EP0057128B1 - Railroad tie renewing machine and method of using it - Google Patents

Railroad tie renewing machine and method of using it Download PDFInfo

- Publication number

- EP0057128B1 EP0057128B1 EP82400091A EP82400091A EP0057128B1 EP 0057128 B1 EP0057128 B1 EP 0057128B1 EP 82400091 A EP82400091 A EP 82400091A EP 82400091 A EP82400091 A EP 82400091A EP 0057128 B1 EP0057128 B1 EP 0057128B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- clamp

- sleeper

- track

- sleepers

- machine according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims description 10

- 241001669679 Eleotris Species 0.000 claims abstract description 27

- 238000006073 displacement reaction Methods 0.000 claims description 10

- 238000000605 extraction Methods 0.000 description 8

- 238000006467 substitution reaction Methods 0.000 description 7

- 244000000231 Sesamum indicum Species 0.000 description 4

- 235000003434 Sesamum indicum Nutrition 0.000 description 4

- 244000185238 Lophostemon confertus Species 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 240000008042 Zea mays Species 0.000 description 2

- 210000003323 beak Anatomy 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 230000000284 resting effect Effects 0.000 description 2

- 244000251953 Agaricus brunnescens Species 0.000 description 1

- 235000001674 Agaricus brunnescens Nutrition 0.000 description 1

- 241000227645 Triplaris cumingiana Species 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 230000006735 deficit Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000009432 framing Methods 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000010408 sweeping Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B29/00—Laying, rebuilding, or taking-up tracks; Tools or machines therefor

- E01B29/06—Transporting, laying, removing or renewing sleepers

- E01B29/09—Transporting, laying, removing or renewing sleepers under, or from under, installed rails

- E01B29/10—Transporting, laying, removing or renewing sleepers under, or from under, installed rails for inserting or removing sleepers

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B27/00—Placing, renewing, working, cleaning, or taking-up the ballast, with or without concurrent work on the track; Devices therefor; Packing sleepers

- E01B27/06—Renewing or cleaning the ballast in situ, with or without concurrent work on the track

- E01B27/11—Renewing or cleaning the ballast in situ, with or without concurrent work on the track combined with concurrent renewal of track components

Definitions

- the railroad superstructure is mainly made up of three elements of uneven longevity: the rails, the sleepers and the ballast.

- the effort to reduce track maintenance costs relates in particular to the search for better harmonization of the reliability specific to each of these three elements.

- the present invention therefore aims to create a machine capable of performing at high speed all the operations necessary for the replacement of wooden sleepers in particular by concrete sleepers, while keeping the track its perfect integrity.

- Such a machine is, in a known manner for example from AU-B-453 660, constituted by a wagon equipped with devices capable of individually replacing old sleepers with new sleepers, and in particular of a sleepers handling group comprising a set of gripping members which make it possible to grip a sleeper or a rail of the track, these members, suspended from a transverse beam and movable both in height as longitudinally and transversely with respect to the direction of the track, comprising a first member constituted by a clamp capable of gripping a cross member and of moving in a transverse direction from one side of the track substantially from a vertical plane passing through a first track rail, a second member and a third member capable of gripping each of one of the rails of the track to lift it, the first gripping member being able to move in transverse direction independently of the other two, while the latter can move together and have side spouts which are capable of to place themselves respectively under each of the rails of the track in order to lift them.

- the invention relates to a machine of this kind, further characterized in that the second gripping member, located between the first and the third and capable of gripping a rail, is, like the first gripping member, a clamp designed to grip a crosspiece, which can thus be gripped successively or simultaneously by a first clamp and by a second clamp, the latter being able to move in a transverse direction substantially in the space separating the vertical planes respectively containing the rails of the way.

- the first clamp evolves in the space located on one side of the track and the second clamp in the space located between the two rails of the track, while the third gripper can evolve in the space located on the other side of the track.

- the first clamp which is intended to perform the major part of the handling operations of the sleepers, should be able to be pivotally actuated around its vertical axis of symmetry, by at least a quarter of a turn so as to be able to '' bring the sleepers parallel to the track, which facilitates their routing on board the machine. It is also advantageous to ensure that the second clamp can move in the transverse direction independently of the third gripping member, so that the latter remains stationary while the second clamp moves transversely to ensure, as will be seen below. , the end of the operation of installing new sleepers.

- the transverse beam of the handling group is a telescopic beam formed of an inner tube, at the end of which is suspended the first clamp and which is movable by sliding in an outer tube connected to a slide able to move in height (thanks to a motor means) along a guide column fixed by its top to a carriage movable in longitudinal direction along guide rails integral with the chassis of the wagon, and along the outer tube can move on a short stroke a sliding part to which are suspended the second clamp and the third gripping member.

- the third member can be suspended directly from said sliding part in the region of its end facing outwards, the second being suspended by means of displacement in transverse direction.

- the amplitude of the transverse stroke which the first clamp and the second clamp can accomplish is preferably close to half the length of a cross member, while the short stroke to which the transverse displacements of the third gripping member can be limited is about the width of a rail shoe.

- a machine according to the invention may advantageously further comprise an earthmoving group comprising a clamshell movable in height and in the longitudinal direction and designed to allow the removal and replacement of the ballast surrounding the crosspiece to be replaced, which leads to fully mechanical handling of the ballast.

- an earthmoving group comprising a clamshell movable in height and in the longitudinal direction and designed to allow the removal and replacement of the ballast surrounding the crosspiece to be replaced, which leads to fully mechanical handling of the ballast.

- this clamshell is subdivided into three parts separated by two intervals forming free spaces where the rails of the track are inscribed when the grab is lowered in contact with the ballast, so that the latter can work on both sides other rails along the entire length of the sleepers.

- the clamshell should be subject to the curvature of the track by giving it the possibility of moving in a transverse direction under the action of a guide means maintaining said free spaces facing the rails of the track.

- the clamshell can be suspended by articulated bars forming a deformable parallelogram located in a transverse plane, these bars being attached to a carriage movable in the longitudinal direction, preferably moving on the same rails as the carriage of the group of handling.

- a machine preferably has a double conveyor, namely a conveyor for removing old sleepers and a conveyor for supplying new sleepers. , both accessible to the first clamp of the handling group.

- This arrangement allows direct new sleepers to be brought ment of a flat wagon coupled to the machine and to evacuate the old sleepers towards it.

- the machine should be equipped with a ballast reserve hopper, so as to be able to dump transversely to the track any quantity of additional ballast necessary to properly stuff the crossbar just installed, with a tamping group. ballast under this crosspiece and finally a leveling brush box to sweep and remove the excess ballast.

- the various movements and displacements of the movable members which it comprises should be obtained by means of motors or jacks, preferably hydraulic, controlled from a control (of course with the exception of the transverse movements of the clamshell bucket of the earthworks, which depend solely on the aforementioned means of guidance on the rails).

- the invention also relates to a method of handling sleepers during substitution operations using a machine as described above.

- This process is in particular characterized by the fact that, after removal of a crosspiece to be replaced, the installation of a new crosspiece takes place in two phases, namely a first phase where the crosspiece, captured in its central region by the first clamp is slid by the latter under the first rail of the track until said clamp is stopped by said rail, and a second phase where the crosspiece, released from the first clamp, is gripped in its central region by the second clamp beyond said rail, the latter clamp completing the positioning of the cross member under the rails of the track.

- This operating mode authorized by the machine according to the invention, is of great importance.

- the new sleepers are grasped and always pulled by their central region, which eliminates this drawback and thus avoids any deformation of the track.

- the removal of an old crosspiece to be replaced it is carried out by means of the first clamp preferably in two successive extraction phases, in each of which the crosspiece is pulled by this clamp of approximately half its length. A transverse stroke of reduced amplitude is therefore sufficient for this clamp, which simplifies the design of the machine.

- Wagon 31 is self-propelled thanks to a propulsion assembly, not shown.

- the handling group 38 comprises a telescopic transverse beam 51 carrying the three clamps 39, 40 and 41 mentioned above and formed of an outer tube 52 of square section and of a inner tube 53 also of square section, capable of moving by sliding in the tube 52 under the action of a long jack 54.

- the tube 52 is fixed to a slide 55 which can move, by means of a motor means not shown, along a vertical column 56 of circular section, which is suspended from a carriage 57 movable in the longitudinal direction of the wagon 31 in guide rails 58 integral with the side members 33.

