EP0010593B2 - Reinforced profile of synthetic material - Google Patents

Reinforced profile of synthetic material Download PDFInfo

- Publication number

- EP0010593B2 EP0010593B2 EP79103316A EP79103316A EP0010593B2 EP 0010593 B2 EP0010593 B2 EP 0010593B2 EP 79103316 A EP79103316 A EP 79103316A EP 79103316 A EP79103316 A EP 79103316A EP 0010593 B2 EP0010593 B2 EP 0010593B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- profiles

- section

- walls

- profile

- plastic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 229920002994 synthetic fiber Polymers 0.000 title 1

- 239000004033 plastic Substances 0.000 claims abstract description 31

- 229920003023 plastic Polymers 0.000 claims abstract description 31

- 230000003014 reinforcing effect Effects 0.000 claims abstract description 14

- 229910052751 metal Inorganic materials 0.000 claims abstract description 9

- 239000002184 metal Substances 0.000 claims abstract description 9

- 238000005192 partition Methods 0.000 claims abstract 5

- 230000002787 reinforcement Effects 0.000 description 30

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000010276 construction Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000001125 extrusion Methods 0.000 description 3

- 230000003068 static effect Effects 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 229920001169 thermoplastic Polymers 0.000 description 2

- 239000004416 thermosoftening plastic Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 239000002990 reinforced plastic Substances 0.000 description 1

- 238000010079 rubber tapping Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/06—Single frames

- E06B3/08—Constructions depending on the use of specified materials

- E06B3/20—Constructions depending on the use of specified materials of plastics

- E06B3/22—Hollow frames

- E06B3/221—Hollow frames with the frame member having local reinforcements in some parts of its cross-section or with a filled cavity

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/06—Single frames

- E06B3/08—Constructions depending on the use of specified materials

- E06B3/20—Constructions depending on the use of specified materials of plastics

- E06B3/22—Hollow frames

- E06B3/221—Hollow frames with the frame member having local reinforcements in some parts of its cross-section or with a filled cavity

- E06B2003/228—Hollow frames with the frame member having local reinforcements in some parts of its cross-section or with a filled cavity with separate reinforcements situated outside the cavity or in the walls

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/06—Single frames

- E06B3/08—Constructions depending on the use of specified materials

- E06B3/20—Constructions depending on the use of specified materials of plastics

- E06B3/205—Constructions depending on the use of specified materials of plastics moulded or extruded around a core

Definitions

- the invention relates to a multi-chambered profile made of plastic, in particular for frames of windows or doors, with chambers formed between two walls running parallel to one another in the longitudinal extension of the profile by transverse walls or webs extending from these and with preferably metallic reinforcement profiles running in the longitudinal extension of the profile which are embedded in the walls or transverse walls or webs.

- Multi-chambered hollow profiles extruded from thermoplastic, are widely used especially in the construction industry, u. a. preferred for the production of frames for windows or doors.

- the low modulus of elasticity of many plastics now makes it necessary, particularly in the case of long profile sections, to increase the strength by means of additional reinforcements or to provide metallic reinforcements from the outset.

- German design specification 1281 664 describes, for example, multi-chambered hollow profiles made of plastic, in which metal reinforcement profiles are provided in the longitudinal extension of the profile into one or more of the hollow chambers by subsequent insertion. From the German Offenlegungsschrift 2 258 420, the French.

- Patent specification 1 201 457, German Auslegeschrift 1 106479, German Offenlegungsschriften 1 931 744 and 1 920 248 hollow profiles are known in which a hollow metallic core is directly covered with a plastic jacket, which is optionally equipped with further external profiling and projections, by extrusion is.

- a reinforced profile is known in which a core profile with cavities and reinforcing inserts, for. B. from metal rods and is coated on the outside with plastic.

- the present invention has for its object to provide multi-chamber profiles made of plastic with a reinforcement, which combines the advantages of the lowest possible material expenditure with an optimum of static load capacity with a simple sufficient fastening option for abutting profiles by means of connecting elements.

- the invention achieves the object with a profile of the shape that an extruded reinforcing profile with a hollow cross section and internal thread formed on the inside of the reinforcing profiles are provided.

- such reinforcement profiles with a relatively small cross section are embedded in particularly suitable locations in the plastic walls or webs, namely in the region of the transverse walls or webs extending from the visible sides of the profile, so that an above-average increase in the static load-bearing capacity is achieved with relatively little stiffening material of the plastic profile is achieved.

- the reinforcement profiles are extruded during the extrusion of the plastic profiles and in this way non-positively connected to the plastic. It can be advantageous here to design the outside of the reinforcement profiles in a profiled or roughened manner in order to achieve improved adhesion. This is also an advantage for profiles that are used in construction and are exposed to weathering, since the reinforcement profiles counteract the deformation of the plastic due to solar radiation and one-sided heat effects and shrinkage of the plastic profile in the longitudinal direction is also reduced.

- the reinforcement profiles can have any cross section, but round profiles are preferred. Since corner connections have to be made from profiles when manufacturing frames for windows or doors, they can be easily manufactured by screwing corner brackets into the reinforcement profiles.

- the reinforcement profiles are preferably made of metal, in particular aluminum profiles.

- the multi-chambered hollow profiles made of plastic which are produced by extrusion and to which the invention is to be applied, are predominantly used in construction.

- the plastic has the advantage of being maintenance-free and weatherproof, but due to its low modulus of elasticity, it has the disadvantage for some constructions that the mechanical resilience of the pure plastic profile is not sufficient.

- one helps one another by means of reinforcing profiles made of suitable materials, in particular metals, which are introduced into the hollow chambers or into a hollow chamber of the profiles.

- suitable materials in particular metals

- This hollow profile 1 shows in cross section a Z-shaped, multi-chambered hollow profile made of thermoplastic, for example hard PVC, which is used for the sash frame of a window.

- This hollow profile 1 has two mutually parallel walls 10, 11 which extend in the longitudinal extent of the profile and which here form the visible sides of the frame. These two main walls 10, 11 are now connected to one another by transverse walls 15, 16 and webs 12, 13, 20, 26, 27 and 25 to form chambers.

- the transverse walls 15, 16 form the central chamber area, which is divided into the two chambers 17, 18 by the intermediate web 25.

- the projections likewise formed with the chambers 22, 23 protrude from this central area in an extension of the visible sides 10, 11.

- the reinforcing profiles 4 here made for example as hollow profiles with a round cross section made of aluminum, are now extruded into the walls or webs, preferably in the areas starting from the walls 10, 11 and the transverse walls 15, 16 or webs 19 extending from them , 20.

- the reinforcing profiles 4 can only protrude into one chamber, such as in the chamber 17, 22 or in the corner region of the walls 11, 16 or in the middle in a web and projecting into two chambers, like the reinforcement profile 4 in the web 19, into the chambers 23 and 18. It is not necessary in the sense according to the invention that the reinforcement profiles should follow an axis of symmetry in every way. For static reasons, however, they will be arranged at suitable locations depending on the specified profile cross section.

- a multi-chamber hollow plastic profile which is designed as an L-profile, is shown and which is used, for example, to produce window frames for windows or doors.

- parallel walls 10, 11 are provided as main walls which extend in the longitudinal extent of the profile and which likewise form visible sides here.

- reinforcement profiles 4 are likewise embedded in the walls and completely enclosed on the outside by the plastic. The number of required reinforcement profiles 4, their cross-sections and their arrangement within the profile cross-sections of the plastic profiles 1 also depends on the intended use of the profiles 1 and on the demands made on them with regard to the mechanical loads.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Wing Frames And Configurations (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

- Window Of Vehicle (AREA)

- Laminated Bodies (AREA)

Abstract

Description

Die Erfindung befaßt sich mit einem mehrkammerigen Profil aus Kunststoff, insbesondere für Rahmen von Fenstern oder Türen, mit zwischen zwei in Längserstreckung des Profils zueinander parallel verlaufenden Wänden durch von diesen abgehende Querwände bzw. Stege gebildeten Kammern und mit in Längserstreckung des Profils verlaufenden vorzugsweise metallischen Verstärkungsprofilen, die in die Wände bzw. Querwände bzw. Stege eingebettet sind.The invention relates to a multi-chambered profile made of plastic, in particular for frames of windows or doors, with chambers formed between two walls running parallel to one another in the longitudinal extension of the profile by transverse walls or webs extending from these and with preferably metallic reinforcement profiles running in the longitudinal extension of the profile which are embedded in the walls or transverse walls or webs.

