WO2023219031A1 - ゲート駆動回路、パワーグッド回路、過電流検出回路、発振防止回路、スイッチング制御回路、および、スイッチング電源装置 - Google Patents

ゲート駆動回路、パワーグッド回路、過電流検出回路、発振防止回路、スイッチング制御回路、および、スイッチング電源装置 Download PDFInfo

- Publication number

- WO2023219031A1 WO2023219031A1 PCT/JP2023/017044 JP2023017044W WO2023219031A1 WO 2023219031 A1 WO2023219031 A1 WO 2023219031A1 JP 2023017044 W JP2023017044 W JP 2023017044W WO 2023219031 A1 WO2023219031 A1 WO 2023219031A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- transistor

- circuit

- voltage

- switch

- power supply

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/08—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters

- H02M1/088—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters for the simultaneous control of series or parallel connected semiconductor devices

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of DC power input into DC power output

- H02M3/02—Conversion of DC power input into DC power output without intermediate conversion into AC

- H02M3/04—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters

- H02M3/10—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

- H02M3/145—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal

- H02M3/155—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05F—SYSTEMS FOR REGULATING ELECTRIC OR MAGNETIC VARIABLES

- G05F1/00—Automatic systems in which deviations of an electric quantity from one or more predetermined values are detected at the output of the system and fed back to a device within the system to restore the detected quantity to its predetermined value or values, i.e. retroactive systems

- G05F1/10—Regulating voltage or current

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/08—Circuits specially adapted for the generation of control voltages for semiconductor devices incorporated in static converters

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/32—Means for protecting converters other than automatic disconnection

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/32—Means for protecting converters other than automatic disconnection

- H02M1/327—Means for protecting converters other than automatic disconnection against abnormal temperatures

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of DC power input into DC power output

- H02M3/02—Conversion of DC power input into DC power output without intermediate conversion into AC

- H02M3/04—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters

- H02M3/10—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

- H02M3/145—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal

- H02M3/155—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only

- H02M3/156—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of output voltage or current, e.g. switching regulators

- H02M3/158—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of output voltage or current, e.g. switching regulators including plural semiconductor devices as final control devices for a single load

-

- H—ELECTRICITY

- H03—ELECTRONIC CIRCUITRY

- H03F—AMPLIFIERS

- H03F3/00—Amplifiers with only discharge tubes or only semiconductor devices as amplifying elements

- H03F3/45—Differential amplifiers

-

- H—ELECTRICITY

- H03—ELECTRONIC CIRCUITRY

- H03K—PULSE TECHNIQUE

- H03K17/00—Electronic switching or gating, i.e. not by contact-making and –breaking

- H03K17/16—Modifications for eliminating interference voltages or currents

-

- H—ELECTRICITY

- H03—ELECTRONIC CIRCUITRY

- H03K—PULSE TECHNIQUE

- H03K17/00—Electronic switching or gating, i.e. not by contact-making and –breaking

- H03K17/22—Modifications for ensuring a predetermined initial state when the supply voltage has been applied

-

- H—ELECTRICITY

- H03—ELECTRONIC CIRCUITRY

- H03K—PULSE TECHNIQUE

- H03K17/00—Electronic switching or gating, i.e. not by contact-making and –breaking

- H03K17/51—Electronic switching or gating, i.e. not by contact-making and –breaking characterised by the components used

- H03K17/56—Electronic switching or gating, i.e. not by contact-making and –breaking characterised by the components used by the use, as active elements, of semiconductor devices

- H03K17/687—Electronic switching or gating, i.e. not by contact-making and –breaking characterised by the components used by the use, as active elements, of semiconductor devices the devices being field-effect transistors

- H03K17/693—Switching arrangements with several input- or output-terminals, e.g. multiplexers, distributors

Definitions

- the invention disclosed herein relates to a gate drive circuit.

- the invention disclosed herein also relates to a power good circuit.

- the invention disclosed herein also relates to an overcurrent detection circuit, an oscillation prevention circuit, a switching control circuit, and a switching power supply device having the overcurrent detection circuit or the oscillation prevention circuit.

- a gate drive circuit that drives the gates of a high-side transistor and a low-side transistor connected in series is known (for example, Patent Document 1).

- the high-side transistor and the low-side transistor are configured by N-channel MOSFETs (metal-oxide-semiconductor field-effect transistors).

- the high-side transistor and the low-side transistor When one of the high-side transistor and the low-side transistor turns on (switches from an off state to an on state) and the other turns off (switches from an on state to an off state), the high-side transistor and the low-side transistor are connected. A voltage change occurs at the node where the voltage is applied. This changes the Vds (drain-source voltage) of the transistor that is turned off. If the slew rate (gradient of change with respect to time) of the voltage change at the node is large, the Vgs (gate-source voltage) of the transistor to be turned off will rise, and there is a possibility that the transistor will self-turn on.

- a power supply IC (Integrated Circuit) including a power good circuit is conventionally known.

- a power good circuit is a circuit that has a function of outputting a flag when the output voltage of a power supply circuit reaches a set voltage value (for example, Patent Document 2). Thereby, for example, it is possible to notify an IC (such as a CPU (Central Processing Unit)) external to the power supply IC that the output voltage has risen normally.

- a set voltage value for example, Patent Document 2.

- a switching power supply device having an error amplifier has been developed (for example, see Patent Document 4).

- the error amplifier generates an error signal according to the difference between a feedback voltage and a reference voltage, and a switching control circuit controls a switching element based on the error signal.

- the conventional lower current detection circuit has room for improvement regarding failure to detect overcurrent (third issue).

- a gate drive circuit that drives a half bridge in which a high-side transistor to be driven and a low-side transistor to be driven are connected in series between a power supply voltage and a ground potential, a high-side pre-driver configured to drive a gate of the high-side transistor to be driven; a low-side pre-driver configured to drive a gate of the low-side transistor to be driven; Equipped with The high side pre-driver has a first high side transistor and a second high side transistor, The low-side pre-driver includes a third high-side transistor and a fourth high-side transistor, between a first gate signal that turns on the first high-side transistor and a second gate signal that turns on the second high-side transistor; A delay is provided between at least one of a third gate signal that turns on the third high-side transistor and a fourth gate signal that turns on the fourth high-side transistor.

- a power good circuit includes a first output transistor having a first end connected to a power good terminal and a second end connected to a ground potential application end; a resistor for applying a voltage based on the first power supply voltage to the control end of the first output transistor; a first inverter stage configured to use a second power supply voltage as a power supply voltage and to be able to input a control input signal; a second output transistor having a control end connected to an output end of the first inverter stage, a first end connected to the power good terminal, and a second end connected to a ground potential application end; , Equipped with The power good terminal can be pulled up to the second power supply voltage.

- the overcurrent detection circuit includes a first current generation circuit configured to generate a first current corresponding to a current flowing through the second switch, and a first current generating circuit configured to generate a first current corresponding to a current flowing through the second switch, and a current generating circuit configured to generate a first current that is larger than zero at a timing when the second switch is switched from off to on. , a second current generating circuit configured to generate a second current that fluctuates in synchronization with switching of the first switch and the second switch; and a voltage according to the first current and the second current. and a comparator configured to compare the threshold value.

- the switching control circuit disclosed herein includes an overcurrent detection circuit configured as described above, and a control section configured to control the first switch and the second switch.

- the switching power supply device disclosed herein includes a switching control circuit having the above configuration, the first switch, and the second switch.

- the oscillation prevention circuit disclosed in this specification includes a signal line, a first circuit, a capacitor connected to the signal line, and a resistor provided between the signal line and the first circuit. and has.

- the first circuit has two poles.

- the first circuit, the capacitor, and the resistor have two poles and one zero point.

- the switching control circuit disclosed herein includes an oscillation prevention circuit configured as described above, an error amplifier whose output end is connected to the signal line, and a switching element configured to control a switching element based on the output voltage of the error amplifier. and a control section configured to.