- the clamp 39 is fixed under the end of the tube 53 emerging from the tube 52, by means of a motorized connecting member 59 enabling it to rotate a quarter of a turn, in one direction or the other, around its vertical axis of symmetry.

- the clamps 40 and 41 are carried by a sliding part 60 capable of moving, over a short stroke, thanks to a jack 61, below and along the tube 52 to which it is suspended by rollers resting on wings 62 which the tube 52 offers laterally.

- the clamp 41 is suspended at one end of the movable part 60 close to the end of the tube 53 opposite that to which the clamp 39 is suspended.

- the clamp 40 is suspended from said part 60 , between the clamps 39 and 41, by means of a translation means constituted by a rotating threaded rod 29 and a nut 30 through which the latter passes, which is mounted under the part 60 parallel to the longitudinal direction of the latter and tubes 52 and 53 forming the telescopic beam 51.

- the clamps 39, 40 and 41 can move in the three directions of space; more precisely, all of said clamps are movable relative to the chassis of the wagon 31, longitudinally by displacement of the carriage 57 along the rails 58, vertically by displacement of the slide 55 along the column 56 and transversely, respectively by sliding of the tube 53 in the tube 52 for the clamp 39, by displacement of the part 60 for the clamps 40 and 41 and, moreover for the clamp 40, by rotation of the threaded rod 29.

- said clamps are each provided with 'an actuating means at the opening and closing of their branches. However, one can dispense with providing such an actuating means the clamp 41, because, as will be seen, unlike the other clamps 39 and 40, it is not used to grip the crosspieces, so that its branches can remain stationary when open.

- Figure 3 shows the clamps 39, 40 and 41 in the initial position, in which the clamps 39 and 41 are located above the sleeper heads of the track 42, therefore on either side of the rails 63, 64 of that -this, while the clamp 40 overhangs the space between these rails, the clamps 40 and 41 lying directly above areas respectively of the rail 63 and of the rail 64 of the track 42 and located on the same side relative to these rails (to the right of these in Figure 3).

- This is provided so that the clamps 40 and 41, distant by a length equal to the spacing of the rails 63, 64 of the track, can be introduced together under these rails by nozzles 81 which their articulated branches present laterally, in view raise track 42.

- the earthmoving group 43 (FIGS. 4 and 5) is suspended from a carriage 65 movable in longitudinal direction, like the carriage 57, along the guide rails 58.

- Its clamshell bucket 44 is subdivided into three parts 44a, 44b and 44c making two free intervals 66 appear corresponding to the location of the rails 63, 64 of the track 42.

- the jaws of this multiple bucket which makes it possible to carry out transverse earthwork of the ballast in a single operation, despite the presence of the rails, are actuated by four jacks 67 by means of articulated rods 68.

- the pivot axis 69 of the jaws of the bucket is supported by vertical plates 70 welded to a common transverse plate 71, to which are also welded sleeves 72 sliding on guide bars 73 during movements in height of this plate 71 and of the bucket 44 under the action of a jack 74 connecting the carriage 65 and the pivot axis 69 of the jaws of the bucket.

- the guide bars 73 are articulated on the one hand to the carriage 65 at 75 and on the other hand at 76 to parts 77 connected by a horizontal rod 78 so as to form a deformable parallelogram in transverse direction.

- articulated arms 79 carrying small liftable wheels 80 which, applied to the rails 63, 64 of the track 42 and guided by them, cause the aforementioned parallelogram to deform in the event of a curve in the track, so that the bucket 44 is offset transversely by the desired quantity so that the intervals 66 between the parts which compose it always remain in line with the rails 63, 64.

- the jack 74 is arranged parallel to the bars 73 and articulated like them at its ends.

- the wagon is further advanced so as to be able to successively actuate the tamping group 48 and the adjustment brush box 49 in the region surrounding the cross member 37.

- the extraction or introduction of the sleepers can be done either on the side of the runway or on the side of the cross-section, by simply inverting the handling group 38 around the column 56.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Machines For Laying And Maintaining Railways (AREA)

Abstract

Description

La superstructure des voies ferrées est principalement constituée de trois éléments de longévité inégale : les rails, les traverses et le ballast. L'effort de réduction des coûts d'entretien des voies porte notamment sur la recherche d'une meilleure harmonisation de la fiabilité propre à chacun de ces trois éléments.The railroad superstructure is mainly made up of three elements of uneven longevity: the rails, the sleepers and the ballast. The effort to reduce track maintenance costs relates in particular to the search for better harmonization of the reliability specific to each of these three elements.

C'est à ce titre, et pour réduire la consommation de bois nobles, que, depuis déjà de nombreuses années, on remplace de plus en plus les traverses en bois par des traverses en béton, qui sont beaucoup moins sensibles aux agents atmosphériques et dont les équipements de fixation des rails ont une stabilité nettement meilleure dans le temps.It is for this reason, and to reduce the consumption of noble woods, that for many years now, wooden sleepers have been increasingly replaced by concrete sleepers, which are much less sensitive to atmospheric agents and whose the rail fastening equipment has significantly better stability over time.

Les traverses en béton, qui exigent des moyens de manutention plus lourds, ont été préférentiellement introduites sur les grands axes à forte densité de circulation, là où les opérations d'entretien s'effectuent avec des moyens mécaniques puissants pour que les cadences d'avancement soient les plus grandes possibles afin de réduire au minimum les désordres occasionnés dans le trafic de telles lignes. Par contre, ces moyens coûteux en dépenses de fonctionnement ne s'imposent pas sur les autres lignes, qui sont le plus souvent non électrifiées et où prédomine généralement un trafic de marchandises. Pourtant, il est certain que le remplacement du plancher de traverses en bois par un plancher de traverses en béton contribuerait à réduire les dépenses d'entretien de telles lignes, à la condition que cette substitution puisse se faire d'une manière très économique.Concrete sleepers, which require heavier handling means, were preferentially introduced on the main axes with high traffic density, where maintenance operations are carried out with powerful mechanical means so that the rates of advancement are as large as possible in order to minimize the disruption caused by traffic on such lines. On the other hand, these means, which are costly in operating expenses, are not essential on the other lines, which are most often not electrified and where goods traffic generally predominates. However, it is certain that replacing the wooden sleeper floor with a concrete sleeper floor would help reduce the maintenance costs of such lines, provided that this substitution can be done in a very economical way.

L'apparition récente de traverses en béton d'épaisseur voisine des traverses classiques en bois permet justement d'envisager une telle substitution économiquement.The recent appearance of concrete sleepers with a thickness close to that of conventional wooden sleepers makes it possible to envisage such a substitution economically.

On sait que le fait de remplacer isolément une traverse ne déstabilise pas la voie :

- - si le moule de ballast dans lequel la traverse est enfermée n'a pas été détruit et surtout si le plan sur lequel s'appuie la traverse est préservé, et

- - si les traverses adjacentes n'ont pas été dérangées.

- - if the ballast mold in which the cross member is enclosed has not been destroyed and especially if the plane on which the cross member rests is preserved, and

- - if the adjacent sleepers have not been disturbed.

Comme jusqu'à ce jour les traverses de remplacement sont en bois et de même épaisseur que les traverses à renouveler, les deux conditions précédentes ont pu être respectées et, de ce fait, les opérations de substitution n'ont jamais posé de problèmes techniques majeurs, si ce n'est au niveau des prix de revient du fait que les méthodes employées sont essentiellement manuelles.As to date the replacement sleepers are made of wood and the same thickness as the sleepers to be renewed, the two previous conditions have been met and, therefore, the substitution operations have never posed major technical problems , if not at the cost price because the methods used are essentially manual.

En remplaçant par exemple une traverse sur cinq dans une première phase de travaux, puis autant au cours d'une phase suivante et ainsi de suite, on voit que toutes les traverses peuvent être changées au terme d'une période dont la durée peut être adaptée à divers impératifs, en particulier à ceux d'ordre budgétaire. Or, une telle méthode exige de pouvoir changer un seul élément à la fois, ce que ne permettent pas les procédés mécanisés lourds, lesquels d'ailleurs perturbent considérablement l'exploitation de la voie.By replacing, for example, one out of five crosspieces in a first phase of work, then as much during a following phase and so on, we see that all the crosspieces can be changed at the end of a period whose duration can be adapted various imperatives, particularly those of a budgetary nature. However, such a method requires being able to change only one element at a time, which heavy mechanized processes do not allow, which moreover considerably disturb the operation of the track.

