plurality of slots 106 extending therethrough which allow some of the incoming moist grain to pass directly into the steeping chamber 96, in order to make up for any shrinkage of the grain which may have occurred as a result of the drying of the grain as it passed through the outer drying columns 68.

- the slots 106 may also be employed to control the moisture content of the grain in the steeping chamber in a manner which will hereinafter become apparent. In the steeping chamber, the moisture in the grain tends to be uniformly distributed amongst all the grain in the chamber.

- the roof 28 may also contain a level control means 104 positioned slightly above the slots 106.

- the level control means 104 functions to actuate an elevator bucket or infeed auger (not shown) to maintain the grain in the wet grain hopper 72 at a level above the slots 106 in order to ensure that there is sufficient moist grain available for adding to the steeping chamber 96 to make up for any shrinkage which may have occurred.

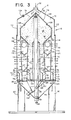

- the grain in the steeping chamber 96 flows downwardly at a controlled rate and passes into a pair of inner drying columns 100 which are also comprised of first and second perforate walls 108 and 110, respectively.

- the perforate walls 108 cooperate with perforate walls 70 and with the housing end walls 14 and 16 to form a pair of substantially enclosed plenum chambers 112.

- the plenum chambers 112 receive the heated airfrom the hot air ducts 62 and distribute the heated air so that it passes outwardly through the outer drying columns 68 and inwardly through the inner drying columns 100 along the entire length of the columns.

- the plenum chambers 112 may include suitable adjustable damper means 114 extending across the plenum chambers 112 between the end walls 14 and 16 to further control the distribution of the heated air to the inner and outer drying columns 68 and 100.

- the damper means 114 limits the amount of air which passes into the lower portion of the plenum chamber 112 to force more air through the upper section of the columns 68 and 100.

- the openings of the adjustable damper means 114 are tapered extending across the plenum chambers with the larger openings being adjacent end wall 14 or in close communication with the hot air ducts 62 to provide a generally uniform distribution of drying air into the lower portion of each plenum chamber.

- Figs. 1, 4 and 6 show a slightly different structural arrangement for evenly distributing the heated air within the plenum chambers 112.

- a pair of tapered perforate tubes 116 (116' in Fig. 6) extend across the plenum chambers 112 between the end walls 14 and 16.

- the larger end of the tapered tubes 116 re connected to and communicate with the hot air ducts 62 to receive the flow of heated air therefrom. Because the tubes 116 are tapered, the amount of heated air that passes along the length of the tube is restricted, thereby providing a uniform static pressure distribution along the length of the tube to ensure a uniform airflow out of the perforations therein.

- the uniform air flow from the tapered tubes 116 provides a generally uniform distribution of the heated air along the tubes and throughout the plenum chamber 112, thereby providing a more uniform flow of the heated air through the columns 68 and 100 along their entire length.

- the tapered tubes 116 may be replaced with constant diameter tubes. (not shown) having perforations varying in size and percentage of total opening along the length of the tubes, (the end of the tubes connected to the hot air ducts 62 having the larger diameter perforations and greater percentage of openings) to provide the desired generally uniform static pressure distribution along the length of the tubes into the plenum chamber.

- the inner drying columns 100 also have a generally vertical partition 118, which divides each column into inner and outer channels 120 and 122 in a manner corresponding to the partitions 76 for the outer drying columns 68.

- Discharge means in the form of metering rolls 124 and 126 are also provided for discharging grain from the inner and outer channels 120 and 122, respectively.

- the metering rolls 124 and 126 also turn at different predetermined rates for discharging the grain from the channels 120 and 122 at different rates.

- the metering rolls 126 adjacent the first perforate walls 108 discharge the material at a rate faster than the metering rolls 124.

- a pair of distribution ducts 127 having triangular cross-sections extend across the plenum chambers 112 between the end walls 14 and 16.

- One end of the distribution ducts 127 is connected to the cool air ducts 56 for receiving the cooling air flow.

- the ducts 127 have one wall provided by the perforated walls 108, which provide for the passage of cooling air into the lower portion of the inner drying columns 100. Adjacent each of the ducts 127 are small access or clean-out doors 129 to provide for the removal of debris which may accumulate within the plenum chambers 112.

- the inner drying columns 100 may also be wider at the bottoms than at the tops in a manner similar to that of the outer drying column 68 for substantially the same reasons as discussed above. Grain from the channels 120 and 122 of the inner drying columns 100 is discharged into a second or inner receiving hopper 130. Grain from the second receiving hopper 130 may be removed from the dryer by means of a discharge tube 132 and may thereafter be transported to a suitable storage facility (not shown).

- the dryer 10 also includes a central inner chamber 134 surrounding the vertical tube member 88 and formed on opposite sides by the innermost perforate walls 110.

- the central chamber 134 extends the entire length of the dryer between end walls 14 and 16 (shown on Fig. 1) and provides the conduit between the hot air fan 44 and the second air inlet opening 49 for the movement of ambient air into the inlet of the hot air fan 44.

- the central chamber 134 also receives and collects both the heating and cooling air exhausted from the inner drying columns 100 and recycles or recirculates this exhausted air back to the hot air fan 44.

- Figs. 7, 8 and 9 show additional details of the lower portion of the dryer, including the grain discharge means.

- metering roll 82 is retained within a plurality of aligned spaced-apart tubular members 136. Adjacent to and above the tubular members 136 are a plurality of inverted V-shaped members 138, which serve as deflectors to direct the downward flow of grain into spaces 140 between the tubular members 136.

- the metering roll 82 further comprises a horizontal rotating grain auger 142 disposed within the tubular members 136.

- the grain auger is supported by, for example, a suitable bearing 144 and is driven, for example, by means of a suitable drive pulley of the type hereinbefore described.

- Grain flowing downwardly in each of the channels of the drying columns is deflected by the inverted V-shaped members 138 into the spaces 140 between the tubular members 136 where it is received and carried by the rotating grain auger 142 as shown by the flow arrows. Thereafter, the grain is discharged from the grain auger 142 through a plurality of openings 146 located between the lower portions of each of the tubular members 136 and the grain enters the receiving hopper 86, as shown in Fig. 3.

- Each of the spaces 140 between the tubular members 136 is enclosed and includes a removable bottom panel 148, which is retained in place as shown by means of a pair of supporting side flanges 150 and a pair of suitably sized U-shaped clamps 152.

- the bottom panels 148 may be conveniently removed for cleaning out the spaces 140 and the grain auger 142.

- the combination of the metering rolls and the inverted V-shaped members 138 provide for a uniform withdrawal of grain across each of columns of the dryer. Additional details concerning the structure and operation of the grain discharge means may be obtained from US-A-4152841.

- the other metering rolls 84,124 and 126 operate and are constructed similarly to metering rolls 82.

- cross flow dryers of the type shown it is desirable to use the same dryer to dry particulate materials or grains of widely varying dimensions. For example, it may be desirable to dry either corn or rice in the same dryer. In order to be able to dry such different types of grains in the same dryer without any considerable loss of product or drying efficiency, it is necessary to have the ability to conveniently vary the size of the openings in the dryer's perforate walls forming the drying columns.

- each module is complete in itself and comprises four generally parallel perforate side panels 110', 108', 70' and 26', which are fixed to a plurality of generally vertical support members or cross braces 172.

- primes are used to designate component parts of the module 160, the primes being dropped when the module 160 is installed in the dryer 10 as shown on Fig. 4 (Fig. 3 does not show the modular construction features of the dryer 10).

- the perforate panels 110', 108', 70' and 26' may all be of one piece construction or may be made up of a plurality of individual smaller panels which are attached to the cross braces 172.

- the perforate panels 110', 108', 70' and 26' cooperate to form a pair of drying columns 100' and 68' with a plenum chamber 112' therebetween.

- a tapered perforate tube 116', a generally triangularly-shaped distribution duct 127' in cross-section having a perforated side wall 108' as a part thereof, and a clean-out door 129' are also included as part of the module 160 as shown.

