EP0046210A2 - Trolley - Google Patents

Trolley Download PDFInfo

- Publication number

- EP0046210A2 EP0046210A2 EP81105808A EP81105808A EP0046210A2 EP 0046210 A2 EP0046210 A2 EP 0046210A2 EP 81105808 A EP81105808 A EP 81105808A EP 81105808 A EP81105808 A EP 81105808A EP 0046210 A2 EP0046210 A2 EP 0046210A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- guide rollers

- trolley

- trolley according

- rail support

- guide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000969 carrier Substances 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61B—RAILWAY SYSTEMS; EQUIPMENT THEREFOR NOT OTHERWISE PROVIDED FOR

- B61B3/00—Elevated railway systems with suspended vehicles

- B61B3/02—Elevated railway systems with suspended vehicles with self-propelled vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C11/00—Trolleys or crabs, e.g. operating above runways

- B66C11/02—Trolleys or crabs, e.g. operating above runways with operating gear or operator's cabin suspended, or laterally offset, from runway or track

- B66C11/04—Underhung trolleys

- B66C11/06—Underhung trolleys running on monorails

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66C—CRANES; LOAD-ENGAGING ELEMENTS OR DEVICES FOR CRANES, CAPSTANS, WINCHES, OR TACKLES

- B66C7/00—Runways, tracks or trackways for trolleys or cranes

- B66C7/02—Runways, tracks or trackways for trolleys or cranes for underhung trolleys or cranes

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/60—Power-operated mechanisms for wings using electrical actuators

- E05F15/603—Power-operated mechanisms for wings using electrical actuators using rotary electromotors

- E05F15/632—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for horizontally-sliding wings

- E05F15/635—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for horizontally-sliding wings operated by push-pull mechanisms, e.g. flexible or rigid rack-and-pinion arrangements

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/684—Rails; Tracks

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2800/00—Details, accessories and auxiliary operations not otherwise provided for

- E05Y2800/26—Form or shape

- E05Y2800/266—Form or shape curved

Definitions

- the invention relates to a trolley with at least one running wheel and guide rollers associated therewith, which rest on superimposed, preferably vertical guide surfaces of a rail support.

- a trolley of this type is known from DE-AS 23 53 622 and has eight guide rollers for each wheel or pair of wheels, which guide the trolley perfectly in the straight and curved rail area on the guide surfaces of the rail support.

- the diabolo roller replaces upper guide rollers, so that only four lower guide rollers are required on a trolley.

- the object of the invention is therefore to design a trolley so that the trolley can be guided correctly on the rail support with little effort.

- This object is achieved in that two diagonally opposite guide rollers are mounted on the trolley for the upper and lower guide surfaces, with imaginary connecting lines crossing between all guide rollers.

- only a total of four guide rollers are required, namely an upper and a lower one on each side, one at the front and the other at the rear end of the trolley.

- the upper guide rollers, together with the lower ones prevent the trolley from tipping on the rail support, and the front guide rollers, together with the rear ones, ensure that the trolley is guided properly in the longitudinal direction of the rail support.

- half of the usual leadership roles were saved.

- the upper and lower guide rollers can each be mounted with their axes in the bearing bores of longitudinal members.

- the upper and the lower longitudinal beams are then connected to one another via a vertical web beam, which can be designed as a torsion bar spring.

- the upper guide rollers are connected to one another via a longitudinal support which has vertical web supports for the lower guide rollers at the longitudinal ends opposite the guide rollers, wherein the web supports can be designed as leaf springs.

- the web carrier is designed as a torsion bar spring or leaf spring, the space mentioned between the guide surfaces and the guide rollers does not have to be present, since the resilient web carrier allows the guide rollers to yield if necessary.

- the axes of the guide rollers can also be displaceably supported in the longitudinal beams under the pressure of springs in the direction of the guide surfaces. In all conceivable designs of the trolley, four of the otherwise usual eight guide rollers are saved without impairing driving behavior.

- trolleys arranged one behind the other in the direction of travel can be articulated to one another via a load carrier.

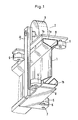

- a trolley 2 with a carrying wheel 3 travels on the running surface la of the rail carrier 1. With the exception of the rear trolley according to FIG. S, this trolley is driven by a traction motor 4. Guide rollers 5 of the trolley 2 rest on the upper and lower vertical guide surfaces 1b of the rail support 1 with a small gap.

