WO2022013921A1 - 作業計画特定プログラム、作業計画特定方法、および情報処理装置 - Google Patents

作業計画特定プログラム、作業計画特定方法、および情報処理装置 Download PDFInfo

- Publication number

- WO2022013921A1 WO2022013921A1 PCT/JP2020/027259 JP2020027259W WO2022013921A1 WO 2022013921 A1 WO2022013921 A1 WO 2022013921A1 JP 2020027259 W JP2020027259 W JP 2020027259W WO 2022013921 A1 WO2022013921 A1 WO 2022013921A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- raw material

- cutting device

- work plan

- objects

- product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/182—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by the machine tool function, e.g. thread cutting, cam making, tool direction control

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/04—Forecasting or optimisation specially adapted for administrative or management purposes, e.g. linear programming or "cutting stock problem"

- G06Q10/043—Optimisation of two dimensional placement, e.g. cutting of clothes or wood

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/418—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS] or computer integrated manufacturing [CIM]

- G05B19/41865—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS] or computer integrated manufacturing [CIM] characterised by job scheduling, process planning, material flow

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q50/00—Information and communication technology [ICT] specially adapted for implementation of business processes of specific business sectors, e.g. utilities or tourism

- G06Q50/04—Manufacturing

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32016—Minimize setup time of machines

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32253—As a function of, change of machine operation

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32257—Tool replacement minimization

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32264—Setup time

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32301—Simulate production, process stages, determine optimum scheduling rules

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/36—Nc in input of data, input key till input tape

- G05B2219/36289—Cutting, machining conditions by optimisation of time, cost, accuracy

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/02—Total factory control, e.g. smart factories, flexible manufacturing systems [FMS] or integrated manufacturing systems [IMS]

Definitions

- This case relates to a work plan identification program, a work plan identification method, and an information processing device.

- a technique for optimizing objective functions such as production cost and production completion time is disclosed in optimizing the order of input of products to a production line (see, for example, Patent Documents 1 and 2).

- a planning method is known to solve as a combinatorial optimization problem such as a cutting problem (Cutting Stock Problem) and a bin packing problem (Bin Packing Problem) for the purpose of using up materials.

- a cutting problem Cutting Stock Problem

- a bin packing problem Bin Packing Problem

- the present invention provides an information processing apparatus, a work plan identification method, and a work plan identification program that can improve an objective function that reflects a step change while suppressing the amount of surplus materials. The purpose.

- the work plan identification program comprises a cutting device and a working device, the raw material of which is a predetermined amount of material for each of the plurality of objects in a work line that generates a plurality of objects in a predetermined order. Partially cut out from the cutting device, the cut material is processed by the working device, and when the raw material is insufficient in the cutting device, the material is switched to the next raw material, and the cutting device and the cutting device are switched to the next raw material.

- Settings for at least one of the working devices are set for each of the plurality of objects, and when the settings are changed, the settings for at least one of the cutting device and the working device are changed.

- FIG. It is a figure which illustrates the production line model stored in the production line model storage part. It is a figure which illustrates the production order information.

- (A) to (d) are diagrams illustrating information stored in the production master. It is a figure which illustrates the flowchart which the information processing apparatus executes. It is a figure which illustrates the result obtained by repeating the exchange of the input order. It is a figure for demonstrating a simulation. It is a figure for demonstrating a simulation. It is a figure which shows the simulation result. It is a figure for demonstrating the effect of an Example.

- (A) to (c) are diagrams illustrating information stored in the production master. It is a block diagram which illustrates the hardware composition of each part other than the display device of an information processing apparatus.

- a planning method is known to solve as a combinatorial optimization problem such as a cutting problem (Cutting Stock Problem) and a bin packing problem (Bin Packing Problem) for the purpose of using up materials.

- the raw materials 1 to 3 are members of the same standard, have the same material and have the same shape, and can be substituted for each other. These raw materials 1 to 3 are partially cut out by a cutting device and used as product parts in a processing device.