- a pair of complementary modules 160 When a pair of complementary modules 160 are placed in position in the dryer housing 12 as shown in Fig. 4, they form the drying columns 68 and 100.

- the upper and lower portions of the modules 160 are suitably contoured to enable the modules to be appropriately positioned within the dryer housing 12 as shown in Fig. 4.

- the tapered perforate tubes 116 are connected to and cooperate with the hot air ducts 62 (shown in Fig. 1) for the distribution of hot air within the plenum chamber 112.

- the triangular-shaped air ducts 127 are connected to and cooperate with the cooing air ducts 56 (shown in Fig. 1) to provide a flow of cooling air when the modules 160 are in place within the dryer housing 12.

- Suitable sealing means may be provided to prevent air leakage from around the connection of the perforate tubes 116 and the triangular-shaped ducts 127 with the hot air ducts 62 and cooling air ducts 56.

- a number of small flanges 178 on the corners of the modules 160 engage suitable complementary flanges 180 on the dryer housing 12 in order to properly position and retain the modules 160 in place within the housing 12.

- a plurality of sealing means, for example, neoprene flaps 182 are employed to close any gaps or openings which may occur along the joint lines where the modules 160 meet the dryer housing 12 and to prevent the leakage of any grain through any such gaps or openings.

- each dryer 10 has one or more pairs of such modules 160.

- Each pair of such modules 160 has perforate side panels 110', 108', 70' and 26' with perforations of a different size than the other pairs of modules.

- one pair of modules have perforations ideally suited for drying rice, whereas another pair of modules will have perforations ideally suited for drying corn. In this manner, greater flexibility and drying efficiency may be achieved with a single basic dryer structure.

- the dryer 10 may be operated as a batch-type dryer or as a continuous flow-type dryer. In either type of dryer operation, an operator makes a determination as to what type of grain is to be dried and the initial moisture content of the grain. The operator then selects the appropriate pair of modules 160 for the grain to be dried and installs the modules in the dryer housing 12 as shown in Fig. 4. The operator also adjusts the adjustable air flow dampers 66 (shown in Fig. 1) to the proper setting to provide the desired air flow to provide optimum drying for the particular grain being dried. Likewise, the operator adjusts the pivotable sections 79 on the partitions 76 and 118 (shown in Fig. 1) to determine the relative portion of the grain which will be rapidly discharged from the grain columns 68 and 100 as described in detail above.

- the dryer is then activated and the grain to be dried is fed into the wet grain inlet 32.

- the grain from the wet grain inlet 32 flows downwardly into the wet grain hopper 72 and is introduced into the top of the outer drying columns 68.

- heated air from the plenum chamber 112 flows outwardly through the grain to heat the grain and remove moisture therefrom.

- the drying air passes outwardly through the outer perforate wall 26 to the atmosphere. As the grain flows downwardly through the column, it becomes increasingly drier due to its continued contact with the heated air.

- the grain flowing down the columns adjacent to perforate walls 70 is dried more rapidly than the grain flowing down the column adjacent outer walls 26. Accordingly, as also discussed in detail above relative to Fig. 3, the grain flowing through the columns 68 adjacent perforate walls 70 is discharged from the columns 68 at a faster rate than the grain flowing down the column adjacent the perforate walls 26.

- All of the grain discharged from the outer columns 68 is received and collected in the first receiving hopper 86.

- the collected grain flows downwardly within the hopper 86 and enters the vertical tube member 88 through the openings 94.

- the rotating grain auger 90 within the vertical tube member 88 transports the grain upwardly to the top of the tube member 88 where it is discharged into the steeping chamber 96.

- the steeping chamber 96 is generally filled with partially dried grain. Due to the relatively large size of the steeping chamber 96 with respect to the inner drying columns 100 which receive the grain discharged from the steeping chamber, the grain introduced to the top of the steeping chamber 96 moves slowly down from the steeping chamber 96 at a predetermined uniform rate. It is anticipated that the grain remains in the steeping chamber for at least a one hour period. While within the steeping chamber, the grain is steeped or sweats in a manner well known in the art.

