WO2022009019A1 - 電極、二次電池、移動体および電子機器 - Google Patents

電極、二次電池、移動体および電子機器 Download PDFInfo

- Publication number

- WO2022009019A1 WO2022009019A1 PCT/IB2021/055785 IB2021055785W WO2022009019A1 WO 2022009019 A1 WO2022009019 A1 WO 2022009019A1 IB 2021055785 W IB2021055785 W IB 2021055785W WO 2022009019 A1 WO2022009019 A1 WO 2022009019A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- secondary battery

- graphene

- active material

- particles

- positive electrode

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/58—Selection of substances as active materials, active masses, active liquids of inorganic compounds other than oxides or hydroxides, e.g. sulfides, selenides, tellurides, halogenides or LiCoFy; of polyanionic structures, e.g. phosphates, silicates or borates

- H01M4/583—Carbonaceous material, e.g. graphite-intercalation compounds or CFx

- H01M4/587—Carbonaceous material, e.g. graphite-intercalation compounds or CFx for inserting or intercalating light metals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/48—Selection of substances as active materials, active masses, active liquids of inorganic oxides or hydroxides

- H01M4/483—Selection of substances as active materials, active masses, active liquids of inorganic oxides or hydroxides for non-aqueous cells

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G11/00—Hybrid capacitors, i.e. capacitors having different positive and negative electrodes; Electric double-layer [EDL] capacitors; Processes for the manufacture thereof or of parts thereof

- H01G11/04—Hybrid capacitors

- H01G11/06—Hybrid capacitors with one of the electrodes allowing ions to be reversibly doped thereinto, e.g. lithium ion capacitors [LIC]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G11/00—Hybrid capacitors, i.e. capacitors having different positive and negative electrodes; Electric double-layer [EDL] capacitors; Processes for the manufacture thereof or of parts thereof

- H01G11/22—Electrodes

- H01G11/30—Electrodes characterised by their material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H01M10/0525—Rocking-chair batteries, i.e. batteries with lithium insertion or intercalation in both electrodes; Lithium-ion batteries

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

- H01M4/133—Electrodes based on carbonaceous material, e.g. graphite-intercalation compounds or CFx

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

- H01M4/134—Electrodes based on metals, Si or alloys

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/362—Composites

- H01M4/364—Composites as mixtures

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/362—Composites

- H01M4/366—Composites as layered products

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/38—Selection of substances as active materials, active masses, active liquids of elements or alloys

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/38—Selection of substances as active materials, active masses, active liquids of elements or alloys

- H01M4/386—Silicon or alloys based on silicon

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/36—Selection of substances as active materials, active masses, active liquids

- H01M4/58—Selection of substances as active materials, active masses, active liquids of inorganic compounds other than oxides or hydroxides, e.g. sulfides, selenides, tellurides, halogenides or LiCoFy; of polyanionic structures, e.g. phosphates, silicates or borates

- H01M4/583—Carbonaceous material, e.g. graphite-intercalation compounds or CFx

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

- H01M4/624—Electric conductive fillers

- H01M4/625—Carbon or graphite

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/20—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders

- H01M50/247—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders specially adapted for portable devices, e.g. mobile phones, computers, hand tools or pacemakers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/20—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders

- H01M50/249—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders specially adapted for aircraft or vehicles, e.g. cars or trains

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/20—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders

- H01M50/251—Mountings; Secondary casings or frames; Racks, modules or packs; Suspension devices; Shock absorbers; Transport or carrying devices; Holders specially adapted for stationary devices, e.g. power plant buffering or backup power supplies

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2220/00—Batteries for particular applications

- H01M2220/20—Batteries in motive systems, e.g. vehicle, ship, plane

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- One aspect of the present invention relates to an electrode and a method for manufacturing the electrode.

- the present invention relates to an active material possessed by an electrode and a method for producing the same.

- the present invention relates to a secondary battery and a method for manufacturing the secondary battery.

- it relates to a mobile body including a vehicle having a secondary battery, a mobile information terminal, an electronic device, and the like.

- the uniform state of the present invention relates to a product, a method, or a manufacturing method.

- the invention relates to a process, machine, manufacture, or composition (composition of matter).

- One aspect of the present invention relates to a semiconductor device, a display device, a light emitting device, a power storage device, a lighting device, an electronic device, or a method for manufacturing the same.

- the electronic device refers to all devices having a power storage device, and the electro-optical device having the power storage device, the information terminal device having the power storage device, and the like are all electronic devices.

- a power storage device refers to an element and a device having a power storage function in general.

- a power storage device also referred to as a secondary battery

- a lithium ion secondary battery such as a lithium ion secondary battery, a lithium ion capacitor, an electric double layer capacitor, and the like.

- Lithium-ion secondary batteries which have particularly high output and high energy density, are portable information terminals such as mobile phones, smartphones, or notebook computers, portable music players, digital cameras, medical devices, or hybrid vehicles (HVs), and electricity.

- HVs hybrid vehicles

- EVs electric vehicles

- PSVs plug-in hybrid vehicles

- Silicon-based materials have a high capacity and are used as active materials for secondary batteries.

- the silicon material can be characterized by the chemical shift value obtained from the NMR spectrum (Patent Document 1).

- Non-Patent Document 1 describes the reaction of a compound having fluorine.

- the capacity of secondary batteries used for moving objects such as electric vehicles and hybrid vehicles needs to be increased in order to increase the mileage.

- the power consumption of mobile terminals and the like is increasing due to the increasing number of functions.

- the secondary battery used for a mobile terminal or the like is required to be smaller and lighter. Therefore, there is a demand for higher capacity in the secondary battery used for the mobile terminal.

- the electrodes of the secondary battery are made of, for example, materials such as an active material, a conductive agent, and a binder.

- the capacity of the secondary battery can be increased by increasing the proportion of the material that contributes to the charge / discharge capacity, for example, the active material. Since the electrode has a conductive agent, the conductivity of the electrode can be enhanced and excellent output characteristics can be obtained. Further, in the charging / discharging of the secondary battery, the active material repeatedly expands and contracts, which may cause the active material to collapse, the conductive path to be short-circuited, or the like at the electrode. In such a case, the electrode having one or both of the conductive agent and the binder can suppress at least one of the collapse of the active material and the short circuit of the conductive path. On the other hand, by using one or both of the conductive agent and the binder, the proportion of the active material is reduced, so that the capacity of the secondary battery may be reduced.

- One aspect of the present invention is to provide an electrode having excellent characteristics. Alternatively, one aspect of the present invention is to provide an active material having excellent properties. Alternatively, one aspect of the present invention is to provide a novel silicon material. Alternatively, one aspect of the present invention is to provide a novel electrode.

- one aspect of the present invention is to provide a durable negative electrode.

- one aspect of the present invention is to provide a durable positive electrode.

- one aspect of the present invention is to provide a negative electrode with less deterioration.

- one aspect of the present invention is to provide a positive electrode having a high capacity.

- one aspect of the present invention is to provide a secondary battery with less deterioration.

- one aspect of the present invention is to provide a highly safe secondary battery.

- one aspect of the present invention is to provide a secondary battery having a high energy density.

- one aspect of the present invention is to provide a novel secondary battery.

- one aspect of the present invention is to provide a novel substance, active material particles, or a method for producing them.

- the material having a sheet-like shape is curved toward the particles by an intermolecular force such as a London dispersion force.

- the electrode of one aspect of the present invention comprises particles and a material having a sheet-like shape, and the particles have a region terminated by a functional group containing oxygen.

- the particles included in the electrode of one aspect of the present invention have a region terminated by a functional group containing oxygen and hydrogen.

- the functional group containing oxygen and hydrogen include a hydroxy group, a carboxy group, a functional group containing a hydroxy group, and the like.

- the material having a sheet-like shape has a first region, and the first region is terminated by a hydrogen atom.

- the first region is, for example, a region composed of one atom that can be bonded to hydrogen and a hydrogen atom that is bonded to the atom.

- the first region is, for example, a region having a plurality of atoms that can be bonded to hydrogen.

- the hydrogen atom of the first region and the oxygen atom of the functional group that terminates the particle can form a hydrogen bond.

- the material having a sheet-like shape clings to the active material.

- the fact that the material having a sheet-like shape clings to the active material means that, for example, the material having a sheet-like shape is arranged so as to partially cover the active material or to stick to the surface of the active material. .. It is preferable that the material having a sheet-like shape and the surface of the active material have a region in which they are in surface contact with each other. Alternatively, it is preferable that the material having a sheet-like shape covers a part of the surface of the active material so as to make surface contact.

- the material having a sheet-like shape clings to the active material for example, the material having a sheet-like shape is superposed on at least a part of the active material.

- the shape of the graphene compound matches at least a part of the shape of the active material.

- the shape of the active material means, for example, the unevenness of a single active material particle or the unevenness formed by a plurality of active materials. Further, it is preferable that a material having a sheet-like shape surrounds at least a part of the active material.

- a material having a sheet-like shape clings to an object means that, for example, the material having a sheet-like shape is arranged so as to partially cover the object or stick to the surface of the object. .. It is preferable that the material having a sheet-like shape and the surface of the object have a region in which they are in surface contact with each other. Alternatively, it is preferable that the material having a sheet-like shape covers a part of the surface of the object so as to make surface contact.

- the active material layer has, for example, an active material and a material having a sheet-like shape.

- the material having a sheet-like shape may cling to, for example, the surface of the active material particles and the surface of the current collector.

- the material having a sheet-like shape is curved toward the particles by an intermolecular force, and the material having a sheet-like shape can cling to the particles by hydrogen bonding. It is preferable that the material having a sheet-like shape has a plurality of regions terminated by hydrogen atoms on the sheet surface.

- the sheet surface has, for example, a surface facing the particles and a surface on the back side thereof. In a region terminated by a hydrogen atom, it is preferable that the hydrogen atom that terminates the atom in the region is provided, for example, on the surface facing the particle.

- the above-mentioned material having a sheet-like shape may have a hydrogen bond region, and the hydrogen bond region may be localized and distributed.

- the oxygen atom possessed by the functional group that terminates the particle and the hydrogen bond region can be tightly clinging to each other by an action such as an intermolecular force.

- the first region may be terminated by a functional group having oxygen.

- the functional group having oxygen include a hydroxy group, an epoxy group, a carboxy group, and the like.

- the hydrogen atom of the hydroxy group, the carboxy group, etc. can form a hydrogen bond with the oxygen atom of the functional group that terminates the particle.

- the oxygen atom contained in the hydroxy group, the epoxy group and the carboxy group can form a hydrogen bond with the hydrogen atom contained in the functional group terminating the particles.

- the fluorine atom possessed by the second region and the hydrogen atom possessed by the functional group terminating the particles are hydrogen. Bonds can be formed. This makes the material having a sheet-like shape more likely to cling to the particles.

- the first region may have a hole formed on the sheet surface, and the hole is composed of, for example, a plurality of atoms bonded in a ring shape and an atom terminating the plurality of atoms. Further, the plurality of atoms may be terminated by a functional group.

- forming a hole means, for example, an atom at the periphery of the opening, an atom at the end of the opening, and the like.

- the particles contained in the electrode of one aspect of the present invention function as, for example, an active material.

- a material that functions as an active material can be used.

- the particles included in the electrode of one aspect of the present invention have, for example, a material that functions as an active material.

- the material having a sheet-like shape possessed by the electrode of one aspect of the present invention functions as, for example, a conductive agent.

- the conductive agent can cling to the active material by hydrogen bonding, so that a highly conductive electrode can be realized.

- the sheet-shaped material clings to the active material to prevent the electrodes from collapsing.

- the material having a sheet-like shape can cling to a plurality of active materials. It is preferable that the material having a sheet-like shape and the surface of the active material have a region in which they are in surface contact with each other. Alternatively, it is preferable that the material having a sheet-like shape covers a part of the surface of the active material so as to make surface contact.

- a material having a large volume change during charging / discharging such as silicon, is used as the active material, the adhesion between the active material and the conductive agent, a plurality of active materials, etc.

- the particles of one aspect of the present invention have silicon atoms terminated by hydroxy groups.

- the particles of one aspect of the invention have silicon and at least a portion of the surface is terminated by hydroxy groups.

- the particles of one embodiment of the present invention are silicon compounds in which at least a part of the surface is terminated by a hydroxy group.

- the particles of one embodiment of the present invention are silicon in which at least a part of the surface is terminated by a hydroxy group.

- the particles of one embodiment of the present invention have a first region having silicon, and at least a part of the surface of the first region is covered with silicon oxide. Further, at least a part of the surface of the silicon oxide has silicon terminated by a hydroxy group.

- the thickness is, for example, 0.3 nm or more, 0.5 nm or more, or 0.8 nm or more, and 30 nm or less, or 10 nm or less.

- the particles of one embodiment of the present invention have a first region having a first metal, and at least a part of the surface of the first region is covered with an oxide of the first metal. Also, at least a portion of the surface of the oxide has a first metal terminated by a hydroxy group.

- the first metal for example, one or more selected from tin, gallium, aluminum, germanium, lead, antimony, bismuth, silver, zinc, and indium can be used.

- the oxide is in the form of a film, the thickness is, for example, 0.3 nm or more, 0.5 nm or more, or 0.8 nm or more, and 30 nm or less, or 10 nm or less.

- a graphene compound as a material having a sheet-like shape.

- the graphene compound for example, it is preferable to use graphene in which carbon atoms are terminated by atoms other than carbon or functional groups in the sheet surface.

- Graphene has a structure in which the edges are terminated by hydrogen. Further, the graphene sheet has a two-dimensional structure formed by a carbon 6-membered ring, and when a defect or a hole is formed in the two-dimensional structure, the carbon atom in the vicinity of the defect and the carbon atom constituting the hole are removed. , May be terminated by atoms such as various functional groups, hydrogen atoms, or fluorine atoms.

- graphene is formed with one or both of defects and pores, and one or more of the carbon atoms in the vicinity of the defects and the carbon atoms constituting the pores are of hydrogen atom, fluorine atom, hydrogen atom and fluorine atom.

- Graphene can be clinging to the particles of the electrode by terminating it with a functional group having one or more of them, a functional group having oxygen, or the like.

- the amount of defects and holes formed in graphene is preferably such that the conductivity of the entire graphene is not significantly impaired.

- forming a hole means, for example, an atom at the periphery of the opening, an atom at the end of the opening, and the like.

- the graphene compound of one aspect of the present invention has a hole composed of a 7-membered ring or more, preferably an 18-membered ring or more, and more preferably a 22-membered ring or more composed of carbon. Further, one of the carbon atoms in the multi-membered ring is terminated by a hydrogen atom. Further, in one aspect of the present invention, one of the carbon atoms of the multi-membered ring is terminated by a hydrogen atom and the other is terminated by a fluorine atom. Further, in one aspect of the present invention, among the carbon atoms of the multi-membered ring, the number of carbon atoms terminated by fluorine is less than 40% of the number of carbon atoms terminated by hydrogen atoms.

- the graphene compound according to one aspect of the present invention has pores, and the pores are composed of a plurality of cyclically bonded carbon atoms and a plurality of atoms or functional groups terminating the carbon atoms.

- One or more of the plurality of carbon atoms bonded in a ring may be replaced with a Group 13 element such as boron, a Group 15 element such as nitrogen, and a Group 16 element such as oxygen.

- carbon atoms other than the edge may be terminated by a functional group having one or more of hydrogen atom, fluorine atom, hydrogen atom and fluorine atom, a functional group having oxygen, and the like.

- the graphene compound according to one aspect of the present invention has, for example, a functional group in which a carbon atom has one or more of a hydrogen atom, a fluorine atom, a hydrogen atom and a fluorine atom in the vicinity of the center of the surface of the graphene, and a functional having oxygen. It is preferably terminated by one or more selected from the group, etc.

- One aspect of the present invention comprises particles having silicon and a graphene compound, wherein the particles are terminated by a functional group containing at least a part of the surface of the particles, and the graphene compound clings to the particles and is a graphene compound.

- one embodiment of the present invention comprises a plurality of particles and a graphene compound, each of the plurality of particles having at least a part of the surface terminated by a functional group containing oxygen, and the graphene compound is a plurality of particles.

- the graphene compound is a graphene having at least one carbon atom terminated by a hydrogen atom and a carbon atom terminated by a fluorine atom in the plane of graphene, at an electrode.

- one embodiment of the present invention comprises a plurality of particles and a graphene compound, each of the plurality of particles having at least a part of the surface terminated by a functional group containing oxygen, and the graphene compound is a plurality of particles.

- a bag-shaped particle-encapsulating graphene compound is an electrode that is a graphene having at least one of a carbon atom terminated by a hydrogen atom and a carbon atom terminated by a fluorine atom in the surface of graphene. ..

- one embodiment of the present invention comprises particles having silicon and a graphene compound, wherein the particles are terminated by a functional group containing at least a part of the surface of the particles, and the graphene compound clings to the particles.

- a graphene compound is an electrode that is a graphene having at least one of a carbon atom terminated by a hydrogen atom and a carbon atom terminated by a fluorine atom in a secondary electric structure formed of a 6-membered carbon ring. ..

- one embodiment of the present invention comprises a plurality of particles and a graphene compound, each of the plurality of particles having at least a part of the surface terminated by a functional group containing oxygen, and the graphene compound is a plurality of particles.

- the graphene compound is composed of at least a carbon atom terminated by a hydrogen atom and a carbon atom terminated by a fluorine atom in a secondary electric structure formed of a carbon 6-membered ring.

- An electrode which is a graphene having one.

- one embodiment of the present invention comprises a plurality of particles and a graphene compound, each of the plurality of particles having at least a part of the surface terminated by a functional group containing oxygen, and the graphene compound is a plurality of particles.

- the graphene compound is in the form of a bag containing particles, and the graphene compound is at least one of a carbon atom terminated by a hydrogen atom and a carbon atom terminated by a fluorine atom in a secondary electric structure formed of a carbon 6-membered ring. It is an electrode, which is a graphene having.

- the functional group is preferably a hydroxy group, an epoxy group or a carboxy group.

- one embodiment of the present invention comprises particles having silicon and a graphene compound having pores, the particles are terminated by a functional group containing at least a part of the surface of oxygen, and the graphene compound is a plurality of. It has a carbon atom and one or more hydrogen atoms, and each of the one or more hydrogen atoms terminates one of a plurality of carbon atoms and is pored by a plurality of carbon atoms and one or more hydrogen atoms. Is the electrode on which is formed.

- the functional group is preferably a hydroxy group, an epoxy group or a carboxy group.

- one aspect of the present invention is a secondary battery having the electrode and the electrolyte according to any one of the above.

- one aspect of the present invention is a mobile body having the secondary battery according to any one of the above.

- an electrode having excellent characteristics. Further, according to one aspect of the present invention, it is possible to provide an active material having excellent properties. Further, according to one aspect of the present invention, a novel silicon material can be provided. Further, according to one aspect of the present invention, a novel electrode can be provided.

- a durable negative electrode can be provided.

- a durable positive electrode can be provided.

- a secondary battery with less deterioration. Further, according to one aspect of the present invention, it is possible to provide a highly safe secondary battery. Further, according to one aspect of the present invention, it is possible to provide a secondary battery having a high energy density. Further, according to one aspect of the present invention, a novel secondary battery can be provided.

- FIG. 1A and 1B are views showing an example of a cross section of an electrode.

- 2A and 2B are examples of models with silicon.

- FIG. 3 is an example of a model having silicon and a model of a graphene compound.

- 4A and 4B are examples of a model having silicon and a model of a graphene compound.

- 5A and 5B are examples of a model having silicon and a model of a graphene compound.

- 6A and 6B are examples of models of graphene compounds.

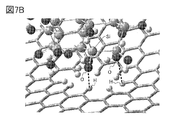

- 7A and 7B are examples of a model having silicon and a model of a graphene compound.

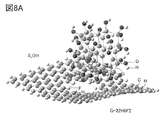

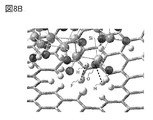

- 8A and 8B are examples of a model having silicon and a model of a graphene compound.

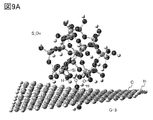

- FIG. 9A and 9B are examples of a model having silicon and a model of a graphene compound.

- FIG. 10 is a diagram showing an example of a method for manufacturing an electrode according to an aspect of the present invention.

- FIG. 11 is a diagram illustrating the crystal structure of the positive electrode active material.

- FIG. 12 is a diagram illustrating the crystal structure of the positive electrode active material.