- FIG. 1A exemplifies material information about the raw material 1. Further, in FIG. 1A, the input order in which each product is input to the production line is described. In the example of FIG. 1A, the product of product number 1 is put into the production line first, and the product of product number 2 is put into the production line second. Material dimensions indicate the dimensions of the amount of raw material used for each product. In the example of FIG. 1A, an amount of 100 is used for the product of product number 1 and an amount of 200 is used for the product of product number 2.

- the product type information represents the setting of at least one of the cutting device and the processing device.

- the type of saw of the cutting device is changed according to the variety.

- the processing method of the processing apparatus is changed according to the product type. Therefore, when the product type information is changed, it is necessary to change the settings of at least one of the cutting device and the processing device, so that it is necessary to change the stage.

- the products of product numbers 1 to 3 do not need to be changed in the middle, but the products of product number 4 need to be changed when they are put on the production line.

- FIG. 1A material information about the raw material 2 is exemplified.

- the raw material 2 is used from the product of product number 8 to be introduced eighth.

- the product of product number 8 is set to product type C. Therefore, a step change is performed to switch the variety from B to C.

- the next 9th product with product number 9 is set to product type B. Therefore, a step change is performed to switch the variety from C to B.

- FIG. 1A illustrates the amount of surplus material of each raw material in this case. Since the material dimensions are different for each product, the amount of surplus material is generated. In the setting of FIG. 1A, assuming that the size of the raw material is 3000, the total material size of the products of product numbers 1 to 7 is 2800, so that the amount of surplus material is 200. The amount of surplus material is also generated for the raw material 2 and the raw material 3.

- FIG. 1B illustrates a case where the order of products to be put into the production line is changed in order to reduce the amount of surplus materials as much as possible.

- the total material size of each product used for the raw material 1 is 2900, so that the amount of surplus material is 100. Therefore, the amount of surplus material is compared with the case of FIG. 1 (a). Can be reduced.

- FIG. 2 is a functional block diagram showing the overall configuration of the information processing apparatus 100 according to the first embodiment.

- the information processing device 100 is a server or the like for optimization processing.

- the information processing apparatus 100 includes a production line model storage unit 10, a production master 20, an input order generation unit 30, a simulator 40, an input order replacement unit 50, a determination unit 60, a result output unit 70, and a display. It is equipped with a device 80 and the like.

- the display device 80 is a device that displays the processing result of the information processing device 100, and is a display or the like.

- the production line model storage unit 10 stores the production line model.

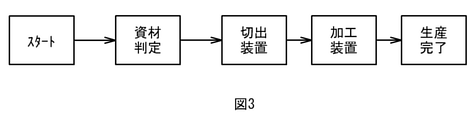

- FIG. 3 is a diagram illustrating a production line model stored in the production line model storage unit 10. As illustrated in FIG. 3, the production line model has a configuration in which a "start” cell, a “material determination” cell, a “cutting device” cell, a “processing device” cell, and a “production completed” cell are arranged in this order. is doing.

- the production master 20 stores the production order information associated with the material dimensions to be used and the product type information in the product number.

- FIG. 4 is a diagram illustrating production order information. As illustrated in FIG. 4, the material dimensions used and the product type information are associated with each product number. Since the product number is unique to each product, multiple products are not duplicated for each product number.

- FIG. 5B is a diagram illustrating device information. As illustrated in FIG. 5B, "50" is stored as the processing time of the cutting device, and "150" is stored as the processing time of the processing device.

- the processing time of the cutting device is the time for cutting out the material from the raw material.

- the processing time of the processing apparatus is the time for processing such as incorporating the cut out material into the product.

- the processing time of the cutting device and the processing time of the processing device may be set for each product.

- FIG. 5C is a diagram illustrating the stage change conditions when the stage change of raw material switching is performed.