- FIG. 2 the guide rollers are dashed at the top right and bottom left and the guide rollers at the bottom right and top left are drawn with solid lines, ie, the former are behind the rail support 1. Only these four, the two visible and the two invisible guide rollers 5 ensure that perfect guidance of the trolley 2 on the rail support 1.

- longitudinal members 8 with bearing holes 7 for the axes 6 of the guide rollers 5 can be seen above and below the rail support 1.

- a vertical web support 9 leads from the upper side member 8 to the side member.

- the upper side member 8 has a recess for the support wheel 3 for rolling on the tread la.

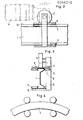

- the rail support 1 is drawn in an exaggeratedly curved manner.

- this figure clearly shows that any guides present in the center of the vehicle - whether wheel flanges or other guide rollers - lead to constraints.

- the trolleys 2 have vertical pins 11 for bearing eyes 12 of a load carrier 13 which protrude above the trolleys 2 and have eyelets 10 at the end for hanging long parts under the longitudinal member 8 fastened to the web carrier 9.

- the trolley according to FIG. 7 with the traction motor 4 indicated has only one upper longitudinal beam 8 with two web carriers 9 for the lower guide rollers 5, of which the one shown on the right lies in front of the rail carrier 1.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Transportation (AREA)

- Carriers, Traveling Bodies, And Overhead Traveling Cranes (AREA)

- Platform Screen Doors And Railroad Systems (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

- Suspension Of Electric Lines Or Cables (AREA)

- Forklifts And Lifting Vehicles (AREA)

Abstract

Auf der Lauffläche (1a) des Schienenträgers (1) fährt eine Laufkatze (2) mit einem Tragrad (3). Dieses wird von einem nicht gezeichneten Fahrmotor angetrieben. An oberen und unteren senkrechten Führungsflächen (1b) des Schienenträgers (1) liegen nur vier sich diagonal gegenüberliegende Führungsrollen (5) der Laufkatze (2) an, und zwar oben vorne links und hinten rechts sowie unten vorne rechts und hinten links. Die Führungsrollen (5) gewährleisten die einwandfreie Führung der Laufkatze (2) am Schienenträger (1). Sie sind mit ihren Achsen (6) in Lagerbohrungen (7) von Längsträgern (8) gelagert. Oberer und unterer Längsträger (8) sind über einen senkrechten Stegträger (9) miteinander verbunden.A trolley (2) with a carrying wheel (3) travels on the running surface (1a) of the rail support (1). This is driven by a drive motor, not shown. Only four diagonally opposite guide rollers (5) of the trolley (2) lie against the upper and lower vertical guide surfaces (1b) of the rail support (1), namely at the top left and rear right and at the bottom front right and rear left. The guide rollers (5) ensure perfect guidance of the trolley (2) on the rail support (1). They are mounted with their axes (6) in bearing bores (7) of side members (8). Upper and lower side members (8) are connected to each other via a vertical cross member (9).

Description

Die Erfindung betrifft eine Laufkatze mit mindestens einem Laufrad und diesem zugeordneten Führungsrollen, die an übereinanderliegenden, vorzugsweise senkrechten Führungsflächen eines Schienenträgers anliegen.The invention relates to a trolley with at least one running wheel and guide rollers associated therewith, which rest on superimposed, preferably vertical guide surfaces of a rail support.

Eine Laufkatze dieser Art ist durch die DE-AS 23 53 622 bekannt und hat für jedes Laufrad bzw. Laufradpaar acht Führungsrollen, die die Laufkatze im geraden und gekrümmten Schienenbereich einwandfrei an den Führungsflächen des Schienenträgers führen. Bei einer Laufkatze mit als Diabolorolle ausgebildetem Laufrad nach der DE-AS 18 08 210 ersetzt die Diabolorolle obere Führungsrollen, so daß an einem Fahrwerk nur vier untere Führungsrollen erforderlich sind. Bei einem stark gekrümmten Schienenträger kommt es zu Zwängungen zwischen dem Rand der Diabolorolle und den oberen Führungsflächen des Schienenträgers einerseits und den unteren Führungsflächen des Schienenträgers mit den unteren Führungsrollen andererseits. Diese Zwängungen lassen sich nur durch einen großen Abstand zwischen den Führungsflächen und den Führungsrollen vermeiden, die dann aber die Laufkatze auf einer geraden Strecke nicht mehr ausreichend führen. Eine ungenaue Führung bedeutet, daß die Stromabnehmer aufwendig sind und daß für die Steuerung der Laufkatze nur Schaltgeräte eingesetzt werden können, die einen sehr großen Schaltabstand zulassen und deshalb sehr teuer sind.A trolley of this type is known from DE-AS 23 53 622 and has eight guide rollers for each wheel or pair of wheels, which guide the trolley perfectly in the straight and curved rail area on the guide surfaces of the rail support. In a trolley with a wheel designed as a diabolo roller according to DE-AS 18 08 210, the diabolo roller replaces upper guide rollers, so that only four lower guide rollers are required on a trolley. In the case of a strongly curved rail support, there are constraints between the edge of the diabolo roller and the upper guide surfaces of the rail support on the one hand and the lower guide surfaces of the rail support with the lower guide rollers on the other hand. These constraints can only be avoided by a large distance between the guide surfaces and the guide rollers, which then no longer adequately guide the trolley on a straight track. Inaccurate guidance means that the pantographs are complex and that only switching devices can be used to control the trolley that allow a very large switching distance and are therefore very expensive.

