WO2022014004A1 - 構造物評価システム、構造物評価装置及び構造物評価方法 - Google Patents

構造物評価システム、構造物評価装置及び構造物評価方法 Download PDFInfo

- Publication number

- WO2022014004A1 WO2022014004A1 PCT/JP2020/027652 JP2020027652W WO2022014004A1 WO 2022014004 A1 WO2022014004 A1 WO 2022014004A1 JP 2020027652 W JP2020027652 W JP 2020027652W WO 2022014004 A1 WO2022014004 A1 WO 2022014004A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- unit

- vehicle

- information

- impact

- evaluation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/44—Processing the detected response signal, e.g. electronic circuits specially adapted therefor

- G01N29/4445—Classification of defects

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/44—Processing the detected response signal, e.g. electronic circuits specially adapted therefor

- G01N29/4454—Signal recognition, e.g. specific values or portions, signal events, signatures

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/04—Analysing solids

- G01N29/043—Analysing solids in the interior, e.g. by shear waves

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/04—Analysing solids

- G01N29/045—Analysing solids by imparting shocks to the workpiece and detecting the vibrations or the acoustic waves caused by the shocks

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/04—Analysing solids

- G01N29/07—Analysing solids by measuring propagation velocity or propagation time of acoustic waves

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/14—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object using acoustic emission techniques

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/22—Details, e.g. general constructional or apparatus details

- G01N29/32—Arrangements for suppressing undesired influences, e.g. temperature or pressure variations, compensating for signal noise

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N29/00—Investigating or analysing materials by the use of ultrasonic, sonic or infrasonic waves; Visualisation of the interior of objects by transmitting ultrasonic or sonic waves through the object

- G01N29/34—Generating the ultrasonic, sonic or infrasonic waves, e.g. electronic circuits specially adapted therefor

- G01N29/341—Generating the ultrasonic, sonic or infrasonic waves, e.g. electronic circuits specially adapted therefor with time characteristics

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2291/00—Indexing codes associated with group G01N29/00

- G01N2291/02—Indexing codes associated with the analysed material

- G01N2291/023—Solids

- G01N2291/0232—Glass, ceramics, concrete or stone

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2291/00—Indexing codes associated with group G01N29/00

- G01N2291/02—Indexing codes associated with the analysed material

- G01N2291/025—Change of phase or condition

- G01N2291/0258—Structural degradation, e.g. fatigue of composites, ageing of oils

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2291/00—Indexing codes associated with group G01N29/00

- G01N2291/10—Number of transducers

- G01N2291/106—Number of transducers one or more transducer arrays

Definitions

- the embodiment of the present invention relates to a structure evaluation system, a structure evaluation device, and a structure evaluation method.

- elastic waves generated inside the structure can be detected. Furthermore, by installing multiple sensors on the surface of the structure, the position of the elastic wave source (hereinafter referred to as “elastic wave source”) can be determined based on the difference in the arrival times of the elastic waves detected by each of the multiple sensors. Can be calibrated. Elastic waves are also generated inside the structure when an impact is applied to the surface of the structure from the outside. Therefore, the position of the elastic wave source can be defined.

- the propagation path of elastic waves is damaged, the propagation of elastic waves is hindered. In such a case, the accuracy of the orientation result of the elastic wave source is lowered. Areas with internal damage when elastic waves are detected by sensors installed facing each other by applying a spatially uniform impact to the surface of a structure, such as a collision with a road surface caused by raindrops during rainfall. Then, the density of the elastic wave source is reduced and observed. Damage inside the structure can be detected by utilizing such characteristics. When a method of applying a uniformly applied impact to the surface of the structure is used, the distribution of the elastic wave source becomes uniform if there is no damage inside the structure. This method is based on the premise that a uniformly applied impact is applied to the surface of the structure. Therefore, if the impact applied to the surface of the structure is not uniform, the evaluation accuracy may decrease.

- the problem to be solved by the present invention is a structure evaluation system, a structure evaluation device, and a structure evaluation device capable of improving the evaluation accuracy of a structure even when the impact applied to the surface of the structure is not uniform. It is to provide a structure evaluation method.

- the structure evaluation system of the embodiment has a plurality of sensors, a position setting unit, a correction unit, and an evaluation unit.

- the plurality of sensors detect elastic waves generated from the structure.

- the position determining unit determines the position of the source of the plurality of elastic waves based on the plurality of elastic waves detected by each of the plurality of sensors.

- the correction unit corrects the information based on the position orientation by the position determination unit by using the correction value determined according to the impact.

- the evaluation unit evaluates the deteriorated state of the structure based on the corrected information.

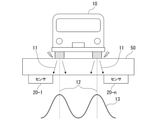

- the figure for demonstrating the outline of the structure evaluation system in an embodiment The figure which shows an example of the elastic wave source density distribution generated based on the detection result of the elastic wave generated by the impact caused by the passage of a traveling part.

- Explanatory drawing when the non-uniform object is a sprinkle

- the structure evaluation system in the embodiment can improve the evaluation accuracy of the structure even when the impact applied to the surface of the structure (hereinafter referred to as “road surface”) is not spatially uniform. It is a system.

- the case where the impact applied to the road surface is not spatially uniform is the case where the position of the impact applied in a predetermined space is biased.

- the vehicle 10 passes through the road surface (the surface of the structure 50) as shown in FIG.

- FIG. 1 is a diagram for explaining an outline of the structure evaluation system in the embodiment.

- a load is applied to the road surface due to the contact between the traveling portion (for example, a tire) of the vehicle 10 and the road surface.

- the load on the road surface is caused by the traveling portion of the vehicle 10.

- the traveling portion of the vehicle 10 gives an impact to the road surface.

- elastic waves 11 are generated in the structure 50.

- no impact is applied to the region of the road surface where the traveling portion of the vehicle 10 does not pass.

- the elastic wave 11 is generated around the position 12 through which the traveling portion of the vehicle 10 has passed.

- the elastic wave 11 propagates in the structure 50 starting from the position 12.

- the elastic wave 11 propagating in the structure 50 is detected by a plurality of sensors 20-1 to 20-n (n is an integer of 3 or more). It is conceivable that the passing position of the vehicle 10 is different for each vehicle. However, depending on the width of the road, it is considered that many vehicles 10 pass through a certain fixed position.

- the frequency distribution of the impact applied positions due to the passage of the traveling portions of a large number of vehicles 10 can be expressed as, for example, the distribution 13 shown at the bottom of FIG.

- the horizontal axis represents the distance of the road width

- the vertical axis represents the frequency of impact.

- the frequency at which the impact is applied is highest at the position 12 where the traveling portion of the vehicle 10 is assumed to pass.

- the elastic wave source density distribution obtained in this case is such that the density of the elastic wave source is equal to or higher than the threshold value (for example, in a dense state) at a position where the traveling portion of the vehicle 10 frequently passes, and the traveling portion of the vehicle 10 passes less frequently.

- the distribution has a bias such that the density is less than the threshold value (for example, a sparse state).

- the elastic wave source density distribution obtained when the impact applied to the road surface is not spatially uniform has a low density of the elastic wave source even when there is no damage in the region where the impact is not applied.

- the density of elastic wave sources tends to be high even if the impacted area is damaged. That is, in the non-impacted region, the density of the elastic wave source is likely to be less than the threshold value even if there is no damage, and in the impacted region, the elastic wave source is elastic even if there is damage. There is a high possibility that the density of the wave source will exceed the threshold value.

- the undamaged region in the structure 50 is evaluated as the damaged region, and the structure is evaluated.

- the damaged area in the object 50 may be evaluated as a healthy area.

- the damaged area is an area where deterioration has occurred inside the structure 50.

- the deteriorated region is a region where a part of the inside of the structure 50 is damaged.

- a healthy area is an area that is not damaged or is damaged but is not expected to be affected by the damage.

- the conventional evaluation method is an evaluation method in which a region where the density of the elastic wave source is less than the threshold value is regarded as a damaged region.

- the conventional evaluation method is a method published in, for example, International Publication No. 2017/217834.

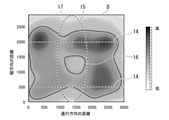

- FIG. 2 is a diagram showing an example of the elastic wave source density distribution D generated based on the detection result of the elastic wave 11 generated by the impact caused by the passage of the traveling portion.

- the horizontal axis represents the distance in the traffic direction of the vehicle

- the vertical axis represents the distance in the width direction.

- the dotted line 14 shown on the elastic wave source density distribution D represents the passing position of the traveling portion of the vehicle 10.

- a plurality of sensors for detecting the elastic wave 11 generated inside the structure 50 and a plurality of elastic wave sources based on the plurality of elastic waves 11 detected by each of the plurality of sensors are used.

- the correction unit that corrects the information based on the position orientation by the position orientation unit for example, elastic wave source density distribution

- the position orientation unit for example, elastic wave source density distribution

- the correction value determined according to the impact is used to correct the information so as to reduce the bias of the information based on the position orientation by the position determination unit. This makes it possible to reduce misdiagnosis. Therefore, even when the impact applied to the road surface is not uniform, it is possible to improve the evaluation accuracy of the structure 50.

- the details of the structure evaluation system 100 in the embodiment will be described.

- FIG. 3 is a diagram showing the configuration of the structure evaluation system 100 in the first embodiment.

- the structure evaluation system 100 is used to evaluate the soundness of the structure 50.

- evaluation means determining the degree of soundness of the structure 50, that is, the deterioration state of the structure 50, based on a certain criterion.

- the structure 50 may be any structure as long as the elastic wave 11 is generated due to the generation or growth of cracks or an external impact (for example, rain, artificial rain, etc.).

- the structure 50 may be a bedrock.

- the bridge is not limited to a structure erected on a river or a valley, but also includes various structures (for example, a viaduct on a highway) provided above the ground.

- the thickness of the structure 50 is, for example, 15 cm or more.

- Damage that affects the evaluation of the deterioration state of the structure 50 includes damage inside the structure that hinders the propagation of elastic waves 11 such as cracks, cavities, and sedimentation.

- the cracks include vertical cracks, horizontal cracks, diagonal cracks, and the like.

- a vertical crack is a crack that occurs in the direction perpendicular to the road surface.

- Lateral cracks are cracks that occur in the horizontal direction with respect to the road surface.

- An oblique crack is a crack that occurs in a direction other than horizontal and vertical with respect to the road surface.

- Sedimentation is deterioration in which concrete changes to a sediment-like shape mainly at the boundary between asphalt and concrete deck.

- the structure evaluation system 100 includes a plurality of sensors 20-1 to 20-n, a signal processing unit 30, and a structure evaluation device 40. Each of the plurality of sensors 20-1 to 20-n and the signal processing unit 30 are connected by wire so as to be communicable. The signal processing unit 30 and the structure evaluation device 40 are communicably connected by wire or wirelessly. In the following description, when the sensors 20-1 to 20-n are not distinguished, the sensor 20 is described.

- the sensor 20 has a piezoelectric element and detects an elastic wave 11 generated from the inside of the structure 50.

- the sensor 20 is installed at a position on the surface of the structure 50 where the elastic wave 11 can be detected.

- the sensor 20 is installed on any surface of the road surface, the side surface, and the bottom surface.

- the sensor 20 converts the detected elastic wave 11 into an electric signal.

- a case where the sensor 20 is installed on the bottom surface of the structure 50 will be described as an example.

- a piezoelectric element having a sensitivity in the range of 10 kHz to 1 MHz is used.

- the sensor 20 has a type such as a resonance type having a resonance peak in the frequency range and a wide band type in which resonance is suppressed, but the type of the sensor 20 may be any.

- the method for detecting the elastic wave 11 by the sensor 20 includes a voltage output type, a resistance change type, a capacitance type, and the like, and any detection method may be used.

- An acceleration sensor may be used instead of the sensor 20.

- the accelerometer detects the elastic wave 11 generated inside the structure 50. Then, the accelerometer converts the detected elastic wave 11 into an electric signal by performing the same processing as the sensor 20.

- An amplifier and an A / D converter (not shown) are provided between the sensor 20 and the signal processing unit 30, for example.

- the amplifier amplifies the electric signal output from the sensor 20.

- the amplifier outputs the amplified electric signal to the A / D converter.

- the amplifier amplifies the electrical signal to the extent that it can be processed by, for example, an A / D converter.

- the A / D converter quantizes the amplified electrical signal and converts it into a digital signal.

- the A / D converter outputs a digital signal to the signal processing unit 30.

- the signal processing unit 30 inputs a digital signal output from the A / D converter.

- the signal processing unit 30 performs signal processing on the input digital signal.

- the signal processing performed by the signal processing unit 30 is, for example, noise removal, parameter extraction, and the like.

- the signal processing unit 30 generates transmission data including a digital signal after signal processing.

- the signal processing unit 30 outputs the generated transmission data to the structure evaluation device 40.

- the signal processing unit 30 is configured by using an analog circuit or a digital circuit.

- the digital circuit is realized by, for example, FPGA (Field Programmable Gate Array) or a microcomputer.

- the digital circuit may be realized by a dedicated LSI (Large-Scale Integration).

- the signal processing unit 30 may be equipped with a non-volatile memory such as a flash memory or a removable memory.

- FIG. 4 is a schematic block diagram showing the functions of the signal processing unit 30 in the first embodiment.

- the signal processing unit 30 includes a waveform shaping filter 301, a gate generation circuit 302, an arrival time determination unit 303, a feature amount extraction unit 304, a transmission data generation unit 305, a memory 306, and an output unit 307.

- the waveform shaping filter 301 removes noise components outside a predetermined band from the input digital signal.

- the waveform shaping filter 301 is, for example, a digital bandpass filter (BPF).

- BPF digital bandpass filter

- the waveform shaping filter 301 outputs a digital signal after noise component removal (hereinafter referred to as “noise removal signal”) to the gate generation circuit 302, the arrival time determination unit 303, and the feature amount extraction unit 304.

- the gate generation circuit 302 inputs the noise reduction signal output from the waveform shaping filter 301.

