CN100509544C - Ship with composite structure - Google Patents

Ship with composite structure Download PDFInfo

- Publication number

- CN100509544C CN100509544C CNB028204778A CN02820477A CN100509544C CN 100509544 C CN100509544 C CN 100509544C CN B028204778 A CNB028204778 A CN B028204778A CN 02820477 A CN02820477 A CN 02820477A CN 100509544 C CN100509544 C CN 100509544C

- Authority

- CN

- China

- Prior art keywords

- ship

- support

- hull

- truss

- space

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002131 composite material Substances 0.000 title claims description 4

- 230000008093 supporting effect Effects 0.000 claims abstract description 30

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 31

- 229910000831 Steel Inorganic materials 0.000 claims description 10

- 239000010959 steel Substances 0.000 claims description 10

- 238000005452 bending Methods 0.000 claims description 8

- 238000010008 shearing Methods 0.000 claims description 7

- 230000002708 enhancing effect Effects 0.000 claims description 6

- 230000000694 effects Effects 0.000 claims description 5

- 239000000463 material Substances 0.000 claims description 5

- 238000003466 welding Methods 0.000 claims description 5

- 239000004567 concrete Substances 0.000 claims description 4

- 239000011521 glass Substances 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims description 4

- 238000012546 transfer Methods 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 claims 2

- 238000013439 planning Methods 0.000 claims 2

- 238000011161 development Methods 0.000 claims 1

- 230000018109 developmental process Effects 0.000 claims 1

- 238000000926 separation method Methods 0.000 claims 1

- 239000007787 solid Substances 0.000 abstract 1

- 230000014509 gene expression Effects 0.000 description 11

- 239000012141 concentrate Substances 0.000 description 3

- 239000004568 cement Substances 0.000 description 2

- 238000009432 framing Methods 0.000 description 2

- 241000238586 Cirripedia Species 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 238000010010 raising Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

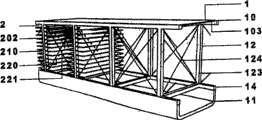

- B63B3/00—Hulls characterised by their structure or component parts

- B63B3/14—Hull parts

- B63B3/26—Frames

- B63B3/36—Combined frame systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B29/00—Accommodation for crew or passengers not otherwise provided for

- B63B29/02—Cabins or other living spaces; Construction or arrangement thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B3/00—Hulls characterised by their structure or component parts

- B63B3/14—Hull parts

- B63B3/48—Decks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B5/00—Hulls characterised by their construction of non-metallic material

- B63B5/02—Hulls characterised by their construction of non-metallic material made predominantly of wood

- B63B5/04—Carcasses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B5/00—Hulls characterised by their construction of non-metallic material

- B63B5/14—Hulls characterised by their construction of non-metallic material made predominantly of concrete, e.g. reinforced

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B3/00—Hulls characterised by their structure or component parts

- B63B3/14—Hull parts

- B63B2003/145—Frameworks, i.e. load bearing assemblies of trusses and girders interconnected at nodal points

Abstract

Description

Claims (32)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2001151085 DE10151085C1 (en) | 2001-10-16 | 2001-10-16 | Ship or submarine, for passengers or cargo, has carrier frame with modular skeletal structure providing all support functions for eliminating loading of water-tight outer cladding |

| DE10151085.3 | 2001-10-16 | ||

| DE2002139926 DE10239926A1 (en) | 2002-08-30 | 2002-08-30 | Sea-going cruise or container ship has box frame steel hull and steel sandwich superstructure |

| DE10239926.3 | 2002-08-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1582240A CN1582240A (en) | 2005-02-16 |

| CN100509544C true CN100509544C (en) | 2009-07-08 |

Family

ID=26010391

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB028204778A Expired - Fee Related CN100509544C (en) | 2001-10-16 | 2002-10-16 | Ship with composite structure |

Country Status (11)

| Country | Link |

|---|---|

| EP (1) | EP1465802B1 (en) |

| JP (1) | JP4369753B2 (en) |

| KR (1) | KR100959819B1 (en) |

| CN (1) | CN100509544C (en) |

| AT (1) | ATE296748T1 (en) |

| DE (1) | DE50203305D1 (en) |

| DK (1) | DK1465802T3 (en) |

| ES (1) | ES2242894T3 (en) |

| HK (1) | HK1073284A1 (en) |

| PT (1) | PT1465802E (en) |

| WO (1) | WO2003033338A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102745307B (en) * | 2012-06-29 | 2015-02-18 | 深圳市海斯比船艇科技股份有限公司 | Manufacturing method of ship |

| CN107554686A (en) * | 2017-05-04 | 2018-01-09 | 江苏省船舶设计研究所有限公司 | A kind of ship heat insulating and corrosion arbor hull based on nano coating |

| CN110162881B (en) * | 2019-05-22 | 2023-05-16 | 中国船舶工业集团公司第七0八研究所 | Method for determining ultimate bearing capacity of midship structure under bending, shearing and twisting combination |

| CN114919710A (en) * | 2022-06-09 | 2022-08-19 | 中国舰船研究设计中心 | Net frame type box floating raft structure and design method thereof |

| KR102587609B1 (en) | 2022-08-02 | 2023-10-12 | 주식회사 크레파머티리얼즈 | Resist composition for lift-off process |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE443599C (en) * | 1925-06-23 | 1927-05-03 | Gustav Wrobbel Dr Ing | Construction system for iron ships with diagonal bracing |

| US4138960A (en) * | 1977-04-22 | 1979-02-13 | Bergstrom Lars R | Sailboat construction |

| DE19733851A1 (en) * | 1997-08-01 | 1998-04-02 | Vincent Dipl Ing Boell | Base module for construction of ships' hulls of different length and beam |

| EP0875447A1 (en) * | 1997-04-29 | 1998-11-04 | Van Schijndel & De Hoog v.o.f. | Method of forming a structure and structure thus formed |

| EP1099621A1 (en) * | 1999-11-12 | 2001-05-16 | Lethe Metallbau GmbH | Construction element for building walls, in particular interior walls and/or ceilings, in particular on ships |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0406598B1 (en) * | 1989-07-07 | 1994-03-23 | Societe Des Produits Nestle S.A. | Protein hydrolysis |

| FI974010A0 (en) * | 1997-10-21 | 1997-10-21 | Kuntoutusyhtymae Rehab Group O | Jakt planerad Foer hotellbruk |

-

2002

- 2002-10-16 CN CNB028204778A patent/CN100509544C/en not_active Expired - Fee Related

- 2002-10-16 DE DE50203305T patent/DE50203305D1/en not_active Expired - Lifetime

- 2002-10-16 ES ES02790292T patent/ES2242894T3/en not_active Expired - Lifetime

- 2002-10-16 DK DK02790292T patent/DK1465802T3/en active

- 2002-10-16 JP JP2003536095A patent/JP4369753B2/en not_active Expired - Fee Related

- 2002-10-16 AT AT02790292T patent/ATE296748T1/en not_active IP Right Cessation

- 2002-10-16 PT PT02790292T patent/PT1465802E/en unknown

- 2002-10-16 WO PCT/EP2002/011592 patent/WO2003033338A1/en active IP Right Grant

- 2002-10-16 KR KR1020047005662A patent/KR100959819B1/en not_active IP Right Cessation

- 2002-10-16 EP EP02790292A patent/EP1465802B1/en not_active Expired - Lifetime

-

2005

- 2005-07-12 HK HK05105942.3A patent/HK1073284A1/en not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE443599C (en) * | 1925-06-23 | 1927-05-03 | Gustav Wrobbel Dr Ing | Construction system for iron ships with diagonal bracing |

| US4138960A (en) * | 1977-04-22 | 1979-02-13 | Bergstrom Lars R | Sailboat construction |

| EP0875447A1 (en) * | 1997-04-29 | 1998-11-04 | Van Schijndel & De Hoog v.o.f. | Method of forming a structure and structure thus formed |

| DE19733851A1 (en) * | 1997-08-01 | 1998-04-02 | Vincent Dipl Ing Boell | Base module for construction of ships' hulls of different length and beam |

| EP1099621A1 (en) * | 1999-11-12 | 2001-05-16 | Lethe Metallbau GmbH | Construction element for building walls, in particular interior walls and/or ceilings, in particular on ships |