- the processing time required for the step change when the raw material is switched is set to "100", and the processing time when the raw material is not switched is set to "1".

- FIG. 5D is a diagram illustrating the stage change conditions when the stage change of product type switching is performed.

- the processing time for switching each product type such as switching from product type A to product type B, is set to "100".

- the stage change time required for switching each product type may be different from each other.

- the input order generation unit 30 generates an initial input order for all products stored in the production master 20 (step S1).

- the initial input order is, for example, an order in which the items are arranged as ordered by the customer, and the user may input in advance using the input device.

- the initial input order may be generated by a random number. Since the initial input order is generated without considering the amount of surplus material and the production completion time, neither the amount of surplus material nor the production completion time is often a good value.

- the simulator 40 performs a line simulation when the products are put into the production line one by one according to the initial putting order (step S2).

- the simulator 40 arranges the products one by one in the "start” cell according to the initial loading order.

- the material dimensions of the product arriving at the “material determination” cell are sequentially subtracted from the raw material dimensions of the raw material information. Thereby, the remaining amount of the raw material is calculated. If the deducted result is positive, the processing time in the "material determination” cell is "1". Therefore, the product stays in the material determination cell for a time corresponding to the processing time "1" in the material determination cell, and moves to the next cell if the product does not stay in the next cell. If the deducted result is negative, the processing time in the "material determination” cell is "100" because the raw material is changed.

- the product stays in the material determination cell for a time corresponding to the processing time "100", and if the product does not stay in the next cell, it moves to the next cell.

- the remaining amount of raw material immediately before the deducted result becomes negative is the amount of surplus material of the raw material. In this case, the material dimensions of the product will be deducted from the new raw material dimensions.

- the product arriving at the "cutting device” cell stays for a time corresponding to the processing time "50". Further, in the “cutting device” cell, it is determined whether or not the product type information arriving at the "cutting device” cell is different from the product type information arriving immediately before. If the product type information arriving at the "cutting device” cell is different from the product type information arriving immediately before, stage change occurs. If the stage change has occurred, the product stays in the "cutting device” cell for a time corresponding to the processing time "100", and then moves to the next cell.

- the determination unit 60 evaluates the KPI (Key Performance Indicator) with respect to the line simulation result performed in step S2 (step S3).

- the determination unit 60 calculates the amount of surplus material and the production completion time for the line simulation result.

- the amount of surplus material is the total value of the remaining amount of raw material of each raw material used.

- the production completion time is the time from when the first product is put into the start to when the last product arrives at the production completion cell.

- the determination unit 60 determines whether or not the surplus material amount and the production completion time calculated in step S3 satisfy the end condition (step S4). For example, the determination unit 60 determines whether or not the amount of surplus material is equal to or less than the threshold value and the production completion time is equal to or less than the threshold value.

- step S4 If it is determined as “Yes” in step S4, the execution of the flowchart ends. If "No” is determined in step S4, the input order replacement unit 50 selects input order candidates for the input order targeted for line simulation in step S2 (step S5). Next, the input order replacement unit 50 crosses the input order targeted for line simulation in step S2 with the input order candidate selected in step S5 (step S6). Next, the input order replacement unit 50 generates an input order by causing a mutation in the result of step S6 (step S7). After that, it is executed again from step S2. In this case, in step S2, a line simulation is performed for the input order generated in step S7.

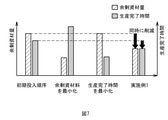

- FIG. 7 is a diagram illustrating the results obtained by repeatedly changing the input order.

- the initial input order since the initial input order often does not consider the amount of surplus material and the production completion time, the amount of surplus material tends to be large and the production completion time tends to be long.

- the input order is optimized so as to reduce only the surplus material amount with respect to this initial input order, the surplus material amount is reduced, but the production completion time is not taken into consideration, so that the input order tends to be long.

- the input order is optimized so that only the production completion time is shortened with respect to the initial input order, the production completion time tends to be short, but it tends to increase because the amount of surplus material is not taken into consideration.

- the input order can be obtained in which the surplus material amount is reduced and the production completion time is shortened.

- FIG. 10 is a diagram showing simulation results. As shown in FIG. 10, regarding the initial input order, the amount of surplus material was large and the production completion time was long. On the other hand, by exchanging the input order so that both the surplus material amount and the production completion time are equal to or less than the threshold value, the input order is obtained in which the surplus material amount is reduced and the production completion time is shortened. .. In the simulation results, the amount of surplus materials was reduced by 10%. Production completion time has been reduced by 30%.

- the amount of surplus materials can be suppressed by performing optimization by exchanging the input order of each product on the production line, and the objective function that reflects the stage change caused by the exchange of the input order. Is also optimized for. As a result, it is possible to improve the objective function that reflects the stage change while suppressing the amount of surplus materials.

- FIG. 11 is a diagram for organizing the effects of this embodiment.

- the input order is optimized so as to reduce only the amount of surplus materials, the amount of surplus materials has a reduction effect, but the production completion time is not taken into consideration, so there is a tendency that there is no effect or an increase. ..

- Optimizing the input order so as to shorten only the production completion time has the effect of shortening the production completion time, but tends to have no effect or increase because the amount of surplus material is not taken into consideration.

- the reduction effect can be obtained for both the surplus material amount and the production completion time.

- Evolutionary algorithms and local exploration methods can be used for the method of changing the input order. These algorithms can also be used for multi-objective optimization. Evolutionary algorithms include evolutionary strategies and genetic algorithms. Local exploration methods include simulated annealing.

- FIG. 12A is a diagram illustrating device information stored in the production master 20. As illustrated in FIG. 12A, “50” is stored as the processing time of the cutting device, “400” is stored as the power consumption of the cutting device, and “400” is stored as the cost of the cutting device. 300 “is stored. Further, “150” is stored as the processing time of the processing apparatus. “200” is stored as the power consumption of the processing device, and “200” is stored as the cost of the processing device. The power consumption of the cutting device is the power consumed to cut out the material.

- the cost of the cutting device is the cost for cutting out the material.

- the power consumption of a processing device is the power consumed to process a product using materials.

- the cost of a processing device is the cost of processing a product using materials.

- the processing time, power consumption and cost of the cutting device and the processing device may be set for each product.

- FIG. 12B is a diagram illustrating processing time, power consumption, and cost when switching raw materials.

- the processing time when the raw material is switched is set to "100”

- the power consumption is set to "50”

- the cost is set to "30”.

- the processing time when the raw material is not switched is set to "1”

- the power consumption is set to "1”

- the cost is set to "1”.

- FIG. 12 (c) is a diagram illustrating processing time, power consumption, and cost when switching between product types.

- the processing time for each product type switching such as product product switching from product type A to product type B

- the power consumption is set to "40”

- the cost is set. It is set to "30”.

- the power consumption in this case is the power required for the stage change for switching the product type.

- the cost in this case is the cost required for the step change for switching the product type.

- the processing time, power consumption, and cost required for switching each product type may be different from each other.

- the "start” cell operates in the same manner as in the first embodiment.

- the material dimensions of the product arriving at the “material determination” cell are sequentially subtracted from the raw material dimensions of the raw material information. Thereby, the remaining amount of the raw material is calculated. If the deducted result is positive, the processing time in the “material determination” cell is “1", the power consumption is "1", and the cost is "1". Therefore, the product stays in the material determination cell for a time corresponding to the processing time "1" in the material determination cell, and moves to the next cell if the product does not stay in the next cell. Further, the power consumption "1" is added to the product, and the cost "1" is added.

- the deducted result is negative, the raw material is changed, so that the processing time in the "material determination” cell is "100", the power consumption is "50", and the cost is "50". Therefore, the product stays in the material determination cell for a time corresponding to the processing time "100", and if the product does not stay in the next cell, it moves to the next cell.

- the remaining amount of raw material immediately before the deducted result becomes negative is the amount of surplus material of the raw material. In this case, the material dimensions of the product will be deducted from the new raw material dimensions.

- the product arriving at the "cutting device” cell stays for a time corresponding to the processing time "50", the power consumption "400" is added to the product, and the cost "300” is added. Will be done. Further, in the “cutting device” cell, it is determined whether or not the product type information arriving at the "cutting device” cell is different from the product type information arriving immediately before. If the product type information arriving at the "cutting device” cell is different from the product type information arriving immediately before, stage change occurs. If the stage change has occurred, the product stays in the "cutting device” cell for a time corresponding to the processing time "100", and then moves to the next cell.

- the determination unit 60 calculates the surplus material amount, the production completion time, the power consumption, and the cost for the line simulation result.

- the amount of surplus material is the total value of the remaining amount of raw material of each raw material used.

- the production completion time is the time from when the first product is put into the start to when the last product arrives at the production completion cell.

- the power consumption is the total value of the power consumption added to each product.

- the cost is the total value of the costs added to each product.

- the determination unit 60 determines whether or not the amount of surplus material is equal to or less than the threshold value and at least one of the production completion time, the power consumption, and the cost is equal to or less than the threshold value.

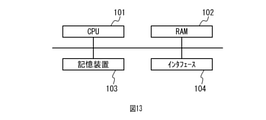

- FIG. 13 is a block diagram illustrating a hardware configuration of each part of the information processing device 100 other than the display device 80.

- the information processing device 100 includes a CPU 101, a RAM 102, a storage device 103, an interface 104, and the like.

- the CPU (Central Processing Unit) 101 is a central processing unit.

- the CPU 101 includes one or more cores.

- the RAM (Random Access Memory) 102 is a volatile memory that temporarily stores a program executed by the CPU 101, data processed by the CPU 101, and the like.

- the storage device 103 is a non-volatile storage device. As the storage device 103, for example, a ROM (Read Only Memory), a solid state drive (SSD) such as a flash memory, a hard disk driven by a hard disk drive, or the like can be used.

- the storage device 103 stores the work plan specifying program.

- the interface 104 is an interface device with an external device. Each part of the information processing apparatus 100 is realized by the CPU 101 executing the work plan specifying program. Hardware such as a dedicated circuit may be used as each part of the information processing apparatus 100.

- the production line is an example of a work line in which a plurality of objects are in a predetermined order.

- a plurality of products put on a production line is an example of the plurality of objects.

- the processing device is an example of a working device that performs work on the plurality of objects.

- the input order replacement unit and the determination unit 60 are optimized execution units that optimize the objective function that reflects the stage change and the surplus amount of each raw material, which is determined according to the input order of a plurality of objects on the work line. This is an example.

- Production line model storage unit 20

- Production master 30

- Input order generation unit 40

- Simulator 50

- Input order replacement unit 60

- Judgment unit 70

- Display device 100

Landscapes

- Engineering & Computer Science (AREA)

- Business, Economics & Management (AREA)

- Human Resources & Organizations (AREA)

- Physics & Mathematics (AREA)

- Strategic Management (AREA)

- Economics (AREA)

- General Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- Manufacturing & Machinery (AREA)

- Theoretical Computer Science (AREA)

- Marketing (AREA)

- Tourism & Hospitality (AREA)

- Quality & Reliability (AREA)

- Operations Research (AREA)

- Development Economics (AREA)

- Entrepreneurship & Innovation (AREA)

- Game Theory and Decision Science (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Primary Health Care (AREA)

- Automation & Control Theory (AREA)

- Human Computer Interaction (AREA)

- General Engineering & Computer Science (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

- General Factory Administration (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022536001A JPWO2022013921A1 (enExample) | 2020-07-13 | 2020-07-13 | |

| PCT/JP2020/027259 WO2022013921A1 (ja) | 2020-07-13 | 2020-07-13 | 作業計画特定プログラム、作業計画特定方法、および情報処理装置 |

| EP20944889.3A EP4180887A4 (en) | 2020-07-13 | 2020-07-13 | WORK SCHEDULE SPECIFICATION PROGRAM, WORK SCHEDULE SPECIFICATION METHOD AND INFORMATION PROCESSING DEVICE |

| CN202080102042.XA CN115769159A (zh) | 2020-07-13 | 2020-07-13 | 作业计划确定程序、作业计划确定方法以及信息处理装置 |

| US18/060,020 US20230147377A1 (en) | 2020-07-13 | 2022-11-30 | Storage medium, work plan specifying method, and information processing device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/JP2020/027259 WO2022013921A1 (ja) | 2020-07-13 | 2020-07-13 | 作業計画特定プログラム、作業計画特定方法、および情報処理装置 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US18/060,020 Continuation US20230147377A1 (en) | 2020-07-13 | 2022-11-30 | Storage medium, work plan specifying method, and information processing device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022013921A1 true WO2022013921A1 (ja) | 2022-01-20 |

Family

ID=79555294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/027259 Ceased WO2022013921A1 (ja) | 2020-07-13 | 2020-07-13 | 作業計画特定プログラム、作業計画特定方法、および情報処理装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20230147377A1 (enExample) |

| EP (1) | EP4180887A4 (enExample) |

| JP (1) | JPWO2022013921A1 (enExample) |

| CN (1) | CN115769159A (enExample) |

| WO (1) | WO2022013921A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023140807A (ja) * | 2022-03-23 | 2023-10-05 | 株式会社東芝 | 作成システム、作成方法、プログラム、及び記憶媒体 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07314297A (ja) * | 1994-05-25 | 1995-12-05 | Toyota Motor Corp | 素材加工システム |

| JP2005092827A (ja) | 2003-09-22 | 2005-04-07 | Mitsubishi Electric Corp | スケジューリングシステムおよびスケジューリングをコンピュータに実行させるためのプログラム |

| JP2011028539A (ja) * | 2009-07-27 | 2011-02-10 | Amada Co Ltd | 板材加工システム及び板材加工システムの加工スケジュール設定方法 |

| JP2016221666A (ja) * | 2015-06-01 | 2016-12-28 | 株式会社Jls | 面材切断加工指示装置と面材切断加工機と面材 |

| JP2019049837A (ja) * | 2017-09-08 | 2019-03-28 | フルサト工業株式会社 | 生産指示装置、生産指示方法及びプログラム |

| JP2019175488A (ja) | 2011-07-22 | 2019-10-10 | パックサイズ,エルエルシー | 包装材料のタイリング生産 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7277768B2 (en) * | 2004-11-05 | 2007-10-02 | International Business Machines Corporation | Method for production design and operations scheduling for plate design in the steel industry |

| US20110258087A1 (en) * | 2010-04-14 | 2011-10-20 | International Business Machines Corporation | Analytics for setting up strategic inventory systems to handle small lot orders in the steel industry |

-

2020

- 2020-07-13 CN CN202080102042.XA patent/CN115769159A/zh active Pending

- 2020-07-13 EP EP20944889.3A patent/EP4180887A4/en not_active Withdrawn

- 2020-07-13 JP JP2022536001A patent/JPWO2022013921A1/ja not_active Ceased

- 2020-07-13 WO PCT/JP2020/027259 patent/WO2022013921A1/ja not_active Ceased

-

2022

- 2022-11-30 US US18/060,020 patent/US20230147377A1/en not_active Abandoned

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07314297A (ja) * | 1994-05-25 | 1995-12-05 | Toyota Motor Corp | 素材加工システム |

| JP2005092827A (ja) | 2003-09-22 | 2005-04-07 | Mitsubishi Electric Corp | スケジューリングシステムおよびスケジューリングをコンピュータに実行させるためのプログラム |