- FIG. 13 is a diagram showing an example of a cross section of the secondary battery.

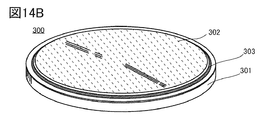

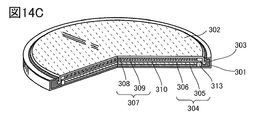

- 14A is an exploded perspective view of the coin-type secondary battery

- FIG. 14B is a perspective view of the coin-type secondary battery

- FIG. 14C is a sectional perspective view thereof.

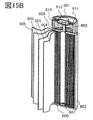

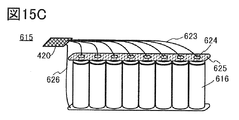

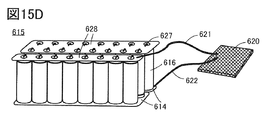

- 15A and 15B are examples of a cylindrical secondary battery

- FIG. 15C is an example of a plurality of cylindrical secondary batteries

- 15D is a storage battery having a plurality of cylindrical secondary batteries. This is an example of a system.

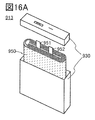

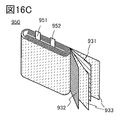

- 16A and 16B are diagrams for explaining an example of a secondary battery

- FIG. 16C is a diagram showing the inside of the secondary battery.

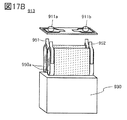

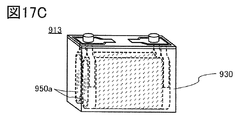

- 17A, 17B, and 17C are diagrams illustrating an example of a secondary battery.

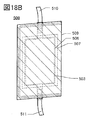

- 18A and 18B are views showing the appearance of the secondary battery.

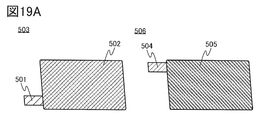

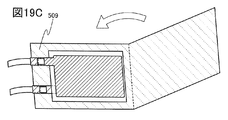

- 19A, 19B, and 19C are diagrams illustrating a method for manufacturing a secondary battery.

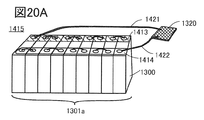

- 20A is a perspective view showing a battery pack

- FIG. 20B is a block diagram of the battery pack

- FIG. 20C is a block diagram of a vehicle having a motor.

- 21A to 21D are diagrams illustrating an example of a moving body.

- 22A and 22B are diagrams illustrating a power storage device.

- 23A to 23D are diagrams illustrating an example of an electronic device.

- FIG. 24 is the result of ToF-SIMS.

- 25A and 25B are surface SEM observation images.

- 26A and 26B are cross-sectional SEM observation images.

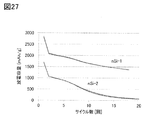

- FIG. 27 is the result of cycle characteristics.

- 28A and 28B are surface SEM observation images.

- 29A to 29E are EELS analysis results.

- 30A to 30E are EELS analysis results.

- Electrode 1 an electrode, an active material, a conductive agent, and the like according to one aspect of the present invention will be described.

- FIG. 1A is a schematic cross-sectional view showing an electrode according to an aspect of the present invention.

- the electrode 570 shown in FIG. 1A can be applied to the positive electrode and the negative electrode of the secondary battery.

- the electrode 570 includes at least the current collector 571 and the active material layer 572 formed in contact with the current collector 571.

- FIG. 1B is an enlarged view of a region surrounded by a broken line in FIG. 1A.

- the active material layer 572 has an electrolyte 581 and particles 582.

- the particles 582 preferably function as an active material.

- a material that functions as an active material can be used.

- the particles 582 preferably have, for example, a material that functions as an active material.

- the material having a sheet-like shape of the electrode 570 functions as a conductive agent, for example.

- the conductive agent can cling to the active material by hydrogen bonding, so that a highly conductive electrode can be realized.

- Various materials can be used as the particles 582. The materials that can be used as the particles 582 will be described later.

- the active material layer 572 preferably has a carbon-based material such as a graphene compound, carbon black, graphite, carbon fiber, and fullerene, and particularly preferably has a graphene compound.

- a carbon-based material such as a graphene compound, carbon black, graphite, carbon fiber, and fullerene

- acetylene black (AB) or the like can be used as the carbon black.

- graphite for example, natural graphite, artificial graphite such as mesocarbon microbeads, or the like can be used.

- These carbon-based materials have high conductivity and can function as a conductive agent in the active material layer.

- these carbon-based materials may function as an active material.

- FIG. 1B shows an example in which the active material layer 572 has the graphene compound 583.

- the graphene compound preferably clings to the particles 582 and one or more selected from carbon black, graphite, carbon fibers, and fullerenes.

- the graphene compound may cling to the particles 582 and the like via a binder.

- the graphene compound has a region in contact with the binder, and the binder has a region in contact with the particles 582.

- the graphene compound may have both a region in contact with the binder and a region in contact with the particles 482.

- the graphene compound may be arranged so as to cover the binder attached to the particles 582.

- carbon fiber such as mesophase pitch type carbon fiber and isotropic pitch type carbon fiber can be used.

- carbon fiber carbon nanofiber, carbon nanotube, or the like can be used.

- the carbon nanotubes can be produced, for example, by a vapor phase growth method.

- the active material layer may have one or more selected from metal powders such as copper, nickel, aluminum, silver, and gold, metal fibers, and conductive ceramic materials as the conductive agent.

- the content of the conductive auxiliary agent with respect to the total amount of the active material layer is preferably 1 wt% or more and 10 wt% or less, and more preferably 1 wt% or more and 5 Wt% or less.

- graphene compounds Unlike granular conductive materials such as carbon black that make point contact with active materials, graphene compounds enable surface contact with low contact resistance, so the amount of granular active materials and graphene compounds is smaller than that of ordinary conductive materials. It is possible to improve the electrical conductivity with. Therefore, the ratio of the active material in the active material layer can be increased. As a result, the discharge capacity of the secondary battery can be increased.

- the graphene compound according to one aspect of the present invention has excellent lithium permeability, the charge / discharge rate of the secondary battery can be increased.

- Particle-like carbon-containing compounds such as carbon black and graphite, and fibrous carbon-containing compounds such as carbon nanotubes easily enter minute spaces.

- the minute space refers to, for example, a region between a plurality of active materials.

- a carbon-containing compound that easily enters a minute space and a sheet-shaped carbon-containing compound such as graphene that can impart conductivity over multiple particles, the density of the electrodes can be increased and an excellent conductive path can be obtained. Can be formed.

- the secondary battery has the electrolyte of one aspect of the present invention, the operational stability of the secondary battery can be enhanced. That is, the secondary battery of one aspect of the present invention can have both high energy density and stability, and is effective as an in-vehicle secondary battery.

- the energy required to move it increases, and the cruising range also decreases.

- the cruising range can be extended with almost no change in the total weight of the vehicle equipped with the secondary battery of the same weight.

- the plurality of graphene compounds 583 are arranged in a three-dimensional network, and particles 582 are provided between the plurality of graphene compounds 583.

- the secondary battery of one aspect of the present invention can be miniaturized due to its high energy density, and can be quickly charged because of its high conductivity. Therefore, the configuration of the secondary battery according to one aspect of the present invention is also effective in a portable information terminal.

- the active material layer 572 preferably has a binder (not shown).

- the binder binds or fixes the electrolyte and the active material, for example. Further, the binder can bind or fix an electrolyte and a carbon-based material, an active material and a carbon-based material, a plurality of active materials, a plurality of carbon-based materials, and the like.

- binders polystyrene, methyl polyacrylate, methyl polymethacrylate (polymethylmethacrylate, PMMA), sodium polyacrylate, polyvinyl alcohol (PVA), polyethylene oxide (PEO), polypropylene oxide, polyimide, polyvinylidene chloride, polytetra It is preferable to use materials such as fluoroethylene, polyethylene, polypropylene, polyisobutylene, polyethylene terephthalate, nylon, polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN), ethylenepropylene diene polymer, polyvinyl acetate, and nitrocellulose.

- PVDF polyvinylidene fluoride

- PAN polyacrylonitrile

- Polyimide has excellent stable properties thermally, mechanically and chemically.

- a dehydration reaction and a cyclization (imidization) reaction are carried out. These reactions can be carried out, for example, by heat treatment.

- graphene having a functional group containing oxygen is used as the graphene compound and polyimide is used as the binder in the electrode of one aspect of the present invention

- the graphene compound can be reduced by the heat treatment, and the process can be simplified. It will be possible.

- heat treatment can be performed at a heating temperature of, for example, 200 ° C. or higher. By performing the heat treatment at a heating temperature of 200 ° C. or higher, the reduction reaction of the graphene compound can be sufficiently performed, and the conductivity of the electrode can be further enhanced.

- Fluoropolymer which is a polymer material having fluorine, specifically polyvinylidene fluoride (PVDF) or the like can be used.

- PVDF is a resin having a melting point in the range of 134 ° C. or higher and 169 ° C. or lower, and is a material having excellent thermal stability.

- a rubber material such as styrene-butadiene rubber (SBR), styrene-isoprene-styrene rubber, acrylonitrile-butadiene rubber, butadiene rubber, or ethylene-propylene-diene copolymer as the binder.

- SBR styrene-butadiene rubber

- fluororubber can be used as the binder.

- a water-soluble polymer for example, a polysaccharide or the like can be used.

- a polysaccharide one or more selected from cellulose derivatives such as carboxymethyl cellulose (CMC), methyl cellulose, ethyl cellulose, hydroxypropyl cellulose, diacetyl cellulose, and regenerated cellulose, and starch and the like can be used. Further, it is more preferable to use these water-soluble polymers in combination with the above-mentioned rubber material.

- the binder may be used in combination of a plurality of the above.

- the graphene compound 583 is flexible and has flexibility, and can cling to the particles 582 like natto. Further, for example, the particles 582 can be compared to soybean, and the graphene compound 583 can be compared to a sticky component, for example, polyglutamic acid.

- a sticky component for example, polyglutamic acid.

- a plurality of graphene compounds 583 form a three-dimensional network structure, a structure in which polygons are arranged, for example, a honeycomb structure in which hexagons are arranged in a matrix, and an electrolyte, a plurality of active substances, and a plurality of carbon systems are formed in the network.

- the graphene compound 583 can form a three-dimensional conductive path and suppress the dropout of the electrolyte from the current collector.

- polygons having different numbers of sides may be mixed and arranged. Therefore, the graphene compound 583 may function as a conductive agent and a binder in the active material layer 572.

- the particles 582 can have various shapes such as a rounded shape and a shape having corners. Further, in the cross section of the electrode, the particles 582 can have various cross-sectional shapes such as a circle, an ellipse, a figure having a curve, a polygon, and the like. For example, FIG. 1B shows an example in which the cross section of the particle 582 has a rounded shape, but the cross section of the particle 582 may have an angle. Further, a part may be rounded and a part may have corners.

- the graphene compound is graphene, multi-layer graphene, multi-graphene, graphene oxide, multi-layer graphene oxide, multi-graphene oxide, reduced graphene oxide, reduced multi-layer graphene oxide, reduced multi-graphene oxide, graphene.

- the graphene compound has carbon, has a flat plate shape, a sheet shape, or the like, and has a two-dimensional structure formed by a carbon 6-membered ring.

- the two-dimensional structure formed by the carbon 6-membered ring may be called a carbon sheet.

- the graphene compound may have a functional group. Further, the graphene compound preferably has a bent shape.

- the graphene compound may also be curled up into carbon nanofibers.

- graphene oxide means, for example, one having carbon and oxygen, having a sheet-like shape, and having a functional group, particularly an epoxy group, a carboxy group or a hydroxy group.

- the reduced graphene oxide in the present specification and the like means, for example, a graphene oxide having carbon and oxygen, having a sheet-like shape, and having a two-dimensional structure formed by a carbon 6-membered ring. It may be called a carbon sheet. Although one reduced graphene oxide functions, a plurality of reduced graphene oxides may be laminated.

- the reduced graphene oxide preferably has a portion having a carbon concentration of more than 80 atomic% and an oxygen concentration of 2 atomic% or more and 15 atomic% or less. By setting such carbon concentration and oxygen concentration, it is possible to function as a highly conductive conductive material even in a small amount.

- the reduced graphene oxide has an intensity ratio G / D of G band to D band of 1 or more in the Raman spectrum.

- the reduced graphene oxide having such an intensity ratio can function as a highly conductive conductive material even in a small amount.

- the sheet-like graphene compound is dispersed substantially uniformly in the internal region of the active material layer. Since the plurality of graphene compounds are formed so as to partially cover the plurality of granular active substances or to stick to the surface of the plurality of granular active substances, they are in surface contact with each other.

- graphene compound net By binding a plurality of graphene compounds to each other, a mesh-like graphene compound sheet (hereinafter referred to as graphene compound net or graphene net) can be formed.

- the graphene net When the active material is covered with graphene net, the graphene net can also function as a binder for binding the active materials to each other. Therefore, since the amount of the binder can be reduced or not used, the ratio of the active material to the electrode volume and the electrode weight can be improved. That is, the charge / discharge capacity of the secondary battery can be increased.

- graphene oxide as a graphene compound, mix it with an active material to form a layer to be an active material layer, and then reduce the amount. That is, it is preferable that the active material layer after completion has reduced graphene oxide.

- the graphene compound can be dispersed substantially uniformly in the internal region of the active material layer.

- the graphene compounds remaining in the active material layer partially overlap and are dispersed to the extent that they are in surface contact with each other. Can form a three-dimensional conductive path.

- the graphene oxide may be reduced, for example, by heat treatment or by using a reducing agent.

- a graphene compound which is a conductive material, is formed as a film by covering the entire surface of the active material, and the active materials are electrically connected to each other with the graphene compound to form a conductive path. It can also be formed.

- the graphene compound may be mixed with the material used for forming the graphene compound and used for the active material layer.

- particles used as a catalyst for forming a graphene compound may be mixed with the graphene compound.

- the catalyst for forming the graphene compound include particles having silicon oxide (SiO 2 , SiO x (x ⁇ 2)), aluminum oxide, iron, nickel, ruthenium, iridium, platinum, copper, germanium and the like. ..

- the particles preferably have a D50 of 1 ⁇ m or less, and more preferably 100 nm or less.

- the graphene compound according to one aspect of the present invention preferably has holes in a part of the carbon sheet.

- the graphene compound of one aspect of the present invention by providing a hole through which carrier ions such as lithium ions can pass in a part of the carbon sheet, carrier ions can be inserted and removed on the surface of the active material covered with the graphene compound. It becomes easier to do so, and the rate characteristics of the secondary battery can be improved.

- the holes provided in a part of the carbon sheet may be referred to as vacancies, defects or voids.

- the graphene compound according to one aspect of the present invention preferably has pores provided by a plurality of carbon atoms and one or more fluorine atoms. Further, it is preferable that the plurality of carbon atoms are bonded in a ring shape, and it is preferable that one or more of the plurality of carbon atoms bonded in a ring shape is terminated by the fluorine. Fluorine has a high electronegativity and tends to be negatively charged. The approach of positively charged lithium ions causes an interaction, which stabilizes the energy and reduces the barrier energy through which the lithium ions pass through the pores. Therefore, since the pores of the graphene compound have fluorine, it is possible to realize a graphene compound in which lithium ions easily pass through even in small pores and have excellent conductivity.

- Negative electrode active materials include materials that can react with carrier ions of secondary batteries, materials that can insert and remove carrier ions, materials that can alloy with metals that become carrier ions, and carrier ions. It is preferable to use a material capable of dissolving and precipitating the metal.

- the following is an example of a negative electrode active material.

- Silicon can be used as the negative electrode active material.

- the electrode 570 it is preferable to use particles having silicon as the particles 582.

- a metal or compound having one or more elements selected from tin, gallium, aluminum, germanium, lead, antimony, bismuth, silver, zinc, cadmium and indium can be used.

- an alloy-based compound using such elements for example, Mg 2 Si, Mg 2 Ge , Mg 2 Sn, SnS 2, V 2 Sn 3, FeSn 2, CoSn 2, Ni 3 Sn 2, Cu 6 Sn 5 , Ag 3 Sn, Ag 3 Sb, Ni 2 MnSb, CeSb 3 , LaSn 3 , La 3 Co 2 Sn 7 , CoSb 3 , InSb, SbSn and the like.

- a material having a low resistance may be used by adding phosphorus, arsenic, boron, aluminum, gallium or the like as impurity elements to silicon.

- a silicon material predoped with lithium may be used.

- a predoping method there are methods such as mixing and annealing lithium fluoride, lithium carbonate and the like with silicon, and a mechanical alloy of lithium metal and silicon.

- lithium is doped by a charge / discharge reaction in combination with an electrode such as lithium metal, and then an electrode that becomes a counter electrode using the doped electrode (for example, a positive electrode with respect to a pre-doped negative electrode). May be combined to produce a secondary battery.

- silicon nanoparticles can be used as the particles 582.

- the average diameter of the silicon nanoparticles is, for example, preferably 5 nm or more and less than 1 ⁇ m, more preferably 10 nm or more and 300 nm or less, and further preferably 10 nm or more and 100 nm or less.

- Silicon nanoparticles may have crystallinity. Further, the silicon nanoparticles may have a crystalline region and an amorphous region.

- the material having silicon for example, a material represented by SiO x (x is preferably smaller than 2, more preferably 0.5 or more and 1.6 or less) can be used.

- a form having a plurality of crystal grains in one particle can be used.

- a form having one or a plurality of silicon crystal grains in one particle can be used.

- the one particle may have silicon oxide around the crystal grain of silicon.

- the silicon oxide may be amorphous. It may be a particle in which a graphene compound is clinging to a secondary particle of silicon.

- Li 2 SiO 3 and Li 4 SiO 4 can be used as the compound having silicon.

- Li 2 SiO 3 and Li 4 SiO 4 may be crystalline or amorphous, respectively.

- NMR nuclear magnetic resonance

- XRD X-ray diffraction

- Raman spectroscopy Raman spectroscopy

- SEM scanning electron microscopy

- TEM transmission electron microscopy

- EDX energy dispersion X-ray spectroscopy

- the negative electrode active material for example, carbon-based materials such as graphite, graphitizable carbon, non-graphitizable carbon, carbon nanotubes, carbon black and graphene compounds can be used.

- the negative electrode active material for example, an oxide having one or more elements selected from titanium, niobium, tungsten and molybdenum can be used.

- the negative electrode active material a plurality of metals, materials, compounds, etc. shown above can be used in combination.

- Examples of the negative electrode active material include SnO, SnO 2 , titanium dioxide (TIO 2 ), lithium titanium oxide (Li 4 Ti 5 O 12 ), lithium-graphite interlayer compound (Li x C 6 ), and niobium pentoxide (Nb 2 O). 5 ) Oxides such as tungsten oxide (WO 2 ) and molybdenum oxide (MoO 2 ) can be used.

- Li 2.6 Co 0.4 N 3 shows a large charge / discharge capacity (900 mAh / g) and is preferable.

- double nitride of lithium and a transition metal as a negative electrode material, preferably can be combined with the material of V 2 O 5, Cr 3 O 8 or the like which does not contain lithium ions as a positive electrode material. Even when a material containing lithium ions is used as the positive electrode material, a double nitride of lithium and a transition metal can be used as the negative electrode material by desorbing the lithium ions contained in the positive electrode material in advance.

- a material that causes a conversion reaction can also be used as a negative electrode active material.

- a transition metal oxide that does not undergo an alloying reaction with lithium such as cobalt oxide (CoO), nickel oxide (NiO), and iron oxide (FeO)

- Materials that cause a conversion reaction include oxides such as Fe 2 O 3 , CuO, Cu 2 O, RuO 2 , Cr 2 O 3 , sulfides such as CoS 0.89 , NiS, and CuS, and Zn 3 N 2. , Cu 3 N, Ge 3 N 4 or the like nitride, NiP 2, FeP 2, CoP 3 etc. phosphide, also at the FeF 3, BiF 3 fluoride and the like. Since the potential of the fluoride is high, it may be used as a positive electrode material.

- the particles 582 may change in volume due to charge / discharge, but by arranging an electrolyte having fluorine between a plurality of particles 582 in the electrode, the particles are slippery even if the volume changes during charge / discharge. Since cracks are suppressed, there is an effect that the cycle characteristics are dramatically improved. It is important that an organic compound having fluorine is present between the plurality of active substances constituting the electrode.

- model S_H hydrogen-terminated silicon

- model S_OH hydroxy group-terminated silicon

- graphene As graphene (model G-1), a structure consisting of 170 carbon atoms and 36 hydrogen atoms was used. All 36 hydrogen atoms terminate the ends of graphene.

- Graphene compounds include graphene having one carbon bonded to an epoxy group (model G-2), graphene having two carbons bonded to a hydroxyl group (model G-3), and graphene having two hydrogen-terminated carbons (model G-3).

- model G-2 graphene having one carbon bonded to an epoxy group

- model G-3 graphene having two carbons bonded to a hydroxyl group

- model G-3 graphene having two hydrogen-terminated carbons

- Five models were used: model G-4) and graphene with two fluorine-terminated carbons (model G-5).

- the functional group, or atom-terminated carbon is located near the center of the graphene plane.

- FIG. 3 shows an example of the interaction between the particles having silicon and the graphene compound after the optimization.

- the optimization shows how the silicon-bearing particles approach the graphene compound in distance.

- the graphene compound was observed to be curved.

- the curvature of the graphene compound is considered to be due to the London dispersion force.

- FIG. 3 shows the state when the hydroxy group-terminated silicon (model S_OH) and graphene (model G-1) approach each other.

- the stabilization energy was calculated for each combination.

- the results are shown in Table 2.

- the energy when the particles having silicon and the graphene compound were arranged at infinity was used as a reference, and the absolute value of the difference from the reference was used as the stabilizing energy.

- the stabilization energy of the hydroxy group-terminated silicon was higher than that of the hydrogen-terminated silicon (model S_H).

- graphene compounds models G-2 to G-5) having carbon bonded to a functional group, a hydrogen atom, or a fluorine atom in terms of graphene have a higher stabilizing energy than graphene (model G-1). it was high.

- FIG. 4A shows a state in which silicon terminated with a hydroxy group (model S_OH) and graphene having carbon bonded to an epoxy group (model G-2) are brought close to each other. It was suggested that a hydrogen bond was formed between the oxygen contained in the epoxy group and the hydroxy group on the silicon surface.

- FIG. 4B shows a state in which silicon terminated with a hydroxy group (model S_OH) and graphene having a carbon bonded to the hydroxy group (model G-3) are brought close to each other. It was suggested that a hydrogen bond was formed between both hydroxy groups.

- FIG. 5A shows a state in which silicon terminated with a hydroxy group (model S_OH) and graphene having carbon terminated by a hydrogen atom (model G-4) are brought close to each other. It was suggested that a hydrogen bond was formed between the hydrogen atom of graphene and the hydroxy group on the silicon surface.

- FIG. 5B shows a state in which silicon terminated with a hydroxy group (model S_OH) and graphene having carbon terminated by a fluorine atom (model G-5) are brought close to each other. It was suggested that a hydrogen bond was formed between the fluorine atom of graphene and the hydroxy group on the silicon surface.

- the stabilization energy is increased by forming a hydrogen bond with the graphene compound by terminating the silicon surface with a hydroxy group.

- FIGS. 6A and 6B show an example of the composition of a graphene compound having pores.

- model G-22H8 The configuration shown in FIG. 6A (hereinafter referred to as model G-22H8) has a 22-membered ring, and 8 carbons out of the carbons constituting the 22-membered ring are each terminated by hydrogen.

- the model G-22H8 has a structure in graphene in which two linked 6-membered rings are removed and the carbon bonded to the removed 6-membered ring is terminated with hydrogen.

- model G-22H6F2 The configuration shown in FIG. 6B (hereinafter referred to as model G-22H6F2) has a 22-membered ring, and 6 of the 8 carbons constituting the 22-membered ring are terminated by hydrogen and 2 carbons are terminated. Carbon is terminated by fluorine.

- the model G-22H6F2 has a structure in graphene in which two linked 6-membered rings are removed and the carbon bonded to the removed 6-membered ring is terminated with hydrogen or fluorine.

- the stabilization energy was calculated for the combination of the particles having silicon and the graphene compound having pores. The results are shown in Table 3.

- FIG. 7A shows the state when the silicon (model S_OH) terminated with a hydroxy group and the model G-22H8 are brought close to each other.

- FIG. 7B is an enlarged view including a region in which the silicon (model S_OH) terminated with a hydroxy group and the model G-22H8 approach each other. As shown by the broken line in FIG. 7B, it was suggested that a hydrogen bond was formed between the hydrogen atom of graphene and the hydroxy group on the silicon surface.

- FIG. 8A shows the state when the hydroxy group-terminated silicon (model S_OH) and the model G-22H6F2 are brought close to each other.

- FIG. 8B is an enlarged view including a region in which the hydroxy group-terminated silicon (model S_OH) and the model G-22H6F2 approach each other. As shown by the broken line in FIG. 8B, it was suggested that a hydrogen bond was formed between the hydrogen atom of graphene and the oxygen of the hydroxy group on the silicon surface. It was also suggested that a hydrogen bond is formed between the fluorine atom of graphene and the hydrogen of the hydroxy group on the silicon surface.

- the graphene compound has fluorine in addition to hydrogen, in addition to the hydrogen bond between the oxygen atom of the hydroxy group and the hydrogen atom of the graphene compound, the hydrogen bond between the hydrogen atom of the hydroxy group and the fluorine atom of the graphene compound. was also formed, suggesting that the interaction between hydrogen-bearing particles and the graphene compound is stronger and the stabilizing energy is even higher.

- the hydrogen-terminated silicon (model S_H) has a stabilization energy with the graphene compound having two types of pores shown in Table 2 as compared with the hydroxy group-terminated silicon (model S_OH). It was small.

- the silicon surface is terminated by a hydroxy group and the graphene compound has pores terminated by hydrogen or fluorine, so that a hydrogen bond is formed and the stabilization energy is increased.

- model S_Ox a model of silicon oxide

- a structure consisting of 20 silicon atoms, 28 hydrogen atoms and 54 oxygen atoms was used.

- the terminal dangling bond was terminated with a hydroxy group.

- FIG. 9A shows an optimized state of silicon oxide and graphene having carbon terminated by a hydroxy group (model G-3), and FIG. 9B shows silicon oxide and carbon terminated by fluorine.

- the graphene having (model G-5) and the optimized state are shown respectively. It was suggested that even in silicon oxide terminated by a hydroxy group, the graphene compound has a functional group or pores, so that the bond becomes stronger.

- FIG. 10 is a flow chart showing an example of a method for manufacturing an electrode according to an aspect of the present invention.

- step S71 particles having silicon are prepared.

- the particles having silicon for example, the particles described as the above particles 582 can be used.

- step S72 prepare a solvent.

- the solvent for example, one or a mixture of water, methanol, ethanol, acetone, tetrahydrofuran (THF), dimethylformamide (DMF), N-methylpyrrolidone (NMP) and dimethyl sulfoxide (DMSO) may be used. Can be done.

- step S73 the particles having silicon prepared in step S71 and the solvent prepared in step S72 are mixed, the mixture is recovered in step S74, and the mixture E-1 is obtained in step S75.