- the switching power supply device disclosed herein includes a switching control circuit having the above configuration and the switching element.

- oscillation of the first circuit having two poles can be prevented.

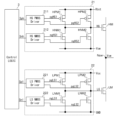

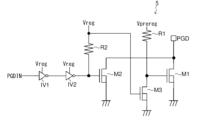

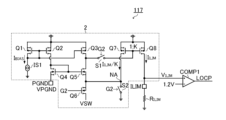

- FIG. 1 is a diagram showing the configuration of a semiconductor device according to a first embodiment of the present disclosure.

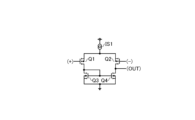

- FIG. 2 is a diagram showing a specific example of the configuration of the gate drive circuit.

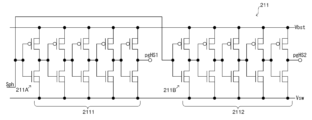

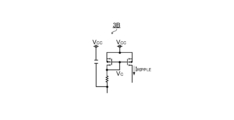

- FIG. 3 is a diagram showing an example of the configuration of the first high side drive section.

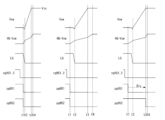

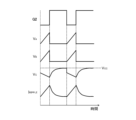

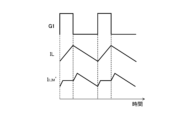

- FIG. 4 is a timing chart showing the operation when the high-side transistor is turned on and the low-side transistor is turned off.

- FIG. 5 is a timing chart showing the operation when the high-side transistor is turned off and the low-side transistor is turned on in the embodiment of the present disclosure.

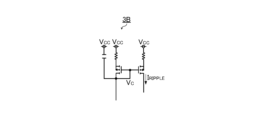

- FIG. 6 is a diagram showing an example of the configuration of the first low-side drive section.

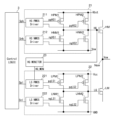

- FIG. 7 is a diagram showing the configuration of a gate drive circuit according to a second embodiment of the present disclosure.

- FIG. 1 is a diagram showing the configuration of a semiconductor device according to a first embodiment of the present disclosure.

- FIG. 2 is a diagram showing a specific example of the configuration of the gate drive circuit.

- FIG. 3 is

- FIG. 8 is a diagram illustrating a configuration example of a high side gate voltage monitor section.

- FIG. 9 is a diagram showing an example of the configuration of the first low-side drive section.

- FIG. 10 is a timing chart showing the operation when the high-side transistor is turned off and the low-side transistor is turned on in the second embodiment.

- FIG. 11 is a timing chart showing the operation when the high-side transistor is turned off and the low-side transistor is turned on in the embodiment of the present disclosure.

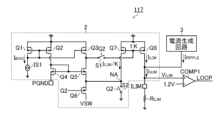

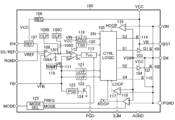

- FIG. 12 is a diagram illustrating the configuration of a semiconductor device according to an exemplary embodiment of the present disclosure.

- FIG. 13 is a diagram showing a part of the internal configuration of the semiconductor device.

- FIG. 14 is a diagram showing an example of the configuration of the preregulator.

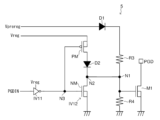

- FIG. 15 is a diagram showing the configuration of a power good circuit according to a comparative example.

- FIG. 16 is a timing chart showing the operation of the power good circuit according to the comparative example at the time of starting up the power supply IC.

- FIG. 17 is a diagram showing the configuration of a power good circuit according to the first embodiment of the present disclosure.

- FIG. 18 is a timing chart showing the operation of the power good circuit according to the first embodiment at startup and shutdown of the power supply IC.

- FIG. 19 is a diagram showing the configuration of a power good circuit according to the second embodiment of the present disclosure.

- FIG. 20 is a timing chart showing the operation of the power good circuit according to the second embodiment at startup and shutdown of the power supply IC.

- FIG. 21 is a diagram showing the configuration of a power good circuit according to the third embodiment of the present disclosure.

- FIG. 22 is a timing chart showing the operation of the power good circuit according to the third embodiment at startup and shutdown of the power supply IC.

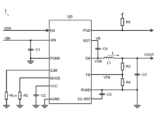

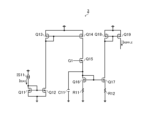

- FIG. 23 is a diagram showing the overall configuration of the switching power supply device.

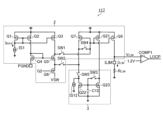

- FIG. 24 is a diagram showing the internal configuration of the semiconductor device.

- FIG. 25 is a diagram showing a comparative example of the lower overcurrent detection circuit.

- FIG. 26 is a timing chart showing ideal waveforms of voltages and currents of each part of the switching power supply device.

- FIG. 27 is a timing chart showing actual waveforms of voltages and currents of each part of the switching power supply device.

- FIG. 28 is a diagram showing a first embodiment of the lower overcurrent detection circuit.

- FIG. 29 is a diagram showing a first configuration example of the current generation circuit.

- FIG. 30 is a timing chart showing actual waveforms of voltages and currents at various parts of the switching power supply device having the lower overcurrent detection circuit according to the first embodiment.

- FIG. 31 is a diagram showing a second configuration example of the current generation circuit.

- FIG. 32 is a diagram showing a third configuration example of the current generation circuit.

- FIG. 33 is a diagram showing a fourth configuration example of the current generation circuit.

- FIG. 34 is a diagram showing a fifth configuration example of the current generation circuit.

- FIG. 35A is a diagram showing a modification of the first circuit.

- FIG. 35B is a diagram showing another modification of the first circuit.

- FIG. 36A is a diagram showing a modification of the second circuit.

- FIG. 36B is a diagram showing another modification of the second circuit.

- FIG. 36C is a diagram showing still another modification of the second circuit.

- FIG. 37 is a timing chart showing actual waveforms of voltages and currents at various parts of a switching power supply device having a current generation circuit of the fifth configuration example.

- FIG. 38 is a diagram showing a second embodiment of the lower overcurrent detection circuit.

- FIG. 39 is a timing chart showing actual waveforms of voltages and currents at various parts of the switching power supply device having the lower overcurrent detection circuit according to the second embodiment.

- FIG. 40 is a diagram showing a third embodiment of the lower overcurrent detection circuit.

- FIG. 41 is a diagram showing the overall configuration of a switching power supply device.

- FIG. 42 is a diagram showing the internal configuration of the semiconductor device.

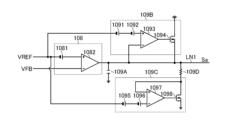

- FIG. 43 is a diagram showing a configuration example of an error amplifier, an upper clamp circuit, and a lower clamp circuit.

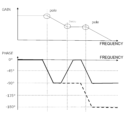

- FIG. 44 is a diagram showing the frequency characteristics of the lower clamp circuit.

- FIG. 45 is a diagram showing the frequency characteristics of the upper clamp circuit.

- FIG. 46 is a diagram showing frequency characteristics of the upper clamp circuit, capacitor, and resistor.

- FIG. 47 is a diagram showing an example of the configuration of a differential amplifier.

- MOSFET Metal-Oxide-Semiconductor Field Effect Transistor

- a field-effect transistor consisting of at least three layers: a semiconductor layer, and a P-type, N-type, or intrinsic semiconductor layer. That is, the structure of the gate of the MOS field effect transistor is not limited to the three-layer structure of metal, oxide, and semiconductor.

- the reference voltage refers to a voltage that is constant in an ideal state, and is actually a voltage that may vary slightly due to temperature changes or the like.

- FIG. 1 is a diagram showing the configuration of a semiconductor device 1 according to a first embodiment of the present disclosure.

- the semiconductor device 1 is a device in which a power supply IC having a DC/DC converter function is packaged. As shown in FIG. 1, the semiconductor device 1 includes a high-side transistor HM, a low-side transistor LM, a gate drive circuit 2, a control logic section 3, and a switch 4 in an integrated manner.