- the grain After passing out of the steeping chamber 96, the grain enters the inner drying columns 100 and passes downwardly therethrough. At the top of the inner drying columns 100, the grain is again exposed to a flow of heated drying air, which passes inwardly from the plenum chambers 112, through the columns 100 and into the central chamber 134, as shown in Fig. 3. As the grain moves further down the inner columns 100, it is exposed to the cooling air which passes inwardly from the cooling air distribution ducts 127, through the columns 100 and into the central chamber 134. The dried and cooled grain is then discharged into the second or inner receiving hopper 130. The grain may then be removed from the dryer by means of the discharge tube 132 for subsequent storage and/or use.

- the slots 106 may be employed in conjunction with the metering rolls 124 and 126 at the bottom of the inner drying columns 100 to further control the moisture content of the grain discharged from the dryer 10. More specifically, by putting the metering rolls 124 and 126 on a separate drive (not shown), the amount of wet grain which enters the steeping chamber 96 through the slots 106 may be accurately controlled.

- the dryer 10 is better able to dry various types of grains having various initial moisture contents to a specified final moisture content.

- the heated air passing through the inner drying columns 100 enters the central chamber 134 and is recycled back to the hot air fan 44 for reuse.

- the cooling air which has passed through the inner columns 100 and has picked up heat from the heated grain within the columns is recycled back to the hot air fan 44 in the same manner.

- the heated air passing through the outer columns 68 is too saturated with moisture which has been removed from the grain, to be of desired use in recycling, and, thus, is exhausted to the atmosphere through the outer perforate walls 26.

- the present invention comprises a multi-stage gravity flow dryer for particulate material in which the particulate material is discharged in a channelized manner in order to provide improved uniformity of drying, as well as prevents overheating and cracking of the particulate material being dried.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Drying Of Solid Materials (AREA)

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82303149T ATE33306T1 (de) | 1981-06-19 | 1982-06-17 | Mehrstufentrockner fuer koerniges material mit kanalisierter abfuehrung. |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US06/275,313 US4398356A (en) | 1981-06-19 | 1981-06-19 | Multi-stage dryer for particulate material |

| US275312 | 1981-06-19 | ||

| US06/275,312 US4423557A (en) | 1981-06-19 | 1981-06-19 | Gravity flow dryer for particulate material having channelized discharge |

| US275313 | 1981-06-19 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86107817A Division EP0206069A3 (fr) | 1981-06-19 | 1982-06-17 | Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisée |

| EP86107817.8 Division-Into | 1982-06-17 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0068734A2 EP0068734A2 (fr) | 1983-01-05 |

| EP0068734A3 EP0068734A3 (en) | 1984-09-12 |

| EP0068734B1 true EP0068734B1 (fr) | 1988-03-30 |

Family

ID=26957361

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19820303149 Expired EP0068734B1 (fr) | 1981-06-19 | 1982-06-17 | Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisé |

| EP86107817A Ceased EP0206069A3 (fr) | 1981-06-19 | 1982-06-17 | Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisée |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86107817A Ceased EP0206069A3 (fr) | 1981-06-19 | 1982-06-17 | Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisée |

Country Status (10)

| Country | Link |

|---|---|

| EP (2) | EP0068734B1 (fr) |

| AR (1) | AR226984A1 (fr) |

| AU (2) | AU565672B2 (fr) |

| BR (1) | BR8203554A (fr) |

| CA (1) | CA1176053A (fr) |

| DE (1) | DE3278292D1 (fr) |

| DK (2) | DK259682A (fr) |

| GR (1) | GR76498B (fr) |

| HU (1) | HU189147B (fr) |

| NZ (1) | NZ200681A (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NZ200681A (en) * | 1981-06-19 | 1987-03-06 | Westelaken C | Gravity flow grain dryer with two stages of drying |

| US5992044A (en) * | 1998-06-12 | 1999-11-30 | Sukup Manufacturing Company | Method and apparatus for drying grain |

| AU2004274520C1 (en) * | 2003-09-25 | 2010-12-09 | Ect Coldry Pty Ltd | Dryer, drying method and drying plant |

| GB201007697D0 (en) | 2010-05-06 | 2010-06-23 | Ucl Business Plc | A supra-threshold test for use in detecting sensitivity loss across the field of vision |

| CN106679393B (zh) * | 2017-01-20 | 2022-04-22 | 中国科学院理化技术研究所 | 一种粮食烘干系统 |

| CN109095017A (zh) * | 2018-09-06 | 2018-12-28 | 云南中烟工业有限责任公司 | 一种新型打叶器进料流量控制装置 |

| CN113280610B (zh) * | 2021-05-31 | 2022-06-07 | 安徽华谷机械科技有限公司 | 一种梯度脱水的粮食烘干机 |

| CN114963740B (zh) * | 2022-04-29 | 2023-07-07 | 江苏经贸职业技术学院 | 一种食品加工烘干装置 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2732630A (en) * | 1956-01-31 | Markowich | ||

| GB190920758A (en) * | 1909-09-10 | 1910-09-12 | Diedrich Uhlhorn | Shaft Drier for Corn with Automatically Regulated Discharge of the Dried Material. |

| GB213799A (en) * | 1923-05-25 | 1924-04-10 | George Richard Schueler | Improvements in apparatus for cooling and drying nuts, cubes and similarly shaped pieces of compressed material for use as food for cattle and other animals, and grain, seed and other material in bulk |

| DE462031C (de) * | 1925-11-07 | 1928-07-03 | Otto Nordstroem | Schachttrockner mit einem aus Siebmaenteln gebildeten Ringschacht |

| DE717052C (de) * | 1939-01-12 | 1942-02-04 | August Gronert | Rieselschachttrockner fuer koerniges Gut |

| US3078590A (en) * | 1960-06-27 | 1963-02-26 | A F Meyer Mfg Co | Grain dryer |

| US3238640A (en) * | 1962-09-04 | 1966-03-08 | Hart Carter Co | Grain dryer |

| DE1604920B2 (de) * | 1965-12-23 | 1973-01-18 | Wilhelm Heine, Malzfabrik, 3150 Peine | Vertikaltrockner fuer getreide bzw. zum schwelken und darren von malz |

| FR93262E (fr) * | 1966-08-31 | 1969-03-07 | Etablissements Rivierre Casali | Séchoir pour produits granuleux. |

| US3426442A (en) * | 1967-06-01 | 1969-02-11 | Toshihiko Satake | Drying apparatus for cereals |

| CH497768A (de) * | 1968-10-10 | 1970-10-15 | Sulzer Ag | Bestrahlungsanlage, insbesondere für körniges Gut |

| US4223452A (en) * | 1979-02-12 | 1980-09-23 | Chambers John M | Drying process and apparatus for accomplishing the same |

| NZ200681A (en) * | 1981-06-19 | 1987-03-06 | Westelaken C | Gravity flow grain dryer with two stages of drying |

| US4423557A (en) * | 1981-06-19 | 1984-01-03 | Westelaken C | Gravity flow dryer for particulate material having channelized discharge |

-

1982

- 1982-05-19 NZ NZ20068182A patent/NZ200681A/en unknown

- 1982-06-09 AU AU84702/82A patent/AU565672B2/en not_active Ceased

- 1982-06-10 DK DK259682A patent/DK259682A/da not_active Application Discontinuation

- 1982-06-11 GR GR68412A patent/GR76498B/el unknown

- 1982-06-17 EP EP19820303149 patent/EP0068734B1/fr not_active Expired

- 1982-06-17 DE DE8282303149T patent/DE3278292D1/de not_active Expired

- 1982-06-17 AR AR28970582A patent/AR226984A1/es active

- 1982-06-17 BR BR8203554A patent/BR8203554A/pt unknown

- 1982-06-17 EP EP86107817A patent/EP0206069A3/fr not_active Ceased

- 1982-06-18 CA CA000405450A patent/CA1176053A/fr not_active Expired

- 1982-06-18 HU HU200182A patent/HU189147B/hu not_active IP Right Cessation

-

1987

- 1987-03-24 AU AU70551/87A patent/AU582301B2/en not_active Ceased

-

1988

- 1988-08-19 DK DK468988A patent/DK468988A/da not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| EP0068734A3 (en) | 1984-09-12 |

| CA1176053A (fr) | 1984-10-16 |

| DK259682A (da) | 1982-12-20 |

| AU7055187A (en) | 1987-07-09 |

| DK468988D0 (da) | 1988-08-19 |

| NZ200681A (en) | 1987-03-06 |

| AR226984A1 (es) | 1982-08-31 |

| AU582301B2 (en) | 1989-03-16 |

| DE3278292D1 (en) | 1988-05-05 |

| EP0068734A2 (fr) | 1983-01-05 |

| EP0206069A3 (fr) | 1987-02-25 |

| HU189147B (en) | 1986-06-30 |

| BR8203554A (pt) | 1983-06-07 |

| EP0206069A2 (fr) | 1986-12-30 |

| GR76498B (fr) | 1984-08-10 |

| AU565672B2 (en) | 1987-09-24 |

| DK468988A (da) | 1988-08-19 |

| HUT35834A (en) | 1985-07-29 |

| AU8470282A (en) | 1982-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4424634A (en) | Modular column dryer for particulate material | |

| US4423557A (en) | Gravity flow dryer for particulate material having channelized discharge | |

| US4125945A (en) | Multiple stage grain dryer with intermediate steeping | |

| US4398356A (en) | Multi-stage dryer for particulate material | |

| CA2868285C (fr) | Sechoir multiproduit de courroie pour produits pateux et/ou pulverulents, en particulier pour boues de station d'epuration ou biomasse | |

| US4477984A (en) | Multi purpose three pass drum dryer | |

| US20060123655A1 (en) | Continuous flow grain dryer | |

| JPS5833470B2 (ja) | レンゾクセンタクドライヤ− | |

| EP0068734B1 (fr) | Séchoir à étages multiples pour matière granuleuse comportant un dispositif d'évacuation canalisé | |

| US4402302A (en) | Air heating apparatus | |

| US4152841A (en) | Flow control meters for gravity flow particle dryers | |

| US6223454B1 (en) | Method of drying moist organic material | |

| KR101823598B1 (ko) | 용량 가변형 열회수 건조기 | |

| US5443539A (en) | Particulate dryer | |

| US5233766A (en) | Vertical grain dryer | |

| US5467535A (en) | Moisture equalizer for a continuous flow grain dryer | |

| US5992044A (en) | Method and apparatus for drying grain | |

| US3869809A (en) | Continuous flow grain drying apparatus | |

| RU2082924C1 (ru) | Циклическая сушилка для сыпучих материалов | |

| NZ213520A (en) | Gravity flow grain dryer:differential flow rates | |

| US5940982A (en) | Particulate material dryer | |

| CA1195108A (fr) | Sechoir a decharges dirigees pour les cereales | |

| KR0135062B1 (ko) | 열풍건조방법 및 그 장치 | |

| US3063159A (en) | Dryer for tobacco or the like | |

| US1751472A (en) | Drying process and apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850302 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 33306 Country of ref document: AT Date of ref document: 19880415 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3278292 Country of ref document: DE Date of ref document: 19880505 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19890607 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19890609 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19890612 Year of fee payment: 8 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19890630 Year of fee payment: 8 Ref country code: GB Payment date: 19890630 Year of fee payment: 8 Ref country code: FR Payment date: 19890630 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19890809 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19890829 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19900617 Ref country code: AT Effective date: 19900617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19900618 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19900630 Ref country code: CH Effective date: 19900630 Ref country code: BE Effective date: 19900630 |

|

| BERE | Be: lapsed |

Owner name: WESTELAKEN CHRISTIANUS MARINUS THERESIA Effective date: 19900630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19910101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19910228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19910301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82303149.7 Effective date: 19910206 |