Mehrkammerige Hohlprofile, extrudiert aus thermoplastischem Kunststoff, werden insbesondere im Bauwesen vielfach angewendet, u. a. bevorzugt zum Herstellen von Rahmen für Fenster oder Türen. Der niedrige Elastizitätsmodul vieler Kunststoffe macht es nun erforderlich, insbesondere bei langen Profilabschnitten, die Festigkeit durch zusätzliche Verstärkungen zu erhöhen bzw. von vornherein metallische Verstärkungen vorzusehen. In der deutschen Auslegeschrift 1281 664 sind beispielsweise mehrkammerige Hohlprofile aus Kunststoff beschrieben, bei denen in Längserstreckung des Profils in eine oder mehrere der Hohlkammern metallische Verstärkungsprofile durch nachträgliches Einschieben vorgesehen sind. Aus der deutschen Offenlegungsschrift 2 258 420, der franz. Patentschrift 1 201 457, der deutschen Auslegeschrift 1 106479, den deutschen Offenlegungsschriften 1 931 744 und 1 920 248 sind Hohlprofile bekannt, bei denen ein hohler metallischer Kern direkt mit einem Kunststoffmantel, der gegebenenfalls mit weiterer äußerer Profilierung und Vorsprüngen ausgestattet ist, durch Extrusion umkleidet ist.Multi-chambered hollow profiles, extruded from thermoplastic, are widely used especially in the construction industry, u. a. preferred for the production of frames for windows or doors. The low modulus of elasticity of many plastics now makes it necessary, particularly in the case of long profile sections, to increase the strength by means of additional reinforcements or to provide metallic reinforcements from the outset. German design specification 1281 664 describes, for example, multi-chambered hollow profiles made of plastic, in which metal reinforcement profiles are provided in the longitudinal extension of the profile into one or more of the hollow chambers by subsequent insertion. From the German Offenlegungsschrift 2 258 420, the French.

Das nachträgliche Einlegen von Verstärkungsprofilen, wie es beispielsweise in der DE-AS-1 281 664 beschrieben wird, bedingt, daß die Verstärkungsprofile in einem separaten Arbeitsgang zugeschnitten und gegebenenfalls mit erheblichem Kraftaufwand infolge der auftretenden Maßtoleranzen in die Kunststoffhohlprofile gegebenenfalls sogar an mehreren Stellen eingeschoben werden müssen und zur Fixierung noch vernietet oder verschraubt werden. Bei der Ummantelung von metallischen Verstärkungsprofilen mit Kunststoff ist die Verstärkung sehr materialintensiv ausgebildet, wodurch die Profile schwer und teuer werden.The subsequent insertion of reinforcement profiles, as described, for example, in DE-AS-1 281 664, requires that the reinforcement profiles are cut in a separate operation and, if necessary, are pushed into the hollow plastic profiles at several points with considerable effort as a result of the dimensional tolerances that occur must be riveted or screwed down for fixation. When sheathing metallic reinforcement profiles with plastic, the reinforcement is very material-intensive, which makes the profiles heavy and expensive.

Aus der US-A-3 470 598 sind verstärkte Profile aus Kunststoff für Fenster bekannt, bei denen ein die Profilwände markierendes mit gelochtes Metallprofil allseitig mit Kunststoff ummantelt wird. Auch diese rundum verstärkten Profile sind sehr materialaufwendig und schwer.From US-A-3 470 598 reinforced profiles made of plastic for windows are known, in which a profile marking the profile walls with a perforated metal profile is coated on all sides with plastic. These all-round reinforced profiles are also very expensive and heavy.

Des weiteres ist gemäß DE-U-1994127 ein verstärktes Profil bekannt, bei dem ein Kernprofil mit Hohlräumen und Verstärkungseinlagen, z. B. aus Metallstäben versehen und außenseitig mit Kunststoff ummantelt ist.Furthermore, according to DE-U-1994127, a reinforced profile is known in which a core profile with cavities and reinforcing inserts, for. B. from metal rods and is coated on the outside with plastic.

Bei diesem Profil dienen die Hohlräume imIn this profile, the cavities in the

Kernprofil zum Einlegen von die Profile untereinander verbindenden Teilen, die jedoch noch einer Fixierung bedürfen.Core profile for inserting parts that connect the profiles to each other, but which still require fixation.

Aus der DE-U-1 864891 ist ein mehrkammeriges Profil aus Kunststoff der eingangs genannten Art bekannt, zu dessen Verstärkung eingespritzte Metallstäbe dienen. Es sind auch bereits Kunststoff hohlprofile bekannt, in die hohle Verstärkungsprofile aus Metall eingeschoben bzw. eingeformt sind, und die Kanäle aufweisen, in die selbstschneidende Schrauben eindrehbar sind (z. B. US-A-3 100 917 oder DE-A-2 614 082).From DE-U-1 864891 a multi-chamber profile made of plastic of the type mentioned is known, for the reinforcement of which injected metal rods are used. Plastic hollow profiles are also already known, into which hollow metal reinforcement profiles are inserted or molded, and have channels into which self-tapping screws can be screwed (e.g. US-A-3 100 917 or DE-A-2 614 082).

Der vorliegenden Erfindung liegt nun die Aufgabe zugrunde, mehrkammerige Profile aus Kunststoff mit einer Verstärkung zu schaffen, die die Vorteile eines möglichst geringen Materialaufwandes bei einem Optimum an statischer Belastbarkeit vereinigt mit einer einfachen ausreichenden Befestigungsmöglichkeit für aneinanderstoßende Profile mittels Verbindungselemente.The present invention has for its object to provide multi-chamber profiles made of plastic with a reinforcement, which combines the advantages of the lowest possible material expenditure with an optimum of static load capacity with a simple sufficient fastening option for abutting profiles by means of connecting elements.

Die Erfindung löst die gestellte Aufgabe mit einem Profil der Gestalt, daß ein extrudierte Verstärkungsprofile mit hohlem Querschnitt und an der Innenseite der Verstärkungsprofile ausgebildetem Innengewinde vorgesehen sind.The invention achieves the object with a profile of the shape that an extruded reinforcing profile with a hollow cross section and internal thread formed on the inside of the reinforcing profiles are provided.

Erfindungsgemäß werden derartige Verstärkungsprofile mit relativ kleinem Querschnitt an besonders geeigneten Stellen in die Kunststoffwandungen bzw. Stege eingebettet, nämlich im Bereich der von den die Sichtseiten des Profils bildenden Wände abgehenden Querwände bzw. Stege, so daß mit relativ wenig Versteifungsmaterial eine überdurchschnittliche Steigerung der statischen Belastbarkeit des Kunststoffprofils erzielt wird. Die Verstärkungsprofile werden hierbei bei der Extrusion der Kunststoffprofile einextrudiert und auf diese Weise kraftschlüssig mit dem Kunststoff verbunden. Hierbei kann es vorteilhaft sein, die Außenseite der Verstärkungsprofile profiliert oder gewindeähnlich aufgerauht auszubilden, um eine verbesserte Haftung zu erzielen. Dies ist auch bei Profilen, die im Bauwesen eingesetzt werden und der Bewitterung ausgesetzt sind, von Vorteil, da durch Sonneneinstrahlung und bei einseitiger Wärmeeinwirkung die Verstärkungsprofile der Verformung des Kunststoffes entgegenwirken und auch Schrumpfungen des Kunststoffprofils in Längsrichtung reduziert werden.According to the invention, such reinforcement profiles with a relatively small cross section are embedded in particularly suitable locations in the plastic walls or webs, namely in the region of the transverse walls or webs extending from the visible sides of the profile, so that an above-average increase in the static load-bearing capacity is achieved with relatively little stiffening material of the plastic profile is achieved. The reinforcement profiles are extruded during the extrusion of the plastic profiles and in this way non-positively connected to the plastic. It can be advantageous here to design the outside of the reinforcement profiles in a profiled or roughened manner in order to achieve improved adhesion. This is also an advantage for profiles that are used in construction and are exposed to weathering, since the reinforcement profiles counteract the deformation of the plastic due to solar radiation and one-sided heat effects and shrinkage of the plastic profile in the longitudinal direction is also reduced.

Die Verstärkungsprofile können beliebigen Querschnitt aufweisen, bevorzugt werden jedoch runde Profile. Da beim Herstellen von Rahmen für Fenster oder Türen aus Profilen Eckverbindungen hergestellt werden müssen, sind diese durch Verschrauben von Eckwinkeln in den Verstärkungsprofilen einfach herstellbar.The reinforcement profiles can have any cross section, but round profiles are preferred. Since corner connections have to be made from profiles when manufacturing frames for windows or doors, they can be easily manufactured by screwing corner brackets into the reinforcement profiles.

Die Verstärkungsprofile werden bevorzugt aus Metall hergestellt, insbesondere aus Aluminiumprofilen.The reinforcement profiles are preferably made of metal, in particular aluminum profiles.

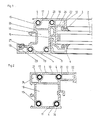

Die Erfindung ist in der Zeichnung an zwei Ausführungsbeispielen dargestellt und wird anhand dieser nachfolgend näher erläutert. Es zeigen die

Figuren 1 und 2 Querschnitte durch mehrkammerige Kunststoffhohlprofile mit erfindungsgemäßer Verstärkung, wobei die dargestellten Profile zum Herstellen von Rahmen für Türen oder Fenster dienen.

- Figures 1 and 2 cross sections through more chambered plastic hollow profiles with reinforcement according to the invention, the profiles shown being used to produce frames for doors or windows.

Die mehrkammerigen Hohlprofile aus Kunststoff, die durch Extrusion hergestellt werden, und auf die die Erfindung angewendet werden soll, kommen überwiegend im Bauwesen zum Einsatz. Der Kunststoff hat hier den Vorteil der Wartungsfreiheit und Witterungsbeständigkeit, hat jedoch aufgrund seines niedrigen E-Moduls für manche Konstruktionen den Nachteil, daß die mechanische Belastbarkeit des reinen Kunststoffprofils nicht ausreichend ist. Hier hilft man sich durch Verstärkungsprofile aus geeigneten Materialien, insbesondere Metallen, die in die hohlen Kammern oder in eine hohle Kammer der Profile eingebracht werden. Da beispielsweise bei der Herstellung von Rahmen für Fenster aus Kunststoffhohlprofilen für kleinere Rahmen die mechanischen Eigenschaften der Kunststoffprofile ausreichend sind und erst bei größeren Rahmen eine zusätzliche Versteifung der Kunststoffprofile erforderlich ist, ist es aus Kostengründen anzustreben, nur bei solchen Profilen nachträglich metallische Verstärkungseinlagen vorzusehen. Dieses nachträgliche Anbringen von Verstärkungseinlagen ist jedoch mit erheblichem Arbeitsaufwand verbunden, während die Herstellung eines von vornhereim mit einextrudiertem Verstärkungsprofil versehenen Kunststoffprofils einfacher ist, jedoch durch die bekannten großquerschnittigen Verstärkungsprofile relativ aufwendig ist. Letzteres gilt insbesondere auch dann, da solche verstärkten Profile auch vielfach zur Anwendung kommen, ohne daß ihre hohe mechanische Belastbarkeit erforderlich wäre. Die Erfindung schafft hier nun einen Mittelweg, um einerseits ein möglichst einfaches Herstellungsverfahren für verstärkte Kunststoffhohlprofile zu schaffen, andererseits jedoch den materialbedingten Aufwand an Verstärkungsprofilen zu reduzieren.The multi-chambered hollow profiles made of plastic, which are produced by extrusion and to which the invention is to be applied, are predominantly used in construction. The plastic has the advantage of being maintenance-free and weatherproof, but due to its low modulus of elasticity, it has the disadvantage for some constructions that the mechanical resilience of the pure plastic profile is not sufficient. Here one helps one another by means of reinforcing profiles made of suitable materials, in particular metals, which are introduced into the hollow chambers or into a hollow chamber of the profiles. For example, since the mechanical properties of the plastic profiles are sufficient for the production of frames for windows made of plastic hollow profiles for smaller frames and additional reinforcement of the plastic profiles is only required for larger frames, it is desirable for cost reasons to provide metallic reinforcement inserts only subsequently for such profiles. This subsequent attachment of reinforcement inserts is associated with considerable work, while the production of a plastic profile provided from the start with an extruded reinforcement profile is simpler, but is relatively complex due to the known large cross-sectional reinforcement profiles. The latter also applies in particular since such reinforced profiles are also used in many cases without their high mechanical strength being necessary. The invention creates a middle ground here, on the one hand to create the simplest possible manufacturing process for reinforced plastic hollow profiles, but on the other hand to reduce the material-related expenditure on reinforcement profiles.

In der Fig. 1 ist im Querschnitt ein Z-förmiges mehrkammeriges Hohlprofil aus thermoplastischem Kunststoff, beispielsweise Hart-PVC dargestellt, das für die Flügelrahmen eines Fensters benutzt wird. Dieses Hohlprofil 1 weist zwei zueinander parallele Wände 10, 11 auf, die in Längserstreckung des Profils verlaufen und die hier die Sichtseiten des Rahmens bilden. Diese beiden Hauptwände 10, 11 sind nun durch Querwände 15, 16 und Stege 12, 13, 20, 26, 27 und 25 miteinander unter Bildung von Kammern verbunden. Die Querwände 15, 16 bilden dabei den zentralen Kammerbereich, der durch den Zwischensteg 25 in die beiden Kammern 17, 18 unterteilt wird. Von diesem zentralen Bereich springen die ebenfalls mit den Kammern 22, 23 ausgebildeten Vorsprünge in Verlängerung der Sichtseiten 10, 11 vor. Die Verstärkungsprofile 4, hier beispielsweise als Hohlprofile mit rundem Querschnitt aus Aluminium hergestellt, sind nun in die Wandungen bzw. Stege einextrudiert und zwar vorzugsweise in den Bereichen ausgehend von den Wänden 10, 11 und den von diesen abgehenden Querwänden 15, 16 bzw. Stegen 19, 20. Die Verstärkungsprofile 4 können hierbei nur in eine Kammer hineinragen, wie in die Kammer 17, 22 bzw. im Eckbereich der Wände 11, 16 oder aber mittig in einen Steg gesetzt und in zwei Kammern hineinragend, wie das Verstärkungsprofil 4 in den Steg 19, in die Kammern 23 und 18. Es ist nicht erforderlich im erfindungsgemäßen Sinn, daß die Verstärkungsprofile in jeder Weise einer Symmetrieachse folgen müßten. Sie werden jedoch aus statischen Grunden je nach dem vorgegebenen Profilquerschnitt an geeigneten Stellen angeordnet sein. Es ist auch denkbar, beispielsweise nur drei Verstärkungsprofile vorzusehen, wie die drei Ecken eines Dreieckes im Querschnitt betrachtet, bilden. Bei dem Flügelrahmenprofil 1 nach Fig. 1 ist noch die Verglasung 2 dargestellt, die unter Zwischenschaltung von Dichtungsprofilen 3 mit der Glashalteleiste 4 an dem Profil 1 befestigt ist.1 shows in cross section a Z-shaped, multi-chambered hollow profile made of thermoplastic, for example hard PVC, which is used for the sash frame of a window. This

In dem Ausführungsbeispiel nach Fig. ist ein mehrkammeriges Kunststoffhohlprofil, das als L-Profil ausgebildet ist, dargestellt und das beispielsweise zum Herstellen von Blendrahmen für Fenster oder Türen dient. Auch bei diesem Profil1 sind zueinander in Längserstreckung des Profils verlaufende parallele Wände 10, 11 als Hauptwände vorgesehen, die hier ebenfalls Sichtseiten bilden. Im Eckbereich der diese beiden Wände 10, 11 miteinander vebindenden Querwände 15, 16 bzw. der hierven abgehenden Stege 20, 21 sind ebenfalls Verstärkungsprofile 4 in die Wandungen eingebettet und vollständig vom Kunststoff außenseitig umschlossen. Die Anzahl der erforderlichen Verstärkungsprofile 4, ihre Querschnitte und ihre Anordnung innerhalb der Profilquerschnitte der Kunststoffprofile 1 richtet sich auch nach dem Verwendungszweck der Profile 1 sowie nach den an diese gerichteten Anforderungen bezüglich der mechanischen Belastungen.In the exemplary embodiment according to FIG. 1, a multi-chamber hollow plastic profile, which is designed as an L-profile, is shown and which is used, for example, to produce window frames for windows or doors. In this

In dem gezeigten Querschnitt des Profils 1 nach Fig. wäre es auch denkbar, das in dem Steg 21 vorgesehene Verstärkungsprofil auch im Eckbereich zwischen Wandung 10 und Außenwandung der Kammer 24 vorzusehen. Eine solche Anordnung käme auch insbesondere dann in Frage, wenn beispielsweise die Kammern 24 und 17 nicht durch den Zwischensteg 21 unterteilt wären.In the cross section of the

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT79103316T ATE1157T1 (en) | 1978-10-05 | 1979-09-06 | REINFORCED PLASTIC PROFILE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2843437 | 1978-10-05 | ||

| DE2843437A DE2843437C2 (en) | 1978-10-05 | 1978-10-05 | Multi-chamber hollow profile made of plastic |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0010593A1 EP0010593A1 (en) | 1980-05-14 |

| EP0010593B1 EP0010593B1 (en) | 1982-06-02 |

| EP0010593B2 true EP0010593B2 (en) | 1986-03-26 |

Family

ID=6051463

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP79103316A Expired EP0010593B2 (en) | 1978-10-05 | 1979-09-06 | Reinforced profile of synthetic material |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0010593B2 (en) |

| AT (1) | ATE1157T1 (en) |

| DE (2) | DE2843437C2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024088752A1 (en) * | 2022-10-28 | 2024-05-02 | Vkr Holding A/S | Roof window comprising polymer profiles with metal reinforcement |

| EP4379160A1 (en) * | 2022-11-29 | 2024-06-05 | VKR Holding A/S | Roof window comprising polymer profiles with metal reinforcement |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3136863A1 (en) * | 1981-04-15 | 1982-11-04 | Schock & Co Gmbh, 7060 Schorndorf | EXTRUDED PLASTIC HOLLOW PROFILE BAR FOR WINDOW FRAME, WINDOW FRAME MADE FROM SUCH PROFILE BARS AND METHOD FOR PRODUCING SUCH A WINDOW FRAME |

| DE3327547C2 (en) * | 1983-07-30 | 1985-08-08 | Gebr. Grotemeyer GmbH & Co, 4401 Altenberge | Plastic hollow profile for windows, doors or the like. |

| DE3512950A1 (en) * | 1985-04-11 | 1986-10-16 | Hubert 5778 Meschede Möller | CAVE PROFILE |

| DE3644704A1 (en) * | 1986-12-30 | 1988-07-14 | Fukubi Kagaku Kogyo Kk | EXTRUDED SHAPED FRAME |

| DE9411703U1 (en) * | 1994-07-20 | 1994-11-10 | Pax Gmbh | Laminated wooden window profile |

| AT406978B (en) * | 1998-07-10 | 2000-11-27 | Actual Fenster Aktiengesellsch | PLASTIC PROFILE FOR WINDOWS AND DOORS |

| FR2836051A1 (en) * | 2002-02-18 | 2003-08-22 | Bernard Bastita | Metal structural frame for building forms integral ducting for fire fighting sprinkler system |

| DE102011119245A1 (en) | 2011-11-22 | 2012-10-25 | Daimler Ag | Braiding-pultrusion method for manufacturing thermoplastic fiber-reinforced plastic multi chamber hollow profile used for side impact protection-carrier for door of motor vehicle, involves consolidating hollow profile mesh under pressure |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH242798A (en) * | 1942-12-16 | 1946-06-15 | Fischl Franz | Window frames. |

| IT563268A (en) * | 1956-12-13 | |||

| DE1106479B (en) * | 1959-06-01 | 1961-05-10 | Kloeckner Werke Ag | Holding frame, especially for putty-free glazing of windows and partitions |

| DE1281664C2 (en) * | 1963-11-06 | 1973-10-11 | PLASTIC PROFILE BAR FOR WINDOW FRAMES, DOOR FRAMES OR DGL. WITH A REINFORCEMENT INSERT | |

| GB1140261A (en) * | 1964-04-29 | 1969-01-15 | Elisa Berthelsen | Improvements in and relating to structural frames such as window frames |

| DE1994127U (en) * | 1968-06-14 | 1968-09-19 | Wilhelm Hachtel | BAR FOR USE ON BUILDINGS AND THEIR EQUIPMENT. |

| DE1920248B2 (en) * | 1969-04-22 | 1978-09-07 | Dynamit Nobel Ag, 5210 Troisdorf | Profile for fixed frames of windows or doors with a load-bearing metal hollow profile and a plastic jacket made of soft PVC that tightly encloses it |

| DE1931744A1 (en) * | 1969-06-23 | 1971-02-04 | Dynamit Nobel Ag | Plastic profile with hollow metal reinforce - ment |

| DE2021926A1 (en) * | 1970-05-05 | 1971-11-25 | Wilhelm Eller | Barred plastic window profiles |

| DE2258420A1 (en) * | 1972-11-29 | 1974-05-30 | Dynamit Nobel Ag | PLASTIC-WRAPPED METAL HOLLOW PROFILE |

-

1978

- 1978-10-05 DE DE2843437A patent/DE2843437C2/en not_active Expired

-

1979

- 1979-09-06 AT AT79103316T patent/ATE1157T1/en not_active IP Right Cessation

- 1979-09-06 EP EP79103316A patent/EP0010593B2/en not_active Expired

- 1979-09-06 DE DE7979103316T patent/DE2963011D1/en not_active Expired

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024088752A1 (en) * | 2022-10-28 | 2024-05-02 | Vkr Holding A/S | Roof window comprising polymer profiles with metal reinforcement |

| WO2024088754A1 (en) * | 2022-10-28 | 2024-05-02 | Vkr Holding A/S | Roof window comprising polymer profile comprising a skin layer |

| EP4379160A1 (en) * | 2022-11-29 | 2024-06-05 | VKR Holding A/S | Roof window comprising polymer profiles with metal reinforcement |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0010593B1 (en) | 1982-06-02 |

| DE2843437C2 (en) | 1985-05-15 |

| DE2843437A1 (en) | 1980-04-24 |

| EP0010593A1 (en) | 1980-05-14 |

| DE2963011D1 (en) | 1982-07-22 |

| ATE1157T1 (en) | 1982-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0829609B1 (en) | Heat-insulating compound profile for doors, windows or facades | |

| EP1196677B1 (en) | Hollow plastic section | |

| EP2191090B1 (en) | Door or window frame assembly made of extruded plastic and fibre-reinforced coextrudate | |

| EP0153758A2 (en) | Compound bar, in particular for window frames, door frames and roller shutters | |

| DE10116049B4 (en) | Use of a plastic profile and method of making the same | |

| DE29512502U1 (en) | Insulating core for composite profiles, especially for windows, doors and facade constructions | |

| EP0010593B2 (en) | Reinforced profile of synthetic material | |

| EP0674081A2 (en) | Window | |

| DE202007004060U1 (en) | Closing-off device for gap in building has inner frame profile positively coupled to connecting profile which is itself connected to outer frame profile | |

| DE19933099A1 (en) | Hollow plastic profile with embedded metal reinforcement, preferably frame profile for windows or doors | |

| DE2840656A1 (en) | Hollow plastics bar door or window frame - has internally hollow extruded metal sections held together inside plastics at corners by perpendicular screws | |

| EP3670808B1 (en) | Frame assembly for a door or window | |

| EP0215456A1 (en) | Hollow plastic extrusion for door and window frames | |

| DE29880053U1 (en) | Profile system for the production of windows or doors | |

| DE19532125A1 (en) | Thermal insulation between light metal profiles of window frames - using strip with two lips which engage with two webs of frame | |

| DE102005035279A1 (en) | Plastic profile for window frame or doorframe has main void with co-extruded strengthening member supported by struts | |

| DE2919437C2 (en) | ||

| EP2428633B1 (en) | Blind frame profile for door, window or facade structure | |

| DE29912375U1 (en) | Hollow plastic profile with embedded strips or strips of fiber-reinforced plastic, preferably a frame profile for windows or doors | |

| DE102005021934A1 (en) | Plastic frame for door or window has a hollow profile construction with an outer metal section for mechanical support without inner bracing | |

| DE20201670U1 (en) | Multi-chamber profile made of plastic for window frames and / or casements for windows and doors | |

| DE2624788A1 (en) | PROFILES FOR WINDOW AND DOOR FRAMES | |

| EP4102021B1 (en) | Window or door cavity profile, system with such a cavity profile and frame made from same | |

| DE3116716A1 (en) | Composite profile bar for windows, doors and wall and facade structures | |

| DE202005007514U1 (en) | Frame for casement windows or doors has a cladding or glazing, an inner side formed of a plastic base part contains several hollow cavities and an outer side is formed of a metal part |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT NL |

|

| 17P | Request for examination filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19820602 |

|

| REF | Corresponds to: |

Ref document number: 1157 Country of ref document: AT Date of ref document: 19820615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 2963011 Country of ref document: DE Date of ref document: 19820722 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: WILH. FRANK GMBH Effective date: 19820914 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19840905 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840912 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19840927 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19840930 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19850926 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19850930 Year of fee payment: 7 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19860326 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE FR GB IT NL |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19860906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19860930 Ref country code: BE Effective date: 19860930 |

|

| BERE | Be: lapsed |

Owner name: DYNAMIT NOBEL A.G. Effective date: 19860930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19870401 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19870527 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19870602 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881118 |