- An inductor L, an output capacitor Cout, and a boot capacitor Cbst are provided outside the semiconductor device 1. These external elements and semiconductor device 1 constitute a step-down DC/DC converter.

- the high-side transistor HM and the low-side transistor LM are both constructed from NMOS transistors (N-channel MOSFETs).

- the drain of the high-side transistor HM is connected to the application terminal of the input voltage Vin.

- the source of the high-side transistor HM is connected to the drain of the low-side transistor LM.

- the source of the low-side transistor LM is connected to a ground potential application terminal. That is, the high-side transistor HM and the low-side transistor LM are connected in series between the input voltage Vin and the ground potential.

- a so-called half bridge is constituted by the high side transistor HM and the low side transistor LM.

- a node Nsw to which the source of the high-side transistor HM and the drain of the low-side transistor LM are connected is connected to one end of the inductor L.

- the other end of the inductor L is connected to one end of the output capacitor Cout.

- the other end of the output capacitor Cout is connected to a ground potential application end.

- An output voltage Vout is generated at one end of the output capacitor Cout.

- the gate drive circuit 2 is a circuit that drives each gate of the high-side transistor HM and the low-side transistor LM, and includes a high-side pre-driver 21 and a low-side pre-driver 22.

- the high-side pre-driver 21 drives the gate of the high-side transistor HM based on the control signal input from the control logic section 3.

- the low-side predriver 22 drives the gate of the low-side transistor LM based on a control signal input from the control logic section 3.

- the input voltage Vin is converted into the output voltage Vout by complementary switching driving of the transistors HM and LM by the pre-drivers 21 and 22.

- the boot capacitor Cbst and switch 4 are used to configure a bootstrap.

- One end of the boot capacitor Cbst is connected to one end of the inductor L.

- the other end of the boot capacitor Cbst is connected to the high side predriver 21.

- the other end of the boot capacitor Cbst is connected via the switch 4 to the application end of the power supply voltage Vcc.

- the power supply voltage Vcc is, for example, an internal voltage generated by an LDO (Low Dropout) based on the input voltage Vin.

- the switch 4 When the high-side transistor HM is off and the low-side transistor LM is on, the switch 4 is turned on and the boot capacitor Cbst is charged. When the high side transistor HM is on and the low side transistor LM is off, the switch 4 is turned off and the boot voltage Vbst generated in the boot capacitor Cbst is supplied to the high side predriver 21. Since the boot voltage Vbst is higher than the input voltage Vin, the high-side transistor HM made of an NMOS transistor can be turned on.

- FIG. 2 is a diagram showing a specific example of the configuration of the gate drive circuit 2.

- the high-side pre-driver 21 includes a first high-side PMOS transistor (P-channel MOSFET) HPM1, a second high-side PMOS transistor HPM2, a first high-side NMOS transistor HNM1, and a second high-side NMOS transistor HNM2.

- the high-side pre-driver 21 includes a first high-side drive section (high-side PMOS drive section) 211 that drives the high-side PMOS transistors HPM1 and HPM2, and a second high-side drive section (high-side drive section) that drives the high-side NMOS transistors HNM1 and HNM2.

- the high side NMOS drive section) 212 is further included.

- the sources of the high-side PMOS transistors HPM1 and HPM2 are connected to the application terminal of the boot voltage Vbst.

- the drains of the high side PMOS transistors HPM1 and HPM2 are connected to the drains of the high side NMOS transistors HNM1 and HNM2.

- the sources of the high-side NMOS transistors HNM1 and HNM2 are connected to the application terminal of the switch voltage Vsw generated at the node Nsw.

- a node to which the drains of the high-side PMOS transistors HPM1 and HPM2 and the drains of the high-side NMOS transistors HNM1 and HNM2 are connected is connected to the gate of the high-side transistor HM.

- the first high-side driving section 211 drives the gates of the high-side PMOS transistors HPM1 and HPM2 by applying gate signals pgHS1 and pgHS2 to the gates of the high-side PMOS transistors HPM1 and HPM2, respectively.

- the second high-side driving section 212 drives the gates of the high-side NMOS transistors HNM1 and HNM2 by applying gate signals ngHS1 and ngHS2 to the gates of the high-side NMOS transistors HNM1 and HNM2, respectively.

- the first high-side drive section 211 outputs the gate signals pgHS1 and pgHS2 at a logic level corresponding to the logic level of the high-side control signal Sph input from the control logic section 3.

- the second high-side drive section 212 outputs the gate signals ngHS1 and ngHS2 at a logic level corresponding to the logic level of the high-side control signal Snh input from the control logic section 3.

- the low-side predriver 22 includes a first low-side PMOS transistor LPM1, a second low-side PMOS transistor LPM2, a first low-side NMOS transistor LNM1, and a second low-side NMOS transistor LNM2.

- the low-side pre-driver 22 includes a first low-side drive section (low-side PMOS drive section) 221 that drives low-side PMOS transistors LPM1 and LPM2, and a second low-side drive section (low-side NMOS drive section) 222 that drives low-side NMOS transistors LNM1 and LNM2. It further has.

- the sources of the low-side PMOS transistors LPM1 and LPM2 are connected to the application terminal of the power supply voltage Vcc.

- the drains of the low-side PMOS transistors LPM1 and LPM2 are connected to the drains of the low-side NMOS transistors LNM1 and LNM2.

- the sources of the low-side NMOS transistors LNM1 and LNM2 are connected to a ground potential application terminal.

- a node to which the drains of the low-side PMOS transistors LPM1 and LPM2 and the drains of the low-side NMOS transistors LNM1 and LNM2 are connected is connected to the gate of the low-side transistor LM.

- the first low-side driving section 221 drives the gates of the low-side PMOS transistors LPM1 and LPM2 by applying gate signals pgLS1 and pgLS2 to the gates of the low-side PMOS transistors LPM1 and LPM2, respectively.

- the second low-side driving section 222 drives the gates of the low-side NMOS transistors LNM1 and LNM2 by applying gate signals ngLS1 and ngLS2 to the gates of the low-side NMOS transistors LNM1 and LNM2, respectively.

- the first low-side drive section 221 outputs the gate signals pgLS1 and pgLS2 at a logic level corresponding to the logic level of the low-side control signal Spl input from the control logic section 3.

- the second low-side drive section 222 outputs the gate signals ngLS1 and ngLS2 at a logic level corresponding to the logic level of the low-side control signal Snl input from the control logic section 3.

- FIG. 3 is a diagram showing an example of the configuration of the first high side drive section 211.

- the first high-side drive section 211 includes a first high-side gate signal generation section 2111 that generates a gate signal pgHS1 based on a high-side control signal Sph, and a second high-side gate signal generation section 2111 that generates a gate signal pgHS2 based on a high-side control signal Sph. It has a gate signal generation section 2112.

- the first high-side gate signal generation section 2111 is composed of five stages of inverters 211A.

- Each inverter 211A is composed of a PMOS transistor and an NMOS transistor connected in series between the boot voltage Vbst and the switch voltage Vsw.

- the high side control signal Sph is input to the first stage inverter 211A, and the gate signal pgHS1 is output from the final stage inverter 211A.

- the second high side gate signal generation section 2112 is composed of five stages of inverters 211B.

- Each inverter 211B is composed of a PMOS transistor and an NMOS transistor connected in series between the boot voltage Vbst and the switch voltage Vsw.

- the high-side control signal Sph is input to the first-stage inverter 211B, and the gate signal pgHS2 is output from the final-stage inverter 211B.

- inverters 211A and 211B are not limited to five stages.

- the configuration of the second high-side drive unit 212 is the same as that shown in FIG. 3, except that the high-side control signal Sph is replaced with the high-side control signal Snh, and the gate signals pgHS1 and pgHS2 are replaced with gate signals ngHS1 and ngHS2. .

- FIG. 4 is a timing chart showing the operation when the high-side transistor HM is turned on and the low-side transistor LM is turned off.

- FIG. 4 shows the case of normal operation.

- the normal operation is an operation when current flows from the node Nsw to the inductor L side (solid arrow in FIG. 1). Note that FIG. 4 shows three patterns to be described later.

- FIG. 4 waveform examples of the switch voltage Vsw, high side gate voltage HG, low side gate voltage LG, gate signals ngHS1, 2, gate signal pgHS1, and gate signal pgHS2 are shown in order from the top.

- the high-side gate voltage HG (FIG. 2) is the voltage applied to the gate of the high-side transistor HM with reference to the switch voltage Vsw, that is, the Vgs of the high-side transistor HM.

- the low-side gate voltage LG (FIG. 2) is a voltage applied to the gate of the low-side transistor LM with reference to the ground potential, that is, Vgs of the low-side transistor LM.

- the left side of FIG. 4 shows the operation when no delay is provided to the gate signals pgHS1 and pgHS2, as a comparative example with the embodiment of the present disclosure.

- the high side transistor HM is in an off state and the low side transistor LM is in an on state.

- the low-side predriver 22 starts discharging the gate of the low-side transistor LM (timing t1).

- the low side PMOS transistors LPM1 and LPM2 are turned off and the low side NMOS transistors LNM1 and LNM2 are turned on, and the low side gate voltage LG starts to decrease.

- the voltage drop in the low-side transistor LM increases due to the current flowing through the low-side transistor LM, and the switch voltage Vsw decreases.

- the low side gate voltage LG drops to the ground potential (timing t2).

- the gate signals ngHS1 and ngHS2 are switched from high level to low level and the high-side NMOS transistors HNM1 and HNM2 are turned off, the gate signals pgHS1 and pgHS2 are switched from high level to low level. This turns on the high side PMOS transistors HPM1 and HPM2. Therefore, a dead time (simultaneous off period) is provided.

- the levels of the gate signals pgHS1 and pgHS2 switch at timing t1, and the high side gate voltage HG starts rising. From timing t2, the switch voltage Vsw increases as the high side gate voltage HG increases. As the high-side gate voltage HG increases, the on-resistance of the high-side transistor HM decreases, and the voltage drop in the high-side transistor HM decreases, so the switch voltage Vsw increases.

- the switch voltage Vsw reaches the input voltage Vin (timing t3).

- the high side gate voltage HG continues to rise after timing t3 and reaches the boot voltage Vbst at timing t4.

- the operation is as shown on the right side of FIG. 4.

- the gate signal pgHS2 is provided with a delay Dly with respect to the gate signal pgHS1.

- the delay time of the delay Dly is set so that the gate signal pgHS2 switches to low level at timing t3 when the switch voltage Vsw reaches the input voltage Vin.

- the high-side PMOS transistor HPM1 is first turned on by switching the gate signal pgHS1 to low level at timing t1, and then the high-side PMOS transistor HPM2 is turned on by switching the gate signal pgHS2 to low level at timing t3. Therefore, during the period (t2 to t3) in which the switch voltage Vsw increases, only HPM1 of the high-side PMOS transistors HPM1 and HPM2 is in the on state, so the driving ability is suppressed and the slope of the high-side gate voltage HG is reduced. The slew rate of switch Vsw becomes smaller.

- the high side control signal Sph is switched to high level in the first high side drive section 211 having the configuration shown in FIG. 3.

- the gate signal generation units 2111 and 2112 cause switching of the gate signals pgHS1 and pgHS2 to occur with a delay from switching of the high side control signal Sph. Such a delay is caused by the on-resistance of the transistors in the inverters 211A and 211B, and the capacitance caused by the wiring, the gates of the transistors, and the like.

- the size of the NMOS transistor of the first stage inverter 211B is made smaller than the size of the NMOS transistor of the first stage inverter 211A, and the on-resistance is increased. I'm making adjustments.

- the size of the transistor in the later-stage inverters 211A and 211B it is necessary to increase the size of the transistors to ensure driving capability, and it is difficult to adjust the on-resistance, so the size is adjusted in the first-stage inverter. Note that, for example, the size of the transistor in the second-stage inverter in addition to the first-stage inverter may be adjusted.

- FIG. 5 is a timing chart showing the operation when the high-side transistor HM is turned off and the low-side transistor LM is turned on in the embodiment of the present disclosure.

- FIG. 5 shows the case of backflow operation.

- the reverse current operation is an operation when current flows from the inductor L to the node Nsw (broken line arrow in FIG. 1).

- waveform examples of the switch voltage Vsw, high side gate voltage HG, low side gate voltage LG, gate signals ngLS1 and ngLS2, gate signal pgLS1, and gate signal pgLS2 are shown in order from the top. As shown in FIG. 5, a delay is provided for gate signals pgLS1 and pgLS2.

- the high-side transistor HM is in the on state and the low-side transistor LM is in the off state.

- the high-side predriver 21 starts discharging the gate of the high-side transistor HM (timing t11).

- the high side PMOS transistors HPM1 and HPM2 are turned off and the high side NMOS transistors HNM1 and HNM2 are turned on, and the high side gate voltage HG starts to decrease.

- the voltage drop at the high-side transistor HM increases due to the current flowing through the high-side transistor HM, and the switch voltage Vsw increases.

- the high side gate voltage HG decreases to the switch voltage Vsw (timing t12).

- the gate signal pgLS1 is switched from high level to low level, so that the low-side PMOS Transistor LPM1 is turned on. Therefore, a dead time is provided.

- the level of the gate signal pgLS1 switches at timing t11, and the low-side gate voltage LG starts to rise. From timing t12, as the low side gate voltage LG increases, the switch voltage Vsw decreases. As the low-side gate voltage LG increases, the on-resistance of the low-side transistor LM decreases, and the voltage drop in the low-side transistor LM decreases, so the switch voltage Vsw decreases.

- the switch voltage Vsw reaches the ground potential (timing t13).

- the gate signal pgLS2 is switched to low level. This turns on the low-side PMOS transistor LPM2.

- the low-side gate voltage LG continues to rise after timing t13, and reaches the power supply voltage Vcc at timing t14.

- the low-side PMOS transistor LPM1 is first turned on by switching the gate signal pgLS1 to low level at timing t11, and then the low-side PMOS transistor LPM2 is turned on by switching the gate signal pgLS2 to low level at timing t13. Therefore, during the period (t12 to t13) in which the switch voltage Vsw decreases, only LPM1 of the low-side PMOS transistors LPM1 and LPM2 is in the on state, so the driving ability is suppressed, the slope of the low-side gate voltage LG is made small, and the switch Vsw slew rate becomes smaller.

- FIG. 6 is a diagram showing an example of the configuration of the first low-side drive section 221.

- the first low-side drive section 221 includes a first low-side gate signal generation section 2211 that generates a gate signal pgLS1 based on a low-side control signal Spl, and a second low-side gate signal generation section 2212 that generates a gate signal pgLS2 based on a low-side control signal Spl. and has.

- the first low-side gate signal generation section 2211 is composed of five stages of inverters 221A.

- Each inverter 221A is composed of a PMOS transistor and an NMOS transistor connected in series between power supply voltage Vcc and ground potential.

- the low-side control signal Spl is input to the first-stage inverter 221A, and the gate signal pgLS1 is output from the final-stage inverter 221A.

- the second low-side gate signal generation section 2212 is composed of five stages of inverters 221B.

- Each inverter 221B is composed of a PMOS transistor and an NMOS transistor connected in series between power supply voltage Vcc and ground potential.

- the low-side control signal Spl is input to the first-stage inverter 221B, and the gate signal pgLS2 is output from the final-stage inverter 221B.

- inverters 221A and 221B are not limited to five stages.

- the configuration of the second low-side drive section 222 is the same as that shown in FIG. 6, in which the low-side control signal Spl is replaced with the low-side control signal Snl, and the gate signals pgLS1 and pgLS2 are replaced with gate signals ngLS1 and ngLS2.