Aufgabe der Erfindung ist es daher, eine Laufkatze so zu gestalten, daß mit geringem Aufwand eine einwandfreie Führung der Laufkatze am Schienenträger ermöglicht ist. Diese Aufgabe wird dadurch gelöst, daß an der Laufkatze für die oberen und unteren Führungsflächen jeweils zwei sich diagonal gegenüberliegende Führungsrollen gelagert sind, wobei sich gedachte Verbindungslinien zwischen allen Führungsrollen kreuzen. Es sind trotz einwandfreier oberer und unterer Führung nur insgesamt vier Führungsrollen erforderlich, nämlich auf jeder Seite eine obere und eine untere, wobei eine am vorderen und die andere am hinteren Ende der Laufkatze angeordnet ist. Es liegen sich keine Führungsrollen direkt gegenüber. Die oberen Führungsrollen verhindern zusammen mit den unteren ein Kippen der Laufkatze am Schienenträger und die vorderen Führungsrollen gewährleisten zusammen mit den hinteren die einwandfreie Führung der Laufkatze in Längsrichtung des Schienenträgers. Somit wurde trotz einwandfreier Führung die Hälfte der sonst üblichen Führungsrollen eingespart. Zwischen den Führungsflächen und den Führungsrollen kann ein kleiner Zwischenraum von etwa 1 mm zum Ausgleichen von Toleranzen am Abstand der Führungsflächen des Schienenträgers voneinander vorhanden sein. Dieser Zwischenraum kann bei Anlagen mit großen Radien etwas kleiner und bei Anlagen mit sehr engen Radien etwas größer gehalten sein.The object of the invention is therefore to design a trolley so that the trolley can be guided correctly on the rail support with little effort. This object is achieved in that two diagonally opposite guide rollers are mounted on the trolley for the upper and lower guide surfaces, with imaginary connecting lines crossing between all guide rollers. Despite proper upper and lower guidance, only a total of four guide rollers are required, namely an upper and a lower one on each side, one at the front and the other at the rear end of the trolley. There are no leadership roles directly opposite. The upper guide rollers, together with the lower ones, prevent the trolley from tipping on the rail support, and the front guide rollers, together with the rear ones, ensure that the trolley is guided properly in the longitudinal direction of the rail support. Thus, despite flawless leadership, half of the usual leadership roles were saved. Can between the guide surfaces and the guide rollers there should be a small space of about 1 mm to compensate for tolerances on the distance between the guide surfaces of the rail support. This space can be kept somewhat smaller in systems with large radii and somewhat larger in systems with very narrow radii.

In einer weiteren Ausgestaltung der Erfindung können jeweils die oberen und unteren Führungsrollen mit ihren Achsen in Lagerbohrungen von Längsträgern gelagert sein. Der obere und der untere Längsträger sind dann über einen senkrechten Stegträger miteinander verbunden, der als Drehstabfeder ausgebildet sein kann.In a further embodiment of the invention, the upper and lower guide rollers can each be mounted with their axes in the bearing bores of longitudinal members. The upper and the lower longitudinal beams are then connected to one another via a vertical web beam, which can be designed as a torsion bar spring.

