CN111032284B - 具有增强的共平面性的微复制型抛光表面 - Google Patents

具有增强的共平面性的微复制型抛光表面 Download PDFInfo

- Publication number

- CN111032284B CN111032284B CN201880050836.9A CN201880050836A CN111032284B CN 111032284 B CN111032284 B CN 111032284B CN 201880050836 A CN201880050836 A CN 201880050836A CN 111032284 B CN111032284 B CN 111032284B

- Authority

- CN

- China

- Prior art keywords

- offset

- polishing

- article

- plane

- polishing pad

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

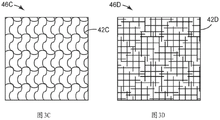

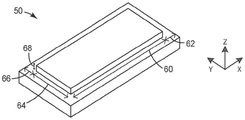

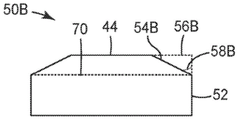

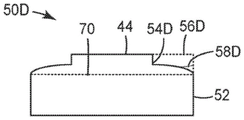

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/12—Lapping plates for working plane surfaces

- B24B37/16—Lapping plates for working plane surfaces characterised by the shape of the lapping plate surface, e.g. grooved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/22—Lapping pads for working plane surfaces characterised by a multi-layered structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/24—Lapping pads for working plane surfaces characterised by the composition or properties of the pad materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D2203/00—Tool surfaces formed with a pattern

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/20—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially organic

- B24D3/28—Resins or natural or synthetic macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/736—Grinding or polishing equipment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/30625—With simultaneous mechanical treatment, e.g. mechanico-chemical polishing

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201762541362P | 2017-08-04 | 2017-08-04 | |

| US62/541,362 | 2017-08-04 | ||

| PCT/IB2018/055815 WO2019026021A1 (en) | 2017-08-04 | 2018-08-02 | MICRO-REPLICATED POLISHING SURFACE WITH IMPROVED COPLANARITY |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111032284A CN111032284A (zh) | 2020-04-17 |

| CN111032284B true CN111032284B (zh) | 2022-11-04 |

Family

ID=65233633

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201880050836.9A Active CN111032284B (zh) | 2017-08-04 | 2018-08-02 | 具有增强的共平面性的微复制型抛光表面 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US12208483B2 (enExample) |

| JP (1) | JP7165719B2 (enExample) |

| KR (1) | KR102608124B1 (enExample) |

| CN (1) | CN111032284B (enExample) |

| TW (1) | TWI803502B (enExample) |

| WO (1) | WO2019026021A1 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11524385B2 (en) * | 2019-06-07 | 2022-12-13 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | CMP polishing pad with lobed protruding structures |

| CN114599482A (zh) * | 2019-11-04 | 2022-06-07 | 3M创新有限公司 | 抛光制品、抛光系统和抛光方法 |

| CN114630726A (zh) * | 2019-11-05 | 2022-06-14 | 3M创新有限公司 | 模制研磨旋转工具 |

| GB2595668B (en) * | 2020-06-02 | 2022-05-25 | Illinois Tool Works | A contact cleaning surface |

| JP7435436B2 (ja) * | 2020-12-24 | 2024-02-21 | 株式会社Sumco | キャリアプレートの研磨方法 |

| CN119927788B (zh) * | 2025-04-08 | 2025-08-01 | 河北同光半导体股份有限公司 | 晶圆的研磨抛光加工方法 |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3211811A (en) | 1964-06-29 | 1965-10-12 | Armorlite Leus Company Inc | Method and apparatus for casting thermosetting plastic lenses |

| US5489233A (en) | 1994-04-08 | 1996-02-06 | Rodel, Inc. | Polishing pads and methods for their use |

| WO1996033839A1 (en) | 1995-04-26 | 1996-10-31 | Minnesota Mining And Manufacturing Company | Method and apparatus for step and repeat exposures |

| US5921855A (en) | 1997-05-15 | 1999-07-13 | Applied Materials, Inc. | Polishing pad having a grooved pattern for use in a chemical mechanical polishing system |

| US6780095B1 (en) * | 1997-12-30 | 2004-08-24 | Micron Technology, Inc. | Method and apparatus for mechanical and chemical-mechanical planarization of microelectronic substrates |

| FR2786118B1 (fr) * | 1998-11-19 | 2000-12-22 | Lam Plan Sa | Dispositif de rodage ou polissage |

| JP2000158327A (ja) * | 1998-12-02 | 2000-06-13 | Rohm Co Ltd | 化学的機械的研磨用研磨布およびそれを用いた化学的機械的研磨装置 |

| TW467802B (en) * | 1999-10-12 | 2001-12-11 | Hunatech Co Ltd | Conditioner for polishing pad and method for manufacturing the same |

| US6776699B2 (en) * | 2000-08-14 | 2004-08-17 | 3M Innovative Properties Company | Abrasive pad for CMP |

| US7160178B2 (en) | 2003-08-07 | 2007-01-09 | 3M Innovative Properties Company | In situ activation of a three-dimensional fixed abrasive article |

| US7048615B2 (en) | 2004-08-05 | 2006-05-23 | United Microelectronics Corp. | Pad backer and CMP process using the same |

| US7169029B2 (en) * | 2004-12-16 | 2007-01-30 | 3M Innovative Properties Company | Resilient structured sanding article |

| US7261625B2 (en) | 2005-02-07 | 2007-08-28 | Inoac Corporation | Polishing pad |

| US20070128991A1 (en) * | 2005-12-07 | 2007-06-07 | Yoon Il-Young | Fixed abrasive polishing pad, method of preparing the same, and chemical mechanical polishing apparatus including the same |

| US7226345B1 (en) * | 2005-12-09 | 2007-06-05 | The Regents Of The University Of California | CMP pad with designed surface features |

| US7410413B2 (en) * | 2006-04-27 | 2008-08-12 | 3M Innovative Properties Company | Structured abrasive article and method of making and using the same |

| US7828634B2 (en) * | 2007-08-16 | 2010-11-09 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Interconnected-multi-element-lattice polishing pad |

| WO2009032815A1 (en) | 2007-09-06 | 2009-03-12 | 3M Innovative Properties Company | Tool for making microstructured articles |

| US20100188751A1 (en) | 2009-01-29 | 2010-07-29 | 3M Innovative Properties Company | Optical films with internally conformable layers and method of making the films |

| US8425278B2 (en) * | 2009-08-26 | 2013-04-23 | 3M Innovative Properties Company | Structured abrasive article and method of using the same |

| CN102686362A (zh) * | 2009-12-30 | 2012-09-19 | 3M创新有限公司 | 包括分相共混聚合物的抛光垫及其制备和使用方法 |

| JP5516051B2 (ja) | 2010-05-13 | 2014-06-11 | 旭硝子株式会社 | 研磨パッドを用いた研磨装置及びガラス板の製造方法 |

| KR101161015B1 (ko) * | 2010-09-10 | 2012-07-02 | 신한다이아몬드공업 주식회사 | Cmp 패드 컨디셔너 및 그 제조방법 |

| WO2012102978A1 (en) | 2011-01-26 | 2012-08-02 | 3M Innovative Properties Company | Abrasive article with replicated microstructured backing and method of using same |

| CN103688343B (zh) * | 2011-03-07 | 2016-09-07 | 恩特格里公司 | 化学机械抛光垫修整器 |

| JP5923353B2 (ja) | 2012-03-21 | 2016-05-24 | 富士紡ホールディングス株式会社 | 研磨パッド用シート及びその製造方法、研磨パッド及びその製造方法、並びに研磨方法 |

| JP6188286B2 (ja) * | 2012-07-13 | 2017-08-30 | スリーエム イノベイティブ プロパティズ カンパニー | 研磨パッド及びガラス、セラミックス、及び金属材料の研磨方法 |

| US9649742B2 (en) * | 2013-01-22 | 2017-05-16 | Nexplanar Corporation | Polishing pad having polishing surface with continuous protrusions |

| US10160092B2 (en) * | 2013-03-14 | 2018-12-25 | Cabot Microelectronics Corporation | Polishing pad having polishing surface with continuous protrusions having tapered sidewalls |

| EP3049215B1 (en) | 2013-09-25 | 2021-04-14 | 3M Innovative Properties Company | Composite ceramic abrasive polishing solution |

| KR102252673B1 (ko) | 2013-09-25 | 2021-05-18 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 다층화된 폴리싱 패드 |

| KR102347711B1 (ko) | 2014-04-03 | 2022-01-06 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 폴리싱 패드 및 시스템과 이의 제조 및 사용 방법 |

| CN204277743U (zh) | 2014-10-29 | 2015-04-22 | 安阳方圆研磨材料有限责任公司 | 硬质抛光垫 |

| JP6789982B2 (ja) | 2015-05-13 | 2020-11-25 | スリーエム イノベイティブ プロパティズ カンパニー | 研磨パッド、並びに当該研磨パッドを使用するためのシステム及び方法 |

| TWI769988B (zh) * | 2015-10-07 | 2022-07-11 | 美商3M新設資產公司 | 拋光墊與系統及其製造與使用方法 |

-

2018

- 2018-08-02 WO PCT/IB2018/055815 patent/WO2019026021A1/en not_active Ceased

- 2018-08-02 JP JP2020505906A patent/JP7165719B2/ja active Active

- 2018-08-02 US US16/636,348 patent/US12208483B2/en active Active

- 2018-08-02 CN CN201880050836.9A patent/CN111032284B/zh active Active

- 2018-08-02 KR KR1020207004255A patent/KR102608124B1/ko active Active

- 2018-08-03 TW TW107127051A patent/TWI803502B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2019026021A1 (en) | 2019-02-07 |

| TW201910056A (zh) | 2019-03-16 |

| TWI803502B (zh) | 2023-06-01 |

| KR102608124B1 (ko) | 2023-11-29 |

| US20200164484A1 (en) | 2020-05-28 |

| JP2020529332A (ja) | 2020-10-08 |

| JP7165719B2 (ja) | 2022-11-04 |

| US12208483B2 (en) | 2025-01-28 |

| KR20200037269A (ko) | 2020-04-08 |

| CN111032284A (zh) | 2020-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111032284B (zh) | 具有增强的共平面性的微复制型抛光表面 | |

| TWI699257B (zh) | 拋光墊及使用該拋光墊之系統及方法 | |

| TWI769988B (zh) | 拋光墊與系統及其製造與使用方法 | |

| CN105517758B (zh) | 复合陶瓷研磨抛光液 | |

| JP3829092B2 (ja) | 研磨パッド用コンディショナーおよびその製造方法 | |

| EP2845221B1 (en) | Cmp conditioner pads with superabrasive grit enhancement | |

| US20070249270A1 (en) | Superhard cutters and associated methods | |

| WO2001026862A1 (en) | Conditioner for polishing pad and method for manufacturing the same | |

| US20100221988A1 (en) | Superhard Cutters and Associated Methods | |

| US20190091832A1 (en) | Composite conditioner and associated methods | |

| KR20170039221A (ko) | 폴리싱 용액 및 그의 사용 방법 | |

| JP2004082323A (ja) | 研磨具およびその製造方法 | |

| US10926378B2 (en) | Abrasive coated disk islands using magnetic font sheet | |

| JP7273796B2 (ja) | 表面突起研磨パッド | |

| KR20090014530A (ko) | 반도체 웨이퍼 폴리싱장치의 패드콘디셔너 및 그 패드콘디셔너 제조방법 | |

| TWI383860B (zh) | Modular dresser | |

| CN110871407A (zh) | 抛光垫修整器及化学机械平坦化的方法 | |

| TW201127554A (en) | Resin bonding pad conditioner with surface recessed pattern and manufacture method thereof | |

| KR200188920Y1 (ko) | 연마패드용 컨디셔너 | |

| Sung et al. | PCD pad conditioners for low pressure chemical mechanical planarisation of semiconductors | |

| JP2005297165A (ja) | 研磨具およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |