CN1009548B - 在浮法制玻璃成型操作中冷却的方法和装置 - Google Patents

在浮法制玻璃成型操作中冷却的方法和装置Info

- Publication number

- CN1009548B CN1009548B CN87105974.6A CN87105974A CN1009548B CN 1009548 B CN1009548 B CN 1009548B CN 87105974 A CN87105974 A CN 87105974A CN 1009548 B CN1009548 B CN 1009548B

- Authority

- CN

- China

- Prior art keywords

- molten metal

- pool

- glass

- refrigerant

- conduit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 24

- 238000000034 method Methods 0.000 title claims description 15

- 239000005329 float glass Substances 0.000 title abstract description 8

- 238000007496 glass forming Methods 0.000 title abstract description 6

- 239000002184 metal Substances 0.000 claims abstract description 51

- 229910052751 metal Inorganic materials 0.000 claims abstract description 51

- 239000011521 glass Substances 0.000 claims abstract description 35

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 26

- 239000003507 refrigerant Substances 0.000 claims description 18

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 7

- 229910002804 graphite Inorganic materials 0.000 claims description 7

- 239000010439 graphite Substances 0.000 claims description 7

- 239000000203 mixture Substances 0.000 claims description 4

- 239000005357 flat glass Substances 0.000 claims description 3

- 238000005086 pumping Methods 0.000 claims 2

- 239000002904 solvent Substances 0.000 claims 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 12

- 239000002826 coolant Substances 0.000 description 5

- 238000000605 extraction Methods 0.000 description 5

- 230000008901 benefit Effects 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 239000011819 refractory material Substances 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 238000006124 Pilkington process Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000003321 amplification Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000001351 cycling effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 238000005816 glass manufacturing process Methods 0.000 description 1

- 230000009931 harmful effect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000001802 infusion Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- -1 silver Chemical class 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

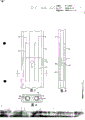

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B18/00—Shaping glass in contact with the surface of a liquid

- C03B18/02—Forming sheets

- C03B18/18—Controlling or regulating the temperature of the float bath; Composition or purification of the float bath

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Glass Compositions (AREA)

- Continuous Casting (AREA)

- Manufacture, Treatment Of Glass Fibers (AREA)

- Re-Forming, After-Treatment, Cutting And Transporting Of Glass Products (AREA)

- Glass Melting And Manufacturing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US000,028 | 1987-01-02 | ||

| US07/000,028 US4741750A (en) | 1987-01-02 | 1987-01-02 | Method and apparatus for cooling in a float glass forming operation |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN87105974A CN87105974A (zh) | 1988-11-09 |

| CN1009548B true CN1009548B (zh) | 1990-09-12 |

Family

ID=21689568

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN87105974.6A Expired CN1009548B (zh) | 1987-01-02 | 1987-12-28 | 在浮法制玻璃成型操作中冷却的方法和装置 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US4741750A (enExample) |

| EP (1) | EP0275438B1 (enExample) |

| JP (1) | JPS63185836A (enExample) |

| CN (1) | CN1009548B (enExample) |

| AT (1) | ATE61325T1 (enExample) |

| CA (1) | CA1287493C (enExample) |

| DE (1) | DE3768467D1 (enExample) |

| ES (1) | ES2020998B3 (enExample) |

| GR (1) | GR3001574T3 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2865470B1 (fr) * | 2004-01-28 | 2007-08-10 | Saint Gobain | Verre plat par flottage sans point fixe |

| KR101412768B1 (ko) | 2011-01-24 | 2014-07-02 | 주식회사 엘지화학 | 유리판 제조 시스템의 플로트 배스 냉각 장치 및 방법 |

| CN103420564A (zh) * | 2012-05-23 | 2013-12-04 | 信义电子玻璃(芜湖)有限公司 | 锡液冷却器 |

| WO2018081664A1 (en) * | 2016-10-31 | 2018-05-03 | Corning Incorporated | Liquid metal viscosity control of molten glass |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| LU50237A1 (enExample) * | 1966-01-11 | 1967-07-11 | ||

| GB1289714A (enExample) * | 1969-09-05 | 1972-09-20 | ||

| GB1289715A (enExample) * | 1969-09-05 | 1972-09-20 | ||

| GB1314537A (en) * | 1970-09-23 | 1973-04-26 | Pilkington Brothers Ltd | Manufacture of flat glass by the float process |

| FR1205906A (fr) * | 1971-04-02 | 1960-02-05 | Glaces De Boussois | Perfectionnements à l'étirage continu du verre en feuille |

| US3928012A (en) * | 1973-03-06 | 1975-12-23 | Ppg Industries Inc | Method and apparatus for regulating the temperature of a glass sheet float tank |

| US4197106A (en) * | 1978-09-11 | 1980-04-08 | Ppg Industries, Inc. | Method and apparatus for asymmetric cooling in a glass sheet forming chamber |

-

1987

- 1987-01-02 US US07/000,028 patent/US4741750A/en not_active Expired - Fee Related

- 1987-12-04 ES ES87117923T patent/ES2020998B3/es not_active Expired - Lifetime

- 1987-12-04 DE DE8787117923T patent/DE3768467D1/de not_active Expired - Lifetime

- 1987-12-04 AT AT87117923T patent/ATE61325T1/de not_active IP Right Cessation

- 1987-12-04 EP EP87117923A patent/EP0275438B1/en not_active Expired

- 1987-12-08 CA CA000553798A patent/CA1287493C/en not_active Expired - Lifetime

- 1987-12-25 JP JP62329411A patent/JPS63185836A/ja active Granted

- 1987-12-28 CN CN87105974.6A patent/CN1009548B/zh not_active Expired

-

1991

- 1991-03-07 GR GR91400192T patent/GR3001574T3/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| JPS63185836A (ja) | 1988-08-01 |

| DE3768467D1 (de) | 1991-04-11 |

| JPH0380739B2 (enExample) | 1991-12-25 |

| CA1287493C (en) | 1991-08-13 |

| EP0275438B1 (en) | 1991-03-06 |

| ATE61325T1 (de) | 1991-03-15 |

| US4741750A (en) | 1988-05-03 |

| EP0275438A1 (en) | 1988-07-27 |

| ES2020998B3 (es) | 1991-10-16 |

| GR3001574T3 (en) | 1992-11-23 |

| CN87105974A (zh) | 1988-11-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO1999051789A1 (en) | Hot dip zincing method and device therefor | |

| CN1009548B (zh) | 在浮法制玻璃成型操作中冷却的方法和装置 | |

| KR900000299B1 (ko) | 일측면에 순수아연코팅이 없는 금속시이트 또는 아연도금강철 스트립의 제조방법과 장치 | |

| CN1007497B (zh) | 带式连续铸造机 | |

| ME00842B (me) | Postupak i uređaj za oblaganje sa kontinualnim namakanjem metalne trake, naročito čelične trake | |

| US7082985B2 (en) | Moulding apparatus | |

| US3938979A (en) | Method and apparatus for vertically drawing a glass ribbon | |

| US3652250A (en) | Apparatus for the treatment or production of flat glass floating on a liquid | |

| CN220636247U (zh) | 一种用于合金铸造的油气润滑结晶装置 | |

| CN217474824U (zh) | 一种用于压铸机连续自动生产的保温炉 | |

| US3645713A (en) | Process for the treatment or production of floating flat glass | |

| US5388756A (en) | Method and apparatus for removing contaminants from solder | |

| EP0176296B1 (en) | Melting furnace | |

| EP0348227B1 (en) | Side wall construction for continuous belt caster | |

| SU1286641A1 (ru) | Электролизер дл получени металлов и сплавов | |

| JP4261272B2 (ja) | 連続鋳造用鋳型 | |

| US3260592A (en) | Copper drossing of lead bullion | |

| CA2038767C (en) | Metallic vapor condenser capable of circulating a liquid metal | |

| CN223083780U (zh) | 一种铸铁流嘴结构及铁水流槽 | |

| CN115583784B (zh) | 一种玻璃板制造设备及其加工方法 | |

| KR880009873A (ko) | 유리성형장치의 냉각시스템 및 그 냉각방법 | |

| CN210412519U (zh) | 一种铸造材料加工用的高品质铸造装置 | |

| CN213706723U (zh) | 一种流滴剂冷却传输装置 | |

| WO2019100027A2 (en) | Glass manufacturing apparatus and methods of fabricating | |

| CN210756740U (zh) | 一种具有油冷降温装置的铣床 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C06 | Publication | ||

| PB01 | Publication | ||

| C13 | Decision | ||

| GR02 | Examined patent application | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C20 | Patent right or utility model deemed to be abandoned or is abandoned | ||

| CF01 | Termination of patent right due to non-payment of annual fee |