In einer anderen Ausgestaltung der Erfindung sind die oberen Führungsrollen über einen Längsträger miteinander verbunden, der an den den Führungsrollen gegenüberliegenden längsseitigen Enden senkrechte Stegträger für die unteren Führungsrollen hat, wobei die Stegträger als Blattfedern ausgebildet sein können. Bei Ausbildung der Stegträger als Drehstabfeder oder Blattfeder muß der erwähnte Zwischenraum zwischen den Führungsflächen und den Führungsrollen nicht vorhanden sein, da nötigenfalls der federnde Stegträger ein Nachgeben der Führungsrollen zuläßt. Die Achsen der Führungsrollen können auch unter dem Druck von Federn in Richtung auf die Führungsflächen in den Längsträgern verschiebbar gelagert sein. Bei allen denkbaren Bauformen der Laufkatze werden vier der sonst üblichen acht Führungsrollen ohne Beeinträchtigung des Fahrverhaltens eingespart.In another embodiment of the invention, the upper guide rollers are connected to one another via a longitudinal support which has vertical web supports for the lower guide rollers at the longitudinal ends opposite the guide rollers, wherein the web supports can be designed as leaf springs. When the web carrier is designed as a torsion bar spring or leaf spring, the space mentioned between the guide surfaces and the guide rollers does not have to be present, since the resilient web carrier allows the guide rollers to yield if necessary. The axes of the guide rollers can also be displaceably supported in the longitudinal beams under the pressure of springs in the direction of the guide surfaces. In all conceivable designs of the trolley, four of the otherwise usual eight guide rollers are saved without impairing driving behavior.

Zum Transportieren größerer Lasten können in Fahrtrichtung hintereinander angeordnete Laufkatzen über einen Lastenträger gelenkig miteinander verbunden sein.To transport larger loads, trolleys arranged one behind the other in the direction of travel can be articulated to one another via a load carrier.

Drei Ausführungsbeispiele der Erfindung sind in der Zeichnung dargestellt und im folgenden erläutert. Es zeigen:

- Fig. 1 eine am Schienenträger angeordnete Laufkatze in perspektivischer Darstellung,

- Fig. 2 ein Teilstück eines Schienenträgers mit einer einfachen Laufkatze in der Seitenansicht,

- Fig. 3 die Stirnansicht von Fig. 2, jedoch ohne Fahrmotor

- Fig. 4 einen gekrümmten Schienenträger mii Führungsrollen in der Draufsicht.

- Fig. 5 ein Teilstück eines Schienenträgers mit einer Doppel-Laufkatze in der Seitenansicht,

- Fig. 6 eine Draufsicht auf Fig. 5.

- Fig. 7 eine andere einrädrige Laufkatze.

- 1 is a perspective view of a trolley arranged on the rail support,

- 2 shows a section of a rail support with a simple trolley in a side view,

- Fig. 3 is the front view of Fig. 2, but without the drive motor

- Fig. 4 shows a curved rail support mii guide rollers in plan view.

- 5 shows a section of a rail support with a double trolley in a side view,

- 6 is a top view of FIG. 5.

- 7 shows another single-wheeled trolley.

Bei beiden Ausführungsbeispielen fährt auf der Lauffläche la des Schienenträgers 1 eine Laufkatze 2 mit einem Tragrad 3. Dieses wird, mit Ausnahme der hinteren Laufkatze nach Fig. S von einem Fahrmotor 4 angetrieben. An oberen und unteren senkrechten Führungsflächen 1b des Schienenträgers 1 liegen mit geringem Zwischenraum Führungsrollen 5 der Laufkatze 2 an.In both exemplary embodiments, a

In Fig. 2 sind die Führungsrollen rechts oben und links unten gestrichelt und die Führungsrollen rechts unten und links oben mit Vollinien gezeichnet, d.h., die erstgenannten liegen hinter dem Schienenträger 1. Nur diese vier, die beiden sichtbaren und die beiden unsichtbaren Führungsrollen 5 gewährleisten die einwandfreie Führung der Laufkatze'2 am Schienenträger 1. In den Fig. 1 bis 3 sind oberhalb und unterhalb des Schienenträgers 1 Längsträger 8 mit Lagerbohrungen 7 für die Achsen 6 der Führungsrollen 5 erkennbar. Vom oberen Längsträger 8 führt ein senkrechter Stegträger 9 zum Längsträger. Der obere Längsträger 8 hat eine Ausnehmung für das Tragrad 3 zum Abrollen auf der Lauffläche la.In Fig. 2, the guide rollers are dashed at the top right and bottom left and the guide rollers at the bottom right and top left are drawn with solid lines, ie, the former are behind the

In der Fig. 4 ist der Schienenträger 1 übertrieben stark gebogen gezeichnet. Diese Figur zeigt aber deutlich, daß etwaige in Fahrzeugmitte vorhandene Führungen - ob Spurkränze oder weitere Führungsrollen - zu Zwängungen führen.4, the

