EP0058607B1 - Dispositif de refroidissement rapide et contrôlé dans un four de recuit en atmosphère neutre ou réductrice - Google Patents

Dispositif de refroidissement rapide et contrôlé dans un four de recuit en atmosphère neutre ou réductrice Download PDFInfo

- Publication number

- EP0058607B1 EP0058607B1 EP82400237A EP82400237A EP0058607B1 EP 0058607 B1 EP0058607 B1 EP 0058607B1 EP 82400237 A EP82400237 A EP 82400237A EP 82400237 A EP82400237 A EP 82400237A EP 0058607 B1 EP0058607 B1 EP 0058607B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- strip

- gas

- blowing

- cooling device

- cooling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000001816 cooling Methods 0.000 title claims description 26

- 238000000137 annealing Methods 0.000 title claims description 6

- 230000007935 neutral effect Effects 0.000 title claims description 4

- 238000007664 blowing Methods 0.000 claims description 17

- 238000000034 method Methods 0.000 claims description 8

- 239000002184 metal Substances 0.000 claims description 6

- 230000001105 regulatory effect Effects 0.000 claims description 4

- 239000007788 liquid Substances 0.000 claims description 3

- 230000003134 recirculating effect Effects 0.000 claims 1

- 238000004804 winding Methods 0.000 description 5

- 239000012530 fluid Substances 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 238000009434 installation Methods 0.000 description 3

- 230000001681 protective effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000004321 preservation Methods 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C21D9/54—Furnaces for treating strips or wire

- C21D9/56—Continuous furnaces for strip or wire

- C21D9/573—Continuous furnaces for strip or wire with cooling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C21D9/54—Furnaces for treating strips or wire

- C21D9/56—Continuous furnaces for strip or wire

- C21D9/561—Continuous furnaces for strip or wire with a controlled atmosphere or vacuum

Definitions

- the present invention relates to the rapid and controlled cooling of a metal strip, in an annealing furnace in a neutral or reducing atmosphere.

- Another technique also well known (see FR-A-2460333), consists in effecting a cooling by contact effect of the strip in continuous travel with a metal roller on which this strip is applied and which is cooled by a liquid.

- This technique has the drawback, for a fixed winding of the strip around the cooled roller, of not allowing the cooling speed to be regulated. It is therefore necessary, in order to be able to maintain the final cooling temperature at a desired level, to vary the length of winding of the strip on the roller, which leads to complex mechanical arrangements, since the rollers and the strip to be cooled are located in a sealed enclosure relative to the outside.

- the present invention proposes to provide a rapid and controlled cooling device in an annealing furnace in a neutral or reducing atmosphere, not having the drawbacks mentioned above of the techniques currently known.

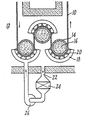

- This device essentially comprises a series of rollers cooled by liquid, arranged in the oven and on which the strip to be treated is applied, and it is characterized in that said rollers have a fixed position, so that the length of the arc winding of the strip around them does not vary during cooling, and in that there is provided, in front of each roller, a gas jet blowing means designed so as to project a gas jet perpendicular to the strip running continuously.

- the final temperature of the strip leaving the device is regulated by varying the blowing speed of the jets striking this strip.

- a protective gas is used in the jet blowing system, in any desired proportion.

- each roller such as 14, a means of blowing by gas jets.

- each of these means is constituted by a box, such as 18, provided with nozzles or slots ensuring a projection of gaseous jets 20 perpendicular to the strip 10, over a length substantially close to that of the arc for winding the strip 10 around the cooled roller 14.

- the passage of the strip being perfectly delimited in space, the geometry of the jets 20 can be chosen so as to give them greater cooling efficiency than that obtained with conventional cooling systems by blowing gas jets.

- the gas blown through the nozzles or the slots in the boxes 18 is, after heat exchange with the strip, taken up by a line 22, to be sent to an exchanger 24 outside the installation, before being recycled, by the through a recirculation fan 26, in the blowing boxes 18.

- the final temperature of the strip 10 leaving the device is regulated by varying the speed of blowing the jets. gas coming to strike the strip. This variation can extend from a value equal to zero up to the maximum value made possible by the characteristics of the recirculation fan 26.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Heat Treatment Of Strip Materials And Filament Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8102744 | 1981-02-12 | ||

| FR8102744A FR2499591A1 (fr) | 1981-02-12 | 1981-02-12 | Dispositif de refroidissement rapide et controle dans un four de recuit en atmosphere neutre ou reductrice |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0058607A1 EP0058607A1 (fr) | 1982-08-25 |

| EP0058607B1 true EP0058607B1 (fr) | 1984-12-27 |

Family

ID=9255114

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82400237A Expired EP0058607B1 (fr) | 1981-02-12 | 1982-02-10 | Dispositif de refroidissement rapide et contrôlé dans un four de recuit en atmosphère neutre ou réductrice |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0058607B1 (enExample) |

| DE (2) | DE58607T1 (enExample) |

| FR (1) | FR2499591A1 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3463162D1 (en) * | 1983-06-11 | 1987-05-21 | Nippon Steel Corp | Method for cooling a steel strip in a continuous-annealing furnace |

| JPS60128220A (ja) * | 1983-12-15 | 1985-07-09 | Mitsubishi Heavy Ind Ltd | 連続焼鈍炉冷却帯のストリツプ温度制御方法 |

| JPS60169524A (ja) * | 1984-02-14 | 1985-09-03 | Mitsubishi Heavy Ind Ltd | 金属ストリツプ冷却装置 |

| JPS62149820A (ja) * | 1985-12-24 | 1987-07-03 | Kawasaki Steel Corp | 鋼帯の冷却方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2460333A1 (fr) * | 1979-06-28 | 1981-01-23 | Nippon Kokan Kk | Procede et appareil pour refroidir des bandes d'acier au cours d'un traitement de recuit en continu |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2023285A (en) * | 1934-08-30 | 1935-12-03 | Gen Electric | Heat treating |

| DE878949C (de) * | 1944-04-04 | 1953-06-08 | Benno Schilde Maschb A G | Durchziehofen zum Warmbehandeln von Baendern und Draehten |

| US2890037A (en) * | 1954-11-10 | 1959-06-09 | United States Steel Corp | Method and apparatus for continuously cooling metal strips |

| JPS54118315A (en) * | 1978-03-08 | 1979-09-13 | Nippon Kokan Kk <Nkk> | Metal belt cooling |

-

1981

- 1981-02-12 FR FR8102744A patent/FR2499591A1/fr active Granted

-

1982

- 1982-02-10 EP EP82400237A patent/EP0058607B1/fr not_active Expired

- 1982-02-10 DE DE1982400237 patent/DE58607T1/de active Pending

- 1982-02-10 DE DE8282400237T patent/DE3261651D1/de not_active Expired

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2460333A1 (fr) * | 1979-06-28 | 1981-01-23 | Nippon Kokan Kk | Procede et appareil pour refroidir des bandes d'acier au cours d'un traitement de recuit en continu |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0058607A1 (fr) | 1982-08-25 |

| FR2499591B1 (enExample) | 1984-06-22 |

| FR2499591A1 (fr) | 1982-08-13 |

| DE58607T1 (de) | 1983-03-03 |

| DE3261651D1 (en) | 1985-02-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0795616B1 (fr) | Procédé et installation de traitement thermique en continu de bandes métalliques dans des atmosphères de nature différente | |

| EP1067204B1 (fr) | Procédé et dispositif de suppression de la vibration des bandes dans des zones de soufflage de gaz, notamment des zones de refroidissement. | |

| EP2376662A1 (fr) | Procede et section de refroidissement d'une bande metallique en defilement par projection d'un liquide | |

| EP0058607B1 (fr) | Dispositif de refroidissement rapide et contrôlé dans un four de recuit en atmosphère neutre ou réductrice | |

| EP1108795B1 (fr) | Procédé et dispositif de réduction des plis de bande dans une zone de refroidissement rapide de ligne de traitement thermique | |

| EP0979879B1 (fr) | Procédé de galvanisation d'une bande métallique | |

| EP2304060A1 (fr) | Procede et dispositif de regulation de refroidissement et de recuperation d' energie d' une bande d' acier en phase de recuit ou de galvanisation | |

| EP0761829B1 (fr) | Dispositif de refroidissement d'un produit laminé | |

| EP3601624B1 (fr) | Section et procédé de refroidissement d'une ligne continue combinant un refroidissement sec et un refroidissement humide. | |

| EP0879897B1 (fr) | Procédé de recuit d'un substrat métallique au défilé | |

| EP3555324B1 (fr) | Procede et section de refroidissement rapide d'une ligne continue de traitement de bandes metalliques | |

| FR2501666A1 (fr) | Procede et dispositif de trempe continue de plaques de verre | |

| EP3596240A1 (fr) | Ligne continue de recuit ou de galvanisation comprenant un bloc tensionneur entre deux fours consécutifs | |

| EP1029933A1 (fr) | Dispositif d'échange de chaleur avec un produit plat | |

| EP0069616B1 (fr) | Dispositif pour le refroidissemnet de spires de fils en acier dans la chaude de laminage | |

| EP0031772A1 (fr) | Procédé et dispositif pour la fabrication de verre par flottage | |

| EP3397786B1 (fr) | Dispositif et procede pour realiser une oxydation controlee de bandes metalliques dans un four de traitement en continu | |

| EP0418166A1 (fr) | Dispositif de refroidissement par contact de rouleaux pour la trempe en continu d'une bande d'acier préchauffée | |

| BE888644A (fr) | Appareil et procede pour supporter un feuillard metallique sous une pression de gaz statique, | |

| BE886651R (fr) | Procede et dispositif de refroidissement accelere de bandes minces | |

| EP0731853B1 (fr) | Dispositif de refroidissement accelere d'un substrat continu en defilement rapide dans un plan vertical | |

| FR2660935A1 (fr) | Procede de traitement d'une tole et four de traitement appliquant ce procede. | |

| FR3151503A1 (fr) | Système de capture de dioxyde de carbone au sein de gaz chargé en dioxyde de carbone | |

| FR2953221A1 (fr) | Dispositif pour maintenir seche l'atmosphere d'un four de recuit pour bande metallique, et four equipe de ce dispositif | |

| WO1999030849A1 (fr) | Dispositif de refroidissement a tres haute puissance specifique d'une bande metallique en mouvement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE GB IT LU NL |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: STUDIO KOHLER FONTANA |

|

| TCNL | Nl: translation of patent claims filed | ||

| 17P | Request for examination filed |

Effective date: 19821001 |

|

| DET | De: translation of patent claims | ||

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): BE DE GB IT LU NL |

|

| REF | Corresponds to: |

Ref document number: 3261651 Country of ref document: DE Date of ref document: 19850207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19850228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19900111 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19900118 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19900131 Year of fee payment: 9 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19900228 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19900430 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19910210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19910228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19910901 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19911101 |