- the size of the NMOS transistor of the first stage inverter 221B is made smaller than the size of the NMOS transistor of the first stage inverter 221A, and the on-resistance is adjusted. are doing.

- the size of the transistor in the later-stage inverters 221A and 221B it is necessary to increase the size of the transistors to ensure driving capability, and it is difficult to adjust the on-resistance, so the size is adjusted in the first-stage inverter. Note that, for example, the size of the transistor in the second-stage inverter in addition to the first-stage inverter may be adjusted.

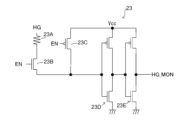

- FIG. 7 is a diagram showing a configuration of a gate drive circuit 2 according to a second embodiment of the present disclosure.

- the gate drive circuit 2 shown in FIG. 7 further includes a high-side gate voltage monitor section 23, unlike the configuration of the first embodiment (FIG. 2) described above.

- a delay is provided to the gate signals pgHS1 and pgHS2 due to the configuration of the first high-side drive section 211 in the high-side predriver 21.

- FIG. 8 is a diagram showing an example of the configuration of the high side gate voltage monitor section 23.

- the high side gate voltage monitor section 23 shown in FIG. 8 includes a resistor 23A, switches 23B and 23C, and inverters 23D and 23E.

- Switch 23B is composed of an NMOS transistor.

- the switch 23C is composed of a PMOS transistor.

- resistor 23A One end of the resistor 23A is connected to the gate of the high-side transistor HM.

- the other end of resistor 23A is connected to the input end of inverter 23D via switch 23B.

- Inverters 23D and 23E include a PMOS transistor and an NMOS transistor connected in series between power supply voltage Vcc and ground potential.

- the output end of inverter 23D is connected to the input end of inverter 23E.

- a switch 23C is connected between the application end of the power supply voltage Vcc and the input end of the inverter 23D.

- the switches 23B and 23C are controlled by an enable signal EN.

- EN When the enable signal EN is at a low level, the switch 23B is turned off, the switch 23C is turned on, and the PMOS transistors of the inverters 23D and 23E are turned off. As a result, the high side gate voltage monitor section 23 becomes disabled.

- the enable signal EN when the enable signal EN is at a high level, the switch 23B is on, the switch 23C is off, and the high-side gate voltage monitor section 23 is enabled.

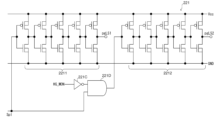

- FIG. 9 is a diagram showing a configuration example of the first low-side drive section 221 according to the second embodiment.

- the first low-side drive section 221 shown in FIG. 9 includes a first low-side gate signal generation section 2211 that generates the gate signal pgLS1 based on the low-side control signal Spl, and a second low-side gate that generates the gate signal pgLS2 based on the low-side control signal Spl. It has a signal generation section 2212.

- the low side drive sections 2211 and 2212 have the same configuration as that shown in FIG. 6 described above.

- the first low-side drive section 221 further includes an inverter 221C and an AND circuit 221D.

- a monitor signal HG_MOM is input to the inverter 221C.

- the output of the inverter 221C is input to one input terminal of the AND circuit 221C, and the low-side control signal Spl is input to the other input terminal.

- the output of the AND circuit 221D is input to the second low-side gate signal generation section 2212.

- the gate signal pgLS1 when the low-side control signal Spl rises to a high level, the gate signal pgLS1 first falls to a low level. Then, when the monitor signal HG_MOM falls to a low level, the output of the AND circuit 221D rises to a high level, and the gate signal pgLS2 falls to a low level. Therefore, it is possible to provide a delay in the gate signal pgLS2 with respect to the gate signal pgLS1.

- FIG. 10 is a timing chart showing the operation when the high-side transistor HM is turned off and the low-side transistor LM is turned on in the second embodiment.

- FIG. 10 shows the case of backflow operation.

- the difference between the timing chart shown in FIG. 10 and FIG. 5 (first embodiment) is the monitor signal HG_MON.

- the low-side control signal Spl is switched to high level

- the gate signal pgLS1 is switched to low level at timing t11.

- the high-side gate voltage monitor section 23 switches the monitor signal HG_MON to a low level. Then, the gate signal pgLS2 is switched to low level. In this manner, also in this embodiment, since a delay is provided to the gate signals pgLS1 and pgHS2, similarly to the first embodiment, it is possible to suppress the self-turn-on of the high-side transistor HM and suppress the decrease in efficiency.

- FIG. 11 is a timing chart showing the operation when the high-side transistor HM is turned off and the low-side transistor LM is turned on in the embodiment of the present disclosure.

- FIG. 11 shows the case of normal operation.

- the left side of FIG. 11 shows the operation in the first embodiment.

- the high-side predriver 21 starts discharging the gate of the high-side transistor HM, and the high-side gate voltage HG starts to decrease.

- the switch voltage Vsw starts decreasing from timing t21.

- the high-side gate voltage HG decreases, the on-resistance of the high-side transistor HM increases, the voltage drop in the high-side transistor HM increases, and the switch voltage Vsw decreases.

- the gate signal pgLS1 is switched to low level.

- the low level PMOS transistor LPM1 is turned on, and the low side gate voltage LG starts to rise.

- the gate signal pgLS2 is switched to low level at timing t23.

- the low-level PMOS transistor LPM2 is turned on, and the low-side gate voltage LG continues to rise further and reaches the power supply voltage Vcc (timing t24).

- the low-side gate voltage LG starts rising after the switch voltage Vsw transitions, so the slope of the low-side gate voltage LG has no relation to the slew rate of the switch voltage Vsw. Therefore, according to the first embodiment, since the gate signal pgLS2 is delayed by a certain amount with respect to pgLS1, the time (t22 to t24) for the low side gate voltage LG to reach the power supply voltage Vcc becomes longer, and the efficiency decreases. . Furthermore, since the rise in the low-side gate voltage LG is delayed, the rise in the switch voltage Vsw is delayed.

- the right side of FIG. 11 shows the operation in the second embodiment.

- the monitor signal HG_MON is switched to low level at timing t22 when the switch voltage Vsw becomes close to the ground potential. Therefore, the gate signal pgLS2 is switched to a low level with almost no delay relative to pgLS1.

- the time (t22 to t24) until the low-side gate voltage LG reaches the power supply voltage Vcc is shortened, and a decrease in efficiency is suppressed.

- the present disclosure can be applied not only to a DC/DC converter but also to driving a transistor in an inverter circuit that performs DC/AC conversion.

- the gate drive circuit (2) A gate drive circuit that drives a half bridge in which a high-side transistor (HM) to be driven and a low-side transistor (LM) to be driven are connected in series between a power supply voltage (Vin) and a ground potential, a high-side pre-driver (21) configured to drive the gate of the high-side transistor to be driven; a low-side predriver (22) configured to drive the gate of the low-side transistor to be driven; Equipped with The high-side pre-driver includes a first high-side transistor (HPM1) and a second high-side transistor (HPM2), The low-side pre-driver includes a third high-side transistor (LPM1) and a fourth high-side transistor (LPM2), between a first gate signal (pgHS1) that turns on the first high-side transistor and a second gate signal (pgHS2) that turns on the second high-side transistor; A delay is provided between at least one of the third gate signal

- the high-side predriver (21) generates the first gate signal (pgHS1) and the second gate signal (pgHS2) based on the high-side control input signal (Sph). It is also possible to have a configuration including a high side drive section (211) configured as follows (second configuration).

- the high side drive section (211) a first high side gate signal generation section (2111) configured to have a plurality of first inverters (211A) and generate the first gate signal (pgHS1); a second high side gate signal generation section (2112) configured to have a plurality of second inverters (211B) and generate the second gate signal (pgHS2); has At least one of the second inverters in the second high-side gate signal generation section may have a transistor size smaller than at least one of the first inverters in the first high-side gate signal generation section ( (3rd configuration).

- the second inverter (211B) at the first stage in the second high side gate signal generation section (2112) is connected to the second inverter (211B) at the first stage in the first high side gate signal generation section (2111). It is also possible to adopt a configuration in which the size of the transistor is smaller than one inverter (211A) (fourth configuration).

- the low side predriver (22) generates the third gate signal (pgLS1) and the fourth gate signal (pgLS2) based on the low side control input signal (Spl). ) (fifth configuration).

- the low side drive section (221) a first low-side gate signal generation section (2211) configured to have a plurality of third inverters (221A) and generate the third gate signal (pgLS1); a second low-side gate signal generation section (2212) configured to have a plurality of fourth inverters (221B) and generate the fourth gate signal (pgLS2); has At least one of the fourth inverters in the second low-side gate signal generation section may have a transistor size smaller than at least one of the third inverters in the first low-side gate signal generation section (sixth configuration).

- the fourth inverter (221B) at the first stage in the second low-side gate signal generation section (2212) is the third inverter at the first stage in the first low-side gate signal generation section (2211).

- (221A) may be configured in which the size of the transistor is smaller (seventh configuration).

- the gate voltage (HG) of the high-side transistor to be driven (HM) is at a low level

- the fourth gate signal (pgLS2) may be generated based on the monitor signal (HG_MON) output from the monitor unit (eighth configuration).

- the monitor section (23) includes a resistor (23A) having a first end connected to the gate of the driven transistor (HM), and a second end connected to the resistor.

- Inverter stages (23D, 23E) having input terminals may also be used (ninth configuration).

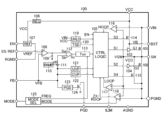

- FIG. 12 is a diagram showing the configuration of a semiconductor device 1 according to an exemplary embodiment of the present disclosure.

- the semiconductor device 1 is a device in which a power supply IC having a DC/DC converter function is packaged. As shown in FIG. 12, the semiconductor device 1 has a VIN (input voltage) terminal, an EN (enable) terminal, a PGND (power ground) terminal, and a VREG (constant voltage) terminal as external terminals for establishing electrical connection with the outside. voltage) terminal, PGD (power good) terminal, BST (bootstrap) terminal, SW (switch) terminal, FB (feedback) terminal, and AGND (analog ground) terminal.

- An input voltage Vin can be applied to the VIN terminal.

- a ground potential can be applied to the PGND terminal.

- An input capacitor CIN is connected between an end to which an input voltage Vin is applied and an end to which a ground potential is applied.

- the semiconductor device 1 has an upper switching element and a lower switching element (not shown). Both the upper switching element and the lower switching element are configured by NMOS transistors (N-channel MOSFETs (metal-oxide-semiconductor field-effect transistors)). The upper switching element and the lower switching element are connected in series between the VIN terminal and the PGND terminal. A node to which the upper switching element and the lower switching element are connected is connected to an SW terminal.

- NMOS transistors N-channel MOSFETs (metal-oxide-semiconductor field-effect transistors)

- the SW terminal is connected to one end of the inductor L.

- the other end of the inductor L is connected to one end of the output capacitor COUT.

- the other end of the output capacitor COUT and the AGND terminal are connected to a ground potential application end.

- an output voltage Vout is generated.

- Voltage dividing resistors Ru and Rl are connected in series between the other end of the inductor L and the AGND terminal.

- a node to which the voltage dividing resistors Ru and Rl are connected is connected to the FB terminal.

- a feedback voltage Vfb generated by dividing the output voltage Vout by voltage dividing resistors Ru and Rl is applied to the FB terminal.

- the semiconductor device 1 has a feedback control section (not shown).

- the feedback control section controls switching of the upper switching element and the lower switching element based on the feedback voltage Vfb. Thereby, the output voltage Vout is controlled to a desired voltage value.

- the feedback control section includes an error amplifier, a control logic section, a driver, and the like.

- a bootstrap capacitor CBST is connected between the BST terminal and the SW terminal. By charging the bootstrap capacitor CBST, the upper switching element formed by the NMOS transistor can be turned on.

- the upper switching element, the lower switching element, and the feedback control section are integrated into the power supply IC and provided in the semiconductor device 1.

- FIG. 13 is a diagram showing a part of the internal configuration of the semiconductor device 1. As shown in FIG. 13, the semiconductor device 1 includes a preregulator (PREREG) 2, a reference voltage generation section 3, and a regulator (REG) 4, and these components are integrated into the power supply IC.

- PREREG preregulator

- REG regulator

- the preregulator 2 generates a first power supply voltage Vprereg based on the input voltage Vin applied to the VIN terminal.

- the first power supply voltage Vprereg is a constant voltage.

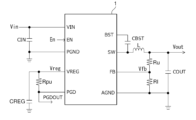

- FIG. 14 is a diagram showing a configuration example of the preregulator 2.

- the preregulator 2 includes voltage dividing resistors 20 and 21, an NMOS transistor 22, a Zener diode 23, a PMOS transistor (P-channel MOSFET) 24, a resistor 25, a Zener diode 26, a capacitor 27, and a resistor 28. , a capacitor 29, and an NMOS transistor 201.

- the voltage dividing resistors 20 and 21 are connected in series between the application terminal of the input voltage Vin and the drain of the NMOS transistor 22.

- the source of the NMOS transistor 22 is connected to a ground potential application terminal.

- the gate of the NMOS transistor 22 is driven by an enable signal En applied to the EN terminal (FIG. 13).

- the anode of the Zener diode 23 is connected to a node N20 to which the voltage dividing resistors 20 and 21 are connected.

- the cathode of the Zener diode 23 is connected to the application terminal of the input voltage Vin. Zener diode 23 clamps the voltage at node N20 to suppress excessive drop.

- the node N20 is connected to the gate of the PMOS transistor 24.

- the source of the PMOS transistor 24 is connected to the application terminal of the input voltage Vin.

- a drain of the PMOS transistor 24 is connected to one end of a resistor 25.

- the other end of the resistor 25 is connected to the cathode of a Zener diode 26.

- the anode of the Zener diode 26 is connected to a ground potential application terminal.

- the cathode of the Zener diode 26 is connected to one end of the capacitor 27.

- the other end of the capacitor 27 is connected to a ground potential application end.

- a cathode of the Zener diode 26 is connected to one end of a resistor 28.

- the other end of the resistor 28 is connected to one end of a capacitor 29.

- the other end of the capacitor 29 is connected to a ground potential application end.

- the resistor 28 and capacitor 29 constitute a low pass filter.

- the other end of the resistor 28 is connected to the gate of the NMOS transistor 201.

- the drain of the NMOS transistor 201 is connected to the application terminal of the input voltage Vin.

- a first power supply voltage Vprereg is generated at the source of the NMOS transistor 201.

- the NMOS transistor 22 is in the on state, a voltage obtained by dividing the input voltage Vin by the voltage dividing resistors 20 and 21 is generated at the node N20, and the PMOS transistor 24 is in the on state.

- Vz is the Zener voltage of the Zener diode 26

- Vgs is the gate-source voltage of the NMOS transistor 201.

- the reference voltage generation section 3 generates the reference voltage Vref based on the first power supply voltage Vprereg.

- the reference voltage generation section 3 is configured by, for example, a bandgap reference.

- the reference voltage Vref is used, for example, to generate the second power supply voltage Vreg in the regulator 4.

- the regulator 4 generates a second power supply voltage Vreg based on the input voltage Vin.

- the regulator 4 is configured by, for example, an LDO (Low Dropout).

- the reference voltage Vref is input to the error amplifier in the LDO.

- a second power supply voltage Vreg is generated at the VREG terminal. As shown in FIG. 12, the VREG terminal is connected to the capacitor CREG.

- the second power supply voltage Vreg is supplied to each part of the power supply IC.

- the second power supply voltage Vreg is supplied, for example, to a power good circuit 5, which will be described later.

- the first power supply voltage Vprereg and the second power supply voltage Vreg may have the same voltage value or may have different voltage values.

- the semiconductor device 1 includes a power good circuit 5.

- the power good circuit 5 is integrated into the power supply IC.

- the power good circuit 5 is connected between the PGD terminal and the end to which a ground potential is applied. As shown in FIG. 12, a pull-up resistor Rpu is connected between the PGD terminal and the VREG terminal. That is, the PGD terminal is pulled up to the second power supply voltage Vreg.

- the power good circuit 5 has a switch (output transistor) not shown in FIG. 13 connected between the PGD terminal and the end to which a ground potential is applied.

- the switch When the switch is on, the flag signal PGDOUT (FIG. 12) output from the PGD terminal is at a low level, and when the switch is off, the flag signal PGDOUT is at a high level.

- the power good circuit 5 detects this based on the feedback voltage Vfb generated at the FB terminal and turns it high.

- a level flag signal PGDOUT is output.

- the flag signal PGDOUT can notify the outside that the output voltage Vout output from the power supply circuit (DC/DC converter) has risen normally.

- FIG. 15 is a diagram showing the configuration of a power good circuit 5 according to a comparative example.

- a comparative example will be described for comparison with the embodiment of the present disclosure described below. The issues will become clear by explaining comparative examples.

- the power good circuit 5 shown in FIG. 15 includes an output transistor MA and inverters IVA and IVB.

- Output transistor MA is composed of an NMOS transistor.

- the drain of output transistor MA is connected to the PGD terminal.

- the source of output transistor MA is connected to a ground potential application terminal.

- the input end of the inverter IVA is connected to the application end of the control input signal PGDIN.

- the control input signal PGDIN is a signal generated inside the power good circuit 5.

- the output end of inverter IVA is connected to the input end of inverter IVB.

- the output terminal of inverter IVB is connected to the gate of output transistor MA.

- the control input signal PGDIN is logically inverted by the inverters IVA and IVB and input to the gate of the output transistor MA.

- Inverters IVA and IVB each have a PMOS transistor and an NMOS transistor (not shown).

- a source of the PMOS transistor is connected to an application terminal of the second power supply voltage Vreg.

- the drain of the PMOS transistor is connected to the drain of the NMOS transistor.

- the source of the NMOS transistor is connected to a ground potential application terminal.

- a gate of the PMOS transistor and a gate of the NMOS transistor are connected to an input terminal of an inverter.

- a node to which the drain of the PMOS transistor and the drain of the NMOS transistor are connected is connected to the output end of the inverter. That is, inverters IVA and IVB use the second power supply voltage Vreg as a power supply voltage.

- FIG. 16 is a timing chart showing the operation of the power good circuit 5 according to the comparative example at the time of starting up the power supply IC.

- the enable signal En the first power supply voltage Vprereg, the second power supply voltage Vreg, the control input signal PGDIN, the on/off state of the output transistor MA, and the flag signal PGDOUT are shown in order from the top.

- the enable signal En switches from a low level indicating disable to a high level indicating enable (timing ta). Then, the preregulator 2 is activated and the first power supply voltage Vprereg starts rising (timing tb). Thereafter, the reference voltage generation section 3 is activated, and the regulator 4 is activated by the reference voltage Vref. At this time, the second power supply voltage Vreg starts rising (timing tc). That is, the preregulator 2, the reference voltage generation section 3, and the regulator 4 are activated in this order.

- Threshold voltage Vth is the threshold voltage of inverters IVA and IVB as well as the threshold voltage of output transistor MA.

- the control input signal PGDIN becomes high level, a high level signal is input to the gate of the output transistor MA, and the output transistor MA is turned on. As a result, the flag signal PGDOUT falls to low level.

- the power good circuit 5 has a problem in that the output transistor MA cannot be turned on when the power supply IC is started, and the flag signal PGDOUT rises.

- embodiments of the present disclosure described below are implemented.

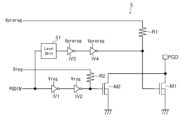

- FIG. 17 is a diagram showing the configuration of the power good circuit 5 according to the first embodiment of the present disclosure.

- the power good circuit 5 shown in FIG. 17 includes an output transistor M1, an output transistor M2, inverters IV1 to IV4, pull-up resistors R1 and R2, and a level shift circuit 51.

- the output transistor M1 is composed of an NMOS transistor.

- the drain of the output transistor M1 is connected to the PGD terminal.

- the source of the output transistor M1 is connected to a ground potential application terminal.

- a pull-up resistor R1 is connected between the gate of the output transistor M1 and the terminal to which the first power supply voltage Vprereg is applied.

- the input terminal of the level shift circuit 51 is connected to the application terminal of the control input signal PGDIN.

- the output terminal of level shift circuit 51 is connected to the input terminal of inverter IV3.

- the output terminal of inverter IV3 is connected to the input terminal of inverter IV4.

- the output terminal of inverter IV4 is connected to the gate of output transistor M1.

- the level shift circuit 51 converts the level of the control input signal PGDIN from the second power supply voltage Vreg to the first power supply voltage Vprereg.

- the level-converted control input signal PGDIN is logically inverted by each of the inverters IV3 and IV4, and is input to the gate of the output transistor M1.

- Inverters IV3 and IV4 have the same configuration as inverters IVA and IVB according to the comparative example described above, except that the first power supply voltage Vprereg is used as the power supply voltage. That is, inverters IV3 and IV4 include a PMOS transistor and an NMOS transistor (not shown).

- the drain of the output transistor M2 is connected to the PGD terminal.

- the source of the output transistor M2 is connected to a ground potential application terminal.

- the input end of the inverter IV1 is connected to the application end of the control input signal PGDIN.

- the output terminal of inverter IV1 is connected to the input terminal of inverter IV2.

- the output terminal of inverter IV2 is connected to the gate of output transistor M2.

- the inverters IV1 and IV2 use the second power supply voltage Vreg as the power supply voltage, and have the same configuration as the inverters IVA and IVB according to the comparative example described above.

- a pull-up resistor R2 is connected between the gate of the output transistor M2 and the application terminal of the second power supply voltage Vreg.

- FIG. 18 is a timing chart showing the operation of the power good circuit 5 according to the first embodiment during startup and shutdown of the power supply IC.

- the enable signal En the first power supply voltage Vprereg, the second power supply voltage Vreg, the control input signal PGDIN, the on/off states of the output transistors M1 and M2, and the flag signal PGDOUT are shown in order from the top.

- the enable signal En switches from low level to high level (timing t1). Then, the first power supply voltage Vprereg starts rising (timing t2). Then, the first power supply voltage Vprereg reaches the threshold voltage Vth1 (timing t3).

- Threshold voltage Vth1 is the threshold voltage of output transistor M1 as well as the threshold voltages of inverters IV3 and IV4.

- the first power supply voltage Vprereg is applied to the gate of the output transistor M1 via the pull-up resistor R1, thereby switching the output transistor M1 from the off state to the on state. .

- the level shift circuit 51 when the second power supply voltage Vreg is at a low level (lower than the threshold voltage Vth2), the level shift circuit 51 outputs a high level signal as an initial value. Until the first power supply voltage Vprereg reaches the threshold voltage Vth1, the outputs of the inverters IV3 and IV4 are logically undefined, but when the first power supply voltage Vprereg reaches the threshold voltage Vth1, the output of the inverter IV4 is determined to be at a high level. The output transistor M1 is turned on.

- the outputs of the inverters IV3 and IV4 become logically undefined, but the pull-up resistor R1 allows the first power supply voltage Vprereg to reach the output transistor.

- the voltage level at the gate of output transistor M1 is determined.

- the second power supply voltage Vreg starts rising (timing t4). Then, the second power supply voltage Vreg reaches the threshold voltage Vth2 (timing t5).

- Threshold voltage Vth2 is the threshold voltage of output transistor M2 as well as the threshold voltages of inverters IV1 and IV2.