Also Published As

| Publication number | Publication date |

|---|---|

| HK1073284A1 (en) | 2005-09-30 |

| PT1465802E (en) | 2005-08-31 |

| WO2003033338A1 (en) | 2003-04-24 |

| KR100959819B1 (en) | 2010-05-28 |

| ATE296748T1 (en) | 2005-06-15 |

| ES2242894T3 (en) | 2005-11-16 |

| EP1465802A1 (en) | 2004-10-13 |

| DE50203305D1 (en) | 2005-07-07 |

| JP2005505473A (en) | 2005-02-24 |

| DK1465802T3 (en) | 2005-08-15 |

| CN1582240A (en) | 2005-02-16 |

| EP1465802B1 (en) | 2005-06-01 |

| JP4369753B2 (en) | 2009-11-25 |

| KR20050037414A (en) | 2005-04-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2579927B2 (en) | Passenger liner | |

| JP2555320B2 (en) | Catamaran | |

| CN112550605A (en) | Horizontal bulkhead supporting structure of container ship | |

| CN100509544C (en) | Ship with composite structure | |

| CN111661263B (en) | Carry on floating platform of container functional unit fast | |

| US4714041A (en) | Structure of surface effect ship with side walls | |

| US8939101B2 (en) | Passenger ship of which the superstructure is equipped with at least one arch | |

| CN111791983A (en) | Hull broadside structure of semi-submersible multifunctional transport assembly and disassembly ship | |

| JP2005505473A5 (en) | ||

| JP3295427B2 (en) | Superstructure of a double-hulled ship | |

| WO2016147103A2 (en) | Modular floating platform | |

| CN105947108A (en) | Portal frame used for shelving and transporting super-large ship body cabin | |

| US4138960A (en) | Sailboat construction | |

| DE10151085C1 (en) | Ship or submarine, for passengers or cargo, has carrier frame with modular skeletal structure providing all support functions for eliminating loading of water-tight outer cladding | |

| CN212386643U (en) | Hull broadside structure of semi-submersible multifunctional transport assembly and disassembly ship | |

| US4069634A (en) | Ground effect vehicle structure | |

| CN114802642B (en) | Construction method of container ship torsion box section and container ship | |

| CN217022797U (en) | Cast steel and steel plate mixed high-strength stem structure of container ship | |

| CN219948483U (en) | Transverse bulkhead structure of container ship with lightweight platform | |

| EP0648669A1 (en) | Hull structure of nonmetallic material | |

| CN117227919A (en) | High-navigational speed semi-submersible platform suitable for high sea conditions | |

| CN117401102A (en) | Watertight transverse bulkhead structure of container ship and container ship comprising same | |

| Bogdaniuk et al. | Concept of barge hull structure made of extruded aluminium panels | |

| CN115416801A (en) | Upper building deck structure without strong frame | |

| CN113928483A (en) | Lightweight lashing bridge structure of container ship |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| ASS | Succession or assignment of patent right |

Owner name: SABINE GRIMM Free format text: FORMER OWNER: MATTHEW AND SCHOTT ENGEER CO.,LTD. Owner name: OLIVER MARTEL S. EVANSIKUSI HUWART SHEN FRIEDRICH Free format text: FORMER OWNER: FRIEDRICH KEGELIMU Effective date: 20050819 |

|

| C41 | Transfer of patent application or patent right or utility model | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20050819 Address after: Stuttgart, Germany Applicant after: Grim Sabine Co-applicant after: Martell Oliver Co-applicant after: Schott Tim Co-applicant after: Grimm Friedrich Address before: Stuttgart, Germany Applicant before: Matthaei & Schotte Ingenieur G. Co-applicant before: Grimm Friedrich |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1073284 Country of ref document: HK |

|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1073284 Country of ref document: HK |

|

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20090708 Termination date: 20161016 |