Beim Ausführungsbeispiel nach den Fig. 5 und 6 haben die Laufkatzen 2 unter dem am Stegträger 9 befestigten Längsträger 8 senkrechte Zapfen 11 für Lageraugen 12 eines Lastenträgers 13, der über die Laufkatzen 2 hinausragt und am Ende ösen 10 zum Einhängen langer Teile hat.In the embodiment according to FIGS. 5 and 6, the

Die Laufkatze nach Fig. 7 mit angedeutetem Fahrmotor 4 hat nur einen oberen Längsträger 8 mit zwei Stegträgern 9 für die unteren Führungsrollen 5, von denen die rechts gezeichnete vor dem Schienenträger 1 liegt.The trolley according to FIG. 7 with the

Claims (9)

dadurch gekennzeichnet,

daß an der Laufkatze (2) für die oberen und unteren Führungsflächen (lb) jeweils zwei sich diagonal gegenüberliegende Führungsrollen (5) gelagert sind, wobei sich gedachte Verbindungslinien zwischen allen vier Führungsrollen (5) kreuzen.1. trolley with at least one impeller and guide rollers assigned to it, which bear against one another, preferably vertical guide surfaces of a rail support,

characterized,

that on the trolley (2) for the upper and lower guide surfaces (lb) two diagonally opposite guide rollers (5) are mounted, with imaginary connecting lines crossing between all four guide rollers (5).

dadurch gekennzeichnet,

daß zwischen den Führungsflächen (lb) und den Führungsrollen (la) ein Zwischenraum (Spiel) vorhanden ist.2. trolley according to claim 1,

characterized,

that there is a space (play) between the guide surfaces (lb) and the guide rollers (la).

dadurch gekennzeichnet,

daß der Zwischenraum ca. 1 mm beträgt.3. trolley according to claim 2,

characterized,

that the space is about 1 mm.

dadurch gekennzeichnet,

daß jeweils die oberen und unteren Führungsrollen (5) mit ihren Achsen (6) in Lagerbohrungen (7) von Längsträgern (8) gelagert sind, und daß der obere und untere Längsträger (8) über einen senkrechten Stegträger (9) miteinander verbunden sind.4. trolley according to claim 1,

characterized,

that the upper and lower guide rollers (5) are mounted with their axes (6) in bearing bores (7) of longitudinal members (8), and that the upper and lower longitudinal members (8) are connected to one another via a vertical web carrier (9).

dadurch gekennzeichnet,

daß der senkrechte Stegträger (9) als Drehstabfeder ausgebildet ist.5. trolley according to claim 4,

characterized,

that the vertical web carrier (9) is designed as a torsion bar spring.

dadurch gekennzeichnet,

daß die oberen Führungsrollen (5) über einen Längsträger (8) miteinander verbunden sind, der an den den Führungsrollen (5) gegenüberliegenden längsseitigen Enden senkrechte Stegträger (9) für Lager (7) der Achsen (6) der unteren Führungsrollen hat.6. trolley according to claim 1,

characterized,

that the upper guide rollers (5) are connected to one another via a longitudinal support (8) which has vertical web supports (9) for bearings (7) of the axles (6) of the lower guide rollers at the longitudinal ends opposite the guide rollers (5).

dadurch gekennzeichnet,

daß die Stegträger (9) als Blattfedern ausgebildet sind.7. trolley according to claim 6,

characterized,

that the web supports (9) are designed as leaf springs.

dadurch gekennzeichnet,

daß die Achsen (6) in den Lagerbohrungen (7) unter dem Druck von Federn in Richtung auf die Führungsflächen (16) verschiebbar gelagert sind.8. trolley according to claim 4,

characterized,

that the axes (6) in the bearing bores (7) under the pressure of springs in the direction of the guide surfaces (16) are slidably mounted.

dadurch gekennzeichnet,

daß in Fahrtrichtung hintereinander angeordnete Laufkatzen (2) über einen Lastenträger (13) gelenkig miteinander verbunden sind.9. trolley according to one or more of the preceding claims,

characterized,

that trolleys (2) arranged one behind the other in the direction of travel are articulatedly connected to one another via a load carrier (13).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81105808T ATE6848T1 (en) | 1980-08-16 | 1981-07-23 | TROLLEY. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3030929 | 1980-08-16 | ||

| DE3030929A DE3030929C2 (en) | 1980-08-16 | 1980-08-16 | Trolley |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0046210A2 true EP0046210A2 (en) | 1982-02-24 |