- the control input signal PGDIN is at a low level, and the outputs of the inverters IV1 and IV2 have an undefined logic. Further, at this time, the second power supply voltage Vreg is applied to the gate of the output transistor M2 via the pull-up resistor R2, but the output transistor M2 is in an off state.

- the output transistor M1 is already turned on by the first power supply voltage Vprereg. This prevents the flag signal PGDOUT output from the PGD terminal from rising.

- the pull-up resistor R2 that pulls up the gate of the output transistor M2 to the second power supply voltage Vreg does not necessarily need to be provided. However, by providing the pull-up resistor R2, even when the output of the inverter IV2 has an undefined logic, the second power supply voltage Vreg can be applied to the gate of the output transistor M2 via the pull-up resistor R2, and the output transistor M2 The voltage level of the gate can be determined.

- the control input signal PGDIN is switched from high level to low level.

- the level of the gates of the output transistors M1 and M2 becomes low level, and both the output transistors M1 and M2 are turned off.

- the flag signal PGDOUT switches from low level to high level.

- the enable signal En falls from high level to low level (timing t6).

- the output voltage Vout falls and the control input signal PGDIN switches from low level to high level.

- both output transistors M1 and M2 are turned on from the off state. Therefore, the flag signal PGDOUT switches from high level to low level.

- the first power supply voltage Vprereg and the second power supply voltage Vreg start falling (timing t7). Since the capacitor CREG is connected to the VREG terminal, the second power supply voltage Vreg falls more slowly than the first power supply voltage Vprereg.

- the output transistor M1 When the first power supply voltage Vprereg falls below the threshold voltage Vth1, the output transistor M1 is turned off (timing t8). At this time, since the second power supply voltage Vreg is equal to or higher than the threshold voltage Vth2, the output transistor M2 is in an on state. Therefore, the flag signal PGDOUT is maintained at a low level.

- the control input signal PGDIN switches from high level to low level (timing t9). This turns the output transistor M2 off.

- both output transistors M1 and M2 are in an off state.

- the output transistors M1 and M2 can be controlled in a state where at least one of the first power supply voltage Vprereg and the second power supply voltage Vreg is activated (period from timing t3 to t9).

- FIG. 19 is a diagram showing the configuration of a power good circuit 5 according to the second embodiment of the present disclosure.

- the power good circuit 5 shown in FIG. 19 further includes a control transistor M3 compared to the configuration according to the first embodiment (FIG. 17). Note that in the configuration shown in FIG. 19, the level shift circuit 51 and inverters IV3 and IV4 are not provided.

- the control transistor M3 is composed of an NMOS transistor.

- the drain of control transistor M3 is connected to the gate of output transistor M1.

- the source of the control transistor M3 is connected to a ground potential application terminal.

- a gate of the control transistor M3 is connected to an application terminal of the second power supply voltage Vreg.

- FIG. 20 is a timing chart showing the operation of the power good circuit 5 according to the second embodiment during startup and shutdown of the power supply IC.

- the enable signal En the first power supply voltage Vprereg, the second power supply voltage Vreg, the control input signal PGDIN, the on/off states of the output transistors M1, M2 and the control transistor M3, and the flag signal PGDOUT are shown. .

- the first power supply voltage Vprereg reaches the threshold voltage Vth1 (timing t11)

- the first power supply voltage Vprereg is applied to the gate of the output transistor M1 via the pull-up resistor R1, and the output transistor M1 is switched from an off state to an on state.

- both the output transistor M2 and the control transistor M3 are in an off state.

- the output transistor M2 and the control transistor M3 are switched from the off state to the on state. Since the control transistor M3 is turned on, the output transistor M1 is turned off.

- the output transistor M1 since the output transistor M1 is in the on state until the second power supply voltage Vreg reaches the threshold voltage Vth2, it is possible to avoid raising the flag signal PGDOUT. Furthermore, since the output transistor M1 is switched from the on state to the off state, the flag signal PGDOUT is subsequently controlled by the output transistor M2. That is, in the present embodiment, the output transistor M1 prioritizes setting the flag signal PGDOUT to a low level at the time of startup by pulling up the flag signal PGDOUT to the first power supply voltage Vprereg using the pull-up resistor R1.

- the enable signal En switches from high level to low level (timing t13).

- the output voltage Vout falls and the control input signal PGDIN switches from low level to high level.

- the output transistor M2 is turned on from the off state. Therefore, the flag signal PGDOUT switches from high level to low level.

- both the output transistor M2 and the control transistor M3 are switched from the on state to the off state. As a result, both output transistors M1 and M2 are turned off.

- FIG. 21 is a diagram showing the configuration of a power good circuit 5 according to the third embodiment of the present disclosure.

- the power good circuit 5 shown in FIG. 21 includes an output transistor M1, voltage dividing resistors R3 and R4, inverters IV11 and IV12, and diodes D1 and D2. That is, in this embodiment, there is one output transistor.

- the voltage dividing resistors R3 and R4 are connected in series between the application end of the first power supply voltage Vprereg and the application end of the ground potential.

- a node N1 to which the voltage dividing resistors R3 and R4 are connected is connected to the gate of the output transistor M1.

- the input end of the inverter IV11 is connected to the application end of the control input signal PGDIN.

- the output terminal of inverter IV11 is connected to the input terminal of inverter IV12.

- the inverter IV11 uses the second power supply voltage Vreg as the power supply voltage, and has the same configuration as the above-mentioned inverter IV1.

- Inverter IV12 includes a PMOS transistor PM and an NMOS transistor NM.

- a source of the PMOS transistor PM is connected to an application terminal of the second power supply voltage Vreg.

- the drain of the PMOS transistor PM is connected to the drain of the NMOS transistor NM.

- the source of the NMOS transistor NM is connected to a ground potential application terminal.

- a node N3 to which the gate of the PMOS transistor PM and the gate of the NMOS transistor NM are connected serves as an input terminal. Further, a node N2 to which the drain of the PMOS transistor PM and the drain of the NMOS transistor NM are connected serves as an output terminal, and the output terminal is connected to the node N1.

- the anode of the diode D1 is connected to the application terminal of the first power supply voltage Vprereg.

- a cathode of the diode D1 is connected to one end of a voltage dividing resistor R3.

- the anode of diode D2 is connected to the drain of PMOS transistor PM.

- the cathode of diode D2 is connected to node N2.

- FIG. 22 is a timing chart showing the operation of the power good circuit 5 according to the third embodiment during startup and shutdown of the power supply IC.

- the enable signal En the first power supply voltage Vprereg, the second power supply voltage Vreg, the control input signal PGDIN, the on/off state of the output transistor M1, and the flag signal PGDOUT are shown in order from the top.

- the enable signal En switches from low level to high level

- the first power supply voltage Vprereg starts rising and reaches the threshold voltage Vth11 (timing t21).

- a voltage obtained by dividing the first power supply voltage Vprereg by the voltage dividing resistors R3 and R4 is applied to the gate of the output transistor M1.

- the output transistor M1 is switched from the off state to the on state.

- the control input signal PGDIN since the control input signal PGDIN is at a low level, the outputs of the inverters IV11 and IV12 are logically undefined.

- Threshold voltage Vth2 is the threshold voltage of output transistor M1, and also the threshold voltage of inverters IV11 and IV12.

- the diode D2 can block the path from the node N1 to the application terminal of the second power supply voltage Vreg, which is at the ground potential level, via the PMOS transistor PM.

- the enable signal En switches from high level to low level (timing t23).

- the output voltage Vout falls and the control input signal PGDIN switches from low level to high level.

- the output transistor M1 is turned on from the off state. Therefore, the flag signal PGDOUT switches from high level to low level.

- the first power supply voltage Vprereg falls to the ground potential. Even if the first power supply voltage Vprereg is at the ground potential, the output of the inverter IV12 is at a high level, so the output transistor M1 is maintained in the on state. At this time, the path from the node N1 to the application end of the first power supply voltage Vprereg, which is at the level of the ground potential, via the voltage dividing resistor R3 can be cut off by the diode D1.