- the gate generation circuit 302 generates a gate signal based on the input noise reduction signal.

- the gate signal is a signal indicating whether or not the waveform of the noise reduction signal is sustained.

- the gate generation circuit 302 is realized by, for example, an envelope detector and a comparator.

- the envelope detector detects the envelope of the denoising signal.

- the envelope is extracted, for example, by squared a noise reduction signal and performing a predetermined process (for example, a process using a low-pass filter or a Hilbert transform) on the squared output value.

- the comparator determines whether or not the envelope of the denoising signal is greater than or equal to a predetermined threshold.

- the gate generation circuit 302 uses a first gate signal indicating that the waveform of the denoising signal is sustained by the arrival time determination unit 303 and the feature amount extraction unit. Output to 304.

- the gate generation circuit 302 sets a second gate signal indicating that the waveform of the noise reduction signal is not sustained by the arrival time determination unit 303 and the feature amount. Output to the extraction unit 304.

- the arrival time determination unit 303 inputs the noise removal signal output from the waveform shaping filter 301 and the gate signal output from the gate generation circuit 302.

- the arrival time determination unit 303 determines the elastic wave arrival time using the noise reduction signal input while the first gate signal is input.

- the arrival time determination unit 303 outputs the determined elastic wave arrival time as time information to the transmission data generation unit 305.

- the arrival time determination unit 303 does not perform processing while the second gate signal is being input.

- the feature amount extraction unit 304 inputs the noise removal signal output from the waveform shaping filter 301 and the gate signal output from the gate generation circuit 302.

- the feature amount extraction unit 304 extracts the feature amount of the noise reduction signal by using the noise reduction signal input while the first gate signal is input.

- the feature amount extraction unit 304 does not perform processing while the second gate signal is input.

- the feature amount is information indicating the feature of the noise reduction signal.

- the features include, for example, the amplitude of the waveform [mV], the rise time of the waveform [usc], the duration of the gate signal [usc], the number of zero cross counts [times], and the energy of the waveform [arb. ], Frequency [Hz], RMS (Root Mean Square) value, etc.

- the feature amount extraction unit 304 outputs parameters related to the extracted feature amount to the transmission data generation unit 305.

- the sensor ID is associated with the parameter related to the feature amount.

- the sensor ID represents identification information for identifying the sensor 20 installed in the area (hereinafter referred to as “evaluation area”) to be evaluated for the soundness of the structure 50.

- the amplitude of the waveform is, for example, the value of the maximum amplitude in the noise reduction signal.

- the rising edge time of the waveform is, for example, the time T1 from the start of rising edge of the gate signal to the time when the noise reduction signal reaches the maximum value.

- the duration of the gate signal is, for example, the time from the start of the rise of the gate signal until the amplitude becomes smaller than the preset value.

- the zero cross count number is, for example, the number of times the noise reduction signal crosses the reference line passing through the zero value.

- the energy of the waveform is, for example, the value obtained by time-integrating the square of the amplitude of the noise reduction signal at each time point.

- the definition of energy is not limited to the above example, and may be approximated by using, for example, a waveform envelope.

- the frequency is the frequency of the noise reduction signal.

- the RMS value is, for example, a value obtained by square root of the amplitude of the noise reduction signal at each time point.

- the transmission data generation unit 305 inputs the sensor ID, time information, and parameters related to the feature amount.

- the transmission data generation unit 305 generates transmission data including the input sensor ID, time information, and parameters related to the feature amount.

- the memory 306 stores transmission data.

- the memory 306 is, for example, a dual port RAM (Random Access Memory).

- the output unit 307 sequentially outputs the transmission data stored in the memory 306 to the structure evaluation device 40.

- the structure evaluation device 40 includes a communication unit 41, a control unit 42, a storage unit 43, and a display unit 44.

- the communication unit 41 receives the transmission data output from the signal processing unit 30.

- the control unit 42 controls the entire structure evaluation device 40.

- the control unit 42 is configured by using a processor such as a CPU (Central Processing Unit) and a memory. By executing the program, the control unit 42 functions as an acquisition unit 421, an event extraction unit 422, a position determination unit 423, a distribution generation unit 424, a correction unit 425, and an evaluation unit 426.

- a processor such as a CPU (Central Processing Unit) and a memory.

- the functional units of the acquisition unit 421, event extraction unit 422, position determination unit 423, distribution generation unit 424, correction unit 425, and evaluation unit 426 are ASIC (Application Specific Integrated Circuit) or PLD (Programmable Logic Device). ), It may be realized by hardware such as FPGA, or it may be realized by collaboration between software and hardware.

- the program may be recorded on a computer-readable recording medium.

- the computer-readable recording medium is, for example, a flexible disk, a magneto-optical disk, a portable medium such as a ROM or a CD-ROM, or a non-temporary storage medium such as a storage device such as a hard disk built in a computer system.

- the program may be transmitted over a telecommunication line.

- Some of the functions of the acquisition unit 421, the event extraction unit 422, the position determination unit 423, the distribution generation unit 424, the correction unit 425, and the evaluation unit 426 do not need to be mounted on the structure evaluation device 40 in advance, and are additional. It may be realized by installing the application program in the structure evaluation device 40.

- the acquisition unit 421 acquires various information. For example, the acquisition unit 421 acquires the transmission data received by the communication unit 41. The acquisition unit 421 stores the acquired transmission data in the storage unit 43. In the first embodiment, the acquisition unit 421 acquires information about the vehicle 10 traveling on the structure 50 to be evaluated (hereinafter referred to as "vehicle information") for a predetermined period.

- vehicle information information about the vehicle 10 traveling on the structure 50 to be evaluated

- the vehicle information is, for example, vehicle type information of the vehicle 10 that has traveled in the structure 50 during a predetermined period, and traffic volume information of the vehicle 10 of the structure 50.

- the vehicle type information of the vehicle 10 includes at least information on the tread width of the vehicle 10.

- the traffic volume information of the vehicle 10 is information indicating how many vehicles 10 of which vehicle type have passed through the structure 50 in a predetermined period.

- the acquisition unit 421 may acquire vehicle information by input of a user, or may acquire vehicle information from a server that stores traffic information.

- the event extraction unit 422 extracts the transmission data in one event from the transmission data stored in the storage unit 43.

- the event represents an elastic wave generation event that has occurred in the structure 50.

- the elastic wave generation event in the present embodiment is the passage of the road surface by the vehicle 10.

- the event extraction unit 422 provides a predetermined time window, and extracts all transmission data whose arrival time is within the range of the time window as transmission data in one event.

- the event extraction unit 422 outputs the transmission data in one extracted event to the position determination unit 423.

- the elastic wave propagation velocity v may be obtained in advance.

- the position determination unit 423 performs position determination of the elastic wave source based on the sensor position information and the sensor ID and time information included in each of the plurality of transmission data extracted by the event extraction unit 422.

- the sensor position information includes information regarding the installation position of the sensor 20 in association with the sensor ID.

- the sensor position information includes information about the installation position of the sensor 20, such as latitude and longitude, or horizontal and vertical distances from a reference position of the structure 50.

- the position setting unit 423 holds the sensor position information in advance.

