WO2025041231A1 - Ion analysis device and ion analysis method - Google Patents

Ion analysis device and ion analysis method Download PDFInfo

- Publication number

- WO2025041231A1 WO2025041231A1 PCT/JP2023/030031 JP2023030031W WO2025041231A1 WO 2025041231 A1 WO2025041231 A1 WO 2025041231A1 JP 2023030031 W JP2023030031 W JP 2023030031W WO 2025041231 A1 WO2025041231 A1 WO 2025041231A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- plasma

- frequency power

- supplied

- high frequency

- power supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J49/00—Particle spectrometers or separator tubes

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/30—Plasma torches using applied electromagnetic fields, e.g. high frequency or microwave energy

Definitions

- the present invention relates to an ion analysis device and an ion analysis method for analyzing ions derived from a target component contained in a sample.

- mass spectrometry In order to identify sample components such as polymer compounds contained in a sample and analyze their structure, mass spectrometry is widely used, in which ions with a specific m/z (mass-to-charge ratio) are selected from ions derived from the sample components, and the ions are dissociated to generate various product ions that are separated and detected according to m/z.

- ions with a specific m/z mass-to-charge ratio

- Patent Document 3 discloses an example of a radical generation device for generating radicals used in the radical-induced dissociation method.

- This radical generation device has a quartz tube and a helical antenna consisting of a strip-shaped conductor wound around its outer circumference.

- a raw material gas such as water vapor is introduced into the quartz tube, and high-frequency power is supplied to the helical antenna to generate plasma inside the quartz tube, and radicals are generated in the plasma.

- a magnet that generates a strong magnetic field is placed on the outside of the quartz tube, and electron cyclotron resonance using this magnetic field is used to increase the density of the plasma inside the quartz tube and stabilize the generation of the plasma.

- This radical generation device uses localized inductive discharge and electron cyclotron resonance to generate and maintain the plasma, and is therefore sometimes called the ECR-LICP (Electron Cyclotron Resonance - Localized Inductively Coupled Plasma) type.

- the above-mentioned plasma generating device requires the supply of high-frequency power to generate plasma, but if a large amount of high-frequency power is continuously supplied, the helical antenna will become hot, raising concerns that components such as the quartz tube may be damaged by thermal expansion.

- the device described in Patent Document 4 uses pulse-width modulation (PWM) control to turn the high-frequency power on and off while supplying it, thereby preventing excessive temperature rise in the helical antenna and other components while supplying the power required to generate plasma.

- PWM pulse-width modulation

- the frequency of the radio frequency power used is on the order of GHz, for example 2.5 GHz, which is relatively close to the sampling frequency (for example 5 GHz) used in the detection system of the time-of-flight mass spectrometry unit in the mass spectrometer. Therefore, noise due to the radio frequency power is superimposed on the ion intensity signal. In addition, switching noise during on/off operation by PWM control may also affect the ion intensity signal.

- the present invention has been made to solve these problems, and its main objective is to provide an ion analysis device and an ion analysis method that can stably generate plasma while suppressing heat generation in the plasma generation device, and can suppress noise caused by the high-frequency power supply for plasma generation.

- One aspect of the ion analysis method is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

- a raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit; a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber; a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step; a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step; has.

- the ion analysis device and ion analysis method according to the above aspect of the present invention can stably generate plasma and radical species while suppressing heat generation in the generation section for generating radical species. Furthermore, the ion analysis device and ion analysis method according to the above aspect of the present invention can suppress noise caused by the supply of high-frequency power for plasma generation and obtain a high-quality ion intensity signal.

- FIG. 1 is a schematic diagram of a mass spectrometer according to an embodiment of the present invention

- FIG. 2 is a configuration diagram of a main part of a radical production device in the mass spectrometer of the present embodiment

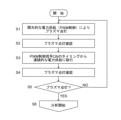

- 4 is a control flowchart at the start of analysis in the mass spectrometer of the present embodiment.

- 3A and 3B are diagrams showing the concept of a control signal waveform and an example of a microwave waveform for generating plasma in the mass spectrometer of the present embodiment.

- FIG. 1 is a schematic diagram of the mass spectrometer of this embodiment.

- This mass spectrometer is a quadrupole time-of-flight (Q-TOF) mass spectrometer equipped with an atmospheric pressure ion source.

- Q-TOF time-of-flight

- this mass spectrometer has an ionization chamber 10 and a vacuum chamber 1.

- the inside of the ionization chamber 10 is at approximately atmospheric pressure.

- the inside of the vacuum chamber 1 is divided into multiple compartments (four compartments in this embodiment), which are, starting from the side closest to the ionization chamber 10, a first intermediate vacuum chamber 11, a second intermediate vacuum chamber 12, a first analysis chamber 13, and a second analysis chamber 14.

- Each of these chambers is evacuated to a vacuum by a vacuum pump (rotary pump and/or turbomolecular pump) (not shown), and the degree of vacuum increases from the ionization chamber 10 to the second analysis chamber 14, forming a multi-stage differential pumping system.

- the ionization chamber 10 is equipped with an electrospray ionization (ESI) probe 101 that applies an electric charge to a liquid sample and sprays it.

- EI electrospray ionization

- the ionization chamber 10 and the first intermediate vacuum chamber 11 are connected through a thin-diameter desolvation tube 102.

- the first intermediate vacuum chamber 11 and the second intermediate vacuum chamber 12 are separated by a skimmer 112 with a small hole at the top.

- the first intermediate vacuum chamber 11 and the second intermediate vacuum chamber 12 are equipped with ion guides 111 and 121, respectively.

- a quadrupole mass filter 131 that separates ions according to m/z, a collision cell 132 equipped with a multipole ion guide 133 inside, and an ion transport electrode 134 for transporting ions are arranged along the ion optical axis C.

- the quadrupole mass filter 131 and the multipole ion guide 133 are each composed of multiple rod electrodes, and the ion transport electrode 134 is composed of multiple ring-shaped electrodes.

- An opening 1320 is formed in the wall of the collision cell 132, and a cylindrical tube connection member 1321 is provided so that one end surrounds this opening 1320.

- a quartz tube 210 extending from the radical generation unit 2 is inserted inside this tube connection member 1321, and the end of the quartz tube 210 protrudes into the collision cell 132 through the opening 1320.

- ions are dissociated by radical species supplied from the radical generation unit 2.

- the collision cell 132 can be supplied with a gas for causing collision induced dissociation (CID) in the collision cell 132, in addition to the radical generation unit 2.

- CID collision induced dissociation

- the second analysis chamber 14 is equipped with an ion transport electrode 141 for transporting ions incident from the first analysis chamber 13, an orthogonal acceleration section 142 including a pair of electrodes arranged opposite each other across the ion optical axis C, an acceleration electrode 143, a flight tube 144 that forms a flight space inside, a reflectron electrode 145 that forms a return trajectory of the ions in the flight space, and an ion detector 146 that detects ions.

- the ion detector 146 is, for example, a multi-channel plate type detector.

- the detection signal from the ion detector 146 is input to the data processing section 4.

- the control section 3 controls the radical generation section 2, the data processing section 4, and also power supplies that apply voltages and the like to each section.

- a typical analytical operation in the mass spectrometer having the above configuration, which is performed under the control of the control unit 3, is as follows.

- the ESI probe 101 sprays a liquid sample supplied from, for example, a column outlet of a liquid chromatograph into the ionization chamber 10 while imparting an electric charge to the liquid sample, thereby ionizing compounds in the liquid sample.

- the generated ions are sent to the first intermediate vacuum chamber 11 through the desolvation tube 102.

- the ions that enter the first intermediate vacuum chamber 11 are sent to the first analysis chamber 13 via the ion guide 111, the small hole of the skimmer 112, and the ion guide 121, and are introduced into the quadrupole mass filter 131.

- Ions introduced into the orthogonal acceleration section 142 along the ion optical axis C are ejected in a direction substantially orthogonal to the ion optical axis C at a predetermined timing.

- the ejected ions are accelerated by the acceleration electrode 143 and introduced into the flight space in the flight tube 144.

- the ions fly in a return flight due to the electric field formed by the reflectron electrode 145, and finally reach the ion detector 146.

- the ion detector 146 outputs a detection signal according to the amount of incident ions to the data processing section 4.

- the radical generating unit 2 includes a plasma generating unit 21.

- the plasma generating unit 21 generates plasma based on a raw material gas such as water vapor supplied from a raw material gas supply source 27, and supplies radicals generated in the plasma to a collision cell 132.

- a microwave power source 26 supplies microwave power (high frequency power) for generating plasma to the plasma generating unit 21.

- the amount of raw material gas supplied from the raw material gas supply source 27 to the plasma generating unit 21 is adjusted by a valve 20 provided in a flow path connecting the raw material gas supply source 27 and a quartz tube 210.

- FIG. 2 is a vertical cross-sectional view of the essential parts of the radical generating section 2, focusing on the plasma generating section 21.

- the plasma generating unit 21 includes a long quartz tube 210, a helical antenna 211 which is a strip-shaped conductor wound in a spiral shape around the outer periphery of a part of the quartz tube 210, an outer conductor part 212 which is coaxial with the quartz tube 210 and is made of a conductor having a cylindrical opening whose inner diameter is one size larger than the outer diameter of the quartz tube 210, a permanent magnet 213 embedded in the outer conductor part 212, a casing 214 which holds the outer conductor part 212, and a permanent magnet 215 which is disposed at the bottom of the casing 214.

- the casing 214 is provided with a microwave supply connector 216, an ultraviolet light source 217, and a photodetector 218.

- the ultraviolet light source 217 irradiates the quartz tube 210 with deep ultraviolet light, electrons are emitted from the wall surface of the quartz tube 210, and the electrons induce ignition of plasma.

- the quartz tube 210 is a raw material introduction tube into which raw material gas is introduced from a raw material gas supply source 27, and its interior serves as a generation chamber and a radical flow path.

- the microwave supply connector 216 is a coaxial connector, and is connected to the microwave power source 26 via a coaxial cable.

- the conductive wire of the microwave supply connector 216 is connected to one end (the lower end in FIG. 2) of the helical antenna 211.

- the outer conductor 212 is grounded. A part of the helical antenna 211 and the outer conductor 212 are electrically connected via a resonator adjustment mechanism 220, and the helical antenna 211 is grounded at the connection position.

- the helical antenna 211, the outer conductor 212, the resonator adjustment mechanism 220, and the like constitute an electron cyclotron resonance resonator.

- the resonator adjustment mechanism 220 is used to adjust the resonator, and is described in, for example, Patent Document 3.

- This plasma generation unit 21 is of a type known as an ECR-LICP type, which uses local inductively coupled discharge and electron cyclotron resonance to generate and maintain plasma.

- a roughly disk-shaped magnet holder 221 is attached to the bottom surface of the casing 214.

- the casing 214 and the magnet holder 221 function as a holding member 222 that holds the quartz tube 210.

- An opening is formed in the center of the magnet holder 221 through which the quartz tube 210 is inserted.

- the plasma generating unit 21 is attached to the outer surface of the vacuum chamber 1 so as to cover the opening 1000 formed in the vacuum chamber 1, and the quartz tube 210 held by the holding member 222 is inserted into the inside of the tube connecting member 1321 that connects the collision cell 132 and the vacuum chamber 1, and reaches the inside of the collision cell 132. Since the inside of the quartz tube 210 and the inside of the collision cell 132 are connected to each other, the inside of the quartz tube 210 is also in a vacuum state when no raw material gas is supplied to the quartz tube 210.

- FIG. 3 is a control flowchart for this operation.

- FIG. 4 is a diagram showing the concept of a control signal waveform for plasma generation and an example of a microwave waveform.

- FIG. 4(A) is a pseudo waveform diagram showing the time passage on the horizontal axis and the magnitude of the supplied microwave power on the vertical axis

- FIG. 4(B) is a diagram showing the change over time in the voltage applied to the helical antenna 211.

- the control unit 3 opens the valve 20 and flows a predetermined flow rate of raw material gas into the quartz tube 210.

- the raw material gas is assumed to be water vapor.

- the control unit 3 inputs a pulse width modulation (PWM) control signal with a predetermined duty ratio (proportion of the on period in one period) as shown in FIG. 4(A) to the microwave power supply 26.

- PWM pulse width modulation

- the microwave power supply 26 outputs microwaves of a predetermined frequency and a predetermined output power during the period when the PWM control signal is "1" (on period), and stops outputting microwaves during the period when the PWM control signal is "0" (off period), as shown in FIG. 4.

- the emission of deep ultraviolet light by the ultraviolet light source 217 to promote plasma lighting is performed continuously regardless of whether the PWM control signal is on or off. However, promoting plasma lighting using this ultraviolet light source 217 is not essential to the present invention.

- control unit 3 and microwave power supply 26 attempt to light the plasma by PWM drive (step S1).

- the frequency of the PWM control signal is 100 Hz, and the duty ratio is 10 to 20%.

- the microwave frequency is 2.5 GHz, and the output power is 250 W. This output power is sufficient to light the plasma.

- these values can be changed as appropriate.

- the PWM control signal When the PWM control signal is on, that is, when microwave power is being supplied to the generation chamber inside the quartz tube 210, the water vapor, which is the raw material gas, is usually ionized and plasma is lit.

- the PWM control signal when the PWM control signal is off, that is, when the supply of microwave power is stopped, the plasma is turned off. Therefore, the plasma repeatedly turns on and off as the PWM control signal turns on and off.

- the PWM control signal changes from off to on and microwave power is being supplied, there may be cases where the plasma does not turn on.

- the photodetector 218 arranged in the generation chamber detects light in a wavelength band that includes the wavelength of the light emitted from the plasma. It is preferable that the photodetector 218 has no sensitivity to the wavelength of light emitted from the ultraviolet light source 217 so as not to detect this light. Therefore, here, a photodiode that has sensitivity in the visible light range (no sensitivity or low sensitivity to the ultraviolet light range) is used as the photodetector 218. This makes it possible to effectively detect the light emitted by the plasma without being affected by the light emitted from the ultraviolet light source 217.

- the control unit 3 monitors the output signal from the photodetector 218 a predetermined time (e.g., 1 to 10 seconds) after the plasma lighting begins, and determines whether the plasma is lit or not based on the signal value.

- a predetermined time e.g. 1 to 10 seconds

- the detection signal by the photodetector 218 also changes accordingly, but here, it is not necessary to detect the change in the on/off cycle (e.g., 100 Hz) of the PWM control signal. This is because, as described above, the plasma is not always turned on when the PWM control signal is turned on, and although the probability is low, there may be cases where the plasma remains off.

- the detection signal by the photodetector 218 is input to a smoothing circuit or integration circuit with an appropriate time constant to obtain a signal obtained by smoothing or integrating the detection signal over a predetermined time, and the signal is compared with a predetermined threshold value to determine whether the plasma is turned on overall.

- a smoothing circuit or integration circuit with an appropriate time constant to obtain a signal obtained by smoothing or integrating the detection signal over a predetermined time, and the signal is compared with a predetermined threshold value to determine whether the plasma is turned on overall.

- processing can be performed digitally, or other circuits can be used to determine whether the plasma is turned on overall during the PWM control period (the period indicated by "PWM" in FIG. 4).

- the control unit 3 waits in step S2 until it is determined that the plasma is in an lit state, and if it is, proceeds to step S3. If a predetermined upper limit time (e.g., an appropriate time of 10 seconds or more) has passed without the plasma being in an lit state, there is a high possibility that some kind of abnormality exists, such as an abnormality in the microwave power supply path or an improper supply of raw material gas, and measures can be taken, such as reporting the abnormality.

- a predetermined upper limit time e.g., an appropriate time of 10 seconds or more

- step S3 the control unit 3 controls the microwave power supply 26 to switch to a continuous supply of microwave power during the on period of the PWM control signal. That is, the mode is switched from an intermittent mode (period indicated by "PWM” in FIG. 4) in which microwave power is intermittently supplied, to a continuous mode (period indicated by "CW” in FIG. 4) in which microwave power is continuously supplied.

- the continuous mode the output power of the microwave power is reduced compared to the output power when microwave power is supplied in the intermittent mode. This is because if a large output power such as that in the intermittent mode is continuously supplied, the helical antenna 211 will generate too much heat, and the quartz tube 210 and other parts in contact with the antenna 211 may become too hot and be damaged by thermal expansion.

- plasma is stably formed in the plasma generation chamber, which is part of the quartz tube 210, and MS/MS analysis can be performed in a state in which radicals generated in the plasma are stably supplied to the collision cell 132. This allows stable and good detection of product ions generated by radical attachment dissociation.

- the antenna 211 when microwave power is supplied to the helical antenna 211, the antenna 211 generates heat, and the temperature of components such as the quartz tube 210 rises.

- the heat from the radical generation section 2 is also transmitted to the mass separation section through the quartz tube 210, etc., and may affect the mass analysis performance.

- the flight tube 144 expands due to heat or the electrode spacing of the reflectron electrode 145 changes, the flight time of ions with the same m/z value may change, resulting in larger mass errors.

- it is practically impossible to suppress the generation of heat in either the intermittent mode or the continuous mode it is desirable to roughly match the amount of heat generated in the intermittent mode and the continuous mode in order to suppress the effect on the mass analysis performance. Therefore, in the mass analysis device of this embodiment, it is preferable to roughly match the power supplied per unit time in the intermittent mode and the continuous mode, that is, the average power obtained by averaging the output power per unit time.

- the ion analyzer according to the present invention is applied to a Q-TOF mass analyzer, but it is clear that the present invention is not limited to Q-TOF types.

- the present invention can also be applied to triple quadrupole mass analyzers, ion trap mass analyzers, ion trap time-of-flight mass analyzers, and the like.

- the present invention can also be applied to devices in general that dissociate ions using radical species generated in plasma and analyze the product ions generated by the dissociation.

- the present invention can also be applied to ion mobility analyzers that separate and detect ions according to ion mobility, and ion mobility-mass analyzers that separate ions using both ion mobility and m/z.

- the configuration of the mass spectrometer described above, particularly the configuration of the radical generation unit 2 that generates radical species, is merely one example, and it goes without saying that any configuration that can generate radical species using plasma can be modified as appropriate.

- the radical species referred to here include hydroxyl radicals, oxygen radicals, nitrogen radicals, hydrogen radicals, and the like that are generally used in radical attachment and dissociation, as well as various molecules and atoms that are in an excited state or in a metastable state when energy is applied.

- One aspect of the ion analyzer according to the present invention is an ion analyzer that introduces radical species generated in a generation unit into a reaction chamber, and brings the radical species into contact with ions derived from a sample in the reaction chamber to dissociate the ions

- the generation unit comprising: a generation chamber into which a source gas is introduced; a power supply unit that supplies high frequency power for generating plasma inside the generation chamber; a control unit that controls the power supply unit to adjust the high frequency power supplied to the generation chamber, the control unit performing control in an intermittent mode in which the high frequency power is intermittently supplied at the start of plasma lighting, and switching the control mode to a continuous mode in which high frequency power having an output power lower than that of the high frequency power supplied in the intermittent mode is continuously supplied at a timing when high frequency power is being supplied during the intermittent mode; Equipped with.

- One aspect of the ion analysis method according to the present invention is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

- a raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit;

- a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber;

- a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step;

- a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step; has.

- the supply of the power is switched to a continuous mode at the timing when the high-frequency power is being supplied. In this continuous mode, the output power is made lower than when the power is supplied in the intermittent mode.

- the ion analysis device described in paragraph 1 and the ion analysis method described in paragraph 4 can stably generate plasma and radical species while suppressing heat generation in the generation section for generating radical species. Furthermore, the ion analysis device described in paragraph 1 and the ion analysis method described in paragraph 4 can suppress noise caused by the supply of high-frequency power for plasma generation and obtain a high-quality ion intensity signal.

- the average power over a given time period can be made uniform between the intermittent mode and the continuous mode.

- the average power over a given time period can be made uniform between the first power supply step and the second power supply step.

- the ion analyzer according to the first or second aspect further includes a detection unit that detects whether or not plasma is lit, After switching the control mode from the intermittent mode to the continuous mode, the control unit can check whether or not plasma is lit using the detection unit, and if plasma is not lit, return to the intermittent mode and retry the lighting operation.

- (6) In the ion analysis method described in 4 or 5, it can be configured to check whether the plasma is lit in the second power supply step, and if not, to return to the first power supply step and retry the lighting operation.

- Whether or not the plasma is lit can be detected, for example, by detecting the light emitted from the plasma. According to the ion analyzer described in paragraph 3, even if the plasma is not lit properly due to a malfunction such as the plasma going out when switching from intermittent to continuous mode, the plasma can be reliably lit by retrying from the intermittent mode, and analysis can be performed under conditions in which radicals are generated.

- Vacuum chamber 1000 Opening 10: Ionization chamber 101: ESI probe 102: Desolvation tube 11: First intermediate vacuum chamber 111: Ion guide 112: Skimmer 12: Second intermediate vacuum chamber 121: Ion guide 13: First analysis chamber 131: Quadrupole mass filter 132: Collision cell 1320: Opening 1321: Tube connection member 133: Multipole ion guide 134: Ion transport electrode 14: Second analysis chamber 141: Ion transport electrode 142: Orthogonal acceleration section 143: Acceleration electrode 144: Flight tube 145: Reflectron electrode 146: Ion detector 2: Radical generation section 20: Valve 21: Plasma generation section 210: Quartz tube 211: Helical antenna 212: Outer conductor section 213, 215: Permanent magnet 214: Casing 216: Microwave supply connector 217: Ultraviolet light source 218: Photodetector 220: Resonator adjustment mechanism 221: Magnet holder 222: Holding member 26: Microwave power source 27: Raw material gas

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Electromagnetism (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Other Investigation Or Analysis Of Materials By Electrical Means (AREA)

Abstract

Description

本発明は、試料に含まれる目的成分由来のイオンを分析するイオン分析装置及びイオン分析方法に関する。 The present invention relates to an ion analysis device and an ion analysis method for analyzing ions derived from a target component contained in a sample.

試料に含まれる高分子化合物等の試料成分を同定したりその構造を解析したりするために、試料成分由来のイオンから特定のm/z(質量電荷比)を有するイオンを選別し、そのイオンを解離させて生成した種々のプロダクトイオンをm/zに応じて分離して検出する質量分析法が広く利用されている。イオンの解離手法としては様々な方法が知られているが、その一つとして、ヒドロキシル(OH)ラジカル、酸素ラジカル、窒素ラジカルなどの各種のラジカルをイオンに付着させることによって、炭素原子の不飽和結合や特定の官能基の位置でイオンを解離させるラジカル誘起(付着)解離法が知られている(特許文献1、2等参照)。

In order to identify sample components such as polymer compounds contained in a sample and analyze their structure, mass spectrometry is widely used, in which ions with a specific m/z (mass-to-charge ratio) are selected from ions derived from the sample components, and the ions are dissociated to generate various product ions that are separated and detected according to m/z. There are various known methods for dissociating ions, one of which is the radical-induced (attachment) dissociation method, in which various radicals such as hydroxyl (OH) radicals, oxygen radicals, and nitrogen radicals are attached to the ions, thereby dissociating the ions at the unsaturated bonds of carbon atoms or at the positions of specific functional groups (see

特許文献3には、ラジカル誘起解離法において使用するラジカルを生成するためのラジカル生成装置の一例が開示されている。このラジカル生成装置は、石英管とその外周に帯状の導電体を巻回した構成であるヘリカルアンテナを有しており、石英管の内部に水蒸気等の原料ガスを導入し、ヘリカルアンテナに高周波電力を供給することによって該石英管の内部にプラズマを発生させ、そのプラズマ中でラジカルを生成させる。また、強い磁場を発生する磁石を石英管の外側に配置し、この磁場を利用した電子サイクロトロン共鳴によって、石英管内のプラズマの密度を高めるとともにプラズマの生成を安定化させる。このラジカル生成装置は、プラズマの生成及び維持に、局所的な誘導型放電と電子サイクロトロン共鳴とを利用しているため、ECR-LICP(Electron Cyclotron Resonance - Localized Inductively Coupled Plasma)型と呼ばれることもある。

上記プラズマ生成装置では、プラズマを生成するために高周波電力を供給する必要があるが、大電力の高周波電力を供給し続けるとヘリカルアンテナが高温になり、石英管等の部材が熱膨張によって破損する等の問題が生じる懸念がある。これを回避するために、特許文献4に記載の装置では、パルス幅変調(PWM)制御により高周波電力をオン/オフさせつつ供給することで、プラズマ生成に必要な電力を供給しつつヘリカルアンテナ等の過度な温度上昇を抑えるようにしている。しかしながら、この制御手法では次のような問題がある。

The above-mentioned plasma generating device requires the supply of high-frequency power to generate plasma, but if a large amount of high-frequency power is continuously supplied, the helical antenna will become hot, raising concerns that components such as the quartz tube may be damaged by thermal expansion. To avoid this, the device described in

(1)使用される高周波電力の周波数は例えば2.5GHz等のGHzオーダーであり、質量分析装置における飛行時間型質量分析部の検出系で使用されているサンプリング周波数(例えば5GHz)に比較的近い。そのため、高周波電力によるノイズがイオン強度信号に重畳する。また、PWM制御によるオン/オフ動作の際のスイッチングノイズもイオン強度信号に影響を及ぼす場合がある。 (1) The frequency of the radio frequency power used is on the order of GHz, for example 2.5 GHz, which is relatively close to the sampling frequency (for example 5 GHz) used in the detection system of the time-of-flight mass spectrometry unit in the mass spectrometer. Therefore, noise due to the radio frequency power is superimposed on the ion intensity signal. In addition, switching noise during on/off operation by PWM control may also affect the ion intensity signal.

(2)PWM制御により供給電力を調整する場合、PWM制御信号のオン/オフの切替えに伴ってプラズマは点灯/消灯を繰り返す筈である。しかしながら、本発明者の実験によれば、こうしたPWM制御によるプラズマ生成では、PWM制御信号がオンであるときにプラズマが点灯しない場合がある。そのため、プラズマの状態が安定せず、プラズマにおけるラジカルの生成が不安定になってイオン解離効率の低下をもたらすおそれがある。 (2) When adjusting the supply power by PWM control, the plasma should repeatedly turn on and off as the PWM control signal is switched on and off. However, according to the inventor's experiments, when generating plasma by such PWM control, there are cases where the plasma does not turn on when the PWM control signal is on. This can lead to an unstable plasma state, which can cause unstable generation of radicals in the plasma and result in a decrease in the ion dissociation efficiency.

本発明はこうした課題を解決するために成されたものであり、その主たる目的は、プラズマ生成装置における発熱を抑えながらプラズマを安定的に生成し、且つプラズマ生成のための高周波電力供給に起因するノイズを抑制することができるイオン分析装置及びイオン分析方法を提供することである。 The present invention has been made to solve these problems, and its main objective is to provide an ion analysis device and an ion analysis method that can stably generate plasma while suppressing heat generation in the plasma generation device, and can suppress noise caused by the high-frequency power supply for plasma generation.

本発明に係るイオン分析装置の一態様は、生成部で生成したラジカル種を反応室に導入し、該反応室において試料由来のイオンにラジカル種を接触させて該イオンを解離させるイオン分析装置であって、前記生成部は、

原料ガスがその内部に導入される生成室と、

前記生成室の内部にプラズマを生じさせるための高周波電力を供給する電力供給部と、

前記生成室に供給する高周波電力を調整するべく前記電力供給部を制御する制御部であって、プラズマの点灯開始時には高周波電力を間欠的に供給する間欠モードでの制御を行い、該間欠モード中であって高周波電力が供給されているタイミングで、該間欠モードにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する連続モードに制御モードを切り替える制御部と、

を備える。

One aspect of the ion analyzer according to the present invention is an ion analyzer that introduces radical species generated in a generation unit into a reaction chamber, and brings the radical species into contact with ions derived from a sample in the reaction chamber to dissociate the ions, the generation unit comprising:

a generation chamber into which a source gas is introduced;

a power supply unit that supplies high frequency power for generating plasma inside the generation chamber;

a control unit that controls the power supply unit to adjust the high frequency power supplied to the generation chamber, the control unit performing control in an intermittent mode in which the high frequency power is intermittently supplied at the start of plasma lighting, and switching the control mode to a continuous mode in which high frequency power having an output power lower than that of the high frequency power supplied in the intermittent mode is continuously supplied at a timing when high frequency power is being supplied during the intermittent mode;

Equipped with.

また本発明に係るイオン分析方法の一態様は、生成部で生成したラジカル種を反応室に導入し、該反応室において試料由来のイオンにラジカル種を接触させて該イオンを解離させるイオン分析方法であって、

前記生成部に含まれる生成室の内部に原料ガスを導入する原料ガス導入ステップと、

前記生成室の内部にプラズマを生じさせるために、プラズマ点灯開始時に高周波電力を間欠的に供給する第1電力供給ステップと、

前記第1電力供給ステップにおいて高周波電力が供給されているタイミングで、間欠的な高周波電力に代えて、該第1電力供給ステップにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する第2電力供給ステップと、

前記第2電力供給ステップにおいて連続的な高周波電力が前記生成室に供給されている状態で、前記反応室において解離されたイオンに対する分析を実施する測定ステップと、

を有する。

One aspect of the ion analysis method according to the present invention is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

A raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit;

a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber;

a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step;

a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step;

has.

本発明に係る上記態様のイオン分析装置及びイオン分析方法によれば、ラジカル種を生成するための生成部における発熱を抑えながら、プラズマを安定的に生成し、ラジカル種も安定的に生成することができる。また、本発明に係る上記態様のイオン分析装置及びイオン分析方法によれば、プラズマ生成のための高周波電力の供給に起因するノイズを抑制し、高品質のイオン強度信号を取得することができる。 The ion analysis device and ion analysis method according to the above aspect of the present invention can stably generate plasma and radical species while suppressing heat generation in the generation section for generating radical species. Furthermore, the ion analysis device and ion analysis method according to the above aspect of the present invention can suppress noise caused by the supply of high-frequency power for plasma generation and obtain a high-quality ion intensity signal.

本発明に係るイオン分析装置及びイオン分析方法の一実施形態について、添付の図面を参照して説明する。以下、イオン分析装置の一実施形態として質量分析装置について説明するが、イオン移動度分析装置やイオン移動度-質量分析装置でもよいことは後述の説明から明らかである。 An embodiment of an ion analysis device and an ion analysis method according to the present invention will be described with reference to the accompanying drawings. Below, a mass spectrometer will be described as an embodiment of an ion analysis device, but it will be clear from the following description that an ion mobility spectrometer or an ion mobility-mass spectrometer may also be used.

図1は、本実施形態の質量分析装置の概略構成図である。この質量分析装置は、大気圧イオン源を備えた四重極-飛行時間型(Q-TOF型)質量分析装置である。 FIG. 1 is a schematic diagram of the mass spectrometer of this embodiment. This mass spectrometer is a quadrupole time-of-flight (Q-TOF) mass spectrometer equipped with an atmospheric pressure ion source.

図1に示すように、この質量分析装置は、イオン化室10と真空チャンバー1とを有する。イオン化室10内は略大気圧雰囲気である。真空チャンバー1の内部は複数(本実施形態では4室)に区画されており、イオン化室10に近い側から順に、第1中間真空室11、第2中間真空室12、第1分析室13、及び第2分析室14となっている。これらの各室はそれぞれ、図示しない真空ポンプ(ロータリーポンプ及び/又はターボ分子ポンプ)により真空排気されており、イオン化室10から第2分析室14に向かうに従って順に真空度が高まる、多段差動排気系の構成を呈する。

As shown in FIG. 1, this mass spectrometer has an

イオン化室10には、液体試料に電荷を付与して噴霧するエレクトロスプレーイオン化(ESI)プローブ101が設置されている。イオン化室10と第1中間真空室11とは、細径の脱溶媒管102を通して連通している。第1中間真空室11と第2中間真空室12とは、頂部に小孔を有するスキマー112で隔てられている。第1中間真空室11及び第2中間真空室12にはそれぞれ、イオンガイド111、121が配置されている。第1分析室13には、イオン光軸Cに沿って、イオンをm/zに応じて分離する四重極マスフィルター131、多重極イオンガイド133を内部に備えたコリジョンセル132、及びイオンを輸送するためのイオン輸送電極134、が配置されている。四重極マスフィルター131及び多重極イオンガイド133はそれぞれ複数のロッド電極で構成され、イオン輸送電極134は複数のリング状電極で構成されている。

The

コリジョンセル132の壁面には開口1320が形成され、一端がこの開口1320を囲うように、筒状の管接続部材1321が設けられている。この管接続部材1321の内側にはラジカル生成部2から延伸する石英管210が挿通され、該石英管210の末端は開口1320を通してコリジョンセル132内に突出している。コリジョンセル132では、後述するように、ラジカル生成部2から供給されるラジカル種によってイオンを解離させる。なお、ここでは図示していないが、コリジョンセル132には、ラジカル生成部2以外に、コリジョンセル132内で衝突誘起解離(CID)を生じさせるためのガスが供給されるようにすることができる。

An

第2分析室14には、第1分析室13から入射したイオンを輸送するためのイオン輸送電極141、イオン光軸Cを挟んで対向配置された一組の電極を含む直交加速部142、加速電極143、飛行空間を内部に形成するフライトチューブ144、飛行空間においてイオンの折り返し軌道を形成するリフレクトロン電極145、及びイオンを検出するイオン検出器146、を備える。イオン検出器146は例えばマルチチャンネルプレート型検出器である。イオン検出器146による検出信号はデータ処理部4に入力される。制御部3は、ラジカル生成部2、データ処理部4のほか、各部に電圧等を印加する電源等を制御する。

The

制御部3の制御の下で行われる、上記構成の質量分析装置における典型的な分析動作は次の通りである。

ESIプローブ101は、例えば液体クロマトグラフのカラム出口から供給される液体試料に電荷を付与しながら該液体試料をイオン化室10内に噴霧し、液体試料中の化合物をイオン化する。生成されたイオンは脱溶媒管102を通って第1中間真空室11へ送られる。第1中間真空室11に入射したイオンは、イオンガイド111、スキマー112の小孔、イオンガイド121を経て、第1分析室13まで送られ、四重極マスフィルター131に導入される。

A typical analytical operation in the mass spectrometer having the above configuration, which is performed under the control of the

The

導入された各種イオンの中で特定のm/z値を有するイオンのみが選択的に四重極マスフィルター131を通過し、コリジョンセル132に導入される。コリジョンセル132内にはラジカル生成部2から石英管210を通してラジカル種が導入され、コリジョンセル132に導入されたイオンはこのラジカル種と反応して解離する。解離により生成された各種のプロダクトイオンは、コリジョンセル132から出てイオン輸送電極134、141を経て直交加速部142に導入される。

Of the various ions introduced, only those having a specific m/z value selectively pass through the

イオン光軸Cに沿って直交加速部142に導入されたイオンは、所定のタイミングでイオン光軸Cに略直交する方向に射出される。射出されたイオンは加速電極143で加速され、フライトチューブ144内の飛行空間に導入される。イオンは、リフレクトロン電極145により形成される電場により折り返し飛行し、最終的にイオン検出器146に到達する。イオン検出器146は、入射したイオンの量に応じた検出信号をデータ処理部4へと出力する。イオンが直交加速部142を出発した時点からイオン検出器146に到達する時点までの時間、つまりイオンの飛行時間は、そのイオンのm/z値に依存する。そこで、データ処理部4は、検出信号に基いて飛行時間とイオン強度との関係を示す飛行時間スペクトルを作成し、飛行時間をm/z値に換算することでマススペクトルを作成する。

Ions introduced into the

次いで、ラジカル生成部2の詳細な構成とその動作を説明する。

図1に示すように、ラジカル生成部2はプラズマ生成部21を含む。プラズマ生成部21は、原料ガス供給源27から供給される、水蒸気等の原料ガスを基にプラズマを生成し、該プラズマ中で発生したラジカルをコリジョンセル132に供給する。マイクロ波電源26は、プラズマを生成するためのマイクロ波電力(高周波電力)をプラズマ生成部21に供給する。原料ガス供給源27からプラズマ生成部21へ供給される原料ガスの量は、原料ガス供給源27と石英管210とを結ぶ流路に設けられたバルブ20によって調整される。

Next, the detailed configuration and operation of the

1, the

図2は、ラジカル生成部2におけるプラズマ生成部21を中心とする要部の縦断面図である。

プラズマ生成部21は、長い石英管210と、石英管210の一部の外周に螺旋状に巻回された帯状の導電体であるヘリカルアンテナ211と、石英管210と同軸で、その内径が石英管210の外径よりも一回り大きい円筒開口を有する導電体からなる外側導体部212と、外側導体部212に埋設された永久磁石213と、外側導体部212を保持するケーシング214と、ケーシング214の底部に配置された永久磁石215と、を有する。ケーシング214には、マイクロ波供給コネクタ216、紫外光光源217、及び光検出器218、が設けられている。紫外光光源217から深紫外光を石英管210に照射すると、石英管210の壁面から電子が放出され、この電子によってプラズマの着火が誘発される。

FIG. 2 is a vertical cross-sectional view of the essential parts of the

The

石英管210は、原料ガス供給源27から原料ガスが導入される原料導入管であるとともに、その内部が生成室及びラジカル流路となる。マイクロ波供給コネクタ216は同軸コネクタであり、同軸ケーブルを介してマイクロ波電源26に接続される。マイクロ波供給コネクタ216の導電線は、ヘリカルアンテナ211の一端(図2では下端)に接続されている。また、図示しないものの、外側導体部212は接地されている。ヘリカルアンテナ211の一部と外側導体部212とは共振器調整機構220を介して電気的に接続されており、その接続位置においてヘリカルアンテナ211は接地されている。ヘリカルアンテナ211、外側導体部212、共振器調整機構220などによって、電子サイクロトロン共鳴の共振器が構成されている。共振器調整機構220は共振器の調整に用いられ、例えば特許文献3に記載のものである。

The

このプラズマ生成部21は、プラズマの生成及び維持に、局所的な誘導結合型放電と電子サイクロトロン共鳴とを利用する、ECR-LICP型と呼ばれる構成である。

This

ケーシング214の底面には、略円盤状の磁石ホルダー221が取り付けられている。ケーシング214と磁石ホルダー221は、石英管210を保持する保持部材222として機能する。磁石ホルダー221の中央部には石英管210を挿通する開口が形成されている。図2に示すように、プラズマ生成部21は真空チャンバー1に形成された開口1000を覆うように真空チャンバー1の外面に装着され、保持部材222により保持された石英管210は、コリジョンセル132と真空チャンバー1との間を繋ぐ管接続部材1321の内側に挿通されてコリジョンセル132内にまで至る。石英管210の内部とコリジョンセル132の内部とは連通しているため、石英管210に原料ガスが供給されない状態では石英管210の内部も真空状態になる。

A roughly disk-shaped

次に、本実施形態の質量分析装置において、ラジカル生成部2を動作させることでラジカル種をコリジョンセル132に供給し、分析を実行する際の制御動作を説明する。図3は、このときの制御フローチャートである。図4は、プラズマ生成のための制御信号波形の概念及びマイクロ波波形の一例を示す図である。図4の(A)は、横軸が時間経過、縦軸が供給されるマイクロ波電力の大きさを示す疑似的な波形図であり、(B)はヘリカルアンテナ211に印加される電圧の時間変化を示す図である。

Next, the control operation when performing analysis by operating the

上述したように、ラジカル生成時には制御部3はバルブ20を開放し、所定流量の原料ガスを石英管210に流す。ここでは原料ガスは水蒸気であるとする。制御部3はプラズマが点灯していない状況で、プラズマを点灯させるために、図4(A)に示すような所定のデューティー比(1周期に占めるオン期間の割合)であるパルス幅変調(PWM)制御信号をマイクロ波電源26に入力する。これに応じてマイクロ波電源26は、図4に示すように、PWM制御信号が「1」である期間(オン期間)には所定周波数で所定出力のマイクロ波を出力し、PWM制御信号が「0」である期間(オフ期間)にはマイクロ波の出力を停止する。

As described above, when generating radicals, the

プラズマの点灯を促すための紫外光光源217による深紫外光の放出は、PWM制御信号のオン/オフに拘わらず連続的に行われる。但し、この紫外光光源217を用いたプラズマ点灯の促進は本発明において必須ではない。

The emission of deep ultraviolet light by the ultraviolet

即ち、制御部3及びマイクロ波電源26は、PWM駆動によりプラズマ点灯を試みる(ステップS1)。一例として、PWM制御信号の周波数は100Hzであり、デューティー比は10~20%である。また、同様に一例として、マイクロ波の周波数は2.5GHzであり、出力電力は250Wである。この出力電力はプラズマが点灯するのに十分な電力である。但し、これら値は適宜に変更可能である。

That is, the

PWM制御信号のオン期間つまりマイクロ波電力が石英管210内である生成室に供給されている期間には、通常、原料ガスである水蒸気が電離されてプラズマが点灯する。一方、PWM制御信号のオフ期間つまりマイクロ波電力の供給が停止されている期間には、プラズマは消灯する。従って、PWM制御信号のオン/オフに伴って、プラズマは点灯、消灯を繰り返す。但し、実際には、PWM制御信号がオフからオンに変化してマイクロ波電力が供給されても、プラズマが点灯しない場合もあり得る。

When the PWM control signal is on, that is, when microwave power is being supplied to the generation chamber inside the

生成室内に配置されている光検出器218は、プラズマから発せられる光の波長を含む波長帯域の光を検出する。光検出器218は、紫外光光源217から発せられる光を検出しないように、該光の波長に対して感度を持たないことが好ましい。従って、ここでは、光検出器218として可視光領域に感度を有する(紫外光領域に対する感度がない又は感度が低い)フォトダイオードを用いる。これにより、紫外光光源217から発せられる光の影響を受けることなく、プラズマの発光を良好に検出することができる。

The

制御部3は、プラズマ点灯開始時点から所定の時間(例えば1秒~10秒)だけ経過した時点において、光検出器218からの出力信号をモニターし、その信号値に基いてプラズマが点灯しているか否かを判断する。

The

なお、PWM制御信号のオン/オフに伴ってプラズマが点灯/消灯すると、それに応じて光検出器218による検出信号も変化するが、ここでは、PWM制御信号のオン/オフの周期(例えば100Hz)の変化を検出する必要はない。何故なら、上述したように、PWM制御信号をオンにしたときに必ずプラズマが点灯するとは限らず、その確率は低いもののプラズマが消灯したままの状態になる場合があり得るからである。そこで、例えば光検出器218による検出信号を適宜の時定数の平滑化回路や積分回路に入力して、検出信号を所定時間に亘り平滑化した又は積分した信号を取得し、その信号を所定の閾値と比較することで、全体としてプラズマが点灯状態となっているか否かを判断することができる。勿論、こうした処理をデジタル的に行うこともできるし、それ以外の回路や用いて、PWM制御期間(図4において「PWM」で示した期間)に全体としてプラズマが点灯状態となっているか否かを判断することもできる。

When the plasma is turned on/off in accordance with the on/off of the PWM control signal, the detection signal by the

制御部3はステップS2においてプラズマが点灯状態であると判断されるまで待ち、点灯状態になったならばステップS3へと移行する。プラズマが点灯状態とならずに所定の上限時間(例えば10秒以上の適宜の時間)が経過した場合には、例えばマイクロ波電力の供給経路に異常がある、原料ガスが適切に供給されていない等の、何らかの異常である可能性が高いため、例えば異常を報知する等の対応を採ることができる。

The

ステップS3において、制御部3は、PWM制御信号のオン期間中のタイミングでマイクロ波電力を連続的に供給するべく切り替えるようにマイクロ波電源26を制御する。即ち、間欠的にマイクロ波電力を供給する間欠モード(図4において「PWM」で示した期間)から連続的にマイクロ波電力を供給する連続モード(図4において「CW」で示した期間)へとモードを切り替える。但し、図4(B)に示すように、連続モードでは、マイクロ波電力の出力電力を、間欠モードにおいてマイクロ波電力が供給されているときの出力電力に比べて低下させる。これは、間欠モードのときのような大きな出力電力を連続的に供給し続けると、ヘリカルアンテナ211の発熱が大きくなり過ぎ、該アンテナ211に接している石英管210等の部品が高温になって熱膨張によって破損する等のおそれがあるからである。

In step S3, the

一般に、プラズマは完全に消灯している状態から点灯し始める際には大きな電力を要するが、一旦プラズマが点灯すると、供給する電力を減らしても点灯状態が維持される。従って、PWM制御信号のオン期間であってプラズマが点灯している状態で間欠モードから連続モードに移行した場合、一般的には、その直前の点灯状態が継続される。しかしながら、上述したように、間欠モードにおいてPWM制御信号のオン期間であっても必ずしもプラズマが点灯状態であるとは限らない。そのため、その直前までPWM制御信号のオン時にプラズマが点灯していたにも拘わらず、たまたまPWM制御信号のオン時にプラズマが点灯せず、その状態であるときに連続モードに移行する制御が行われることもある。その場合には、連続モードに移行したあとも消灯状態である。また、PWM制御信号のオン時にプラズマが点灯した状態であるときに連続モードに移行する制御が行われた場合であっても、連続モードへの移行時にプラズマが消灯してしまうことも起こり得る。 Generally, plasma requires a large amount of power to start turning on from a completely off state, but once the plasma is turned on, it will remain on even if the power supply is reduced. Therefore, when the intermittent mode is switched to the continuous mode while the PWM control signal is on and the plasma is on, the immediately preceding turned-on state is generally continued. However, as described above, the plasma is not necessarily in a turned-on state even during the on period of the PWM control signal in the intermittent mode. Therefore, even if the plasma was on when the PWM control signal was on until just before, the plasma may not be turned on when the PWM control signal was on, and control to switch to the continuous mode may be performed when the plasma is not turned on when the PWM control signal is on. In that case, the plasma remains off even after switching to the continuous mode. Also, even if control to switch to the continuous mode is performed when the plasma is on when the PWM control signal is on, the plasma may be turned off when switching to the continuous mode.

そこで、制御部3は間欠モードから連続モードへ移行したあとに、光検出器218からの出力信号をモニターし、その信号値に基いてプラズマが点灯しているか否かを確認する(ステップS4)。そして、プラズマが点灯していると判断できた場合には、ステップS5からS6へと進み、ラジカル付着解離を利用したMS/MS分析を開始する。一方、連続モードへの移行後にプラズマが点灯していないと判断できる場合(ステップS5でNO)には、ステップS1へと戻り、制御部3はプラズマの点灯開始制御を再試行する。

Then, after switching from intermittent mode to continuous mode, the

連続モードでは、間欠モード中のマイクロ波電力供給時に比べて出力電力は低いものの、プラズマの点灯/消灯が繰り返されないため、プラズマの状態が安定し易い。従って、本実施形態の質量分析装置では、石英管210内の一部であるプラズマ生成室内に安定的にプラズマが形成され、該プラズマ中で生成されたラジカルが安定してコリジョンセル132内に供給される状態でMS/MS分析を実行することができる。それにより、ラジカル付着解離によって生成されたプロダクトイオンを、安定的に且つ良好に検出することができる。

In continuous mode, although the output power is lower than when microwave power is supplied in intermittent mode, the plasma state is more likely to be stable because the plasma is not repeatedly turned on and off. Therefore, in the mass spectrometer of this embodiment, plasma is stably formed in the plasma generation chamber, which is part of the

また、マイクロ波に起因するノイズは、マイクロ波の出力電力に依存するため、連続モードにおいてマイクロ波の出力電力を間欠モードにおける電力供給時よりも抑えることで、検出信号に重畳するマイクロ波帯のノイズの影響を軽減することができる。また、MS/MS分析時には、PWM制御によるオン/オフに伴うスイッチングノイズも無くなるので、この点でも検出信号に重畳するノイズの影響を軽減することができる。 In addition, because noise caused by microwaves depends on the microwave output power, by reducing the microwave output power in continuous mode compared to when power is supplied in intermittent mode, the effect of microwave band noise superimposed on the detection signal can be reduced. In addition, during MS/MS analysis, there is no switching noise associated with on/off by PWM control, so in this respect too, the effect of noise superimposed on the detection signal can be reduced.

上述したように、ヘリカルアンテナ211にマイクロ波電力が供給されると該アンテナ211が発熱し、石英管210等の部材の温度が上昇する。ラジカル生成部2の熱は石英管210等を通して質量分離部へも伝わり、質量分析性能に影響を与える場合がある。例えば、熱によってフライトチューブ144が膨張したり、リフレクトロン電極145の電極間隔が変化したりすると、同じm/z値を有するイオンの飛行時間が変化し質量誤差が大きくなる等の影響が考えられる。間欠モード、連続モードのいずれでも熱の発生を抑えることは実質的にできないが、質量分析性能への影響を抑えるには、間欠モードと連続モードとで発熱量を概ね揃えることが望ましい。そこで、本実施形態の質量分析装置では、間欠モードと連続モードとで単位時間当たりに供給する電力、つまりは出力電力を単位時間当たりで平均した平均電力を概ね揃えるようにするとよい。

As described above, when microwave power is supplied to the

具体的には、間欠モードの電力供給時における出力電力をPa、間欠モードにおけるPWM制御信号のデューティー比をD(但し、常時オンではD=1、常時オフではD=0とする)、連続モードにおける出力電力をPbとした場合、

Pa×D≒Pb …(1)

となるようにすればよい。

これにより、間欠モードから連続モードに移行した際のラジカル生成部2での発熱量の変化を抑え、連続モード移行後にすぐにMS/MS分析を開始しても質量分析性能の低下を軽減することができる。

Specifically, when the output power during power supply in the intermittent mode is Pa, the duty ratio of the PWM control signal in the intermittent mode is D (however, D=1 for always on and D=0 for always off), and the output power in the continuous mode is Pb,

Pa × D ≒ Pb ... (1)

It is sufficient to make it so that:

This suppresses the change in the amount of heat generated in the

上記実施形態は、本発明に係るイオン分析装置をQ-TOF型質量分析装置に適用した例であるが、Q-TOF型に限らないことは明らかである。具体的には、トリプル四重極型質量分析装置、イオントラップ型質量分析装置、イオントラップ飛行時間型質量分析装置などにも本発明を適用可能である。また、本発明は、プラズマ中で生成したラジカル種を用いてイオンを解離させ、その解離により生成されたプロダクトイオンを分析する装置全般に適用し得る。具体的には、例えば、イオンをイオン移動度に応じて分離して検出するイオン移動度分析装置や、イオンをイオン移動度とm/zの両方を用いて分離するイオン移動度-質量分析装置などにも本発明を適用し得る。 The above embodiment is an example in which the ion analyzer according to the present invention is applied to a Q-TOF mass analyzer, but it is clear that the present invention is not limited to Q-TOF types. Specifically, the present invention can also be applied to triple quadrupole mass analyzers, ion trap mass analyzers, ion trap time-of-flight mass analyzers, and the like. The present invention can also be applied to devices in general that dissociate ions using radical species generated in plasma and analyze the product ions generated by the dissociation. Specifically, the present invention can also be applied to ion mobility analyzers that separate and detect ions according to ion mobility, and ion mobility-mass analyzers that separate ions using both ion mobility and m/z.

また、上記説明した質量分析装置の構成、特にラジカル種を生成するラジカル生成部2の構成は単に一例であり、プラズマによりラジカル種を生成可能な構成であれば適宜に変形可能であることは当然である。また、ここいうラジカル種は、一般的にラジカル付着解離に利用されるヒドロキシルラジカル、酸素ラジカル、窒素ラジカル、水素ラジカルなどのほか、エネルギーが与えられて励起された状態にある又は準安定な状態になる各種の分子、原子なども含む。

Furthermore, the configuration of the mass spectrometer described above, particularly the configuration of the

即ち、上記実施形態は本発明の単なる一例にすぎず、本発明の趣旨の範囲で適宜に変形、追加等を行っても本願特許請求の範囲に包含されることは明らかである。 In other words, the above embodiment is merely one example of the present invention, and it is clear that any modifications, additions, etc. made within the spirit of the present invention are also encompassed within the scope of the claims of this application.

[種々の態様]

上述した例示的な実施形態は、以下の態様の具体例であることが当業者により理解される。

[Various aspects]

It will be appreciated by those skilled in the art that the exemplary embodiments described above are examples of the following aspects.

(第1項)本発明に係るイオン分析装置の一態様は、生成部で生成したラジカル種を反応室に導入し、該反応室において試料由来のイオンにラジカル種を接触させて該イオンを解離させるイオン分析装置であって、前記生成部は、

原料ガスがその内部に導入される生成室と、

前記生成室の内部にプラズマを生じさせるための高周波電力を供給する電力供給部と、

前記生成室に供給する高周波電力を調整するべく前記電力供給部を制御する制御部であって、プラズマの点灯開始時には高周波電力を間欠的に供給する間欠モードでの制御を行い、該間欠モード中であって高周波電力が供給されているタイミングで、該間欠モードにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する連続モードに制御モードを切り替える制御部と、

を備える。

(Item 1) One aspect of the ion analyzer according to the present invention is an ion analyzer that introduces radical species generated in a generation unit into a reaction chamber, and brings the radical species into contact with ions derived from a sample in the reaction chamber to dissociate the ions, the generation unit comprising:

a generation chamber into which a source gas is introduced;

a power supply unit that supplies high frequency power for generating plasma inside the generation chamber;

a control unit that controls the power supply unit to adjust the high frequency power supplied to the generation chamber, the control unit performing control in an intermittent mode in which the high frequency power is intermittently supplied at the start of plasma lighting, and switching the control mode to a continuous mode in which high frequency power having an output power lower than that of the high frequency power supplied in the intermittent mode is continuously supplied at a timing when high frequency power is being supplied during the intermittent mode;

Equipped with.

(第4項)本発明に係るイオン分析方法の一態様は、生成部で生成したラジカル種を反応室に導入し、該反応室において試料由来のイオンにラジカル種を接触させて該イオンを解離させるイオン分析方法であって、

前記生成部に含まれる生成室の内部に原料ガスを導入する原料ガス導入ステップと、

前記生成室の内部にプラズマを生じさせるために、プラズマ点灯開始時に高周波電力を間欠的に供給する第1電力供給ステップと、

前記第1電力供給ステップにおいて高周波電力が供給されているタイミングで、間欠的な高周波電力に代えて、該第1電力供給ステップにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する第2電力供給ステップと、

前記第2電力供給ステップにおいて連続的な高周波電力が前記生成室に供給されている状態で、前記反応室において解離されたイオンに対する分析を実施する測定ステップと、

を有する。

(Item 4) One aspect of the ion analysis method according to the present invention is an ion analysis method comprising: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

A raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit;

a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber;

a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step;

a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step;

has.

一般に、プラズマは完全に(つまり或る程度の時間継続して)消灯している状態では、比較的大きな電力を供給しないと点灯しにくいが、一旦、点灯すると、供給する電力を減らしても点灯状態が継続し易い。第1項に記載のイオン分析装置及び第4項に記載のイオン分析方法では、プラズマの点灯開始時には、出力電力が比較的大きい高周波電力(典型的にはマイクロ波電力)を供給することでプラズマを良好に点灯させる。但し、大出力の高周波電力を連続的に供給すると発熱が問題となるため、PWM制御等により間欠的に高周波電力を供給する。そうして間欠的な高周波電力の供給を適宜の期間実施したあと、高周波電力が供給されているタイミングで、その電力の供給を連続モードに切り替える。この連続モードでは、出力電力を間欠モード中の電力供給時よりも低くする。

Generally, when plasma is completely off (i.e., for a certain period of time), it is difficult to light it unless a relatively large amount of power is supplied, but once it is turned on, it tends to remain on even if the power supply is reduced. In the ion analysis device described in

このようにして第1項に記載のイオン分析装置及び第4項に記載のイオン分析方法によれば、ラジカル種を生成するための生成部における発熱を抑えながら、プラズマを安定的に生成し、ラジカル種も安定的に生成することができる。また、第1項に記載のイオン分析装置及び第4項に記載のイオン分析方法によれば、プラズマ生成のための高周波電力の供給に起因するノイズを抑制し、高品質のイオン強度信号を取得することができる。

In this way, the ion analysis device described in

(第2項)第1項に記載のイオン分析装置では、前記間欠モードと前記連続モードとで所定時間における平均電力を揃えるものとすることができる。 (2) In the ion analyzer described in 1, the average power over a given time period can be made uniform between the intermittent mode and the continuous mode.

(第5項)第4項に記載のイオン分析方法では、前記第1電力供給ステップと前記第2電力供給ステップとで所定時間における平均電力を揃えるものとすることができる。 (5) In the ion analysis method described in 4, the average power over a given time period can be made uniform between the first power supply step and the second power supply step.

第2項に記載のイオン分析装置では、間欠モードから連続モードに制御モードを切り替えても、所定時間における平均電力が殆ど変化しない。そのため、生成部における発熱量に大きな変化が生じず、生成部やその周囲に存在する様々な部材における熱膨張量の差異などに起因する分析精度の低下を抑えることができる。それによって、高い精度の分析を実施することができる。

In the ion analyzer described in

(第3項)第1項又は第2項に記載のイオン分析装置は、プラズマが点灯しているか否かを検出する検出部、をさらに備え、

前記制御部は、前記間欠モードから前記連続モードに制御モードを切り替えたあとに、前記検出部によりプラズマが点灯しているか否かを確認し、点灯していない場合には前記間欠モードに戻って点灯動作を再試行するものとすることができる。

(3) The ion analyzer according to the first or second aspect further includes a detection unit that detects whether or not plasma is lit,

After switching the control mode from the intermittent mode to the continuous mode, the control unit can check whether or not plasma is lit using the detection unit, and if plasma is not lit, return to the intermittent mode and retry the lighting operation.

(第6項)第4項又は第5項に記載のイオン分析方法では、前記第2電力供給ステップにおいてプラズマが点灯しているか否かを確認し、点灯していない場合には前記第1電力供給ステップに戻って点灯動作を再試行するものとすることができる。 (6) In the ion analysis method described in 4 or 5, it can be configured to check whether the plasma is lit in the second power supply step, and if not, to return to the first power supply step and retry the lighting operation.

プラズマが点灯しているか否かの検出は、例えばプラズマから放出される光を検出することにより行うことができる。第3項に記載のイオン分析装置によれば、間欠モードから連続モードへの切替え時にプラズマが消える等の不具合によってプラズマ点灯がうまくいかない場合であっても、間欠モードから再試行を行うことによって、確実にプラズマを点灯させ、ラジカルが生成される状態の下で分析を実施することができる。

Whether or not the plasma is lit can be detected, for example, by detecting the light emitted from the plasma. According to the ion analyzer described in

1…真空チャンバー

1000…開口

10…イオン化室

101…ESIプローブ

102…脱溶媒管

11…第1中間真空室

111…イオンガイド

112…スキマー

12…第2中間真空室

121…イオンガイド

13…第1分析室

131…四重極マスフィルター

132…コリジョンセル

1320…開口

1321…管接続部材

133…多重極イオンガイド

134…イオン輸送電極

14…第2分析室

141…イオン輸送電極

142…直交加速部

143…加速電極

144…フライトチューブ

145…リフレクトロン電極

146…イオン検出器

2…ラジカル生成部

20…バルブ

21…プラズマ生成部

210…石英管

211…ヘリカルアンテナ

212…外側導体部

213、215…永久磁石

214…ケーシング

216…マイクロ波供給コネクタ

217…紫外光光源

218…光検出器

220…共振器調整機構

221…磁石ホルダー

222…保持部材

26…マイクロ波電源

27…原料ガス供給源

3…制御部

4…データ処理部

Reference Signs List 1: Vacuum chamber 1000: Opening 10: Ionization chamber 101: ESI probe 102: Desolvation tube 11: First intermediate vacuum chamber 111: Ion guide 112: Skimmer 12: Second intermediate vacuum chamber 121: Ion guide 13: First analysis chamber 131: Quadrupole mass filter 132: Collision cell 1320: Opening 1321: Tube connection member 133: Multipole ion guide 134: Ion transport electrode 14: Second analysis chamber 141: Ion transport electrode 142: Orthogonal acceleration section 143: Acceleration electrode 144: Flight tube 145: Reflectron electrode 146: Ion detector 2: Radical generation section 20: Valve 21: Plasma generation section 210: Quartz tube 211: Helical antenna 212:

Claims (6)

原料ガスがその内部に導入される生成室と、

前記生成室の内部にプラズマを生じさせるための高周波電力を供給する電力供給部と、

前記生成室に供給する高周波電力を調整するべく前記電力供給部を制御する制御部であって、プラズマの点灯開始時には高周波電力を間欠的に供給する間欠モードでの制御を行い、該間欠モード中であって高周波電力が供給されているタイミングで、該間欠モードにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する連続モードに制御モードを切り替える制御部と、

を備えるイオン分析装置。 An ion analyzer that introduces radical species generated in a generation unit into a reaction chamber, and dissociates the ions by contacting the radical species with ions derived from a sample in the reaction chamber, the generation unit comprising:

a generation chamber into which a source gas is introduced;

a power supply unit that supplies high frequency power for generating plasma inside the generation chamber;

a control unit that controls the power supply unit to adjust the high frequency power supplied to the generation chamber, the control unit performing control in an intermittent mode in which the high frequency power is intermittently supplied at the start of plasma lighting, and switching the control mode to a continuous mode in which high frequency power having an output power lower than that of the high frequency power supplied in the intermittent mode is continuously supplied at a timing when high frequency power is being supplied during the intermittent mode;

An ion analyzer comprising:

前記制御部は、前記間欠モードから前記連続モードに制御モードを切り替えたあとに、前記検出部によりプラズマが点灯しているか否かを確認し、点灯していない場合には前記間欠モードに戻って点灯動作を再試行する、請求項1に記載のイオン分析装置。 A detection unit for detecting whether or not the plasma is lit is further provided,

2. The ion analysis device according to claim 1, wherein after switching the control mode from the intermittent mode to the continuous mode, the control unit checks whether or not plasma is lit by the detection unit, and if plasma is not lit, returns to the intermittent mode and retries the lighting operation.

前記生成部に含まれる生成室の内部に原料ガスを導入する原料ガス導入ステップと、

前記生成室の内部にプラズマを生じさせるために、プラズマ点灯開始時に高周波電力を間欠的に供給する第1電力供給ステップと、

前記第1電力供給ステップにおいて高周波電力が供給されているタイミングで、間欠的な高周波電力に代えて、該第1電力供給ステップにおける高周波電力供給時に比べて出力電力が低い高周波電力を連続的に供給する第2電力供給ステップと、

前記第2電力供給ステップにおいて連続的な高周波電力が前記生成室に供給されている状態で、前記反応室において解離されたイオンに対する分析を実施する測定ステップと、

を有するイオン分析方法。 A method for ion analysis comprising the steps of: introducing radical species generated in a generation unit into a reaction chamber; and contacting the radical species with ions derived from a sample in the reaction chamber to dissociate the ions,

A raw material gas introduction step of introducing a raw material gas into a generation chamber included in the generation unit;

a first power supply step of intermittently supplying high frequency power at the start of plasma lighting in order to generate plasma inside the generation chamber;

a second power supply step of continuously supplying, instead of the intermittent high frequency power, high frequency power having an output power lower than that of the high frequency power supplied in the first power supply step, at a timing when the high frequency power is supplied in the first power supply step;

a measurement step of performing an analysis on the ions dissociated in the reaction chamber while continuous high frequency power is being supplied to the generation chamber in the second power supply step;

The ion analysis method according to claim 1,

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2023/030031 WO2025041231A1 (en) | 2023-08-21 | 2023-08-21 | Ion analysis device and ion analysis method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2023/030031 WO2025041231A1 (en) | 2023-08-21 | 2023-08-21 | Ion analysis device and ion analysis method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2025041231A1 true WO2025041231A1 (en) | 2025-02-27 |

Family

ID=94731834

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2023/030031 Pending WO2025041231A1 (en) | 2023-08-21 | 2023-08-21 | Ion analysis device and ion analysis method |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2025041231A1 (en) |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06349594A (en) * | 1993-06-07 | 1994-12-22 | Mitsubishi Electric Corp | Plasma generating device |

| WO2023002712A1 (en) * | 2021-07-21 | 2023-01-26 | 株式会社島津製作所 | Mass spectrometry device and mass spectrometry method |

-

2023

- 2023-08-21 WO PCT/JP2023/030031 patent/WO2025041231A1/en active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06349594A (en) * | 1993-06-07 | 1994-12-22 | Mitsubishi Electric Corp | Plasma generating device |

| WO2023002712A1 (en) * | 2021-07-21 | 2023-01-26 | 株式会社島津製作所 | Mass spectrometry device and mass spectrometry method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2610892B1 (en) | Mass spectrometer and mass spectrometry | |

| EP3234978B1 (en) | Ionization device and mass spectrometer therewith | |

| US7385185B2 (en) | Molecular activation for tandem mass spectroscopy | |

| US9589775B2 (en) | Plasma cleaning for mass spectrometers | |

| US7365315B2 (en) | Method and apparatus for ionization via interaction with metastable species | |

| JP7556472B2 (en) | Mass spectrometer and how to operate the mass spectrometer | |

| JP7616390B2 (en) | Mass spectrometer and mass spectrometry method | |

| US11133168B2 (en) | Method for spectrometry | |

| WO2025041231A1 (en) | Ion analysis device and ion analysis method | |

| US11217437B2 (en) | Electron capture dissociation (ECD) utilizing electron beam generated low energy electrons | |

| TW202109613A (en) | Mass spectrometer comprising an ionization device | |

| WO2025041271A1 (en) | Ion analysis device | |

| JP7396508B2 (en) | Radical generator and ion analyzer | |

| US20250132142A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| US20250198965A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| US20250130201A1 (en) | Ion Analyzer and Ion Analyzing Method | |

| JP7735882B2 (en) | Mass spectrometer and method for adjusting mass spectrometer | |

| WO2024171416A1 (en) | Mass spectrometry device and mass spectrometry method | |

| JP2025029786A (en) | Ion Analysis Equipment | |

| JP2024057924A (en) | Mass Spectrometer | |

| JP2024051420A (en) | Mass Spectrometer | |

| JP2024157097A (en) | Mass Spectrometer | |

| EP4193382A1 (en) | Identification of harmonics in rf quadrupole fourier transform mass spectra |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 23949692 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2025541187 Country of ref document: JP Kind code of ref document: A |