| EP0046210A3 EP0046210A3 (en) | 1982-04-14 |

| EP0046210B1 EP0046210B1 (en) | 1984-03-28 |

Family

ID=6109704

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81105808A Expired EP0046210B1 (en) | 1980-08-16 | 1981-07-23 | Trolley |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4423685A (en) |

| EP (1) | EP0046210B1 (en) |

| AT (1) | ATE6848T1 (en) |

| DE (1) | DE3030929C2 (en) |

| ES (1) | ES504699A0 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0151641A1 (en) * | 1983-08-01 | 1985-08-21 | Tsubakimoto Chain Co. | Overhead travelling crane |

| US4752011A (en) * | 1985-08-06 | 1988-06-21 | M.A.N.-Swf-Elektrozug Gmbh | Rail mounted cranes |

| WO1992011404A1 (en) * | 1990-12-24 | 1992-07-09 | Schubert & Salzer Maschinenfabrik Ag | Travelling device for automatic maintenance mechanism on spinning or twisting machines |

| EP0681988A1 (en) * | 1994-04-15 | 1995-11-15 | MANNESMANN Aktiengesellschaft | Running gear for a hoist |

Families Citing this family (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS596168A (en) * | 1982-06-30 | 1984-01-13 | 株式会社椿本チエイン | Conveyor |

| GB2126550B (en) * | 1982-09-07 | 1986-07-02 | Nobuyuki Tsuboi | Roller device |

| US4555138A (en) * | 1983-10-19 | 1985-11-26 | R. S. Hughes Ind. Inc. | Nurse's seat |

| DE3672652D1 (en) * | 1985-03-29 | 1990-08-23 | Shinko Electric Co Ltd | RAILWAY VEHICLE WITH LINEAR MOTOR. |

| DE3521013A1 (en) * | 1985-06-12 | 1986-12-18 | Seiwert Stahl- und Apparatebau GmbH, 6638 Dillingen | Electric suspended railway |

| US4805537A (en) * | 1986-10-28 | 1989-02-21 | Romeo Desroches | Vehicle and joist monorail trackway and method of transporting roof decking thereover |

| DE3722345A1 (en) * | 1987-07-07 | 1989-01-26 | Pagendarm Beschichtungstechnik | DEVICE FOR PULLING IN THE BEGINNING OF A MATERIAL RAIL IN A TREATMENT PLANT |

| EP0374175A1 (en) * | 1987-08-29 | 1990-06-27 | S.R. Gent PLC | Overhead conveyor system |

| US5064883A (en) * | 1987-09-21 | 1991-11-12 | Ciba-Geigy Corporation | Stabilization of acid catalyzed thermoset resins with n-hydroxy hindered amines |

| GB2214146B (en) * | 1987-12-26 | 1991-11-20 | Daifuku Kk | "conveyor trolley" |

| DE3903949A1 (en) * | 1989-02-10 | 1990-08-16 | Wampfler Gmbh | TRANSPORT DEVICE |

| US5016543A (en) * | 1989-07-26 | 1991-05-21 | Yamaha Hatsudoki Kabushiki Kaisha | Freight system |

| ES2048067B1 (en) * | 1990-10-15 | 1997-07-01 | Daifuku Kk | MONO-RAIL WAGON TYPE CONVEYOR. |

| DE4033373C2 (en) * | 1990-10-18 | 1996-04-25 | Mannesmann Ag | Trolley |

| US5305890A (en) * | 1991-08-22 | 1994-04-26 | Marushin Company Limited | Circulatory storage apparatus |

| CA2180248A1 (en) * | 1994-01-03 | 1995-07-13 | Kenneth E. Burkhalter | Track for sortation handling equipment |

| DE4432330C2 (en) * | 1994-09-10 | 1997-12-04 | Manfred Boettcher | Hoist on an oval beam |

| US5662045A (en) * | 1995-09-06 | 1997-09-02 | Symorex, Ltd. | Locomotive for material handling train |

| US5704086A (en) * | 1996-01-02 | 1998-01-06 | Fmc Corporation | Passenger boarding bridge |

| JP3910257B2 (en) * | 1996-04-19 | 2007-04-25 | デマーク・クレーンズ・アンド・コンポーネンツ・ゲゼルシャフト・ミット・ベシュレンクテル・ハフツング | Trolley equipment |

| DE59709497D1 (en) * | 1997-01-31 | 2003-04-17 | Denipro Ag Weinfelden | Rail-guided means of transport and transport system with such means of transport |

| US6205929B1 (en) | 1998-01-15 | 2001-03-27 | Vgk Inc. | Trolley wheel |

| GB2338018B (en) * | 1998-06-04 | 2002-09-04 | Stanley Works | Top guide with spring loaded wheel |

| EP1140600A4 (en) * | 1999-01-14 | 2003-05-28 | Three One Systems Llc | Load bearing material handling system having pneumatic and electrical delivery capabilities |

| NZ502388A (en) * | 1999-02-04 | 2000-03-27 | Konrad Dopplemayr & Sohn Masch | Installation for moving individuals from a mountain station into a valley station |

| JP2001260874A (en) * | 2000-03-17 | 2001-09-26 | Hitachi Ltd | Monorail car |

| KR100350719B1 (en) * | 2000-11-30 | 2002-08-29 | 삼성전자 주식회사 | apparatus for transferring in a semiconductor fabricating |

| US6446480B1 (en) | 2001-02-02 | 2002-09-10 | Vgk, Inc. | Process for producing improved rail |

| DE20302643U1 (en) * | 2003-02-18 | 2003-05-08 | Winden- und Maschinenbau Greßbach GmbH, 63785 Obernburg | Crane gantry moving lift trolley has box frame and radial telescopic swing-arm |

| JP3733130B2 (en) * | 2003-07-09 | 2006-01-11 | 泉陽機工株式会社 | Traveling device |

| US20070261590A1 (en) * | 2006-05-11 | 2007-11-15 | Vgk, Inc. | Trolley wheel assembly |

| KR100958885B1 (en) * | 2008-07-01 | 2010-05-20 | 현대삼호중공업 주식회사 | carrier |

| US8677905B2 (en) * | 2009-09-30 | 2014-03-25 | Ray Givens | Single-bridge manipulator maneuvering system |

| US8613255B1 (en) * | 2012-10-12 | 2013-12-24 | Brian Justin Chow | Monorail transport system |

| TN2015000572A1 (en) * | 2013-07-05 | 2016-06-29 | Univ King Abdullah Sci & Tech | System and method for conveying an assembly |

| KR101641908B1 (en) * | 2015-08-10 | 2016-07-22 | 주식회사 토시스 | Trolly |

| EP3335958A1 (en) * | 2016-12-18 | 2018-06-20 | Ilmatie Oy | Suspension railway system |

| CN109775575A (en) * | 2018-07-23 | 2019-05-21 | 安徽省雄峰起重机械有限公司 | A kind of bridge crane |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3115848A (en) * | 1960-05-11 | 1963-12-31 | Weldon F Appelt | Monorail vehicle |

| DE2343502A1 (en) * | 1973-08-29 | 1975-04-03 | Demag Ag | CAT MOVING ON A CARRIER |

| US3902432A (en) * | 1973-09-24 | 1975-09-02 | Rizzi Limited | Trolleys |

| DE1808210B2 (en) * | 1968-11-11 | 1977-03-10 | Rene Blaser Hebe- und Förderanlagen Maschinenbau, Luzern (Schweiz); Translift Gesellschaft für Hebe- und Förderanlagen mbH, 7889 Grenzach-Wyhlen | Trolley for monorail |

| DE2353622B2 (en) * | 1973-10-26 | 1977-04-21 | Mannesmann AG, 4000 Düsseldorf | RAILWAY VEHICLE |

-

1980

- 1980-08-16 DE DE3030929A patent/DE3030929C2/en not_active Expired

-

1981

- 1981-07-23 EP EP81105808A patent/EP0046210B1/en not_active Expired

- 1981-07-23 AT AT81105808T patent/ATE6848T1/en not_active IP Right Cessation

- 1981-07-30 US US06/288,482 patent/US4423685A/en not_active Expired - Lifetime

- 1981-08-12 ES ES504699A patent/ES504699A0/en active Granted

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3115848A (en) * | 1960-05-11 | 1963-12-31 | Weldon F Appelt | Monorail vehicle |

| DE1808210B2 (en) * | 1968-11-11 | 1977-03-10 | Rene Blaser Hebe- und Förderanlagen Maschinenbau, Luzern (Schweiz); Translift Gesellschaft für Hebe- und Förderanlagen mbH, 7889 Grenzach-Wyhlen | Trolley for monorail |

| DE2343502A1 (en) * | 1973-08-29 | 1975-04-03 | Demag Ag | CAT MOVING ON A CARRIER |

| US3902432A (en) * | 1973-09-24 | 1975-09-02 | Rizzi Limited | Trolleys |

| DE2353622B2 (en) * | 1973-10-26 | 1977-04-21 | Mannesmann AG, 4000 Düsseldorf | RAILWAY VEHICLE |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0151641A1 (en) * | 1983-08-01 | 1985-08-21 | Tsubakimoto Chain Co. | Overhead travelling crane |

| EP0151641A4 (en) * | 1983-08-01 | 1985-12-11 | Tsubakimoto Chain Co | Overhead travelling crane. |

| US4752011A (en) * | 1985-08-06 | 1988-06-21 | M.A.N.-Swf-Elektrozug Gmbh | Rail mounted cranes |

| WO1992011404A1 (en) * | 1990-12-24 | 1992-07-09 | Schubert & Salzer Maschinenfabrik Ag | Travelling device for automatic maintenance mechanism on spinning or twisting machines |

| US5269228A (en) * | 1990-12-24 | 1993-12-14 | Rieter Ingolstadt Spinnereimaschinenbau Ag | Travelling mechanism of an automatic service carriage for spinning or twisting machines |

| EP0681988A1 (en) * | 1994-04-15 | 1995-11-15 | MANNESMANN Aktiengesellschaft | Running gear for a hoist |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0046210A3 (en) | 1982-04-14 |

| US4423685A (en) | 1984-01-03 |

| ES8301158A1 (en) | 1982-12-01 |

| ATE6848T1 (en) | 1984-04-15 |

| DE3030929C2 (en) | 1983-01-05 |

| ES504699A0 (en) | 1982-12-01 |

| DE3030929A1 (en) | 1982-03-11 |

| EP0046210B1 (en) | 1984-03-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0046210B1 (en) | Trolley | |

| DE4109971C2 (en) | Monorail underflange trolley | |

| DE1294405B (en) | Guide system for vehicles with pneumatic tires and guide wheels with vertical axis | |

| DE3900616A1 (en) | Transport system with a rail-guided vehicle and a rail switch | |

| DE3020582C2 (en) | ||

| DE2263568C2 (en) | Conveyor system with transport containers | |

| EP0483169B1 (en) | Rail-mounted, high-lift stacking vehicle | |

| DE2854776A1 (en) | Tram carriage steering control with electronic regulation - controlling drive devices either side of centre coupling between carriages to maintain stability and facilitate cornering | |

| DE69301698T2 (en) | Adjustment device for a tire vehicle bogie | |

| DE2308273A1 (en) | SINGLE-AXLE RAILWAY TRUCK, IN PARTICULAR FOR MOVABLE INTERFACES | |

| DE3009195C2 (en) | A lift truck that is divided transversely within the wheel base | |

| DE3842292C2 (en) | ||

| DE4413537C2 (en) | Chassis for hoists | |

| DE3229709C1 (en) | Three-axle bogie for rail vehicles | |

| CH687199A5 (en) | Transfer conveyor. | |

| DE3601837C2 (en) | ||

| DE3425682C2 (en) | Storage and retrieval machine | |

| DE10350841B4 (en) | Dolly and such a transport vehicle comprehensive transport system | |

| DE2559451C3 (en) | Curve guide device for a hose line attached to a trolley and used for hydraulic pit conveyance | |

| DE4122401B4 (en) | trolley | |

| EP0264616A1 (en) | Guiding device for a track-bound vehicle | |

| CH375865A (en) | Crane drive | |

| DE4207804C2 (en) | Support frame for semitrailers to be transported on railway wagons | |

| DE948878C (en) | Automatic track brake | |

| DE2135150C3 (en) | Electric linear motor with a low profile secondary part attached to a rail |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT NL SE |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT NL SE |

|

| RHK1 | Main classification (correction) |

Ipc: B66C 9/02 |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: MODIANO & ASSOCIATI S.R.L. |

|

| TCNL | Nl: translation of patent claims filed | ||

| 17P | Request for examination filed |

Effective date: 19820308 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 6848 Country of ref document: AT Date of ref document: 19840415 Kind code of ref document: T |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19840516 Year of fee payment: 4 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19840630 Year of fee payment: 4 Ref country code: BE Payment date: 19840630 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19840716 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19840731 Year of fee payment: 4 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19850723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19850724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19850731 Ref country code: CH Effective date: 19850731 Ref country code: BE Effective date: 19850731 |

|

| BERE | Be: lapsed |

Owner name: MANNESMANN A.G. Effective date: 19850731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19860201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| ITTA | It: last paid annual fee | ||

| EUG | Se: european patent has lapsed |

Ref document number: 81105808.0 Effective date: 19860730 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980612 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980629 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990731 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990723 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |