CN110999871B - Cage is bred in migratory locust experiment - Google Patents

Cage is bred in migratory locust experiment Download PDFInfo

- Publication number

- CN110999871B CN110999871B CN201911385715.2A CN201911385715A CN110999871B CN 110999871 B CN110999871 B CN 110999871B CN 201911385715 A CN201911385715 A CN 201911385715A CN 110999871 B CN110999871 B CN 110999871B

- Authority

- CN

- China

- Prior art keywords

- plate

- cage

- experimental

- cage body

- automatic feeding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; CARE OF BIRDS, FISHES, INSECTS; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K67/00—Rearing or breeding animals, not otherwise provided for; New breeds of animals

- A01K67/033—Rearing or breeding invertebrates; New breeds of invertebrates

Abstract

The invention belongs to the technical field of pest biological control research equipment, and particularly relates to a migratory locust experimental culture cage. Including the cage body frame, the cage body and automatic feeding device, the cage body realizes the assembly through the shaft hole on the connecting plate and the fixed axle cooperation on the support, fixed plate and feedbox hoist and mount in the automatic feeding device are on the roof, and the lid of feedbox is located the feed inlet department on the roof. The automatic feeding device adopts the rotating wheel to drive the puncture needle to rotate so as to take the fodder, after the migratory locust eats the fodder, the light of the signal lamp is received by the photoelectric sensor, and then the motor is controlled to rotate so as to feed, thereby realizing automatic feeding and solving the problem that the quantity of the fodder fed manually in the prior art is not easy to control.

Description

Technical Field

The invention belongs to the technical field of pest biological control research equipment, and particularly relates to a migratory locust experimental culture cage.

Background

Migratory locusts are important agricultural pests in the world, are widely distributed in Asia, Africa, oceania and European vast areas, and are widely harmful to gramineous food crops such as corns, sorghum, rice and the like. The large-scale artificial cultivation of the migratory locust is an important basis for systematically researching the physiological characteristics of the migratory locust and scientifically preventing and treating the migratory locust. The migratory locust breeding cage is key equipment for artificial migratory locust breeding. The locusts grow from one year to one adult, daily food consumption is increased continuously, the addition of feed needs to be estimated by culture personnel in the existing culture cage, if the feed added at one time is less, after the locusts eat the feed, hungry locusts can be forced to eat locusts with slow movement or smaller body type, so that loss is caused, if the feed added at one time is more, the locusts can not eat any more after fresh feed is evaporated and dehydrated because the air temperature in the culture cage is higher, so that feed waste and fresh feed shortage are caused.

Disclosure of Invention

The invention provides a migratory locust experimental culture cage aiming at the problems.

In order to achieve the purpose, the invention adopts the following technical scheme:

an experimental locusta migratoria culture cage comprises a cage body frame, a cage body and an automatic feeding device;

the cage body frame comprises a base and a support, the support is in a shape of Jiong, the support is fixedly arranged on the base, fixing shafts which are bilaterally symmetrical are arranged on the inner side of the support, the top of the support is connected with a plurality of illuminating lamps through metal hoses and used for irradiating the cage body in an omnibearing manner, and the illuminating lamps are also electrically connected with a timing controller so as to automatically control the irradiation time;

the cage body comprises a bottom plate, a top plate, upright posts, a connecting plate and a separation net, wherein the bottom plate and the top plate are transparent plates, the upright posts and the connecting plate are arranged between the bottom plate and the top plate and are used for connecting the bottom plate and the top plate, the connecting plate is arranged in the middle of the left side and the right side of the bottom plate and the top plate, the bottom plate, the top plate, the upright posts and the connecting plate form a frame of the cage body, the separation net is wrapped around the frame to form a closed cage body, a shaft hole is formed in the middle of the connecting plate, a feed inlet is formed in the top plate, an operating hole is formed in the top plate, a waste material hole is formed in each of the front portion and the rear portion of the bottom plate, a closed curtain is arranged in each of the operating hole and the waste material hole, a binding rope is arranged on the closed curtain and is used for binding the closed curtain, a sawtooth body perpendicular, a vibration motor is fixedly arranged on the frame;

the automatic feeding device comprises a feedbox, two fixed plates, a rotating wheel and a rotating shaft, wherein an opening is formed below the feedbox, the upper half part of the feedbox is reserved close to the side wall of the rotating wheel, a cover body is hinged above the feedbox, the rotating wheel is installed at the lower parts of the two fixed plates through the rotating shaft, a plurality of puncture needles are uniformly arranged on the rotating wheel and used for puncturing feed blocks in the feedbox, mounting plates are arranged on the outer sides of the two fixed plates, a motor is arranged on one of the mounting plates, an output shaft of the motor is connected with the rotating shaft, connecting rods are arranged on the two mounting plates, and a signal lamp and a photoelectric sensor are arranged on the two connecting rods respectively;

the cage body is matched with a fixed shaft on the support through a shaft hole on the connecting plate to realize assembly, the fixed plate and the feed box in the automatic feeding device are hoisted on the top plate, and the cover body of the feed box is positioned at the feed inlet on the top plate.

Furthermore, still be provided with the climbing net on the bottom plate, and climb the net and be parallel with the connecting plate.

Still further, the light includes incandescent lamp and ultraviolet light filling lamp, incandescent lamp is used for the illumination, and ultraviolet light filling lamp is used for supplementing the ultraviolet ray, simulates the sunshine disinfection, reduces the pathogenic microorganism level in the environment, prevents migratory locust crowd disease and spreads.

Still further, be provided with the mounting groove on roof and the connecting plate be provided with the screening plate in the mounting groove, just the screening plate is located the place ahead of the sawtooth body, one side on right angle triangular prism inclined plane in the sawtooth body promptly be provided with the silica gel sealing pad in the mounting groove to seal the mounting groove when the screening plate is extracted, prevent that the migratory locust from escaping.

Furthermore, corresponding positioning holes are formed in the support and the connecting plate, and positioning columns are movably arranged in the positioning holes.

Furthermore, the automatic feeding device also comprises a residual material removing plate which is arc-shaped and is connected to the two fixing plates through a fixing rod, the lower end of the residual material removing plate is positioned below the rotating wheel and close to the root of the puncture needle, the upper end of the residual material removing plate exceeds the rotating outer diameter of the puncture needle, and a channel which can be just passed by the puncture needle is arranged on the residual material removing plate.

Furthermore, a semiconductor refrigeration sheet and a temperature sensor are arranged in the feed box and used for maintaining the humidity in the feed box and keeping the freshness of the feed.

Furthermore, elastic bands are arranged on the closed curtain in the circumferential direction so as to prevent locusts from escaping when hands of people stretch into the cage body.

Still further, the inclined plane of right angle triangular prism is rough surface in the sawtooth body to make things convenient for migratory locust to scramble, the vertical face of right angle triangular prism is smooth surface in the sawtooth body, in order to prevent migratory locust to scramble.

Furthermore, the separation net is a hard metal net with the separation net of 30-80 meshes, and the screening plate is a hard metal net with the pore diameter of 3-10 mm.

Compared with the prior art, the invention has the following advantages:

1. the automatic feeding device adopts the rotating wheel to drive the puncture needle to rotate so as to take the fodder, after the migratory locust eats the fodder, the light of the signal lamp is received by the photoelectric sensor, and then the motor is controlled to rotate so as to feed, thereby realizing automatic feeding and solving the problem that the quantity of the fodder fed manually in the prior art is not easy to control.

2. The climbing net arranged in the invention can increase the moving area of the migratory locust and avoid the mass accumulation of the migratory locust;

3. the invention is provided with the screening plate which can screen and distinguish large and small locusts in the later period.

Drawings

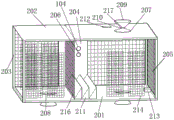

FIG. 1 is a schematic structural view of the present invention;

FIG. 2 is a schematic structural view of the cage of the present invention;

FIG. 3 is a schematic structural view of the cage of the present invention;

FIG. 4 is a schematic view of the mounting structure of the cage and the automatic feeding device of the present invention;

FIG. 5 is a schematic view of the automatic feeding apparatus of the present invention;

FIG. 6 is a schematic view of the automatic feeding apparatus of the present invention;

the automatic feeding device comprises a cage frame-1, a cage body-2, an automatic feeding device-3, a base-101, a support-102, a fixed shaft-103, a positioning hole-104, a positioning column-105, a metal hose-106, an illuminating lamp-107, a bottom plate-201, a top plate-202, a stand column-203, a connecting plate-204, an isolation net-205, a shaft hole-206, an operation hole-207, a waste hole-208, a closed curtain-209, a binding rope-210, a sawtooth body-211, a feed inlet-212, a vibrating motor-213, a climbing net-214, a mounting groove-215, a screening plate-216, an elastic band-217, a feed box-301, two fixing plates-302, a rotating wheel-303, a rotating shaft-304, a puncture needle-305, a feed block-306, a cover body-307, a mounting plate-308, a motor-309, a connecting rod-310, a signal lamp-311, a photoelectric sensor-312, a residual material removing plate-313.

Detailed Description

In order to further illustrate the technical solution of the present invention, the present invention is further illustrated with reference to the following examples.

As shown in fig. 1 to 6, the experimental locusts migratorius cultivation cage comprises a cage body frame 1, a cage body 2 and an automatic feeding device 3;

the cage body frame 1 comprises a base 101 and a support 102, the support 102 is in a shape of Jiong, the support 102 is fixedly arranged on the base 101, fixing shafts 103 which are bilaterally symmetrical are arranged on the inner side of the support 102, the top of the support 102 is connected with a plurality of illuminating lamps 107 through metal hoses 106 and used for irradiating the cage body 2 in an omnibearing manner, and the illuminating lamps 107 are also electrically connected with a timing controller so as to automatically control the irradiation time; the illuminating lamp 107 comprises an incandescent lamp and an ultraviolet light supplement lamp, the incandescent lamp is used for illuminating, the ultraviolet light supplement lamp is used for supplementing ultraviolet rays, the sterilization effect of sunlight is simulated, the level of pathogenic microorganisms in the environment is reduced, and the disease spreading of locusta migratoria population is prevented.

The cage body 2 comprises a bottom plate 201, a top plate 202, upright posts 203, connecting plates 204 and isolating nets 205, wherein the upright posts 203 and the connecting plates 204 are arranged between the bottom plate 201 and the top plate 202 and are used for connecting the bottom plate 201 and the top plate 202, the connecting plates 204 are arranged in the middles of the left side and the right side of the bottom plate 201 and the top plate 202, the bottom plate 201, the top plate 202, the upright posts 203 and the connecting plates 204 form a frame of the cage body 2, the isolating nets 205 are wrapped around the frame to form the closed cage body 2, the isolating nets 205 are hard metal nets with 30-80 meshes, shaft holes 206 are arranged in the middles of the connecting plates 204, feed ports 212 are arranged on the top plate 202, operation holes 207 are arranged on the top plate 202, waste holes 208 are respectively arranged at the front part and the rear part of the bottom plate 201, and closed curtains 209 are arranged at the operation holes 207 and the waste holes 208, a binding rope 210 is arranged on the closed curtain 209 and is used for binding the closed curtain 209, and an elastic band 217 is circumferentially arranged on the closed curtain 209 so as to prevent locusts from escaping when human hands extend into the cage body 2. Bottom plate 201 middle part is provided with the sawtooth body 211 of perpendicular to connecting plate 204, the sawtooth body 211 is arranged by a plurality of right angle triangular prism and constitutes, the inclined plane of right angle triangular prism is rough surface in the sawtooth body 211 to make things convenient for migratory locust to climb, the vertical face of right angle triangular prism is smooth surface in the sawtooth body 211, in order to prevent migratory locust to climb. The bottom plate 201 is further provided with a climbing net 214, and the climbing net 214 is parallel to the connecting plate 204. A vibration motor 213 is fixedly arranged on the frame; the top plate 202 and the connecting plate 204 are provided with mounting grooves 215, a screening plate 216 is arranged in the mounting grooves 215, the screening plate 216 is positioned in front of the sawtooth body 211, and the screening plate 216 is a hard metal mesh with the aperture of 3 mm-10 mm. A silica gel sealing gasket is arranged in the mounting groove 215 to seal the mounting groove 215 when the screening plate 216 is pulled out, so that locusts can be prevented from escaping.

The automatic feeding device 3 comprises a feedbox 301, two fixing plates 302, a rotating wheel 303, a rotating shaft 304 and a residual material removing plate 313, wherein the feedbox 301 is provided with an opening at the lower part, the feedbox 301 keeps the upper half part close to the side wall of the rotating wheel 303, a cover 307 is hinged at the upper part of the feedbox 301, the rotating wheel 303 is arranged at the lower part of the two fixing plates 302 through the rotating shaft 304, a plurality of puncture needles 305 are uniformly arranged on the rotating wheel 303 and used for puncturing the feedbacks 306 in the feedbox 301, the feedbacks 306 are radish blocks, grass blocks and the like, the puncture needles 305 are also provided with branches to more stably fix the feedbacks 306, mounting plates 308 are arranged at the outer sides of the two fixing plates 302, a motor 309 is arranged on one mounting plate 308, the output shaft of the motor 309 is connected with the rotating shaft 304, connecting rods 310 are arranged on the two mounting plates 308, the two connecting rods 310 are respectively provided with a signal lamp 311 and a photoelectric sensor 312; the residual material removing plate 313 is arc-shaped and is respectively connected to the two fixing plates 302 through two fixing rods 314, the lower end of the residual material removing plate is positioned below the rotating wheel 303 and close to the root of the puncture needle 305, the upper end of the residual material removing plate exceeds the rotating outer diameter of the puncture needle 305, and a channel 315 through which the puncture needle 305 can just pass is arranged on the residual material removing plate 313. A semiconductor refrigeration sheet and a temperature sensor are arranged in the feed box 301 and used for maintaining the humidity in the feed box 301 and keeping the freshness of feed.

The cage body 2 is assembled by matching the shaft hole 206 on the connecting plate 204 with the fixed shaft 103 on the bracket 102, the two fixed plates 302 and the feed box 301 in the automatic feeding device 3 are hung on the top plate 202, and the cover 307 of the feed box 301 is positioned at the feed port 212 on the top plate 202. The bracket 102 and the connecting plate 204 are provided with corresponding positioning holes 104, and positioning columns 105 are movably arranged in the positioning holes 104.

The working principle is as follows: the cultivated migratory locust is put into the cage body 2 and fed by the automatic feeding device 3, when the feed block 306 on the puncture needle 305 at the lowest part is eaten by the migratory locust, the photoelectric sensor 312 senses the signal on the signal lamp 311 under the condition that the feed block 306 does not block, thereby controlling the motor 309 to rotate clockwise for a fixed angle, the puncture needles 305 evenly arranged on the rotating wheel 303 are enabled to orderly carry out the circulation of material taking and feeding, the residual material removing plate 313 is used for removing the residual old forage on the puncture needle 305 to prevent the influence on the next material taking, the semiconductor refrigeration sheet in the feedbox 301 carries out power output adjustment according to the temperature sensed by the temperature sensor to keep the forage in the feedbox 301 fresh, the migratory locust is evenly distributed in the cage body 2 by adopting omnibearing light irradiation, when the residual forage and the migratory locust in the cage body 2 need to be cleaned, the positioning column 105 is pulled out, rotating the cage body 2 and vibrating by adopting a vibrating motor 213 to make migratory locust fall in a false manner, gathering all migratory locust to one side of the inclined plane of the sawtooth body 211, turning the cage body 2 forward, rotating the illuminating lamp 107 to one side of the vertical plane of the sawtooth body 211, waiting for a period of time, removing the false death state of living migratory locust, climbing from the inclined plane of the sawtooth body 211 to the vertical plane of the sawtooth body 211 under the luring of light and food, because the vertical plane of the sawtooth body is a smooth plane, migratory locust is difficult to climb vertically and turn over reversely, so that the movement behavior of migratory locust can be restricted, thereby forming one-way passing, after all migratory locust go, opening the waste hole 208 on one side of the inclined plane of the sawtooth body 211 to clean up dead migratory locust and other waste in the cage body 2, after the migratory locust grows up, vibrating all migratory locust to the inclined plane side of the sawtooth body 211 by adopting the method, inserting the screening plate 216, the locusts are attracted by light and food, but due to the existence of the screening plate 216, only locusts with small body shapes can pass through the screening plate 216, and locusts with large body shapes cannot pass through the screening plate 216, so that the screening of locusts with different body shapes is realized.

While there have been shown and described what are at present considered to be the essential features and advantages of the invention, it will be apparent to those skilled in the art that the invention is not limited to the details of the foregoing exemplary embodiments, but is capable of other specific forms without departing from the spirit or essential characteristics thereof. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein.

Furthermore, it should be understood that although the present description refers to embodiments, not every embodiment may contain only a single embodiment, and such description is for clarity only, and those skilled in the art should integrate the description, and the embodiments may be combined as appropriate to form other embodiments understood by those skilled in the art.

Claims (10)

1. The utility model provides a cage is bred in migratory locust experiment which characterized in that: comprises a cage body frame (1), a cage body (2) and an automatic feeding device (3);

the cage body frame (1) comprises a base (101) and a support (102), the support (102) is in the shape of Jiong, the support (102) is fixedly arranged on the base (101), fixing shafts (103) which are bilaterally symmetrical are arranged on the inner side of the support (102), the top of the support (102) is connected with a plurality of illuminating lamps (107) through metal hoses (106) and used for irradiating the cage body (2) in an omnibearing manner, and the illuminating lamps (107) are also electrically connected with a timing controller so as to automatically control the irradiation time;

the cage body (2) comprises a bottom plate (201), a top plate (202), upright posts (203), connecting plates (204) and isolating nets (205), wherein the upright posts (203) and the connecting plates (204) are arranged between the bottom plate (201) and the top plate (202) and are used for connecting the bottom plate (201) and the top plate (202), the connecting plates (204) are arranged in the middle parts of the left side and the right side of the bottom plate (201) and the top plate (202), the bottom plate (201), the top plate (202), the upright posts (203) and the connecting plates (204) form a frame of the cage body (2), the isolating nets (205) are wrapped around the frame to form a closed cage body (2), shaft holes (206) are arranged in the middle parts of the connecting plates (204), a feeding hole (212) is arranged on the top plate (202), an operating hole (207) is arranged on the top plate (202), and waste material holes (208) are respectively arranged at the front part and the rear part of the bottom, closed curtains (209) are arranged at the operating hole (207) and the waste material hole (208), binding ropes (210) are arranged on the closed curtains (209) and used for binding the closed curtains (209), a sawtooth body (211) perpendicular to the connecting plate (204) is arranged in the middle of the bottom plate (201), the sawtooth body (211) is formed by arranging a plurality of right-angle triangular prisms, and a vibration motor (213) is fixedly arranged on the frame;

the automatic feeding device (3) comprises a feedbox (301), two fixing plates (302), a rotating wheel (303) and a rotating shaft (304), wherein the feedbox (301) is provided with an opening at the lower part, the side wall of the feedbox (301) close to the rotating wheel (303) keeps the upper half part, a cover body (307) is hinged above the feedbox (301), the rotating wheel (303) is arranged at the lower part of the two fixing plates (302) through the rotating shaft (304), a plurality of puncture needles (305) are uniformly arranged on the rotating wheel (303) and used for puncturing feedblocks (306) in the feedbox (301), mounting plates (308) are arranged at the outer sides of the two fixing plates (302), a motor (309) is arranged on one mounting plate (308), the output shaft of the motor (309) is connected with the rotating shaft (304), connecting rods (310) are arranged on the two mounting plates (308), the two connecting rods (310) are respectively provided with a signal lamp (311) and a photoelectric sensor (312);

the cage body (2) is matched with a fixed shaft (103) on the support (102) through a shaft hole (206) on the connecting plate (204) to realize assembly, two fixed plates (302) and a feed box (301) in the automatic feeding device (3) are hung on the top plate (202), and a cover body (307) of the feed box (301) is positioned at a feed port (212) on the top plate (202).

2. The experimental locusta migratoria culture cage according to claim 1, characterized in that: the bottom plate (201) is further provided with a climbing net (214), and the climbing net (214) is parallel to the connecting plate (204).

3. The experimental locusta migratoria culture cage according to claim 1, characterized in that: the illuminating lamp (107) comprises an incandescent lamp and an ultraviolet light supplement lamp, the incandescent lamp is used for illuminating, the ultraviolet light supplement lamp is used for supplementing ultraviolet light, the sterilizing effect of sunlight is simulated, the level of pathogenic microorganisms in the environment is reduced, and the disease spreading of locusta migratoria population is prevented.

4. The experimental locusta migratoria culture cage according to claim 1, characterized in that: be provided with mounting groove (215) on roof (202) and connecting plate (204) be provided with screening plate (216) in mounting groove (215), just screening plate (216) are located the place ahead of sawtooth body (211) be provided with the silica gel sealed pad in mounting groove (215) to seal mounting groove (215) when screening plate (216) are extracted, prevent that the migratory locust from escaping.

5. The experimental locusta migratoria culture cage according to claim 1, characterized in that: corresponding positioning holes (104) are formed in the support (102) and the connecting plate (204), and positioning columns (105) are movably arranged in the positioning holes (104).

6. The experimental locusta migratoria culture cage according to claim 1, characterized in that: the automatic feeding device (3) further comprises a residual material removing plate (313), the residual material removing plate (313) is arc-shaped and is connected to the two fixing plates (302) through a fixing rod (314), the lower end of the residual material removing plate is located below the rotating wheel (303) and close to the root of the puncture needle, the upper end of the residual material removing plate exceeds the rotating outer diameter of the puncture needle (305), and a channel (315) through which the puncture needle (305) can just pass is formed in the residual material removing plate (313).

7. The experimental locusta migratoria culture cage of claim 6, wherein: the semiconductor refrigeration piece and the temperature sensor are arranged in the feed box (301) and used for maintaining the humidity in the feed box (301) and keeping the freshness of feed.

8. The experimental locusta migratoria culture cage according to claim 1, characterized in that: elastic bands (217) are circumferentially arranged on the closed curtain (209) to prevent locusts from escaping when hands of people extend into the cage body (2).

9. The experimental locusta migratoria culture cage according to claim 1, characterized in that: the inclined plane of right angle triangular prism is rough surface in sawtooth body (211) to make things convenient for migratory locust to climb, the vertical face of right angle triangular prism is smooth surface in sawtooth body (211), in order to prevent migratory locust to climb.

10. The experimental locusta migratoria culture cage of claim 4, wherein: the separation net (205) is a hard metal net with 30-80 meshes, and the screening plate (216) is a hard metal net with the aperture of 3-10 mm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911385715.2A CN110999871B (en) | 2019-12-29 | 2019-12-29 | Cage is bred in migratory locust experiment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911385715.2A CN110999871B (en) | 2019-12-29 | 2019-12-29 | Cage is bred in migratory locust experiment |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN110999871A CN110999871A (en) | 2020-04-14 |

| CN110999871B true CN110999871B (en) | 2020-12-25 |

Family

ID=70119324

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201911385715.2A Active CN110999871B (en) | 2019-12-29 | 2019-12-29 | Cage is bred in migratory locust experiment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN110999871B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114698596A (en) * | 2021-12-27 | 2022-07-05 | 山东农业工程学院 | Escape-preventing method for locusta migratoria culture |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201718334U (en) * | 2010-08-13 | 2011-01-26 | 重庆大学 | Device for cultivating Asiatic migratory locusts |

| CN202310910U (en) * | 2011-12-03 | 2012-07-11 | 黑龙江八一农垦大学 | Indoor grasshopper raising cage |

| CN102669001A (en) * | 2012-05-11 | 2012-09-19 | 倪建伟 | Automatic pet feeder |

| CN202722239U (en) * | 2012-08-08 | 2013-02-13 | 孙跃国 | Environment-friendly net cage |

| CN103858784A (en) * | 2012-12-17 | 2014-06-18 | 梁达先 | Automatic livestock feed distribution system |

| DE102014018936B3 (en) * | 2014-12-22 | 2015-12-31 | Speetect GmbH | Detection of toxic substances and radiation by means of a "Drosophila Oximeter" |

| CN204949033U (en) * | 2015-05-31 | 2016-01-13 | 侯春光 | Pig device of feeding based on photoelectric encoder and photoelectricity response |

| CN205547042U (en) * | 2016-04-16 | 2016-09-07 | 李国女 | Case feeding device is raised to locust |

| CN205694905U (en) * | 2016-05-04 | 2016-11-23 | 张育棣 | Plant's unmanned automatic feeding intelligence system |

| KR20170138769A (en) * | 2016-06-08 | 2017-12-18 | 대한민국(농촌진흥청장) | Artificial breeding method of Locusta migratoria |

| CN207626339U (en) * | 2017-12-25 | 2018-07-20 | 哈尔滨市一舍科技有限公司 | A kind of feeder based on panorama |

| CN208402957U (en) * | 2018-07-10 | 2019-01-22 | 南京林业大学 | A kind of interior locust rearging cage |

| CN109757392A (en) * | 2019-03-13 | 2019-05-17 | 杜书增 | A kind of cattle feed raising supply system and working method |

| CN110521673A (en) * | 2019-08-09 | 2019-12-03 | 张昕然 | A kind of locust breeding automatic intelligent incubator |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016005296A1 (en) * | 2014-07-05 | 2016-01-14 | Unger Katharina | System and method for breeding and harvesting insects |

-

2019

- 2019-12-29 CN CN201911385715.2A patent/CN110999871B/en active Active

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201718334U (en) * | 2010-08-13 | 2011-01-26 | 重庆大学 | Device for cultivating Asiatic migratory locusts |

| CN202310910U (en) * | 2011-12-03 | 2012-07-11 | 黑龙江八一农垦大学 | Indoor grasshopper raising cage |

| CN102669001A (en) * | 2012-05-11 | 2012-09-19 | 倪建伟 | Automatic pet feeder |

| CN202722239U (en) * | 2012-08-08 | 2013-02-13 | 孙跃国 | Environment-friendly net cage |

| CN103858784A (en) * | 2012-12-17 | 2014-06-18 | 梁达先 | Automatic livestock feed distribution system |

| DE102014018936B3 (en) * | 2014-12-22 | 2015-12-31 | Speetect GmbH | Detection of toxic substances and radiation by means of a "Drosophila Oximeter" |

| CN204949033U (en) * | 2015-05-31 | 2016-01-13 | 侯春光 | Pig device of feeding based on photoelectric encoder and photoelectricity response |

| CN205547042U (en) * | 2016-04-16 | 2016-09-07 | 李国女 | Case feeding device is raised to locust |

| CN205694905U (en) * | 2016-05-04 | 2016-11-23 | 张育棣 | Plant's unmanned automatic feeding intelligence system |

| KR20170138769A (en) * | 2016-06-08 | 2017-12-18 | 대한민국(농촌진흥청장) | Artificial breeding method of Locusta migratoria |

| CN207626339U (en) * | 2017-12-25 | 2018-07-20 | 哈尔滨市一舍科技有限公司 | A kind of feeder based on panorama |

| CN208402957U (en) * | 2018-07-10 | 2019-01-22 | 南京林业大学 | A kind of interior locust rearging cage |

| CN109757392A (en) * | 2019-03-13 | 2019-05-17 | 杜书增 | A kind of cattle feed raising supply system and working method |

| CN110521673A (en) * | 2019-08-09 | 2019-12-03 | 张昕然 | A kind of locust breeding automatic intelligent incubator |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110999871A (en) | 2020-04-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203897070U (en) | Indoor prodenia litura larva raising device | |

| CN203775946U (en) | Three-dimensional individualbreeding scientific research and teaching system for shrimp and crab class aquatic animals | |

| CN105557641A (en) | Method and device for collecting and conserving habrobracon hebetor | |

| CN110999871B (en) | Cage is bred in migratory locust experiment | |

| KR101594950B1 (en) | Mass culture and seeding apparatus for free-living gametophyte of Brown seaweed | |

| CN106857414A (en) | The mass rearing method of prodenia litura | |

| CN211607961U (en) | Photovoltaic formula pest removing equipment for farming | |

| CN108012995A (en) | A kind of indoor feeding method and device of green wing thin,tough silk open country snout moth's larva | |

| CN205213688U (en) | Low -cost high -quality seed case that educates | |

| CN204540438U (en) | A kind of worm breeding box of living | |

| CN206498811U (en) | Environment-friendly multifunctional insecticidal lamp | |

| CN211091389U (en) | Sturgeon fry running water culture pond | |

| CN1196402C (en) | Production technique of fast-production regeneration animal protein 'fly larva protein' | |

| CN105393986B (en) | A method of the parasitic wasp of release Chilo spp larvae | |

| CN210929209U (en) | Simulation artificial climate room structure is bred to lugworm stinkbug | |

| CN212728205U (en) | Vegetable production is with device of growing seedlings | |

| CN210275472U (en) | Novel rat scientific research rearging cage | |

| CN107711308A (en) | A kind of edible mushroom culture apparatus | |

| CN210840795U (en) | Cultivation device is used in prevention and cure of ugly mandarin orange pest | |

| CN107853253B (en) | Indoor circulating breeding device and method for macrobrachium giganteum | |

| CN218007776U (en) | Device of raising of tea seed weevil adult | |

| CN201967554U (en) | Trap type fly catcher | |

| CN211581261U (en) | Cage is bred to locust | |

| CN205946976U (en) | Multifunctional insect -killing lamp | |

| CN206101072U (en) | Greenhouse |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |