WO2025041231A1 - Dispositif d'analyse d'ions et procédé d'analyse d'ions - Google Patents

Dispositif d'analyse d'ions et procédé d'analyse d'ions Download PDFInfo

- Publication number

- WO2025041231A1 WO2025041231A1 PCT/JP2023/030031 JP2023030031W WO2025041231A1 WO 2025041231 A1 WO2025041231 A1 WO 2025041231A1 JP 2023030031 W JP2023030031 W JP 2023030031W WO 2025041231 A1 WO2025041231 A1 WO 2025041231A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- plasma

- frequency power

- supplied

- high frequency

- power supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J49/00—Particle spectrometers or separator tubes

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/30—Plasma torches using applied electromagnetic fields, e.g. high frequency or microwave energy

Definitions

- the present invention relates to an ion analysis device and an ion analysis method for analyzing ions derived from a target component contained in a sample.

- mass spectrometry In order to identify sample components such as polymer compounds contained in a sample and analyze their structure, mass spectrometry is widely used, in which ions with a specific m/z (mass-to-charge ratio) are selected from ions derived from the sample components, and the ions are dissociated to generate various product ions that are separated and detected according to m/z.

- ions with a specific m/z mass-to-charge ratio

- Patent Document 3 discloses an example of a radical generation device for generating radicals used in the radical-induced dissociation method.

- This radical generation device has a quartz tube and a helical antenna consisting of a strip-shaped conductor wound around its outer circumference.

- a raw material gas such as water vapor is introduced into the quartz tube, and high-frequency power is supplied to the helical antenna to generate plasma inside the quartz tube, and radicals are generated in the plasma.

- a magnet that generates a strong magnetic field is placed on the outside of the quartz tube, and electron cyclotron resonance using this magnetic field is used to increase the density of the plasma inside the quartz tube and stabilize the generation of the plasma.

- This radical generation device uses localized inductive discharge and electron cyclotron resonance to generate and maintain the plasma, and is therefore sometimes called the ECR-LICP (Electron Cyclotron Resonance - Localized Inductively Coupled Plasma) type.

- the above-mentioned plasma generating device requires the supply of high-frequency power to generate plasma, but if a large amount of high-frequency power is continuously supplied, the helical antenna will become hot, raising concerns that components such as the quartz tube may be damaged by thermal expansion.

- the device described in Patent Document 4 uses pulse-width modulation (PWM) control to turn the high-frequency power on and off while supplying it, thereby preventing excessive temperature rise in the helical antenna and other components while supplying the power required to generate plasma.

- PWM pulse-width modulation

- the frequency of the radio frequency power used is on the order of GHz, for example 2.5 GHz, which is relatively close to the sampling frequency (for example 5 GHz) used in the detection system of the time-of-flight mass spectrometry unit in the mass spectrometer. Therefore, noise due to the radio frequency power is superimposed on the ion intensity signal. In addition, switching noise during on/off operation by PWM control may also affect the ion intensity signal.

- the present invention has been made to solve these problems, and its main objective is to provide an ion analysis device and an ion analysis method that can stably generate plasma while suppressing heat generation in the plasma generation device, and can suppress noise caused by the high-frequency power supply for plasma generation.

- One aspect of the ion analysis method is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

- a raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit; a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber; a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step; a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step; has.

- the ion analysis device and ion analysis method according to the above aspect of the present invention can stably generate plasma and radical species while suppressing heat generation in the generation section for generating radical species. Furthermore, the ion analysis device and ion analysis method according to the above aspect of the present invention can suppress noise caused by the supply of high-frequency power for plasma generation and obtain a high-quality ion intensity signal.

- FIG. 1 is a schematic diagram of a mass spectrometer according to an embodiment of the present invention

- FIG. 2 is a configuration diagram of a main part of a radical production device in the mass spectrometer of the present embodiment

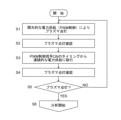

- 4 is a control flowchart at the start of analysis in the mass spectrometer of the present embodiment.

- 3A and 3B are diagrams showing the concept of a control signal waveform and an example of a microwave waveform for generating plasma in the mass spectrometer of the present embodiment.

- FIG. 1 is a schematic diagram of the mass spectrometer of this embodiment.

- This mass spectrometer is a quadrupole time-of-flight (Q-TOF) mass spectrometer equipped with an atmospheric pressure ion source.

- Q-TOF time-of-flight

- this mass spectrometer has an ionization chamber 10 and a vacuum chamber 1.

- the inside of the ionization chamber 10 is at approximately atmospheric pressure.

- the inside of the vacuum chamber 1 is divided into multiple compartments (four compartments in this embodiment), which are, starting from the side closest to the ionization chamber 10, a first intermediate vacuum chamber 11, a second intermediate vacuum chamber 12, a first analysis chamber 13, and a second analysis chamber 14.

- Each of these chambers is evacuated to a vacuum by a vacuum pump (rotary pump and/or turbomolecular pump) (not shown), and the degree of vacuum increases from the ionization chamber 10 to the second analysis chamber 14, forming a multi-stage differential pumping system.

- the ionization chamber 10 is equipped with an electrospray ionization (ESI) probe 101 that applies an electric charge to a liquid sample and sprays it.

- EI electrospray ionization

- the ionization chamber 10 and the first intermediate vacuum chamber 11 are connected through a thin-diameter desolvation tube 102.

- the first intermediate vacuum chamber 11 and the second intermediate vacuum chamber 12 are separated by a skimmer 112 with a small hole at the top.

- the first intermediate vacuum chamber 11 and the second intermediate vacuum chamber 12 are equipped with ion guides 111 and 121, respectively.

- a quadrupole mass filter 131 that separates ions according to m/z, a collision cell 132 equipped with a multipole ion guide 133 inside, and an ion transport electrode 134 for transporting ions are arranged along the ion optical axis C.

- the quadrupole mass filter 131 and the multipole ion guide 133 are each composed of multiple rod electrodes, and the ion transport electrode 134 is composed of multiple ring-shaped electrodes.

- An opening 1320 is formed in the wall of the collision cell 132, and a cylindrical tube connection member 1321 is provided so that one end surrounds this opening 1320.

- a quartz tube 210 extending from the radical generation unit 2 is inserted inside this tube connection member 1321, and the end of the quartz tube 210 protrudes into the collision cell 132 through the opening 1320.

- ions are dissociated by radical species supplied from the radical generation unit 2.

- the collision cell 132 can be supplied with a gas for causing collision induced dissociation (CID) in the collision cell 132, in addition to the radical generation unit 2.

- CID collision induced dissociation

- the second analysis chamber 14 is equipped with an ion transport electrode 141 for transporting ions incident from the first analysis chamber 13, an orthogonal acceleration section 142 including a pair of electrodes arranged opposite each other across the ion optical axis C, an acceleration electrode 143, a flight tube 144 that forms a flight space inside, a reflectron electrode 145 that forms a return trajectory of the ions in the flight space, and an ion detector 146 that detects ions.

- the ion detector 146 is, for example, a multi-channel plate type detector.

- the detection signal from the ion detector 146 is input to the data processing section 4.

- the control section 3 controls the radical generation section 2, the data processing section 4, and also power supplies that apply voltages and the like to each section.

- a typical analytical operation in the mass spectrometer having the above configuration, which is performed under the control of the control unit 3, is as follows.

- the ESI probe 101 sprays a liquid sample supplied from, for example, a column outlet of a liquid chromatograph into the ionization chamber 10 while imparting an electric charge to the liquid sample, thereby ionizing compounds in the liquid sample.

- the generated ions are sent to the first intermediate vacuum chamber 11 through the desolvation tube 102.

- the ions that enter the first intermediate vacuum chamber 11 are sent to the first analysis chamber 13 via the ion guide 111, the small hole of the skimmer 112, and the ion guide 121, and are introduced into the quadrupole mass filter 131.

- Ions introduced into the orthogonal acceleration section 142 along the ion optical axis C are ejected in a direction substantially orthogonal to the ion optical axis C at a predetermined timing.

- the ejected ions are accelerated by the acceleration electrode 143 and introduced into the flight space in the flight tube 144.

- the ions fly in a return flight due to the electric field formed by the reflectron electrode 145, and finally reach the ion detector 146.

- the ion detector 146 outputs a detection signal according to the amount of incident ions to the data processing section 4.

- the radical generating unit 2 includes a plasma generating unit 21.

- the plasma generating unit 21 generates plasma based on a raw material gas such as water vapor supplied from a raw material gas supply source 27, and supplies radicals generated in the plasma to a collision cell 132.

- a microwave power source 26 supplies microwave power (high frequency power) for generating plasma to the plasma generating unit 21.

- the amount of raw material gas supplied from the raw material gas supply source 27 to the plasma generating unit 21 is adjusted by a valve 20 provided in a flow path connecting the raw material gas supply source 27 and a quartz tube 210.

- FIG. 2 is a vertical cross-sectional view of the essential parts of the radical generating section 2, focusing on the plasma generating section 21.

- the plasma generating unit 21 includes a long quartz tube 210, a helical antenna 211 which is a strip-shaped conductor wound in a spiral shape around the outer periphery of a part of the quartz tube 210, an outer conductor part 212 which is coaxial with the quartz tube 210 and is made of a conductor having a cylindrical opening whose inner diameter is one size larger than the outer diameter of the quartz tube 210, a permanent magnet 213 embedded in the outer conductor part 212, a casing 214 which holds the outer conductor part 212, and a permanent magnet 215 which is disposed at the bottom of the casing 214.

- the casing 214 is provided with a microwave supply connector 216, an ultraviolet light source 217, and a photodetector 218.

- the ultraviolet light source 217 irradiates the quartz tube 210 with deep ultraviolet light, electrons are emitted from the wall surface of the quartz tube 210, and the electrons induce ignition of plasma.

- the quartz tube 210 is a raw material introduction tube into which raw material gas is introduced from a raw material gas supply source 27, and its interior serves as a generation chamber and a radical flow path.

- the microwave supply connector 216 is a coaxial connector, and is connected to the microwave power source 26 via a coaxial cable.

- the conductive wire of the microwave supply connector 216 is connected to one end (the lower end in FIG. 2) of the helical antenna 211.

- the outer conductor 212 is grounded. A part of the helical antenna 211 and the outer conductor 212 are electrically connected via a resonator adjustment mechanism 220, and the helical antenna 211 is grounded at the connection position.

- the helical antenna 211, the outer conductor 212, the resonator adjustment mechanism 220, and the like constitute an electron cyclotron resonance resonator.

- the resonator adjustment mechanism 220 is used to adjust the resonator, and is described in, for example, Patent Document 3.

- This plasma generation unit 21 is of a type known as an ECR-LICP type, which uses local inductively coupled discharge and electron cyclotron resonance to generate and maintain plasma.

- a roughly disk-shaped magnet holder 221 is attached to the bottom surface of the casing 214.

- the casing 214 and the magnet holder 221 function as a holding member 222 that holds the quartz tube 210.

- An opening is formed in the center of the magnet holder 221 through which the quartz tube 210 is inserted.

- the plasma generating unit 21 is attached to the outer surface of the vacuum chamber 1 so as to cover the opening 1000 formed in the vacuum chamber 1, and the quartz tube 210 held by the holding member 222 is inserted into the inside of the tube connecting member 1321 that connects the collision cell 132 and the vacuum chamber 1, and reaches the inside of the collision cell 132. Since the inside of the quartz tube 210 and the inside of the collision cell 132 are connected to each other, the inside of the quartz tube 210 is also in a vacuum state when no raw material gas is supplied to the quartz tube 210.

- FIG. 3 is a control flowchart for this operation.

- FIG. 4 is a diagram showing the concept of a control signal waveform for plasma generation and an example of a microwave waveform.

- FIG. 4(A) is a pseudo waveform diagram showing the time passage on the horizontal axis and the magnitude of the supplied microwave power on the vertical axis

- FIG. 4(B) is a diagram showing the change over time in the voltage applied to the helical antenna 211.

- the control unit 3 opens the valve 20 and flows a predetermined flow rate of raw material gas into the quartz tube 210.

- the raw material gas is assumed to be water vapor.

- the control unit 3 inputs a pulse width modulation (PWM) control signal with a predetermined duty ratio (proportion of the on period in one period) as shown in FIG. 4(A) to the microwave power supply 26.

- PWM pulse width modulation

- the microwave power supply 26 outputs microwaves of a predetermined frequency and a predetermined output power during the period when the PWM control signal is "1" (on period), and stops outputting microwaves during the period when the PWM control signal is "0" (off period), as shown in FIG. 4.

- the emission of deep ultraviolet light by the ultraviolet light source 217 to promote plasma lighting is performed continuously regardless of whether the PWM control signal is on or off. However, promoting plasma lighting using this ultraviolet light source 217 is not essential to the present invention.

- control unit 3 and microwave power supply 26 attempt to light the plasma by PWM drive (step S1).

- the frequency of the PWM control signal is 100 Hz, and the duty ratio is 10 to 20%.

- the microwave frequency is 2.5 GHz, and the output power is 250 W. This output power is sufficient to light the plasma.

- these values can be changed as appropriate.

- the PWM control signal When the PWM control signal is on, that is, when microwave power is being supplied to the generation chamber inside the quartz tube 210, the water vapor, which is the raw material gas, is usually ionized and plasma is lit.

- the PWM control signal when the PWM control signal is off, that is, when the supply of microwave power is stopped, the plasma is turned off. Therefore, the plasma repeatedly turns on and off as the PWM control signal turns on and off.

- the PWM control signal changes from off to on and microwave power is being supplied, there may be cases where the plasma does not turn on.

- the photodetector 218 arranged in the generation chamber detects light in a wavelength band that includes the wavelength of the light emitted from the plasma. It is preferable that the photodetector 218 has no sensitivity to the wavelength of light emitted from the ultraviolet light source 217 so as not to detect this light. Therefore, here, a photodiode that has sensitivity in the visible light range (no sensitivity or low sensitivity to the ultraviolet light range) is used as the photodetector 218. This makes it possible to effectively detect the light emitted by the plasma without being affected by the light emitted from the ultraviolet light source 217.

- the control unit 3 monitors the output signal from the photodetector 218 a predetermined time (e.g., 1 to 10 seconds) after the plasma lighting begins, and determines whether the plasma is lit or not based on the signal value.

- a predetermined time e.g. 1 to 10 seconds

- the detection signal by the photodetector 218 also changes accordingly, but here, it is not necessary to detect the change in the on/off cycle (e.g., 100 Hz) of the PWM control signal. This is because, as described above, the plasma is not always turned on when the PWM control signal is turned on, and although the probability is low, there may be cases where the plasma remains off.

- the detection signal by the photodetector 218 is input to a smoothing circuit or integration circuit with an appropriate time constant to obtain a signal obtained by smoothing or integrating the detection signal over a predetermined time, and the signal is compared with a predetermined threshold value to determine whether the plasma is turned on overall.

- a smoothing circuit or integration circuit with an appropriate time constant to obtain a signal obtained by smoothing or integrating the detection signal over a predetermined time, and the signal is compared with a predetermined threshold value to determine whether the plasma is turned on overall.

- processing can be performed digitally, or other circuits can be used to determine whether the plasma is turned on overall during the PWM control period (the period indicated by "PWM" in FIG. 4).

- the control unit 3 waits in step S2 until it is determined that the plasma is in an lit state, and if it is, proceeds to step S3. If a predetermined upper limit time (e.g., an appropriate time of 10 seconds or more) has passed without the plasma being in an lit state, there is a high possibility that some kind of abnormality exists, such as an abnormality in the microwave power supply path or an improper supply of raw material gas, and measures can be taken, such as reporting the abnormality.

- a predetermined upper limit time e.g., an appropriate time of 10 seconds or more

- step S3 the control unit 3 controls the microwave power supply 26 to switch to a continuous supply of microwave power during the on period of the PWM control signal. That is, the mode is switched from an intermittent mode (period indicated by "PWM” in FIG. 4) in which microwave power is intermittently supplied, to a continuous mode (period indicated by "CW” in FIG. 4) in which microwave power is continuously supplied.

- the continuous mode the output power of the microwave power is reduced compared to the output power when microwave power is supplied in the intermittent mode. This is because if a large output power such as that in the intermittent mode is continuously supplied, the helical antenna 211 will generate too much heat, and the quartz tube 210 and other parts in contact with the antenna 211 may become too hot and be damaged by thermal expansion.

- plasma is stably formed in the plasma generation chamber, which is part of the quartz tube 210, and MS/MS analysis can be performed in a state in which radicals generated in the plasma are stably supplied to the collision cell 132. This allows stable and good detection of product ions generated by radical attachment dissociation.

- the antenna 211 when microwave power is supplied to the helical antenna 211, the antenna 211 generates heat, and the temperature of components such as the quartz tube 210 rises.

- the heat from the radical generation section 2 is also transmitted to the mass separation section through the quartz tube 210, etc., and may affect the mass analysis performance.

- the flight tube 144 expands due to heat or the electrode spacing of the reflectron electrode 145 changes, the flight time of ions with the same m/z value may change, resulting in larger mass errors.

- it is practically impossible to suppress the generation of heat in either the intermittent mode or the continuous mode it is desirable to roughly match the amount of heat generated in the intermittent mode and the continuous mode in order to suppress the effect on the mass analysis performance. Therefore, in the mass analysis device of this embodiment, it is preferable to roughly match the power supplied per unit time in the intermittent mode and the continuous mode, that is, the average power obtained by averaging the output power per unit time.

- the ion analyzer according to the present invention is applied to a Q-TOF mass analyzer, but it is clear that the present invention is not limited to Q-TOF types.

- the present invention can also be applied to triple quadrupole mass analyzers, ion trap mass analyzers, ion trap time-of-flight mass analyzers, and the like.

- the present invention can also be applied to devices in general that dissociate ions using radical species generated in plasma and analyze the product ions generated by the dissociation.

- the present invention can also be applied to ion mobility analyzers that separate and detect ions according to ion mobility, and ion mobility-mass analyzers that separate ions using both ion mobility and m/z.

- the configuration of the mass spectrometer described above, particularly the configuration of the radical generation unit 2 that generates radical species, is merely one example, and it goes without saying that any configuration that can generate radical species using plasma can be modified as appropriate.

- the radical species referred to here include hydroxyl radicals, oxygen radicals, nitrogen radicals, hydrogen radicals, and the like that are generally used in radical attachment and dissociation, as well as various molecules and atoms that are in an excited state or in a metastable state when energy is applied.

- One aspect of the ion analyzer according to the present invention is an ion analyzer that introduces radical species generated in a generation unit into a reaction chamber, and brings the radical species into contact with ions derived from a sample in the reaction chamber to dissociate the ions

- the generation unit comprising: a generation chamber into which a source gas is introduced; a power supply unit that supplies high frequency power for generating plasma inside the generation chamber; a control unit that controls the power supply unit to adjust the high frequency power supplied to the generation chamber, the control unit performing control in an intermittent mode in which the high frequency power is intermittently supplied at the start of plasma lighting, and switching the control mode to a continuous mode in which high frequency power having an output power lower than that of the high frequency power supplied in the intermittent mode is continuously supplied at a timing when high frequency power is being supplied during the intermittent mode; Equipped with.

- One aspect of the ion analysis method according to the present invention is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

- a raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit;

- a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber;

- a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step;

- a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step; has.

- the supply of the power is switched to a continuous mode at the timing when the high-frequency power is being supplied. In this continuous mode, the output power is made lower than when the power is supplied in the intermittent mode.

- the ion analysis device described in paragraph 1 and the ion analysis method described in paragraph 4 can stably generate plasma and radical species while suppressing heat generation in the generation section for generating radical species. Furthermore, the ion analysis device described in paragraph 1 and the ion analysis method described in paragraph 4 can suppress noise caused by the supply of high-frequency power for plasma generation and obtain a high-quality ion intensity signal.

- the average power over a given time period can be made uniform between the intermittent mode and the continuous mode.

- the average power over a given time period can be made uniform between the first power supply step and the second power supply step.

- the ion analyzer according to the first or second aspect further includes a detection unit that detects whether or not plasma is lit, After switching the control mode from the intermittent mode to the continuous mode, the control unit can check whether or not plasma is lit using the detection unit, and if plasma is not lit, return to the intermittent mode and retry the lighting operation.

- (6) In the ion analysis method described in 4 or 5, it can be configured to check whether the plasma is lit in the second power supply step, and if not, to return to the first power supply step and retry the lighting operation.

- Whether or not the plasma is lit can be detected, for example, by detecting the light emitted from the plasma. According to the ion analyzer described in paragraph 3, even if the plasma is not lit properly due to a malfunction such as the plasma going out when switching from intermittent to continuous mode, the plasma can be reliably lit by retrying from the intermittent mode, and analysis can be performed under conditions in which radicals are generated.

- Vacuum chamber 1000 Opening 10: Ionization chamber 101: ESI probe 102: Desolvation tube 11: First intermediate vacuum chamber 111: Ion guide 112: Skimmer 12: Second intermediate vacuum chamber 121: Ion guide 13: First analysis chamber 131: Quadrupole mass filter 132: Collision cell 1320: Opening 1321: Tube connection member 133: Multipole ion guide 134: Ion transport electrode 14: Second analysis chamber 141: Ion transport electrode 142: Orthogonal acceleration section 143: Acceleration electrode 144: Flight tube 145: Reflectron electrode 146: Ion detector 2: Radical generation section 20: Valve 21: Plasma generation section 210: Quartz tube 211: Helical antenna 212: Outer conductor section 213, 215: Permanent magnet 214: Casing 216: Microwave supply connector 217: Ultraviolet light source 218: Photodetector 220: Resonator adjustment mechanism 221: Magnet holder 222: Holding member 26: Microwave power source 27: Raw material gas

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Electromagnetism (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Other Investigation Or Analysis Of Materials By Electrical Means (AREA)

Abstract

Un aspect d'un dispositif d'analyse d'ions selon la présente invention introduit une espèce radicalaire générée dans une unité de génération dans une chambre de réaction, et amène l'espèce radicalaire en contact avec des ions dérivés d'un échantillon dans la chambre de réaction pour dissocier les ions, l'unité de génération comprenant : une chambre de génération dans laquelle un gaz de matériau est introduit ; une unité d'alimentation électrique qui fournit une puissance haute fréquence pour générer un plasma à l'intérieur de la chambre de génération ; et une unité de commande qui commande l'unité d'alimentation électrique afin d'ajuster la puissance haute fréquence fournie à la chambre de génération, l'unité de commande effectuant une commande (S1) dans un mode intermittent dans lequel la puissance haute fréquence est fournie par intermittence au début de l'allumage du plasma, et, à un instant (S2) auquel la puissance haute fréquence est fournie pendant le mode intermittent, commute (S3) le mode de commande vers un mode continu dans lequel la puissance haute fréquence ayant une puissance de sortie inférieure à celle lorsque la puissance haute fréquence est fournie dans le mode intermittent est fournie en continu. Ceci permet de générer de manière stable un plasma tout en supprimant la génération de chaleur dans l'unité de génération.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2023/030031 WO2025041231A1 (fr) | 2023-08-21 | 2023-08-21 | Dispositif d'analyse d'ions et procédé d'analyse d'ions |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2023/030031 WO2025041231A1 (fr) | 2023-08-21 | 2023-08-21 | Dispositif d'analyse d'ions et procédé d'analyse d'ions |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2025041231A1 true WO2025041231A1 (fr) | 2025-02-27 |

Family

ID=94731834

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2023/030031 Pending WO2025041231A1 (fr) | 2023-08-21 | 2023-08-21 | Dispositif d'analyse d'ions et procédé d'analyse d'ions |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2025041231A1 (fr) |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06349594A (ja) * | 1993-06-07 | 1994-12-22 | Mitsubishi Electric Corp | プラズマ発生装置 |

| WO2023002712A1 (fr) * | 2021-07-21 | 2023-01-26 | 株式会社島津製作所 | Dispositif de spectrométrie de masse et procédé de spectrométrie de masse |

-

2023

- 2023-08-21 WO PCT/JP2023/030031 patent/WO2025041231A1/fr active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06349594A (ja) * | 1993-06-07 | 1994-12-22 | Mitsubishi Electric Corp | プラズマ発生装置 |

| WO2023002712A1 (fr) * | 2021-07-21 | 2023-01-26 | 株式会社島津製作所 | Dispositif de spectrométrie de masse et procédé de spectrométrie de masse |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2610892B1 (fr) | Spectromètre de masse et spectrométrie de masse | |

| EP3234978B1 (fr) | Dispositif d'ionisation et spectromètre de masse en étant équipé | |

| US7385185B2 (en) | Molecular activation for tandem mass spectroscopy | |

| US9589775B2 (en) | Plasma cleaning for mass spectrometers | |

| US7365315B2 (en) | Method and apparatus for ionization via interaction with metastable species | |

| JP7556472B2 (ja) | 質量分析装置及び質量分析装置の操作方法 | |

| JP7616390B2 (ja) | 質量分析装置及び質量分析方法 | |

| US11133168B2 (en) | Method for spectrometry | |

| WO2025041231A1 (fr) | Dispositif d'analyse d'ions et procédé d'analyse d'ions | |

| US11217437B2 (en) | Electron capture dissociation (ECD) utilizing electron beam generated low energy electrons | |

| TW202109613A (zh) | 包含離子化裝置的質譜儀 | |

| WO2025041271A1 (fr) | Dispositif d'analyse d'ions | |

| JP7396508B2 (ja) | ラジカル発生装置及びイオン分析装置 | |

| US20250132142A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| US20250198965A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| US20250130201A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| JP7735882B2 (ja) | 質量分析装置及び質量分析装置の調整方法 | |

| WO2024171416A1 (fr) | Dispositif de spectrométrie de masse et procédé de spectrométrie de masse | |

| JP2025029786A (ja) | イオン分析装置 | |

| JP2024057924A (ja) | 質量分析装置 | |

| JP2024051420A (ja) | 質量分析装置 | |

| JP2024157097A (ja) | 質量分析装置 | |

| EP4193382A1 (fr) | Identification d'harmoniques dans des spectres de masse quadripolaires à transformée de fourier acquis par radiofréquence |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 23949692 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2025541187 Country of ref document: JP Kind code of ref document: A |