- the sensor position information may be stored in the position determination unit 423 at any timing before the position determination unit 423 performs position determination of the elastic wave source.

- the sensor position information may be stored in the storage unit 43.

- the position determination unit 423 acquires the sensor position information from the storage unit 43 at the timing of performing the position determination.

- a Kalman filter, a least squares method, or the like may be used to determine the position of the elastic wave source.

- the position setting unit 423 outputs the position information of the elastic wave source obtained during the measurement period to the distribution generation unit 424.

- the distribution generation unit 424 inputs the position information of a plurality of elastic wave sources output from the position determination unit 423.

- the distribution generation unit 424 uses the input position information of the plurality of elastic wave sources to generate an elastic wave source distribution.

- the elastic wave source distribution represents a distribution in which the position of the elastic wave source is shown. More specifically, the elastic wave source distribution is the position of the elastic wave source on the virtual data representing the structure 50 to be evaluated, with the horizontal axis as the distance in the passage direction and the vertical axis as the distance in the width direction. The points shown are the distributions shown.

- the distribution generation unit 424 generates an elastic wave source density distribution using the elastic wave source distribution. For example, the distribution generation unit 424 generates an elastic wave source density distribution by representing the position of the elastic wave source with a contour diagram as shown in FIG.

- the correction unit 425 corrects the information based on the position setting by the position setting unit 423 by using the correction value determined according to the impact.

- the correction value determined in response to the impact in the first embodiment is a correction value obtained from the vehicle information acquired by the acquisition unit 421.

- the correction value has an extreme value at the passing position of the traveling portion of the vehicle 10.

- the information based on the position orientation is the information obtained before the position orientation (for example, the amplitude of the elastic wave) or by using the orientation result.

- the information based on position orientation is the elastic wave source density distribution. In the following description, the case where the information based on the position orientation is the elastic wave source density distribution will be described as an example.

- the evaluation unit 426 evaluates the deterioration state of the structure 50 based on the corrected information. Specifically, the evaluation unit 426 evaluates the deteriorated state of the structure 50 using the corrected elastic wave source density distribution. For example, the evaluation unit 426 evaluates a region where the density of the elastic wave source is equal to or higher than the threshold value as a healthy region, and evaluates a region where the density of the elastic wave source is less than the threshold value as a damaged region.

- the storage unit 43 stores the transmission data and vehicle information acquired by the acquisition unit 421.

- the storage unit 43 is configured by using a storage device such as a magnetic hard disk device or a semiconductor storage device.

- the display unit 44 displays the evaluation result according to the control of the evaluation unit 426.

- the display unit 44 is an image display device such as a liquid crystal display or an organic EL (ElectroLuminescence) display.

- the display unit 44 may be an interface for connecting the image display device to the structure evaluation device 40. In this case, the display unit 44 generates a video signal for displaying the evaluation result, and outputs the video signal to the image display device connected to the display unit 44.

- FIG. 5 is a sequence diagram showing a flow of evaluation processing of a deteriorated state by the structure evaluation system 100 in the first embodiment.

- the process of FIG. 5 is executed according to the vehicle 10 traveling on the structure 50 to be evaluated.

- the traveling portion of the vehicle 10 comes into contact with the road surface.

- elastic waves 11 are generated in the structure 50.

- Each of the plurality of sensors 20 detects the elastic wave 11 generated in the structure 50 (step S101).

- Each of the plurality of sensors 20 converts the detected elastic wave 11 into an electric signal and outputs it to the signal processing unit 30 (step S102).

- the electric signal output from each of the plurality of sensors 20 is amplified by an amplifier (not shown).

- the amplified electric signal is converted into a digital signal by an A / D converter.

- the signal processing unit 30 inputs the digital signal output from the A / D converter.

- the arrival time determination unit 303 of the signal processing unit 30 determines the arrival time of each elastic wave 11 using the input digital signal (step S103). Specifically, the arrival time determination unit 303 determines the elastic wave arrival time using the noise reduction signal which is a digital signal input while the first gate signal is input.

- the arrival time determination unit 303 outputs the determined elastic wave arrival time as time information to the transmission data generation unit 305.

- the arrival time determination unit 303 performs this processing on all the input digital signals.

- the feature amount extraction unit 304 of the signal processing unit 30 extracts the feature amount of the noise reduction signal by using the noise reduction signal which is a digital signal input while the first gate signal is input (step S104). ).

- the feature amount extraction unit 304 outputs parameters related to the extracted feature amount to the transmission data generation unit 305.

- the transmission data generation unit 305 generates transmission data including the sensor ID, time information, and parameters related to the feature amount (step S105).

- the output unit 307 sequentially outputs the transmission data to the structure evaluation device 40 (step S106).

- the communication unit 41 of the structure evaluation device 40 receives the transmission data output from the signal processing unit 30.

- the acquisition unit 421 acquires the transmission data received by the communication unit 41.

- the acquisition unit 421 records the acquired transmission data in the storage unit 43 (step S107).

- the event extraction unit 422 extracts the transmission data in one event from the transmission data stored in the storage unit 43.

- the event extraction unit 422 outputs the transmission data in one extracted event to the position determination unit 423 and the distribution generation unit 424.

- the position determination unit 423 determines the position of the elastic wave source based on the sensor ID and time information included in the transmission data output from the event extraction unit 422 and the sensor position information held in advance (step S108). Specifically, first, the position setting unit 423 calculates the difference in the arrival time of the elastic wave 11 to each of the plurality of sensors 20. Next, the position setting unit 423 positions the position of the elastic wave source using the sensor position information and the information of the difference in arrival time.

- the position setting unit 423 executes the process of step S108 every time the transmission data of one event is output from the event extraction unit 422 during the measurement period. As a result, the position setting unit 423 positions the positions of the plurality of elastic wave sources. The position setting unit 423 outputs position information of a plurality of elastic wave sources to the distribution generation unit 424.

- the distribution generation unit 424 generates an elastic wave source distribution using the position information of a plurality of elastic wave sources output from the position determination unit 423. Specifically, the distribution generation unit 424 generates an elastic wave source distribution by plotting the positions of the elastic wave sources indicated by the position information of the obtained plurality of elastic wave sources on virtual data. The distribution generation unit 424 generates an elastic wave source density distribution by representing the generated elastic wave source distribution in a contour diagram (step S109). The distribution generation unit 424 outputs the generated elastic wave source density distribution to the correction unit 425.

- the correction unit 425 inputs the elastic wave source density distribution output from the distribution generation unit 424 and the vehicle information stored in the storage unit 43.

- the correction unit 425 corrects the elastic wave source density distribution with the correction value obtained by using the input vehicle information (step S110).

- the correction unit 425 calculates the correction value f (x, y) based on the following equation (1) using the vehicle information.

- Equation (1) y is the distance in the width direction of the road, k is the coefficient, a is the position of the traveling portion, and w is the degree of variation in the passing position.

- the correction value obtained by the equation (1) has a peak at the passing position of the traveling portion in the y direction and has a constant value in the passage direction in the x direction.

- the traveling portion position used at the time of correction the tread width of the vehicle 10 included in the vehicle information can be referred to.

- the tread width is about 1900 mm for a 10t truck. Therefore, the traveling portion position a can be set to a position ⁇ 950 mm from the center of the lane. In the case of an ordinary vehicle, the tread width is about 1500 mm. Therefore, the traveling portion position a can be set to ⁇ 750 mm from the center of the lane.

- the position of the traveling part is also possible to determine the position of the traveling part according to the traffic conditions of the structure 50 to be evaluated.

- the structure 50 to be evaluated is a road through which a large vehicle does not pass, for example, a tread width of about 1500 mm for a normal vehicle may be adopted and set to ⁇ 750 mm from the center of the lane.

- Information on the traffic conditions of the structure 50 may be input to the structure evaluation device 40 from the outside, or may be included in the vehicle information.

- the correction unit 425 may determine the traveling unit position a based on the statistical value of the vehicle type information included in the vehicle information. For example, the correction unit 425 may set the tread width of the vehicle type having the largest number of passages as the traveling unit position a from the statistical result of the vehicle type information included in the vehicle information. For example, the correction unit 425 may use the tread width of the vehicle having the largest tread width as the traveling unit position a or the average tread width as the traveling unit position a based on the statistical results of the vehicle type information included in the vehicle information. good.

- the variation in the passage position can be determined by the condition of the structure 50 to be evaluated. For example, on a highway or a wide road, the variation in the passage position of each vehicle 10 becomes large. On the other hand, on a narrow road where only one vehicle 10 can pass, all the vehicles pass at substantially the same position, so that the variation is small. Therefore, the correction unit 425 appropriately sets the parameters related to the degree of variation in the traffic position by referring to the traffic volume information, the road width, the frequency of lane changes, and the like.

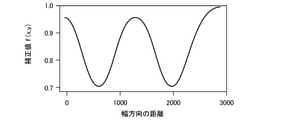

- FIG. 6 shows an example of the correction value calculated based on the above equation (1).

- the horizontal axis represents the distance in the width direction

- the vertical axis represents the correction value f (x, y).

- the correction value f (x, y) is a value that reduces at least a position value (for example, density) on the elastic wave source density distribution corresponding to the passing position of the traveling portion of the vehicle 10. It is represented by the distribution it has. That is, the correction value f (x, y) has a value that most decreases the value of the position on the elastic wave source density distribution corresponding to the passing position of the traveling portion of the vehicle 10 and does not decrease as far as the position away from the passing position. It is represented by a distribution.

- FIG. 6 shows an example of a correction value f (x, y) when there are two passing positions of the traveling portion of the vehicle 10. Therefore, the correction value f (x, y) shown in FIG. 6 has two values that most reduce the value of the position on the elastic wave source density distribution corresponding to the passing position of the traveling portion of the vehicle 10. Depending on the evaluation area, there may be one passing position of the traveling portion of the vehicle 10. Therefore, the correction value f (x, y) may have one or more values that most reduce the value of the position on the elastic wave source density distribution corresponding to the passing position of the traveling portion of the vehicle 10.

- the correction unit 425 corrects the elastic wave source density distribution by multiplying the calculated correction value f (x, y) by the elastic wave source density distribution. Specifically, the correction unit 425 multiplies the width direction of the elastic wave source density distribution by the correction value f (x, y) according to the distance in the width direction of the calculated correction value f (x, y). do.

- the correction unit 425 is set at a position of a distance "500" in the width direction of the calculated correction value f (x, y) with respect to a density value at a position of a distance "500” in the width direction of the elastic wave source density distribution. Multiply the corresponding correction value f (x, y). Similarly, the correction unit 425 multiplies the passage direction of the elastic wave source density distribution by the correction value f (x, y) according to the distance in the width direction. For example, the correction unit 425 calculates the correction value f (for all the density values at the position of the distance "0 to 3000" in the traffic direction corresponding to the position of the distance "500” in the width direction of the elastic wave source density distribution. The correction value f (x, y) corresponding to the position of the distance "500” in the width direction of x, y) is multiplied.

- the correction unit 425 corrects the elastic wave source density distribution by the above processing to generate the corrected elastic wave source density distribution AD shown in FIG. 7.

- the correction unit 425 outputs the corrected elastic wave source density distribution AD to the evaluation unit 426.

- FIG. 7 is a diagram showing an example of the corrected elastic wave source density distribution AD.

- the horizontal axis represents the distance in the traffic direction of the vehicle, and the vertical axis represents the distance in the width direction.

- the corrected elastic wave source density distribution AD shown in FIG. 7 is less affected by the passage of the traveling portion of the vehicle 10 than the elastic wave source density distribution D shown in FIG.

- the effect of the passage of the traveling portion of the vehicle 10 is that the density of the elastic wave source at the position where the traveling portion of the vehicle 10 has passed increases.

- the evaluation unit 426 evaluates the deterioration state of the structure 50 using the corrected elastic wave source density distribution AD output from the correction unit 425 (step S111).

- the evaluation unit 426 evaluates a region having a density lower than the threshold value 15 set in the elastic wave source density distribution AD corrected by the conventional evaluation method as a damaged region. In this case, the region 16 shown in FIG. 7 is evaluated as a damaged region.

- the evaluation unit 426 outputs the evaluation result to the display unit 44.

- the display unit 44 displays the evaluation result output from the evaluation unit 426 (step S112). For example, the display unit 44 may display the corrected elastic wave source density distribution as an evaluation result, or may display a region that is considered to be a damaged region in a different display mode from other regions.

- the correction value f (x, y) determined according to the impact is used to correct the information so as to reduce the bias of the information based on the position orientation by the position determination unit. More specifically, the structure evaluation device 40 calculates a correction value f (x, y) for a future impact from the vehicle information of the vehicle 10 traveling on the structure 50 to be evaluated. Then, the structure evaluation device 40 uses the calculated correction value f (x, y) to correct the influence of the impact caused by the passage of the traveling portion of the vehicle 10 in the elastic wave source density distribution which is the information based on the position orientation. do. This makes it possible to reduce misdiagnosis. Therefore, even when the impact applied to the road surface is not uniform, it is possible to improve the evaluation accuracy of the structure 50.

- the correction unit 425 corrects the elastic wave source density distribution with a correction value f (x, y) having at least one extreme value portion for correcting information at a position where an impact is applied.

- the information at the position where the impact is applied is, for example, the information at the position affected by the passage of the traveling portion of the vehicle 10.

- the correction unit 425 corrects the correction value f (x, y) having one or more extreme value portions in order to reduce the influence caused by the passage of the traveling unit of the vehicle 10. This makes it possible to reduce the influence caused by the passage of the traveling portion of the vehicle 10. As a result, it is possible to improve the evaluation accuracy of the structure 50 even when the impact applied to the road surface is not uniform.

- the correction unit 425 corrects the elastic wave source density distribution in the traffic direction of the vehicle 10 by using the correction value f (x, y) determined for each distance in the width direction of the road.

