CN100430543C - 碳纤维织物和用该织物的纤维强化塑料成品以及该成品的制造方法 - Google Patents

碳纤维织物和用该织物的纤维强化塑料成品以及该成品的制造方法 Download PDFInfo

- Publication number

- CN100430543C CN100430543C CNB981178553A CN98117855A CN100430543C CN 100430543 C CN100430543 C CN 100430543C CN B981178553 A CNB981178553 A CN B981178553A CN 98117855 A CN98117855 A CN 98117855A CN 100430543 C CN100430543 C CN 100430543C

- Authority

- CN

- China

- Prior art keywords

- aforementioned

- fiber

- resin

- fabric

- carbon

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 title claims abstract description 238

- 229920000049 Carbon (fiber) Polymers 0.000 title claims abstract description 132

- 239000004917 carbon fiber Substances 0.000 title claims abstract description 132

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 title claims abstract description 130

- 229920002430 Fibre-reinforced plastic Polymers 0.000 title claims description 48

- 239000011151 fibre-reinforced plastic Substances 0.000 title claims description 48

- 238000000465 moulding Methods 0.000 title claims description 32

- 238000004519 manufacturing process Methods 0.000 title claims description 28

- 239000002759 woven fabric Substances 0.000 title description 2

- 238000010137 moulding (plastic) Methods 0.000 title 1

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 133

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 129

- 239000000835 fiber Substances 0.000 claims description 222

- 229920005989 resin Polymers 0.000 claims description 158

- 239000011347 resin Substances 0.000 claims description 158

- 239000000463 material Substances 0.000 claims description 129

- 238000007493 shaping process Methods 0.000 claims description 42

- 238000000034 method Methods 0.000 claims description 40

- 230000015572 biosynthetic process Effects 0.000 claims description 17

- 239000004753 textile Substances 0.000 claims description 17

- 238000002844 melting Methods 0.000 claims description 14

- 229920000728 polyester Polymers 0.000 claims description 9

- 238000009792 diffusion process Methods 0.000 claims description 8

- 238000007789 sealing Methods 0.000 claims description 5

- 238000005187 foaming Methods 0.000 claims description 3

- 239000002990 reinforced plastic Substances 0.000 claims description 3

- 238000003475 lamination Methods 0.000 description 29

- 238000005470 impregnation Methods 0.000 description 18

- 239000004918 carbon fiber reinforced polymer Substances 0.000 description 13

- 229920000642 polymer Polymers 0.000 description 13

- 239000000945 filler Substances 0.000 description 11

- 238000005755 formation reaction Methods 0.000 description 11

- 230000008018 melting Effects 0.000 description 11

- 239000004952 Polyamide Substances 0.000 description 10

- 229920002647 polyamide Polymers 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 9

- 239000003365 glass fiber Substances 0.000 description 9

- 239000011230 binding agent Substances 0.000 description 7

- -1 copolyamide Polymers 0.000 description 6

- 238000007598 dipping method Methods 0.000 description 6

- 229920001567 vinyl ester resin Polymers 0.000 description 6

- 239000000853 adhesive Substances 0.000 description 5

- 230000001070 adhesive effect Effects 0.000 description 5

- 230000006837 decompression Effects 0.000 description 5

- 230000000694 effects Effects 0.000 description 5

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 229920000742 Cotton Polymers 0.000 description 4

- 239000004411 aluminium Substances 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 229920001778 nylon Polymers 0.000 description 4

- 229920000915 polyvinyl chloride Polymers 0.000 description 4

- 229920001187 thermosetting polymer Polymers 0.000 description 4

- 229920004934 Dacron® Polymers 0.000 description 3

- 239000004677 Nylon Substances 0.000 description 3

- 208000034189 Sclerosis Diseases 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 239000005020 polyethylene terephthalate Substances 0.000 description 3

- 239000004800 polyvinyl chloride Substances 0.000 description 3

- 239000012783 reinforcing fiber Substances 0.000 description 3

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 150000001721 carbon Chemical class 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 230000004927 fusion Effects 0.000 description 2

- 229920001568 phenolic resin Polymers 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- 238000003892 spreading Methods 0.000 description 2

- 229920006337 unsaturated polyester resin Polymers 0.000 description 2

- 238000009941 weaving Methods 0.000 description 2

- OEPOKWHJYJXUGD-UHFFFAOYSA-N 2-(3-phenylmethoxyphenyl)-1,3-thiazole-4-carbaldehyde Chemical compound O=CC1=CSC(C=2C=C(OCC=3C=CC=CC=3)C=CC=2)=N1 OEPOKWHJYJXUGD-UHFFFAOYSA-N 0.000 description 1

- 125000003903 2-propenyl group Chemical group [H]C([*])([H])C([H])=C([H])[H] 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920002799 BoPET Polymers 0.000 description 1

- 229920001634 Copolyester Polymers 0.000 description 1

- 238000006424 Flood reaction Methods 0.000 description 1

- 239000005041 Mylar™ Substances 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- LSNNMFCWUKXFEE-UHFFFAOYSA-N Sulfurous acid Chemical compound OS(O)=O LSNNMFCWUKXFEE-UHFFFAOYSA-N 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- 206010000210 abortion Diseases 0.000 description 1

- 231100000176 abortion Toxicity 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 238000003556 assay Methods 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 239000007767 bonding agent Substances 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 235000012241 calcium silicate Nutrition 0.000 description 1

- 230000009194 climbing Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000005007 epoxy-phenolic resin Substances 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 230000002344 fibroplastic effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 235000015203 fruit juice Nutrition 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000012948 isocyanate Substances 0.000 description 1

- 150000002513 isocyanates Chemical class 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920006267 polyester film Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 229920006389 polyphenyl polymer Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 229920002050 silicone resin Polymers 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

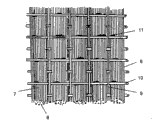

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/242—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads inorganic, e.g. basalt

- D03D15/275—Carbon fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/06—Fibrous reinforcements only

- B29C70/10—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres

- B29C70/16—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres using fibres of substantial or continuous length

- B29C70/22—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres using fibres of substantial or continuous length oriented in at least two directions forming a two dimensional structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

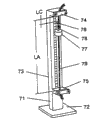

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/44—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using isostatic pressure, e.g. pressure difference-moulding, vacuum bag-moulding, autoclave-moulding or expanding rubber-moulding

- B29C70/443—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using isostatic pressure, e.g. pressure difference-moulding, vacuum bag-moulding, autoclave-moulding or expanding rubber-moulding and impregnating by vacuum or injection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/54—Component parts, details or accessories; Auxiliary operations, e.g. feeding or storage of prepregs or SMC after impregnation or during ageing

- B29C70/546—Measures for feeding or distributing the matrix material in the reinforcing structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/54—Component parts, details or accessories; Auxiliary operations, e.g. feeding or storage of prepregs or SMC after impregnation or during ageing

- B29C70/546—Measures for feeding or distributing the matrix material in the reinforcing structure

- B29C70/548—Measures for feeding or distributing the matrix material in the reinforcing structure using distribution constructions, e.g. channels incorporated in or associated with the mould

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/20—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads

- D03D15/242—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the material of the fibres or filaments constituting the yarns or threads inorganic, e.g. basalt

- D03D15/267—Glass

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D15/00—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used

- D03D15/50—Woven fabrics characterised by the material, structure or properties of the fibres, filaments, yarns, threads or other warp or weft elements used characterised by the properties of the yarns or threads

- D03D15/573—Tensile strength

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2307/00—Use of elements other than metals as reinforcement

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2101/00—Inorganic fibres

- D10B2101/02—Inorganic fibres based on oxides or oxide ceramics, e.g. silicates

- D10B2101/06—Glass

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2101/00—Inorganic fibres

- D10B2101/10—Inorganic fibres based on non-oxides other than metals

- D10B2101/12—Carbon; Pitch

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2101/00—Inorganic fibres

- D10B2101/20—Metallic fibres

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2201/00—Cellulose-based fibres, e.g. vegetable fibres

- D10B2201/01—Natural vegetable fibres

- D10B2201/02—Cotton

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2321/00—Fibres made from polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D10B2321/10—Fibres made from polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds polymers of unsaturated nitriles, e.g. polyacrylonitrile, polyvinylidene cyanide

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2331/00—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products

- D10B2331/02—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyamides

- D10B2331/021—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyamides aromatic polyamides, e.g. aramides

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2331/00—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products

- D10B2331/04—Fibres made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products polyesters, e.g. polyethylene terephthalate [PET]

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2401/00—Physical properties

- D10B2401/06—Load-responsive characteristics

- D10B2401/063—Load-responsive characteristics high strength

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Mechanical Engineering (AREA)

- Inorganic Chemistry (AREA)

- Reinforced Plastic Materials (AREA)

- Moulding By Coating Moulds (AREA)

- Woven Fabrics (AREA)

- Laminated Bodies (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP20921397 | 1997-08-04 | ||

| JP209213/97 | 1997-08-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1210913A CN1210913A (zh) | 1999-03-17 |

| CN100430543C true CN100430543C (zh) | 2008-11-05 |

Family

ID=16569233

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB981178553A Expired - Lifetime CN100430543C (zh) | 1997-08-04 | 1998-08-03 | 碳纤维织物和用该织物的纤维强化塑料成品以及该成品的制造方法 |

Country Status (10)

| Country | Link |

|---|---|

| EP (1) | EP0909845B1 (enExample) |

| JP (1) | JP3991439B2 (enExample) |

| KR (1) | KR100570229B1 (enExample) |

| CN (1) | CN100430543C (enExample) |

| AU (1) | AU743038B2 (enExample) |

| CA (1) | CA2244361C (enExample) |

| DE (1) | DE69841431D1 (enExample) |

| ES (1) | ES2339909T3 (enExample) |

| HU (1) | HU227725B1 (enExample) |

| TW (1) | TW475953B (enExample) |

Families Citing this family (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000238140A (ja) * | 1999-02-17 | 2000-09-05 | Toray Ind Inc | Frp筒状体およびその製造方法 |

| US20030186038A1 (en) * | 1999-11-18 | 2003-10-02 | Ashton Larry J. | Multi orientation composite material impregnated with non-liquid resin |

| BR0102038A (pt) * | 2000-02-01 | 2004-08-24 | Wellstream Inc | Conjunto de tiras compostas e método para a sua formação |

| US20020160252A1 (en) * | 2001-02-28 | 2002-10-31 | Mitsubishi Chemical Corporation | Conductive carbonaceous-fiber sheet and solid polymer electrolyte fuel cell |

| JP4839523B2 (ja) * | 2001-04-17 | 2011-12-21 | 東レ株式会社 | 繊維強化樹脂の製造方法 |

| EP1541312B1 (en) | 2002-07-18 | 2012-05-30 | Mitsubishi Rayon Co., Ltd. | Prepreg and method for production |

| EP1550766A4 (en) * | 2002-09-25 | 2009-07-22 | Mitsubishi Chem Corp | TEXTILE STRUCTURE OF FIBER carbonaceous, WRAP OF TEXTILE FABRIC FROM carbon-FIBER, GAS DIFFUSION LAYER MATERIAL FOR SOLID POLYMER FUEL CELL, PROCESS FOR PRODUCING A sheet of carbon-FIBER AND METHOD FOR PRODUCING A SOLID POLYMER FUEL CELL |

| JP4542588B2 (ja) * | 2002-10-09 | 2010-09-15 | 東レ株式会社 | Rtm成形方法 |

| AU2003262050B2 (en) * | 2002-11-14 | 2009-07-02 | Toray Industries, Inc. | Reinforcing fiber substrate, composite material and method for producing the same |

| JP4370797B2 (ja) * | 2003-04-11 | 2009-11-25 | 東レ株式会社 | Frp製薄板の製造方法 |

| US7168272B2 (en) | 2003-09-30 | 2007-01-30 | Owens Corning Fiberglas Technology, Inc. | Crimp-free infusible reinforcement fabric |

| CA2537941C (en) * | 2003-09-30 | 2012-01-24 | Owens Corning | Crimp-free infusible reinforcement fabric and composite reinforced material therefrom |

| JP4603297B2 (ja) * | 2004-06-07 | 2010-12-22 | 旭化成せんい株式会社 | ポリヘキサメチレンアジパミド繊維 |

| EP1685947B1 (en) | 2005-02-01 | 2011-04-13 | Honda Motor Co., Ltd. | Method for the manufacture of FRP composites |

| EP2014806B1 (en) * | 2006-04-28 | 2012-11-28 | Toray Industries, Inc. | Process for producing woven carbon fiber fabric |

| JP5136876B2 (ja) * | 2006-11-28 | 2013-02-06 | 東レ株式会社 | 強化繊維積層体およびその製造方法 |

| US20090013538A1 (en) * | 2007-03-29 | 2009-01-15 | Acme United Corporation | Cutting instrument |

| CN101532253B (zh) * | 2008-03-12 | 2012-09-05 | 比亚迪股份有限公司 | 碳纤维复合材料制品及其制造方法 |

| TWI472656B (zh) * | 2008-04-11 | 2015-02-11 | Toray Industries | 碳纖維前驅物纖維及碳纖維與其製法 |

| KR100957100B1 (ko) * | 2008-05-30 | 2010-05-13 | 현대자동차주식회사 | 차량용 범퍼 백빔 성형방법 |

| WO2011081486A2 (ko) | 2009-12-30 | 2011-07-07 | 코오롱인더스트리 주식회사 | 에어백 쿠션 및 이를 포함하는 에어백 시스템 |

| US8940222B2 (en) * | 2011-11-03 | 2015-01-27 | The Boeing Company | High flow edge breather and method |

| JP5726713B2 (ja) * | 2011-11-21 | 2015-06-03 | 津田駒工業株式会社 | 炭素繊維基材及び炭素繊維強化プラスチック |

| TWI474919B (zh) * | 2012-03-28 | 2015-03-01 | Blade Structure and Fabrication Method of Composite Material Wind Turbine | |

| US9017539B2 (en) | 2012-08-22 | 2015-04-28 | Infineon Technologies Ag | Method for fabricating a heat sink, and a heat sink |

| US8985270B2 (en) * | 2013-03-11 | 2015-03-24 | Molded Acoustical Products Of Easton, Inc. | Clean burn muffler packing with stitched fiberglass envelope |

| CN103352297A (zh) * | 2013-07-02 | 2013-10-16 | 山东万泰创业投资有限公司 | 一种薄荷纤维莫代尔棉炭黑牛仔面料及其生产方法 |

| EP3342908B1 (en) | 2015-08-24 | 2021-10-27 | Uchino Co., Ltd. | Multiple woven gauze fabric |

| CN107400959A (zh) * | 2017-06-23 | 2017-11-28 | 太仓大唐化纤厂 | 一种竖孔发泡纤维布 |

| EP3705289A4 (en) | 2017-11-01 | 2021-08-25 | Nitto Denko Corporation | LAMINATE AND REINFORCEMENT SHEET |

| JP2019093685A (ja) * | 2017-11-28 | 2019-06-20 | 東洋製罐グループホールディングス株式会社 | 繊維強化積層体及びその製造方法 |

| CN111705469A (zh) * | 2020-06-22 | 2020-09-25 | 科纺勒特种纺织品(太仓)有限公司 | 一种碳纤维织物均匀处理方法及设备 |

| CN113136653B (zh) * | 2021-03-12 | 2023-01-03 | 山东莱蔚特复合材料有限责任公司 | 一种玻璃纤维表面毡糊制装置 |

| CN113831687B (zh) * | 2021-09-26 | 2023-07-21 | 西安工程大学 | 一种压电纱线增强树脂基复合材料的制备方法 |

| GB202210346D0 (en) | 2022-07-14 | 2022-08-31 | Rolls Royce Plc | Woven structure, method and apparatus for a flanged composite component |

| WO2025051626A1 (de) | 2023-09-06 | 2025-03-13 | Teijin Carbon Europe Gmbh | Automatisches ablegeverfahren zur herstellung eines vorformlings mittels gewebeband |

| CN118650940B (zh) * | 2024-08-20 | 2025-03-07 | 泉州市富合新材料科技有限公司 | 一种具备石墨烯导电膜的面料及制备方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4714642A (en) * | 1983-08-30 | 1987-12-22 | Basf Aktiengesellschaft | Carbon fiber multifilamentary tow which is particularly suited for weaving and/or resin impregnation |

| US4902215A (en) * | 1988-06-08 | 1990-02-20 | Seemann Iii William H | Plastic transfer molding techniques for the production of fiber reinforced plastic structures |

| US4906506A (en) * | 1986-12-16 | 1990-03-06 | Toray Industries, Inc. | Preformed material for fiber reinforced plastics |

| CN1153514A (zh) * | 1994-07-21 | 1997-07-02 | 阿克佐诺贝尔公司 | 环酮过氧化物配制剂 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2162174A1 (de) * | 1971-12-15 | 1973-06-28 | Willy Muehlau | Verfahren zur herstellung von verbundelementen mit deckschichten aus haertbaren kunststoffen durch anbringung zusaetzlicher fliesskanaele |

| JPH0771804B2 (ja) * | 1990-10-12 | 1995-08-02 | 株式会社神戸製鋼所 | 炭素繊維プリプレグ及び炭素繊維強化樹脂 |

| JP3094835B2 (ja) * | 1994-03-08 | 2000-10-03 | 東レ株式会社 | 補強織物とその製造方法および製造装置 |

-

1998

- 1998-04-16 JP JP10645898A patent/JP3991439B2/ja not_active Expired - Lifetime

- 1998-07-29 AU AU78562/98A patent/AU743038B2/en not_active Expired

- 1998-07-29 DE DE69841431T patent/DE69841431D1/de not_active Expired - Lifetime

- 1998-07-29 TW TW087112430A patent/TW475953B/zh not_active IP Right Cessation

- 1998-07-29 EP EP98114188A patent/EP0909845B1/en not_active Expired - Lifetime

- 1998-07-29 ES ES98114188T patent/ES2339909T3/es not_active Expired - Lifetime

- 1998-07-30 CA CA002244361A patent/CA2244361C/en not_active Expired - Lifetime

- 1998-08-03 CN CNB981178553A patent/CN100430543C/zh not_active Expired - Lifetime

- 1998-08-03 HU HU9801783A patent/HU227725B1/hu unknown

- 1998-08-04 KR KR1019980031678A patent/KR100570229B1/ko not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4714642A (en) * | 1983-08-30 | 1987-12-22 | Basf Aktiengesellschaft | Carbon fiber multifilamentary tow which is particularly suited for weaving and/or resin impregnation |

| US4906506A (en) * | 1986-12-16 | 1990-03-06 | Toray Industries, Inc. | Preformed material for fiber reinforced plastics |

| US4902215A (en) * | 1988-06-08 | 1990-02-20 | Seemann Iii William H | Plastic transfer molding techniques for the production of fiber reinforced plastic structures |

| CN1153514A (zh) * | 1994-07-21 | 1997-07-02 | 阿克佐诺贝尔公司 | 环酮过氧化物配制剂 |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2339909T3 (es) | 2010-05-26 |

| JPH11107105A (ja) | 1999-04-20 |

| TW475953B (en) | 2002-02-11 |

| CN1210913A (zh) | 1999-03-17 |

| HUP9801783A2 (hu) | 2000-04-28 |

| EP0909845B1 (en) | 2010-01-06 |

| JP3991439B2 (ja) | 2007-10-17 |

| DE69841431D1 (de) | 2010-02-25 |

| HUP9801783A3 (en) | 2000-06-28 |

| KR100570229B1 (ko) | 2006-07-21 |

| AU743038B2 (en) | 2002-01-17 |

| HU227725B1 (en) | 2012-01-30 |

| EP0909845A1 (en) | 1999-04-21 |

| AU7856298A (en) | 1999-02-11 |

| CA2244361C (en) | 2006-10-17 |

| CA2244361A1 (en) | 1999-02-04 |

| HU9801783D0 (en) | 1998-09-28 |

| KR19990023333A (ko) | 1999-03-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100430543C (zh) | 碳纤维织物和用该织物的纤维强化塑料成品以及该成品的制造方法 | |

| US5484642A (en) | Textile material useful for producing composite laminated articles by injection molding | |

| US6355584B1 (en) | Complex fabric having layers made from glass fibers and tissue paper | |

| AU2011335297B2 (en) | Uni-directional fibre preform having slivers and consisting of reinforcing fibre bundles, and a composite material component | |

| US6881288B2 (en) | Method of making a reinforcing mat for a pultruded part | |

| US6872273B2 (en) | Method of making a pultruded part with a reinforcing mat | |

| US20080295950A1 (en) | Open Grid Fabric Resin Infusion Media and Reinforcing Composite Lamina | |

| EP3758923B1 (en) | A stitched multi-axial reinforcement and a method of producing the same | |

| EP2687356A1 (en) | A unidirectional reinforcement and a method of producing a unidirectional reinforcement | |

| US20020123288A1 (en) | Pultruded part with reinforcing mat | |

| CN113573875B (zh) | 缝合的多轴增强件 | |

| JP3530956B2 (ja) | 複合強化原糸を用いた複合材料及びその製造法並びに構造体 | |

| CN101575811A (zh) | 连续长丝垫席 | |

| JP3991440B2 (ja) | 繊維強化プラスチックおよび繊維強化プラスチックの成形方法 | |

| WO2003049928A1 (en) | Reinforcing mat for a pultruded part | |

| CN119137320A (zh) | 混合织物 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term |

Granted publication date: 20081105 |

|

| CX01 | Expiry of patent term |