Il est, par conséquent, nécessaire de pouvoir remplacer aisément une à une les vieilles traverses en bois par des traverses neuves en béton, avec des moyens mécaniques permettant de ne pas détériorer la qualité et la sécurité de la voie, de ne pas déranger l'exploitation et d'obtenir la meilleure cadence possible d'avancement des travaux.It is therefore necessary to be able to easily replace one by one the old wooden sleepers with new concrete sleepers, with mechanical means making it possible not to deteriorate the quality and safety of the track, not to disturb the operation and to obtain the best possible rate of progress of the works.

Si les méthodes manuelles actuelles peuvent demeurer pour les remplacements isolés de traverses en bois par des traverses en bois, ces méthodes doivent être écartées pour le remplacement par des traverses en béton. En effet, d'une part les traverses en béton ont une masse trop importante pour être manutentionnées manuellement et, d'autre part, en raison des goujons scellés qu'elles comportent, les traverses en béton ont un encombrement en hauteur plus important que les traverses en bois, ce qui oblige, pour être en mesure de les introduire sous la voie sans soulever celle-ci, à dégarnir complètement le moule de ballast jusqu'à une profondeur de 5 à 10 cm au-dessous de chaque traverse. Par conséquent, le moule de ballast est détruit et la nouvelle traverse devra donc être calée.If the current manual methods can remain for the isolated replacement of wooden sleepers with wooden sleepers, these methods must be discarded for the replacement by concrete sleepers. Indeed, on the one hand the concrete sleepers have a mass too large to be handled manually and, on the other hand, because of the sealed studs that they comprise, the concrete sleepers have a larger size in height than the wooden sleepers, which requires, to be able to introduce them under the track without lifting it, to completely strip the ballast mold to a depth of 5 to 10 cm below each sleeper. Consequently, the ballast mold is destroyed and the new cross member will therefore have to be wedged.

Pour tenter de résoudre les problèmes que pose la manutention proprement dite des traverses en béton, des petites machines appelées « substitueuses de traverses sont apparues. Elles permettent d'extraire les anciennes traverses et d'introduire les nouvelles. Malheureusement, ces petites machines très légères, en prenant appui sur la voie, exercent sur celle-ci d'importants efforts transversaux, notamment lors de l'introduction des nouvelles traverses, de sorte qu'elles impriment à la voie des déformations locales qu'elles ne savent pas corriger. En outre, il faut dégarnir manuellement le moule de ballast, caler manuellement la nouvelle traverse et dresser manuellement la voie. On voit que toutes ces opérations restant à effectuer manuellement sont trop importantes pour que les rendements demeurent acceptables. En outre, la voie est déstabilisée, ce qui peut nécessiter la mise en place de ralentissement en attendant les opérations ultérieures de ballastage et de bourrage mécanique lourd.In an attempt to resolve the problems posed by the actual handling of concrete sleepers, small machines called "sleeper substitutes" have appeared. They make it possible to extract the old sleepers and introduce the new ones. Unfortunately, these very light small machines, by resting on the track, exert on it significant transverse forces, in particular during the introduction of the new sleepers, so that they give the track local deformations that they cannot correct. In addition, the ballast mold must be stripped manually, the new crosspiece must be manually wedged and the track manually prepared. We see that all these operations remaining to be performed manually are too important for the yields to remain acceptable. In addition, the track is destabilized, which may require the setting up of a slowdown pending the subsequent ballasting and heavy mechanical stuffing operations.

La présente invention a donc pour but de créer une machine capable d'effectuer à cadence élevée toutes les opérations nécessaires pour le remplacement de traverses en bois notamment par des traverses en béton, en conservant à la voie sa parfaite intégrité.The present invention therefore aims to create a machine capable of performing at high speed all the operations necessary for the replacement of wooden sleepers in particular by concrete sleepers, while keeping the track its perfect integrity.

Une telle machine est, d'une manière connue par exemple du AU-B-453 660, constituée par un wagon équipé de dispositifs propres à effectuer le remplacement individuel de traverses anciennes par des traverses neuves, et notamment d'un groupe de manutention des traverses comportant un jeu d'organes de préhension qui permettent de saisir une traverse ou un rail de la voie, ces organes, suspendus à une poutre transversale et déplaçables aussi bien en hauteur que longitudinalement et transversalement par rapport à la direction de la voie, comprenant un premier organe constitué par une pince susceptible de saisir une traverse et de se déplacer en direction transversale d'un côté de la voie sensiblement à partir d'un plan vertical passant par un premier rail de la voie, un deuxième organe et un troisième organe susceptibles de saisir chacun l'un des rails de la voie pour le soulever, le premier organe de préhension pouvant se déplacer en direction transversale indépendamment des deux autres, tandis que ces derniers peuvent se déplacer ensemble et possèdent des becs latéraux susceptibles de venir se placer respectivement sous chacun des rails de la voie en vue de soulever ceux-ci.Such a machine is, in a known manner for example from AU-B-453 660, constituted by a wagon equipped with devices capable of individually replacing old sleepers with new sleepers, and in particular of a sleepers handling group comprising a set of gripping members which make it possible to grip a sleeper or a rail of the track, these members, suspended from a transverse beam and movable both in height as longitudinally and transversely with respect to the direction of the track, comprising a first member constituted by a clamp capable of gripping a cross member and of moving in a transverse direction from one side of the track substantially from a vertical plane passing through a first track rail, a second member and a third member capable of gripping each of one of the rails of the track to lift it, the first gripping member being able to move in transverse direction independently of the other two, while the latter can move together and have side spouts which are capable of to place themselves respectively under each of the rails of the track in order to lift them.

L'invention a pour objet une machine de ce genre, caractérisée en outre par le fait que le deuxième organe de préhension, situé entre le premier et le troisième et susceptible de saisir un rail, est, comme le premier organe de préhension, une pince conçue pour saisir une traverse, laquelle peut ainsi être saisie successivement ou simultanément par une première pince et par une deuxième pince, cette dernière pouvant pour sa part se déplacer en direction transversale sensiblement dans l'espace séparant les plans verticaux contenant respectivement les rails de la voie. On voit que la première pince évolue dans l'espace situé d'un côté de la voie et la deuxième pince dans l'espace situé entre les deux rails de la voie, tandis que le troisième organe de préhension peut évoluer dans l'espace situé de l'autre côté de la voie.The invention relates to a machine of this kind, further characterized in that the second gripping member, located between the first and the third and capable of gripping a rail, is, like the first gripping member, a clamp designed to grip a crosspiece, which can thus be gripped successively or simultaneously by a first clamp and by a second clamp, the latter being able to move in a transverse direction substantially in the space separating the vertical planes respectively containing the rails of the way. We see that the first clamp evolves in the space located on one side of the track and the second clamp in the space located between the two rails of the track, while the third gripper can evolve in the space located on the other side of the track.

Il convient que la première pince, qui est destinée à assurer la majeure partie des opérations de manutention des traverses, puisse être actionnée en pivotement autour de son axe vertical de symétrie, d'au moins un quart de tour de manière à être en mesure d'amener les traverses en situation parallèle à la voie, ce qui facilite leur acheminement à bord de la machine. Il est par ailleurs avantageux de faire en sorte que la deuxième pince puisse se déplacer en direction transversale indépendamment du troisième organe de préhension, de manière que ce dernier demeure immobile alors que la deuxième pince se déplace transversalement pour assurer, comme on le verra plus loin, la fin de l'opération de mise en place des nouvelles traverses.The first clamp, which is intended to perform the major part of the handling operations of the sleepers, should be able to be pivotally actuated around its vertical axis of symmetry, by at least a quarter of a turn so as to be able to '' bring the sleepers parallel to the track, which facilitates their routing on board the machine. It is also advantageous to ensure that the second clamp can move in the transverse direction independently of the third gripping member, so that the latter remains stationary while the second clamp moves transversely to ensure, as will be seen below. , the end of the operation of installing new sleepers.

En ce qui concerne les mouvements en hauteur et en direction longitudinale des trois organes de préhension, ceux-ci les exécutent tous trois ensemble avec la poutre transversale qui les supporte.As regards the movements in height and in the longitudinal direction of the three gripping members, these perform all three of them together with the transverse beam which supports them.

Dans une forme d'exécution préférée, la poutre transversale du groupe de manutention est une poutre télescopique formée d'un tube intérieur, à l'extrémité duquel est suspendue la première pince et qui est mobile en coulissement dans un tube extérieur relié à un coulisseau pouvant se déplacer en hauteur (grâce à un moyen moteur) le long d'une colonne de guidage fixée par son sommet à un chariot mobile en direction longitudinale le long de rails de guidage solidaires du châssis du wagon, et le long du tube extérieur peut se déplacer sur une faible course une pièce coulissante à laquelle sont suspendus la deuxième pince et le troisième organe de préhension. Pour assurer l'indépendance en direction transversale de ces deux organes de préhension l'un par rapport à l'autre, le troisième organe peut être suspendu directement à ladite pièce coulissante dans la région de son extrémité tournée vers l'extérieur, le deuxième y étant suspendu par l'intermédiaire d'un moyen de déplacement en direction transversale.In a preferred embodiment, the transverse beam of the handling group is a telescopic beam formed of an inner tube, at the end of which is suspended the first clamp and which is movable by sliding in an outer tube connected to a slide able to move in height (thanks to a motor means) along a guide column fixed by its top to a carriage movable in longitudinal direction along guide rails integral with the chassis of the wagon, and along the outer tube can move on a short stroke a sliding part to which are suspended the second clamp and the third gripping member. To ensure the independence in transverse direction of these two gripping members from each other, the third member can be suspended directly from said sliding part in the region of its end facing outwards, the second being suspended by means of displacement in transverse direction.

L'amplitude de la course transversale que peuvent accomplir la première pince et la deuxième pince est de préférence voisine de la moitié de la longueur d'une traverse, alors que la faible course à laquelle peuvent se limiter les déplacements transversaux du troisième organe de préhension est de l'ordre de la largeur d'un patin de rail.The amplitude of the transverse stroke which the first clamp and the second clamp can accomplish is preferably close to half the length of a cross member, while the short stroke to which the transverse displacements of the third gripping member can be limited is about the width of a rail shoe.

Une machine selon l'invention peut comporter avantageusement en outre un groupe de terrassement comprenant une benne preneuse déplaçable en hauteur et en direction longitudinale et conçue pour permettre l'enlèvement et la remise en place du ballast environnant la traverse à remplacer, ce qui conduit à une manipulation entièrement mécanique du ballast.A machine according to the invention may advantageously further comprise an earthmoving group comprising a clamshell movable in height and in the longitudinal direction and designed to allow the removal and replacement of the ballast surrounding the crosspiece to be replaced, which leads to fully mechanical handling of the ballast.

De préférence, cette benne preneuse est subdivisée en trois parties séparées par deux intervalles formant des espaces libres où s'inscrivent les rails de la voie lorsque la benne est descendue au contact du ballast, de sorte que celle-ci peut travailler de part et d'autre des rails sur toute la longueur des traverses. Afin de pouvoir donner à ces intervalles une largeur minimale correspondant à la largeur des patins de rails, malgré le déport du châssis du wagon par rapport aux rails dans une voie en courbe, il convient d'assujettir la benne preneuse à la courbure de la voie en lui donnant la possibilité de se déplacer en direction transversale sous l'action d'un moyen de guidage maintenant lesdits espaces libres en regard des rails de la voie. A cet effet, la benne preneuse peut être suspendue par des barres articulées formant un parallélogramme déformable situé dans un plan transversal, ces barres étant accrochées à un chariot mobile en direction longitudinale, se déplaçant de préférence sur les mêmes rails que le chariot du groupe de manutention.Preferably, this clamshell is subdivided into three parts separated by two intervals forming free spaces where the rails of the track are inscribed when the grab is lowered in contact with the ballast, so that the latter can work on both sides other rails along the entire length of the sleepers. In order to be able to give at these intervals a minimum width corresponding to the width of the rail pads, despite the offset of the wagon chassis relative to the rails in a curved track, the clamshell should be subject to the curvature of the track by giving it the possibility of moving in a transverse direction under the action of a guide means maintaining said free spaces facing the rails of the track. For this purpose, the clamshell can be suspended by articulated bars forming a deformable parallelogram located in a transverse plane, these bars being attached to a carriage movable in the longitudinal direction, preferably moving on the same rails as the carriage of the group of handling.

Pour éviter le déchargement préalable en piste des traverses de remplacement ainsi que le rechargement des traverses remplacées, une machine selon l'invention possède de préférence un double convoyeur, savoir un convoyeur d'évacuation des traverses anciennes et un convoyeur d'approvisionnement en traverses neuves, tous deux accessibles à la première pince du groupe de manutention. Cette disposition permet d'amener les traverses neuves directement d'un wagon plat attelé à la machine et d'évacuer vers celui-ci les traverses anciennes. Il convient en outre que la machine soit équipée d'une trémie de réserve de ballast, de façon à pouvoir déverser transversalement à la voie toute quantité de ballast complémentaire nécessaire pour bourrer convenablement la traverse venant d'être installée, d'un groupe de bourrage du ballast sous cette traverse et enfin d'un caisson-brosse de régalage pour balayer et éliminer le ballast excédentaire.To avoid the prior unloading of replacement sleepers on the track and the reloading of replaced sleepers, a machine according to the invention preferably has a double conveyor, namely a conveyor for removing old sleepers and a conveyor for supplying new sleepers. , both accessible to the first clamp of the handling group. This arrangement allows direct new sleepers to be brought ment of a flat wagon coupled to the machine and to evacuate the old sleepers towards it. In addition, the machine should be equipped with a ballast reserve hopper, so as to be able to dump transversely to the track any quantity of additional ballast necessary to properly stuff the crossbar just installed, with a tamping group. ballast under this crosspiece and finally a leveling brush box to sweep and remove the excess ballast.

Afin de mécaniser complètement l'ensemble des opérations de renouvellement des traverses, il convient que les divers mouvements et déplacements des organes mobiles qu'elle comporte soient obtenus au moyen de moteurs ou vérins, de préférence hydrauliques, pilotés à partir d'un poste de commande (bien entendu à l'exception des mouvements transversaux de la benne preneuse du groupe de terrassement, qui dépendent uniquement du moyen précité de guidage sur les rails).In order to completely mechanize all of the sleeper renewal operations, the various movements and displacements of the movable members which it comprises should be obtained by means of motors or jacks, preferably hydraulic, controlled from a control (of course with the exception of the transverse movements of the clamshell bucket of the earthworks, which depend solely on the aforementioned means of guidance on the rails).

L'invention a également pour objet un procédé de manutention de traverses au cours d'opérations de substitution à l'aide d'une machine telle que décrite ci-dessus. Ce procédé est en particulier caractérisé par le fait que, après retrait d'une traverse à remplacer, la mise en place d'une traverse neuve s'effectue en deux phases, savoir une première phase où la traverse, saisie dans sa région centrale par la première pince, est glissée par celle-ci sous le premier rail de la voie jusqu'à ce que ladite pince soit arrêtée par ledit rail, et une deuxième phase où la traverse, libérée de la première pince, est saisie dans sa région centrale par la deuxième pince au-delà dudit rail, cette dernière pince achevant la mise en place de la traverse sous les rails de la voie. Ce mode opératoire, autorisé par la machine selon l'invention, présente une grande importance. En effet, les efforts transversaux infligés par les machines connues jusqu'ici ont principalement pour cause que les traverses neuves sont, lors de leur mise en place, poussées sous les rails par leur extrémité postérieure, de sorte qu'elles pénètrent en refoulant le ballast, lequel gêne considérablement leur progression. Par contre, selon l'invention, les traverses neuves sont saisies et tirées toujours par leur région centrale, ce qui élimine cet inconvénient et évite ainsi toute déformation de la voie. Quant au retrait d'une traverse ancienne à remplacer, il s'effectue au moyen de la première pince de préférence en deux phases d'extraction successives, dans chacune desquelles la traverse est tirée par cette pince d'environ la moitié de sa longueur. Une course transversale d'amplitude réduite suffit ainsi pour cette pince, ce qui simplifie la conception de la machine.The invention also relates to a method of handling sleepers during substitution operations using a machine as described above. This process is in particular characterized by the fact that, after removal of a crosspiece to be replaced, the installation of a new crosspiece takes place in two phases, namely a first phase where the crosspiece, captured in its central region by the first clamp is slid by the latter under the first rail of the track until said clamp is stopped by said rail, and a second phase where the crosspiece, released from the first clamp, is gripped in its central region by the second clamp beyond said rail, the latter clamp completing the positioning of the cross member under the rails of the track. This operating mode, authorized by the machine according to the invention, is of great importance. Indeed, the transverse forces inflicted by the machines known until now mainly because the new sleepers are, during their establishment, pushed under the rails by their rear end, so that they penetrate by driving back the ballast , which considerably hinders their progress. On the other hand, according to the invention, the new sleepers are grasped and always pulled by their central region, which eliminates this drawback and thus avoids any deformation of the track. As for the removal of an old crosspiece to be replaced, it is carried out by means of the first clamp preferably in two successive extraction phases, in each of which the crosspiece is pulled by this clamp of approximately half its length. A transverse stroke of reduced amplitude is therefore sufficient for this clamp, which simplifies the design of the machine.

La description qui va suivre, en regard des dessins annexés à titre d'exemples non limitatifs, permettra de bien comprendre comment la présente invention peut être mise en pratique.

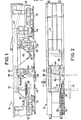

- Les figures 1 et 2 représentent de manière simplifiée, respectivement en élévation latérale et en plan, une machine selon l'invention.

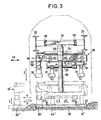

- La figure 3 représente, en élévation frontale et à plus grande échelle, le groupe de manutention de la machine et en montre plusieurs positions de fonctionnement dans les premières phases d'une opération de substitution de traverses, savoir les phases d'extraction d'une traverse ancienne.

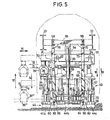

- La figure 4 représente une vue suivant la flèche IV de l'objet de la figure 3, montrant le groupe de manutention et le groupe de terrassement.

- La figure 5 représente une vue analogue à celle de la figure 3 ; elle montre les phases opératoires suivantes et fait apparaître le groupe de terrassement.

- La figure 6 représente une vue suivant la flèche VI de l'objet de la figure 5.

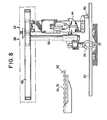

- Les figures 7 et 8 représentent, à la manière des figures 3 et 4, les éléments montrés sur ces figures, mais ici dans les dernières phases opératoires (mise en place de la nouvelle traverse).

- Figures 1 and 2 show in simplified manner, respectively in side elevation and in plan, a machine according to the invention.

- Figure 3 shows, in front elevation and on a larger scale, the handling group of the machine and shows several operating positions in the first phases of a sleeper substitution operation, namely the extraction phases of a old crosses.

- Figure 4 shows a view along arrow IV of the object of Figure 3, showing the handling group and the earthmoving group.

- Figure 5 shows a view similar to that of Figure 3; it shows the following operating phases and shows the earthworks group.

- FIG. 6 represents a view along arrow VI of the object of FIG. 5.

- Figures 7 and 8 represent, in the manner of Figures 3 and 4, the elements shown in these figures, but here in the last operating phases (establishment of the new cross member).

Une machine à substituer les traverses ou « substitueuse de traverses selon l'invention se présente, comme le montrent les figures 1 et 2, sous la forme d'un wagon 31 à boggies 32, comportant un châssis surélevé formé de deux forts longerons 33. Ce wagon est équipé essentiellement des dispositifs suivant, énoncés dans l'ordre où ils se présentent d'une extrémité à l'autre du wagon :

- - deux convoyeurs à rouleaux 34, 35 jumelés, permettant respectivement l'évacuation des traverses anciennes 36 à remplacer et l'approvisionnement en traverses neuves 37 à mettre en place. Certains au moins des rouleaux de ces convoyeurs sont motorisés de manière à assurer le déplacement des traverses dans le sens des flèches portées sur la figure 2 ;

- - un groupe de manutention 38 comportant trois pinces de préhension 39, 40 et 41 et destiné à effectuer d'une part l'enlèvement des traverses anciennes 36 de la voie ferrée 42 et leur dépôt sur le convoyeur d'évacuation 34 (qui les dirige vers un wagon plat voisin non représenté) et d'autre part la prise en charge des traverses neuves 37 (acheminées du même wagon plat par le convoyeur d'approvisionnement 35) et leur mise en place dans la voie 42 ;

- - un groupe de terrassement 43 permettant, grâce à une benne preneuse 44, d'enlever ou de déverser du ballast dans la région d'une traverse de la voie 42 ;

- - une trémie à

ballast 45 située à peu près au milieu du wagon et dotée d'un obturateur de sortie 46 ; cette trémie peut être réalimentée, à partir d'un autre wagon voisin également non représenté, à l'aide d'un transporteur à bande 47 ; - - un groupe de bourrage mécanique lourd 48, complété d'un dispositif de maintien à niveau par vieillissement artificiel et d'un dispositif de damage ;

- - un caisson-brosse de régalage 49 destiné à parachever l'opération de remplacement de traverses par balayage du ballast excédentaire, ce dispositif étant complété

par un volet 50 de reprofilage de banquette.

- - Two

twin roller conveyors old sleepers 36 to be replaced and the supply ofnew sleepers 37 to put in place. At least some of the rollers of these conveyors are motorized so as to ensure the displacement of the crosspieces in the direction of the arrows shown in FIG. 2; - - A

handling group 38 comprising threegrippers old sleepers 36 from therailway 42 and their deposition on the evacuation conveyor 34 (which directs them towards a neighboring flat wagon not shown) and on the other hand taking charge of the new sleepers 37 (routed from the same flat wagon by the supply conveyor 35) and placing them intrack 42; - - An

earthmoving group 43 allowing, thanks to aclamshell 44, to remove or pour ballast in the region of a cross member of thetrack 42; - - a

ballast hopper 45 located approximately in the middle of the wagon and provided with anoutlet shutter 46; this hopper can be replenished, from another neighboring wagon also not shown, using aconveyor belt 47; - a heavy

mechanical tamping group 48, supplemented with a level-keeping device by artificial aging and a tamping device; - - A

leveling brush box 49 intended to complete the operation of replacing sleepers by sweeping the excess ballast, this device being supplemented by aflap 50 for reprofiling the seat.

Le wagon 31 est automoteur grâce à un ensemble de propulsion non représenté.

On voit notamment sur les figures 3 et 4 comment est constitué le groupe de manutention 38. Il comprend une poutre transversale 51 télescopique portant les trois pinces 39, 40 et 41 précitées et formé d'un tube extérieur 52 de section carrée et d'un tube intérieur 53 également de section carrée, susceptible de se déplacer en coulissant dans le tube 52 sous l'action d'un long vérin 54. Le tube 52 est fixé à un coulisseau 55 pouvant se déplacer, grâce à un moyen moteur non représenté, le long d'une colonne verticale 56 de section circulaire, laquelle est suspendue à un chariot 57 mobile suivant la direction longitudinale du wagon 31 dans des rails de guidage 58 solidaires des longerons 33.We see in particular in FIGS. 3 and 4 how the

La pince 39 est fixée sous l'extrémité du tube 53 émergeant du tube 52, par l'intermédiaire d'un organe de liaison 59 motorisé permettant de la faire pivoter d'un quart de tour, dans un sens ou dans l'autre, autour de son axe vertical de symétrie.The

Les pinces 40 et 41 sont portées par une pièce coulissante 60 susceptible de se déplacer, sur une faible course, grâce à un vérin 61, au-dessous et le long du tube 52 auquel elle est suspendue par des galets de roulement reposant sur des ailes 62 qu'offre latéralement le tube 52. La pince 41 est suspendue à une extrémité de la pièce mobile 60 voisine de l'extrémité du tube 53 opposée à celle à laquelle est suspendue la pince 39. La pince 40 est suspendue à ladite pièce 60, entre les pinces 39 et 41, par l'intermédiaire d'un moyen de translation constitué par une tige filetée 29 rotative et un écrou 30 que traverse cette dernière, laquelle est montée sous la pièce 60 parallèlement à la direction longitudinale de celle-ci et des tubes 52 et 53 formant la poutre télescopique 51.The

On voit ainsi que les pinces 39,40 et 41 peuvent se déplacer dans les trois directions de l'espace ; plus précisément, l'ensemble desdites pinces est mobile par rapport au châssis du wagon 31, longitudinalement par déplacement du chariot 57 le long des rails 58, verticalement par déplacement du coulisseau 55 le long de la colonne 56 et transversalement, respectivement par coulissement du tube 53 dans le tube 52 pour la pince 39, par déplacement de la pièce 60 pour les pinces 40 et 41 et, au surplus pour la pince 40, par mise en rotation de la tige filetée 29. Bien entendu, lesdites pinces sont chacune pourvues d'un moyen d'actionnement à l'ouverture et à la fermeture de leurs branches. Toutefois, on peut se dispenser de doter d'un tel moyen d'actionnement la pince 41, car, comme on le verra, contrairement aux autres pinces 39 et 40, elle ne sert pas à saisir les traverses, de sorte que ses branches peuvent demeurer fixes en situation d'ouverture.It can thus be seen that the

La figure 3 montre les pinces 39, 40 et 41 en position initiale, dans laquelle les pinces 39 et 41 sont situées au-dessus des têtes de traverses de la voie 42, donc de part et d'autre des rails 63, 64 de celle-ci, tandis que la pince 40 surplombe l'espace compris entre ces rails, les pinces 40 et 41 se trouvant à l'aplomb de zones respectivement voisines du rail 63 et du rail 64 de la voie 42 et situées d'un même côté par rapport à ces rails (à droite de ceux-ci sur la figure 3). Ceci est prévu afin que les pinces 40 et 41, distantes d'une longueur égale à l'écartement des rails 63, 64 de la voie, puissent être introduites ensemble sous ces rails par des becs 81 que leurs branches articulées présentent latéralement, en vue d'effectuer un soulèvement de la voie 42.Figure 3 shows the

Le groupe de terrassement 43 (figures 4 et 5) est suspendu à un chariot 65 mobile en direction longitudinale, comme le chariot 57, le long des rails de guidage 58. Sa benne preneuse 44 est subdivisée en trois parties 44a, 44b et 44c faisant apparaître deux intervalles libres 66 correspondant à l'emplacement des rails 63, 64 de la voie 42. Les mâchoires de cette benne multiple, qui permet d'effectuer un terrassement transversal du ballast en une seule opération, malgré la présence des rails, sont actionnées par quatre vérins 67 par l'intermédiaire de tiges articulées 68. L'axe de pivotement 69 des mâchoires de la benne, subdivisé de même en trois parties, est soutenu par des plaques verticales 70 soudées à une plaque transversale 71 commune, à laquelle sont également soudés des manchons 72 coulissant sur des barres de guidage 73 lors des déplacements en hauteur de cette plaque 71 et de la benne 44 sous l'action d'un vérin 74 reliant le chariot 65 et l'axe de pivotement 69 des mâchoires de la benne.The earthmoving group 43 (FIGS. 4 and 5) is suspended from a

Les barres de guidage 73 sont articulées d'une part au chariot 65 en 75 et d'autre part en 76 à des pièces 77 reliées par une tige horizontale 78 de manière à former un parallélogramme déformable en direction transversale. A la tige 78 sont articulés des bras 79 portant de petites roues 80 relevables qui, appliquées sur les rails 63, 64 de la voie 42 et guidées par ceux-ci, font se déformer le parallélogramme précité en cas de courbe dans la voie, de sorte que la benne 44 est déportée transversalement de la quantité voulue pour que les intervalles 66 entre les parties qui la composent demeurent toujours à l'aplomb des rails 63, 64. Pour ne pas gêner ce mouvement, le vérin 74 est disposé parallèlement aux barres 73 et articulé comme elles à ses extrémités.The guide bars 73 are articulated on the one hand to the

Le fonctionnement d'une machine selon l'invention va maintenant être décrit. Les différentes phases qui le composent sont numérotées dans l'ordre de leur déroulement et les déplacements correspondants des organes de la machine sont indiqués sur les figures par des flèches portant les mêmes numéros.The operation of a machine according to the invention will now be described. The different phases that make it up are numbered in the order of their progress and the corresponding movements of the machine's components are indicated in the figures by arrows bearing the same numbers.

La machine 31 est d'abord amenée sur le chantier en une position (figure 1) telle que le milieu des rails de guidage 58 supportant les groupes 38 et 43 se trouve à peu près au-dessus de la traverse 36 à changer, préalablement détire- fonnée.

- 1. Le groupe de manutention 38 est amené à l'aplomb de la traverse 36 par. déplacement de

son chariot 57 sur les rails 58. - 2. Les pinces 39, 40, 41 en position d'ouverture sont abaissées (par descente du coulisseau 55 le long de la colonne 56 et, par suite, de la poutre télescopique 51 qui vient en 51'). Les pinces 40

et 41 viennent ainsi en 40' et 41' à côté des rails 63et 64, encadrant par leurs branches ouvertes latraverse 36, leurs becs 81 se trouvant au-dessous du niveau des patins desdits rails. - 3. Les pinces 40' et 41' sont déplacées latéralement d'une petite quantité (par actionnement du vérin 61) de manière que leurs becs 81 viennent se placer au-dessous des rails 63, 64. La poutre 51 est alors remontée de quelques centimètres le long de la colonne 56 afin de soulever d'autant lesdits rails et de dégager ainsi la

traverse 36. - 4.

La pince 39, venue en 39', est fermée sur latraverse 36, puis déplacée transversalement jusqu'en 39" (par actionnement du vérin 54) de manière à extraire la traverse 36 de dessous les rails 63, 64. - 5. La course du

tube 53 porteur de la pince 39 dans letube 52 étant insuffisante pour permettre l'extraction de la traverse 36 en une seule fois,la pince 39" lâche la traverse, vient en 39', la saisit de nouveau, en achève l'extraction et s'ouvre. - 6. Les pinces 40' et 41' redescendent et se dégagent de dessous les rails 63

et 64, qui reprennent leur position normale. - 7. La pince 39" reprend

la traverse 36 et soulève celle-ci au-dessus du niveau du champignon des rails 63, 64, par montée d'une trentaine de centimètres de la poutre 51 (les pinces 40 et 41 exécutent évidemment les mêmes mouvements que celle-ci, mais restent inopérantes). - 8. Le groupe de manutention 38 se déplace le long des rails 58 en direction des convoyeurs 34, 35.

- 9. La pince portant la

traverse 36, venue en 39"', fait tourner celle-ci d'un quart de tour (grâce à son dispositif rotatif 59) de manière à la mettre en 36"' parallèlement à la voie 42. - 10. Par remontée de la poutre 51,

la traverse 36 est soulevée un peu au-dessus du niveau du convoyeur 34. - 11.

Le tube 53 rentre dans letube 52 sous l'action du vérin 54 et la traverse 36 vient au-dessus du convoyeur 34 ; lapince 39 s'ouvre et libère ladite traverse, qui est évacuée par ledit convoyeur. - 12.

Le tube 53 rentre à fond dans letube 52, ce qui amène la pince 39 au-dessus du convoyeur 35, où attend, arrêtéepar une butée 82, une traverse neuve 37 (en béton à blochets) que la pince 39 vient saisir. - 13.

Le tube 53 est remis en extension. - 14. La poutre 51 descend.

- 15. La pince 39 fait faire un quart de tour à la

traverse 37. - 16. Le groupe de manutention 38 retourne dans sa position initiale.

- 1. The

handling group 38 is brought into line with thecross member 36 by. displacement of itscarriage 57 on therails 58. - 2. The clamps 39, 40, 41 in the open position are lowered (by descent of the

slide 55 along thecolumn 56 and, consequently, of thetelescopic beam 51 which comes in 51 '). Theclamps rails crosspiece 36, theirbeaks 81 being below the level of the pads of said rails. - 3. The clamps 40 'and 41' are moved laterally by a small amount (by actuation of the jack 61) so that their

beaks 81 are placed below therails beam 51 is then raised by a few centimeters along thecolumn 56 in order to raise the said rails accordingly and thus to release the cross-member 36. - 4. The

clamp 39, coming in 39 ′, is closed on the cross-member 36, then moved transversely to 39 "(by actuation of the jack 54) so as to extract the cross-member 36 from below therails - 5. The stroke of the

tube 53 carrying theclamp 39 in thetube 52 is insufficient to allow the extraction of thecross member 36 at one time, theclamp 39 "releases the cross member, comes at 39 ', grasps it again, completes the extraction and opens. - 6. The

clamps 40 ′ and 41 ′ descend and disengage from below therails - 7. The

clamp 39 "takes up thecrosspiece 36 and lifts it above the level of the head of therails clamps - 8. The

handling group 38 moves along therails 58 in the direction of theconveyors - 9. The clamp carrying the cross-member 36, coming in 39 "', makes it turn a quarter of a turn (thanks to its rotary device 59) so as to put it in 36"' parallel to the

track 42. - 10. By raising the

beam 51, the cross-member 36 is raised a little above the level of theconveyor 34. - 11. The

tube 53 enters thetube 52 under the action of thejack 54 and the cross-member 36 comes above theconveyor 34; theclamp 39 opens and releases said cross member, which is evacuated by said conveyor. - 12. The

tube 53 fully returns into thetube 52, which brings theclamp 39 above theconveyor 35, where waits, stopped by astop 82, a new cross member 37 (in concrete with blocks) that theclamp 39 comes grab. - 13. The

tube 53 is returned to extension. - 14. The

beam 51 descends. - 15. The

clamp 39 causes the cross-member 37 to make a quarter turn. - 16. The

handling unit 38 returns to its initial position.

Pendant que se déroulent les opérations 8 à 16 relatives aux traverses, d'autres opérations - numérotées 17 à 20 - sont effectuées, ces dernières concernant le groupe de terrassement 43.

- 17. Le groupe de terrassement est déplacé sur les rails 58 pour être amené au-dessus de l'espace 136 où se trouvait la

traverse 36. - 18.

La benne preneuse 44, préalablement ouverte, est descendue par mise en extension du vérin 74, et elle se saisit du ballastentourant l'espace libre 136. - 19.

La benne 44 remonte avec sa charge de ballast. - 20. Le groupe de terrassement 43 revient dans sa position initiale en dégageant l'emplacement de l'espace 136 afin de permettre dans les opérations suivantes la mise en place de la

traverse neuve 37. - 21. Les pinces 39, 40 et 41 descendent avec la poutre 51,

la traverse 37 venant se placer à un niveau inférieur à celui du patin des rails 63, 64. - 22.

Le tube 53 de la poutre 51 se rétracte, de sorte que latraverse 37, toujours saisie par la pince 39, est introduite dans l'espace 136 sous lepremier rail 63 jusqu'à une position 37' correspondant à la position 39' que la pince 39 ne peut dépasser à cause de la présence duditrail 63. - 23. La traverse 37' est alors lâchée par la pince 39' et saisie par la pince 40, par-delà le

rail 63. - 24. La pince 40 vient en 40" et amène la traverse 37' dans

sa position finale 37", étant commandée en translation par la vis 29 mise alors en rotation. - 25. La traverse 37", toujours tenue par la pince 40" est, par légère remontée de celle-ci, plaquée sous les rails 63, 64. Elle est alors (manuellement) fixée à ceux-ci.

- 26. La pince 40" s'ouvre et revient en 40.

- 27. Les pinces 39, 40 et 41 sont remontées au-dessus du niveau des rails 63, 64.

- 28. Le groupe de terrassement 43 vient prendre la place du groupe de manutention 38.

La benne 44 s'ouvre et lâche le ballast qu'elle contenait à l'emplacement de la nouvelletraverse 37.

- 17. The earthmoving group is moved on the

rails 58 to be brought above thespace 136 where thecrosspiece 36 was located. - 18. The

clamshell bucket 44, previously open, is lowered by extension of thejack 74, and it takes hold of the ballast surrounding thefree space 136. - 19. The

bucket 44 rises with its ballast load. - 20. The

earthmoving group 43 returns to its initial position, clearing the location of thespace 136 in order to allow, in the following operations, the installation of thenew cross-member 37. - 21. The clamps 39, 40 and 41 descend with the

beam 51, the cross-member 37 coming to be placed at a level lower than that of the runner of therails - 22. The

tube 53 of thebeam 51 retracts, so that the cross-member 37, still gripped by theclamp 39, is introduced into thespace 136 under thefirst rail 63 to a position 37 'corresponding to position 39 'that theclamp 39 cannot exceed because of the presence of saidrail 63. - 23. The cross-member 37 'is then released by the clamp 39' and gripped by the

clamp 40, beyond therail 63. - 24. The

clamp 40 comes in 40 "and brings the crosspiece 37 'into itsfinal position 37", being controlled in translation by thescrew 29 then rotated. - 25. The

cross member 37 ", still held by theclamp 40" is, by slight rise thereof, pressed under therails - 26. The 40 "clamp opens and returns to 40.

- 27. The clamps 39, 40 and 41 are raised above the level of the

rails - 28. The

earthmoving group 43 takes the place of thehandling group 38. Thebucket 44 opens and releases the ballast it contained at the location of thenew cross member 37.

Après quoi, l'ensemble 38, 43 revient en position initiale.After which, the

Etant donné que l'on a remplacé, dans le présent exemple, une traverse en bois 36 par une traverse en béton 37, il y a pour cette dernière un déficit de ballast. Afin d'y remédier, on fait avancer le wagon 31 jusqu'à ce que sa trémie 45, contenant une réserve de ballast, vienne à l'aplomb de la traverse 37, et on y déverse une quantité complémentaire convenable de ballast par ouverture momentanée de l'obturateur 46.Given that in this example, a

Ensuite, on fait encore avancer le wagon de manière à pouvoir mettre en action successivement le groupe de bourrage 48 et le caisson-brosse de réglage 49 dans la région environnant la traverse 37.Then, the wagon is further advanced so as to be able to successively actuate the

La substitution de traverses est alors terminée. On voit qu'elle s'est effectuée en un seul passage de la machine selon l'invention, que deux agents suffisent à conduire, grâce à la mécanisation de toutes les opérations. De plus, les nouvelles traverses ne sont pas seulement calées, mais définitivement établies par bourrage du ballast. Par ailleurs, les vieilles traverses sont récupérées et non pas déposées le long de la voie. Ainsi, après les travaux de substitution de traverses, la voie se trouve parfaitement stabilisée et dégagée, sans qu'il soit besoin d'aucune opération complémentaire de bourrage ou de ramassage.The substitution of sleepers is then complete. We see that it was carried out in a single pass of the machine according to the invention, that two agents are enough to drive, thanks to the mechanization of all operations. In addition, the new sleepers are not only fixed, but definitively established by stuffing the ballast. In addition, the old sleepers are recovered and not deposited along the way. Thus, after the work of replacing sleepers, the track is perfectly stabilized and cleared, without the need for any additional tamping or pickup operation.

L'extraction ou l'introduction des traverses peut se faire soit du côté de la piste, soit du côté de l'entrevoie, par simple retournement du groupe de manutention 38 autour de la colonne 56.The extraction or introduction of the sleepers can be done either on the side of the runway or on the side of the cross-section, by simply inverting the

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82400091T ATE7613T1 (en) | 1981-01-22 | 1982-01-18 | DEVICE FOR REPLACING SLEEPER IN RAILWAY TRACKS AND METHOD OF USE OF SUCH DEVICE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8101128 | 1981-01-22 | ||

| FR8101128A FR2498220A1 (en) | 1981-01-22 | 1981-01-22 | MACHINE FOR SUBSTITUTING RAILWAY CROSSINGS AND METHOD OF USE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0057128A1 EP0057128A1 (en) | 1982-08-04 |

| EP0057128B1 true EP0057128B1 (en) | 1984-05-23 |

Family

ID=9254391

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82400091A Expired EP0057128B1 (en) | 1981-01-22 | 1982-01-18 | Railroad tie renewing machine and method of using it |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0057128B1 (en) |

| AT (1) | ATE7613T1 (en) |

| DE (1) | DE3260165D1 (en) |

| FR (1) | FR2498220A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3634399A1 (en) * | 1986-02-12 | 1987-08-13 | Plasser Bahnbaumasch Franz | TRACKING MACHINE WITH LIFTING, STOPPING AND, IF NECESSARY, DIRECTIONAL UNIT |

| AT398592B (en) * | 1992-02-19 | 1994-12-27 | Plasser Bahnbaumasch Franz | LOADING TROLLEYS TO RECEIVE, RETURN AND SHIP BULK GOODS |

| WO2015024626A1 (en) | 2013-08-20 | 2015-02-26 | Matisa Materiel Industriel Sa | Method for replacing sleepers and ballast under a raised rail section |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1210796B (en) * | 1987-06-08 | 1989-09-20 | Enrico Valditerra | Railcar for renovating railways |

| AT389541B (en) * | 1987-07-23 | 1989-12-27 | Plasser Bahnbaumasch Franz | THRESHOLD REPLACEMENT MACHINE |

| AT391501B (en) * | 1987-07-23 | 1990-10-25 | Plasser Bahnbaumasch Franz | TRACKING MACHINE |

| DE3814733C2 (en) * | 1987-07-23 | 1998-10-22 | Plasser Bahnbaumasch Franz | Track tamping machine |

| AT391335B (en) * | 1988-03-08 | 1990-09-25 | Plasser Bahnbaumasch Franz | TRACKING MACHINE |

| AT400341B (en) * | 1990-08-24 | 1995-12-27 | Plasser Bahnbaumasch Franz | THRESHOLDING MACHINE |

| AT400729B (en) * | 1990-08-24 | 1996-03-25 | Plasser Bahnbaumasch Franz | MACHINE FOR REPLACING THE SILLS OF A TRACK |

| US5063856A (en) * | 1990-10-16 | 1991-11-12 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Machine for picking up tie plates |

| US5937763A (en) * | 1996-04-23 | 1999-08-17 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Machine and method of distributing ballast |

| AT7113U3 (en) * | 2004-06-07 | 2005-07-25 | Plasser Bahnbaumasch Franz | METHOD FOR REPLACING DAMAGED THREADS OF A TRACK AND MACHINE |

| AT510423B1 (en) * | 2011-01-11 | 2012-04-15 | Franz Plasser Bahnbaumaschinen-Industriegesellscha | METHOD AND VEHICLE FOR THE SECTIONAL REPLACEMENT OF ALTERNATIVE WAVES OF A TRACK THROUGH NEW WAVES |

| FR2998591B1 (en) * | 2012-11-23 | 2014-12-19 | Europ De Travaux Ferroviaires Etf | ROUTE RENEWAL METHOD AND HIGH YIELD BALLAST. |

| CN107178015A (en) * | 2017-07-06 | 2017-09-19 | 中铁上海工程局集团有限公司 | A kind of long sleeper replacement constructing device of girder steel open bridge floors synthetic resin and method |

| CN108263970A (en) * | 2018-02-07 | 2018-07-10 | 北京好运达智创科技有限公司 | Concrete sleeper enters steam-cured double track translation crane |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU453660B2 (en) * | 1970-10-09 | 1974-09-20 | Aresco Trak-Chief Proprietary Limited | Railroad tie renewing and crib scarifying machine |

| US3675580A (en) * | 1971-01-18 | 1972-07-11 | Kershaw Mfg Co Inc | Apparatus for replacing old cross tie with new cross tie |

| AT359111B (en) * | 1977-10-04 | 1980-10-27 | Plasser Bahnbaumasch Franz | MACHINE ARRANGEMENT FOR MACHINING THE TRACK, ESPECIALLY WITH A BULLET BED CLEANING MACHINE |

-

1981

- 1981-01-22 FR FR8101128A patent/FR2498220A1/en active Granted

-

1982

- 1982-01-18 AT AT82400091T patent/ATE7613T1/en not_active IP Right Cessation

- 1982-01-18 EP EP82400091A patent/EP0057128B1/en not_active Expired

- 1982-01-18 DE DE8282400091T patent/DE3260165D1/en not_active Expired

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3634399A1 (en) * | 1986-02-12 | 1987-08-13 | Plasser Bahnbaumasch Franz | TRACKING MACHINE WITH LIFTING, STOPPING AND, IF NECESSARY, DIRECTIONAL UNIT |

| AT398592B (en) * | 1992-02-19 | 1994-12-27 | Plasser Bahnbaumasch Franz | LOADING TROLLEYS TO RECEIVE, RETURN AND SHIP BULK GOODS |

| WO2015024626A1 (en) | 2013-08-20 | 2015-02-26 | Matisa Materiel Industriel Sa | Method for replacing sleepers and ballast under a raised rail section |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE7613T1 (en) | 1984-06-15 |

| DE3260165D1 (en) | 1984-06-28 |

| FR2498220B1 (en) | 1983-08-12 |

| EP0057128A1 (en) | 1982-08-04 |

| FR2498220A1 (en) | 1982-07-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0057128B1 (en) | Railroad tie renewing machine and method of using it | |

| EP0004985B1 (en) | Train for the renewal of a railway track | |

| EP2091677B1 (en) | Support system for manufacturing metal reinforcements, and method of implementing it | |

| EP0355240B1 (en) | Train for renewing a railway track | |

| FR2558859A1 (en) | METHOD AND MACHINE FOR CLEANING A RAILWAY BALLAST BED | |

| FR2713679A1 (en) | Work train to replace old railway sleepers with new sleepers and process for the implementation thereof. | |

| FR2666103A1 (en) | Machine for replacing sleepers | |

| FR2666102A1 (en) | MACHINE FOR REPLACING THE RAILS OF A RAILWAY TRACK. | |

| FR2618466A1 (en) | EXCHANGE MACHINE OF TRAVERSES | |

| FR2667883A1 (en) | MACHINE FOR COLLECTING RIBBED SADDLES OF A RAILWAY. | |

| FR2706348A1 (en) | Unit for sawing up blocks of material such as stone, marble or granite | |

| FR2562572A1 (en) | ROLL-UP SYSTEM AND METHOD FOR RECEIVING AND / OR INSTALLING RAILWAY WORKS | |

| FR2683837A1 (en) | WORKING STRUCTURE, IN PARTICULAR FOR CROCHING CROSSES BY VEHICLES AND SYSTEM FOR TRANSPORTING AND REMOVING THE STRUCTURE. | |

| FR2535359A1 (en) | Method for the replacement of railway lines and handling frame for implementing the same | |

| FR2777024A1 (en) | MACHINE COMPRISING A DEVICE FOR CLEANING CROSS-CROSS BOXES | |

| EP0505240A1 (en) | Device for placing and replacing rail components and procedure for using this device | |

| EP0061227A1 (en) | Ballast levelling machine movable along a track | |

| EP0773153B1 (en) | Mobile platform for surmounting height deviations | |

| EP0160898B1 (en) | Handling apparatus for assembled railway switches or crossings | |

| EP0467001B1 (en) | Train for laying new tracks and method for their laying using such a train | |

| FR2695328A1 (en) | Sorting plant for long material, especially sawn timber. | |

| FR2476513A1 (en) | Vertical continuous casting plant - has extra track carrying two trolleys for manipulating cut lengths of cast billet, and starter dummy billet | |

| FR2666358A1 (en) | RAILWAY TREATMENT PROCESS AND MACHINE. | |

| FR2649638A2 (en) | Line for automatically producing reinforced concrete shuttering (formwork) beams for slab flooring | |

| CH683011A5 (en) | Device for replacement of railway tracks - includes two trucks connected by pivot resting on two bogies and intermediate bogie with translational device adapted to roll or slide in the grooves of old sleepers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19820119 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LU NL SE |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| TCAT | At: translation of patent claims filed | ||

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 7613 Country of ref document: AT Date of ref document: 19840615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3260165 Country of ref document: DE Date of ref document: 19840628 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19930131 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19930709 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930712 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930713 Year of fee payment: 12 Ref country code: GB Payment date: 19930713 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19930720 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930730 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19930803 Year of fee payment: 12 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940118 Ref country code: GB Effective date: 19940118 Ref country code: AT Effective date: 19940118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19940119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940131 Ref country code: CH Effective date: 19940131 Ref country code: BE Effective date: 19940131 |

|

| BERE | Be: lapsed |

Owner name: SOTRAMEF Effective date: 19940131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940801 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940118 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||