- One vehicle 10 travels on the road with the same tread width. Therefore, when viewed in the traffic direction of the vehicle 10, an impact (dotted line 14) is linearly applied to the road surface as shown in FIG. Therefore, the correction unit 425 calculates the correction value f (x, y) for each distance in the width direction, and obtains the same correction value f (x, y) in the passage direction as seen from the position of the distance in one width direction. Use.

- the correction unit 425 uses the same correction value f (x, y) for the value at the position of the distance "0 to 3000" in the passage direction as seen from the position "500" of the distance in the width direction. As a result, it is not necessary to calculate all the correction values at positions where the distance in the width direction is the same but the distance in the traffic direction is different. Therefore, the correction can be easily performed.

- the correction unit 425 calculates the correction value based on the position where the impact generated by the contact between the traveling unit of the vehicle 10 and the road surface is generated. As a result, the correction unit 425 can calculate the correction value in consideration of the position where the influence of the passage of the traveling unit of the vehicle 10 is further reduced. For example, the correction unit 425 can calculate a correction value that most reduces the value at a position where the influence of the passage of the traveling unit of the vehicle 10 is large. This makes it possible to reduce misdiagnosis. Therefore, even when the impact applied to the road surface is not uniform, it is possible to improve the evaluation accuracy of the structure 50.

- the correction value is not limited to the form obtained by the equation (1).

- the correction value may be a rectangle or a distribution represented by a function having a shape close to a rectangle.

- the correction unit 425 superimposes a weighted distribution on the tread width for each vehicle type according to the ratio of the vehicle types of the vehicle 10 obtained from the vehicle information to obtain a correction value f (x, y) closer to the actual value. It may be calculated.

- the evaluation unit 426 may be configured to evaluate the deterioration state of the region of the evaluation target region where the frequency of impact is assumed to be equal to or higher than the threshold value.

- the correction unit 425 shows a configuration in which the correction value f (x, y) is calculated using the tread width of the vehicle 10 in the vehicle information and the traffic volume information, but the correction unit 425 is a vehicle.

- the correction value f (x, y) may be calculated based on the tread width of 10.

- the correction unit 425 calculates the correction value f (x, y) with the degree of variation w of the passing position as 1 in the above equation (1).

- the traveling portion position a may be obtained in the same manner as in the above embodiment.

- the correction unit 425 can calculate the correction value f (x, y) from the tread width information even if the traffic volume information cannot be obtained. Therefore, it is possible to perform correction with a small amount of information.

- the correction unit 425 shows a configuration in which the correction value f (x, y) is calculated using the vehicle information.

- the second embodiment a configuration will be described in which the position where the vehicle 10 has passed is estimated based on the electric signal obtained from the sensor 20 and the correction value f (x, y) is acquired.

- FIG. 9 is a diagram showing the configuration of the structure evaluation system 100a in the second embodiment.

- the structure evaluation system 100a in the second embodiment is the same as the first embodiment except that the structure evaluation device 40a is provided in place of the structure evaluation device 40.

- the configuration of the structure evaluation device 40a according to the difference will be described.

- the structure evaluation device 40a includes a communication unit 41, a control unit 42a, a storage unit 43a, and a display unit 44.

- the control unit 42a controls the entire structure evaluation device 40a.

- the control unit 42a is configured by using a processor such as a CPU and a memory. By executing the program, the control unit 42a functions as an acquisition unit 421a, an event extraction unit 422, a position determination unit 423, a distribution generation unit 424, a correction unit 425a, and an evaluation unit 426.

- a part or all of the functional parts of the acquisition unit 421a, the event extraction unit 422, the position determination unit 423, the distribution generation unit 424, the correction unit 425a, and the evaluation unit 426 are realized by hardware such as ASIC, PLD, and FPGA. It may be realized by the cooperation of software and hardware.

- the program may be recorded on a computer-readable recording medium.

- the computer-readable recording medium is a non-temporary storage medium such as a flexible disk, a magneto-optical disk, a portable medium such as a ROM or a CD-ROM, or a storage device such as a hard disk built in a computer system.

- the program may be transmitted over a telecommunication line.

- Some of the functions of the acquisition unit 421a, the event extraction unit 422, the position determination unit 423, the distribution generation unit 424, the correction unit 425a, and the evaluation unit 426 do not need to be mounted on the structure evaluation device 40a in advance, and additional functions are required. It may be realized by installing the application program in the structure evaluation device 40a.

- the control unit 42a is different from the control unit 42 in that the acquisition unit 421a and the correction unit 425a are provided in place of the acquisition unit 421 and the correction unit 425.

- the differences will be described below.

- the acquisition unit 421a acquires various types of information. For example, the acquisition unit 421a acquires the transmission data received by the communication unit 41. The acquisition unit 421a stores the acquired transmission data in the storage unit 43. In the second embodiment, the acquisition unit 421a acquires information indicating the position of a sound region in the structure 50 to be evaluated (hereinafter referred to as “healthy position information”). The acquisition unit 421a acquires sound position information by input from the user.

- the correction unit 425a corrects the information based on the position orientation by the position determination unit 423 by using the correction value f (x, y) determined according to the impact.

- the correction value determined in response to the impact in the second embodiment is a correction value obtained based on the electric signal obtained from the sensor 20.

- the correction value determined in response to the impact in the second embodiment is a correction value obtained by calculating the tread width based on the electric signal obtained from the sensor 20.

- the storage unit 43a stores the transmission data and sound position information acquired by the acquisition unit 421a.

- the storage unit 43a is configured by using a storage device such as a magnetic hard disk device or a semiconductor storage device.

- the correction unit 425a inputs the elastic wave source density distribution output from the distribution generation unit 424 and the sound position information stored in the storage unit 43a.

- the correction unit 425a corrects the elastic wave source density distribution based on the input elastic wave source density distribution and the sound position information (step S110). Specifically, first, the correction unit 425a estimates the passing position of the traveling unit of the vehicle 10 by using the elastic wave source density distribution.

- the correction unit 425a estimates the passing position of the traveling unit of the vehicle 10 based on the first condition and the second condition.

- the first condition is that the regions where the density is equal to or higher than the first threshold value in the traffic direction of the elastic wave source density distribution are continuous for the first distance or longer.

- the second condition is that there are two or more regions in the width direction that satisfy the first condition.

- the correction unit 425a estimates each of the regions satisfying the first condition as the passing position of the traveling unit of the vehicle 10.

- the correction unit 425a calculates a correction value f (x, y) that reduces the value of the position on the elastic wave source density distribution corresponding to the estimated passing position of the traveling unit of the vehicle 10 by a threshold value or more. For example, the correction unit 425a calculates a correction value f (x, y) that most reduces the value of the position on the elastic wave source density distribution corresponding to the estimated passing position of the traveling unit of the vehicle 10.

- the correction unit 425a uses sound position information when calculating the correction value f (x, y). For example, the correction unit 425a calculates the correction value f (x, y) with reference to the density value of the region indicated by the sound position information (hereinafter referred to as “reference value”).

- the correction unit 425a determines the minimum value of the correction value so as to match the value of the position on the elastic wave source density distribution corresponding to the estimated passing position of the traveling unit of the vehicle 10 with the reference value.

- the correction unit 425a corrects the elastic wave source density distribution by multiplying the calculated correction value f (x, y) by the elastic wave source density distribution.

- the correction value f (x, y) determined according to the impact is acquired from the elastic wave source density distribution. More specifically, the structure evaluation device 40a calculates the correction value f (x, y) for the past impact from the elastic wave source density distribution obtained by the vehicle 10 traveling on the structure 50 to be evaluated. .. Then, the structure evaluation device 40a uses the calculated correction value f (x, y) to correct the influence of the impact caused by the passage of the traveling portion of the vehicle 10 in the elastic wave source density distribution which is the information based on the position orientation. do. This makes it possible to reduce misdiagnosis. Therefore, even when the impact applied to the road surface is not uniform, it is possible to improve the evaluation accuracy of the structure 50.

- the correction unit 425a may estimate the passing position of the traveling unit of the vehicle 10 as follows.

- the correction unit 425a estimates that one region satisfying the first condition is the passing position of the traveling unit of the vehicle 10 when the first condition is satisfied and the second condition is not satisfied.

- the correction unit 425a calculates a correction value f (x, y) that most reduces the value of the position on the elastic wave source density distribution corresponding to the estimated passing position of the traveling unit of the vehicle 10.

- the correction unit 425a has shown a configuration in which the passing position of the vehicle 10 is estimated from the elastic wave source density distribution and the correction value f (x, y) is acquired.

- the correction unit 425a may be configured to correct the elastic wave source density distribution using the correction value f (x, y) generated by the user.

- the distribution generation unit 424 outputs the generated elastic wave source density distribution to the display unit 44 in the process of step S109.

- the display unit 44 displays the elastic wave source density distribution.

- the user grasps the position where the traveling portion of the vehicle 10 has passed by referring to the elastic wave source density distribution displayed on the display unit 44. Then, the user generates a correction value f (x, y) capable of suppressing the influence caused by the passage of the traveling portion of the vehicle 10 and inputs it to the structure evaluation device 40a.

- the correction value f (x, y) that can suppress the influence is a value that can reduce the value corresponding to the density of the elastic wave source that has increased due to the passage of the traveling portion of the vehicle 10.

- the correction value f (x, y) capable of suppressing the influence is a value that can cancel the influence caused by the passage of the traveling portion of the vehicle 10.

- the correction unit 425a corrects the elastic wave source density distribution using the input correction value f (x, y).

- the position where the traveling portion of the vehicle 10 has passed is grasped by the user's visual recognition. This makes it possible to roughly estimate the position where the traveling portion of the vehicle 10 has passed.

- the user generates a correction value f (x, y) capable of suppressing the influence caused by the passage of the traveling portion of the vehicle 10, and inputs the correction value f (x, y) to the structure evaluation device 40a.

- the structure evaluation device 40a does not need to calculate the correction value f (x, y). Therefore, the processing load can be reduced, and the evaluation accuracy of the structure 50 can be improved even when the impact applied to the road surface is not uniform.

- the evaluation unit 426a may be configured to evaluate the deterioration state of the region of the evaluation target region where the frequency of impact is assumed to be equal to or higher than the threshold value. With such a configuration, the processing load can be reduced and misdiagnosis can be suppressed.

- FIG. 10 is a diagram showing the configuration of the structure evaluation system 100b according to the third embodiment.

- the structure evaluation system 100b in the third embodiment is the same as the first embodiment except that the structure evaluation device 40b is provided in place of the structure evaluation device 40.

- the configuration of the structure evaluation device 40b according to the difference will be described.

- the structure evaluation device 40b includes a communication unit 41, a control unit 42b, a storage unit 43b, and a display unit 44.

- the control unit 42b controls the entire structure evaluation device 40b.

- the control unit 42b is configured by using a processor such as a CPU and a memory. By executing the program, the control unit 42b functions as an acquisition unit 421b, an event extraction unit 422, a position determination unit 423, a distribution generation unit 424, and an evaluation unit 426b.

- a part or all of the functional parts of the acquisition unit 421b, the event extraction unit 422, the position determination unit 423, the distribution generation unit 424, and the evaluation unit 426b may be realized by hardware such as ASIC, PLD, or FPGA. It may be realized by the cooperation of software and hardware.

- the program may be recorded on a computer-readable recording medium.

- the computer-readable recording medium is, for example, a flexible disk, a magneto-optical disk, a portable medium such as a ROM or a CD-ROM, or a non-temporary storage medium such as a storage device such as a hard disk built in a computer system.

- the program may be transmitted over a telecommunication line.

- Some of the functions of the acquisition unit 421b, the event extraction unit 422, the position determination unit 423, the distribution generation unit 424, and the evaluation unit 426b do not need to be mounted on the structure evaluation device 40b in advance, and an additional application program is structured. It may be realized by installing it in the object evaluation device 40b.

- the control unit 42b is different from the control unit 42 in that the acquisition unit 421b and the evaluation unit 426b are provided in place of the acquisition unit 421 and the evaluation unit 426, and the correction unit 425 is not provided. The differences will be described below.

- the acquisition unit 421b acquires various types of information. For example, the acquisition unit 421b acquires the transmission data received by the communication unit 41. The acquisition unit 421b stores the acquired transmission data in the storage unit 43b. In the third embodiment, the acquisition unit 421b acquires information about the structure 50 to be evaluated. The information about the structure 50 to be evaluated includes at least the information on the road width of the structure 50.

- the evaluation unit 426b evaluates the deteriorated state of the structure 50 based on the frequency of applying impact. Specifically, the evaluation unit 426b evaluates the deterioration state of the region where the impact frequency is assumed to be equal to or higher than the threshold value, and does not evaluate the deterioration state of the region where the impact application frequency is assumed to be less than the threshold value. For example, the evaluation unit 426b evaluates a region where the density of the elastic wave source is equal to or higher than the threshold value in a region where the impact application frequency is assumed to be equal to or higher than the threshold value, and evaluates a region where the impact application frequency is assumed to be equal to or higher than the threshold value. A region where the density of the elastic wave source is less than the threshold value is evaluated as a damaged region.

- the storage unit 43b stores the transmission data acquired by the acquisition unit 421b and the information regarding the structure 50 to be evaluated.

- the storage unit 43b is configured by using a storage device such as a magnetic hard disk device or a semiconductor storage device.

- the evaluation unit 426b evaluates the structure to be evaluated based on the road width information included in the information about the structure 50 to be evaluated acquired by the acquisition unit 421b. It is determined whether or not the condition that the road width of 50 is very narrow is satisfied.

- the condition that the road width is very narrow shall be set in advance.

- the condition that the road width is very narrow is that the road width is the same as the tread width of a specific vehicle (for example, an ordinary vehicle) or is wider by a predetermined width (for example, +10 mm).

- the following processing is executed when the condition that the road width of the structure 50 to be evaluated is very narrow is satisfied.

- the condition that the road width of the structure 50 to be evaluated is very narrow is not satisfied, the following processing is not executed.

- the structure evaluation system 100 executes the processes from step S101 to step S109 shown in FIG. After that, the evaluation unit 426b evaluates the deterioration state of the region of the evaluation target region where the frequency of impact is assumed to be equal to or higher than the threshold value.

- the structure evaluation system 100c configured as described above does not evaluate the deterioration state of the region where the frequency of impact is assumed to be less than the threshold value. This makes it possible to reduce misdiagnosis. Therefore, even when the impact applied to the road surface is not uniform, it is possible to improve the evaluation accuracy of the structure 50.

- the signal processing unit 30 may be provided in the structure evaluation devices 40, 40a, 40b.

- a configuration is shown in which a plurality of sensors 20-1 to 20-n are connected to one signal processing unit 30.

- the structure evaluation systems 100, 100a, 100b include a plurality of signal processing units 30, and each sensor 20 may be connected to a different signal processing unit 30.

- Each functional unit included in the structure evaluation devices 40, 40a, 40b may be partially or completely provided in another device.

- the display unit 44 included in the structure evaluation devices 40, 40a, 40b may be provided in another device.

- the structure evaluation devices 40, 40a, 40b transmit the evaluation results to another device including the display unit 44.

- Another device including the display unit 44 displays the received evaluation result.

- non-uniform target that gives a spatially non-uniform impact to the road surface is the traveling portion of the vehicle 10

- the non-uniform object need not be limited to the traveling portion of the vehicle 10.

- non-uniform objects include sprinkler vehicles, manually pushed vehicles, fixed sprinklers, and the like. Hereinafter, it will be described in detail.

- a sprinkler vehicle is a vehicle that can travel on the road surface while sprinkling water.

- a sprinkler vehicle is a vehicle equipped with a sprinkler for sprinkling water behind the vehicle.

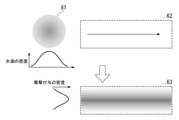

- the sprinkler sprinkles water droplets (objects) in a distribution having a normal distribution with the center of the circular region 61 of FIG. 11 as the peak. In this case, the impact applied to the road surface is water droplets.

- FIG. 11 is an explanatory diagram when the non-uniform object is a sprinkler vehicle.

- a distribution 63 for example, an elastic wave source density distribution

- the correction units 425 and 425a calculate a correction value f (x, y) capable of suppressing the bias of the distribution 63. Then, the correction units 425 and 425a correct the elastic wave source density distribution by multiplying the calculated correction value f (x, y) by the elastic wave source density distribution.

- a person may give a spatially non-uniform impact to the road surface by spraying a plurality of objects such as water and ice by a predetermined method.

- a predetermined method a person carries a watering device and sprays it, or a method of spraying water or ice directly on the road surface without using the device (for example, holding water or ice in his hand on the road surface). Method of sprinkling) and the like.

- a hand-held vehicle is a vehicle that can give an impact to the road surface at regular intervals by traveling on the road surface manually.

- a push vehicle is a vehicle equipped with a striking mechanism.

- the striking mechanism is, for example, a rotation mechanism of a tooth profile.

- the tooth profile rotation mechanism comes into contact with the road surface at regular intervals, so that the tooth profile rotation mechanism gives an impact to the road surface.

- a distribution for example, elastic wave source density distribution

- the correction units 425 and 425a calculate a correction value f (x, y) that cancels out the bias of this distribution. Then, the correction units 425 and 425a correct the elastic wave source density distribution by multiplying the calculated correction value f (x, y) by the elastic wave source density distribution.

- the striking mechanism is not limited to the rotation mechanism of the tooth profile, and may be any mechanism as long as an impact can be applied to the road surface.

- the method of applying an impact to the road surface by the striking mechanism is not limited to the hand-pushed vehicle, and may be a method of towing the striking mechanism with the vehicle.

- a fixed sprinkler is a spraying device capable of spraying water droplets on a predetermined range of a road surface at regular time intervals.

- the impact applied to the road surface is water droplets.

- the fixed sprinklers are installed on each of a plurality of streets installed outside the road on which the vehicle 10 can travel. When water droplets are sprayed on the road surface by such a fixed sprinkler, an impact is applied to a predetermined range of the road surface.

- the distribution generation unit 424 generates an elastic wave source density distribution based on the applied impact. Since different water droplets are applied to the road surface for each fixed sprinkler, the distribution generation unit 424 generates an elastic wave source density distribution according to the water droplets applied from each fixed sprinkler.

- the correction units 425 and 425a calculate a correction value f (x, y) for each fixed sprinkler so as to cancel the bias according to the water droplets applied from each fixed sprinkler. Then, the correction units 425 and 425a correct each elastic wave source density distribution by multiplying each of the calculated correction values f (x, y) by the elastic source density distribution corresponding to each fixed sprinkler.

- the elastic wave source density distribution was described as an example as information based on the position orientation.

- the information based on the position orientation may be any information as long as it is the information obtained by using the orientation result.

- the information based on position orientation may be average amplitude.

- the average amplitude is calculated by averaging the amplitude of the elastic wave of the first hit detected by the sensor 20 for each impact in each predetermined region.

- the predetermined area is a area having a predetermined size.

- the amplitude of the first hit elastic wave is used to calculate the average in a predetermined region including the position where the first hit elastic wave is generated. Therefore, the average amplitude is close to 0 in a predetermined region where elastic waves are not generated because no impact is applied.

- the correction unit 425 corrects the average amplitude value for each predetermined region using the correction value f (x, y) determined according to the impact. For example, the correction unit 425 corrects with a correction value f (x, y) that reduces the value of the average amplitude in a predetermined region corresponding to the passing position of the traveling unit of the vehicle 10.

- the evaluation unit 426 evaluates the deterioration state of the structure 50 for each predetermined region based on the corrected average amplitude value. Specifically, the evaluation unit 426 evaluates a predetermined region corresponding to the passing position of the traveling portion of the vehicle 10 as a damaged region in which the corrected average amplitude value is less than the threshold value. Whether or not the region corresponds to the passing position of the traveling portion of the vehicle 10 may be determined based on the tread width information, or may be input from the outside.

- the evaluation unit 426 may evaluate as follows in addition to the conventional evaluation method.

- the evaluation unit 426 sets a plurality of regions within a predetermined range on the corrected elastic wave source density distribution AD. As a result, the evaluation unit 426 divides each region on the corrected elastic wave source density distribution AD.

- the evaluation unit 426 makes a comparison with the threshold value 15 for each divided region (hereinafter referred to as “divided region”). For example, the evaluation unit 426 compares the density in the divided region with the threshold value 15. As a result of comparison, the evaluation unit 426 evaluates a region having a density lower than the threshold value 15 as a damaged region.

- the plurality of sensors detect elastic waves generated from the structure.

- the position determination unit positions the positions of the sources of the plurality of elastic waves based on the plurality of elastic waves detected by each of the plurality of sensors.

- the correction unit corrects the information based on the position setting by the position setting unit by using the correction value determined according to the impact.

- the evaluation unit evaluates the deterioration state of the structure based on the corrected information. This makes it possible to improve the evaluation accuracy of the structure even when the impact applied to the surface of the structure is not uniform.

Landscapes

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- General Health & Medical Sciences (AREA)

- Health & Medical Sciences (AREA)