| JP2011028539A (ja) * | 2009-07-27 | 2011-02-10 | Amada Co Ltd | 板材加工システム及び板材加工システムの加工スケジュール設定方法 |

| JP2019175488A (ja) | 2011-07-22 | 2019-10-10 | パックサイズ,エルエルシー | 包装材料のタイリング生産 |

| JP2016221666A (ja) * | 2015-06-01 | 2016-12-28 | 株式会社Jls | 面材切断加工指示装置と面材切断加工機と面材 |

| JP2019049837A (ja) * | 2017-09-08 | 2019-03-28 | フルサト工業株式会社 | 生産指示装置、生産指示方法及びプログラム |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023140807A (ja) * | 2022-03-23 | 2023-10-05 | 株式会社東芝 | 作成システム、作成方法、プログラム、及び記憶媒体 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20230147377A1 (en) | 2023-05-11 |

| EP4180887A4 (en) | 2023-08-16 |

| CN115769159A (zh) | 2023-03-07 |

| EP4180887A1 (en) | 2023-05-17 |

| JPWO2022013921A1 (enExample) | 2022-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109284858A (zh) | 一种钢筋下料优化方法、装置及存储设备 | |

| CN113379087A (zh) | 一种基于改进遗传算法的生产制造排产优化方法 | |

| CN112882449A (zh) | 一种多品种小批量多目标柔性作业车间能耗优化调度方法 | |

| CN114399227A (zh) | 一种基于数字孪生的生产调度方法、装置及计算机设备 | |

| KR20220009348A (ko) | 생산라인 최적화 시뮬레이터 및 이를 이용한 생산라인 최적화 시뮬레이션 방법 | |

| CN116414094A (zh) | 一种焊接装配智能调度方法及系统 | |

| CN112016801A (zh) | 带传输和切换时间的柔性作业车间调度方法及系统 | |

| CN117707078B (zh) | 基于超启发式算法的半导体封测键合工序快响应调度方法及系统 | |

| WO2022013921A1 (ja) | 作業計画特定プログラム、作業計画特定方法、および情報処理装置 | |

| CN117114370B (zh) | 一种适配设备故障的小产品生产车间调度方法 | |

| CN115081779A (zh) | 产线排程方法、产线系统及计算机可读存储介质 | |

| CN110750079A (zh) | 一种允许工序跳跃的混合流水车间调度优化方法 | |

| CN108062594B (zh) | 一种电力系统网络的负荷的预测方法及其装置 | |

| CN119849325B (zh) | 一种电缆生产调度建模方法 | |

| CN112700109B (zh) | 一种订单生产顺序优化方法、系统、设备及可读存储介质 | |

| JP2017021764A (ja) | シミュレーション装置 | |

| CN114676987A (zh) | 一种基于超启发式算法的智能柔性作业车间主动调度方法 | |

| JP7070713B2 (ja) | 情報処理装置、段取り作業修正方法、および段取り作業修正プログラム | |

| CN118627806A (zh) | 一种基于改进nsga-ii的织造柔性调度方法及系统 | |

| Jong et al. | Applying ant colony system algorithm in the navigation process for plastic injection mould manufacturing scheduling optimisation | |

| CN117649079A (zh) | 一种机械手搬运的柔性作业车间调度方法及设备 | |

| CN118350594A (zh) | 一种基于变邻域和社会文明算法的平行机调度方法 | |

| Churchill et al. | Tool sequence optimization using synchronous and asynchronous parallel multi-objective evolutionary algorithms with heterogeneous evaluations | |

| JP7526155B2 (ja) | 最適化問題求解装置及び最適化問題求解方法 | |

| CN116128334A (zh) | 质检任务调度方法、设备及介质 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20944889 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2022536001 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2020944889 Country of ref document: EP Effective date: 20230213 |