- a kneader or the like can be used for mixing.

- the kneading machine for example, a rotation / revolution mixer or the like can be used.

- step S80 the graphene compound is prepared.

- step S81 the mixture E-1 and the graphene compound prepared in step S80 are mixed, and in step S82, the mixture is recovered.

- the recovered mixture is preferably in a high viscosity state. Due to the high viscosity of the mixture, solid kneading (kneading at high viscosity) can be performed in the next step S83.

- kneading is performed in step S83.

- the kneading can be performed using, for example, a spatula. By kneading, it is possible to form a mixture in which the particles having silicon and the graphene compound are well mixed and the graphene compound has excellent dispersibility.

- step S84 the kneaded mixture is mixed.

- a kneader or the like can be used for mixing.

- the mixed mixture is recovered in step S85.

- n is, for example, a natural number of 2 or more and 10 or less.

- a solvent when the mixture is in a dry state, it is preferable to add a solvent. Further, for example, there may be a case where the solvent is added or a case where the solvent is not added in step S83 in n repetitions. On the other hand, if too much solvent is added, the viscosity decreases and the effect of kneading decreases.

- step S86 After repeating steps S83 to S85 n times, the mixture E-2 is obtained (step S86).

- step S87 prepare a binder.

- the materials described above can be used, and it is particularly preferable to use polyimide.

- a precursor of a material used as a binder may be prepared.

- a polyimide precursor is prepared.

- step S88 the mixture E-2 and the binder prepared in step S87 are mixed.

- step S89 the viscosity is adjusted. Specifically, for example, a solvent of the same type as the solvent prepared in step S72 is prepared and added to the mixture obtained in step S88. By adjusting the viscosity, for example, the thickness, density, etc. of the electrode obtained in step S97 may be adjusted.

- step S92 the mixture whose viscosity was adjusted in step S89 is mixed in step S90 and recovered in step S91 to obtain a mixture E-3 (step S92).

- the mixture E-3 obtained in step S92 is called, for example, a slurry.

- step S94 the mixture E-3 is applied onto the current collector prepared in step S93.

- a slot die method, a gravure method, a blade method, a method combining them, or the like can be used.

- a continuous coating machine or the like may be used for coating.

- step S95 the first heating is performed.

- the first heating causes the solvent to volatilize.

- the first heating may be performed in a temperature range of 50 ° C. or higher and 200 ° C. or lower, preferably 60 ° C. or higher and 150 ° C. or lower.

- heat treatment is performed on a hot plate in an atmospheric atmosphere under the conditions of 30 ° C. or higher and 70 ° C. or lower for 10 minutes or longer, and then, for example, under a reduced pressure environment under the conditions of room temperature or higher and 100 ° C. or lower for 1 hour or longer and 10 hours or lower.

- the heat treatment may be performed.

- the heat treatment may be performed using a drying oven or the like.

- heat treatment may be performed at a temperature of 30 ° C. or higher and 120 ° C. or lower for 30 seconds or longer and 2 hours or shorter.

- the temperature may be raised step by step.

- the heat treatment may be further performed at a temperature of 65 ° C. or higher for 1 minute or longer.

- step S96 the second heating is performed.

- the cycloaddition reaction of the polyimide occurs by the second heating.

- the second heating may cause a dehydration reaction of the polyimide.

- the first heating may cause a dehydration reaction of the polyimide.

- the cyclization reaction of the polyimide may occur in the first heating.

- the reduction reaction of the graphene compound occurs in the second heating.

- step S97 an electrode having an active material layer provided on the current collector is obtained.

- the thickness of the active material layer thus formed may be, for example, preferably 5 ⁇ m or more and 300 ⁇ m or less, and more preferably 10 ⁇ m or more and 150 ⁇ m or less.

- the amount of the active material supported by the active material layer may be, for example, preferably 2 mg / cm 2 or more and 50 mg / cm 2 or less.

- the active material layer may be formed on both sides of the current collector, or may be formed on only one side. Alternatively, it may have a region in which active material layers are partially formed on both sides.

- pressing may be performed by a compression method such as a roll press method or a flat plate press method. Heat may be applied when pressing.

- the positive electrode active material examples include a layered rock salt type crystal structure or a composite oxide having a spinel type crystal structure.

- a positive electrode active material for example, a compound having an olivine type crystal structure can be mentioned.

- the positive electrode active material include compounds such as LiFePO 4 , LiFeO 2 , LiNiO 2 , LiMn 2 O 4 , V 2 O 5 , Cr 2 O 5 , and MnO 2 .

- a lithium manganese composite oxide that can be represented by the composition formula Li a Mn b M c Od can be used.

- the element M a metal element selected from other than lithium and manganese, silicon, and phosphorus are preferably used, and nickel is more preferable.

- the lithium manganese composite oxide refers to an oxide containing at least lithium and manganese, and includes chromium, cobalt, aluminum, nickel, iron, magnesium, molybdenum, zinc, indium, gallium, copper, titanium, niobium, and silicon. And at least one element selected from the group consisting of phosphorus and the like may be contained.

- a material having a layered rock salt type crystal structure such as lithium cobalt oxide (LiCoO 2 ) has a high discharge capacity and is excellent as a positive electrode active material for a secondary battery.

- the material having a layered rock salt type crystal structure include a composite oxide represented by LiMO 2.

- the metal M contains the metal Me1.

- the metal Me1 is one or more metals containing cobalt.

- the metal M can further contain the metal X in addition to the metal Me1.

- Metal X is one or more metals selected from magnesium, calcium, zirconium, lanthanum, barium, copper, potassium, sodium and zinc.

- the positive electrode active material will be described with reference to FIGS. 11 and 12.

- the positive electrode active material produced according to one aspect of the present invention can reduce the displacement of the CoO 2 layer in repeated deep charging and discharging. Furthermore, the change in volume can be reduced. Therefore, the compound can realize excellent cycle characteristics. In addition, the compound can have a stable crystal structure in a state of deep charging depth. Therefore, the compound may not easily cause a short circuit when the state of deep charge depth is maintained. In such a case, safety is further improved, which is preferable.

- the difference in volume between a sufficiently discharged state and a state with a high charging depth is small when compared with the change in crystal structure and the same number of transition metal atoms.

- the positive electrode active material is preferably represented by a layered rock salt type structure, and the region is represented by a space R-3m.

- the positive electrode active material is a region having lithium, metal Me1, oxygen and metal X.

- FIG. 11 shows an example of the crystal structure before and after charging and discharging the positive electrode active material.

- the surface layer portion of the positive electrode active material has titanium, magnesium and oxygen in addition to or in place of the region represented by the layered rock salt type structure described in FIG. 11 and the like below, and is different from the layered rock salt type structure. It may have a crystal represented by a structure. For example, it may have titanium, magnesium and oxygen, and may have crystals represented by a spinel structure.

- the crystal structure of FIG. 11 at a charge depth of 0 (discharged state) is R-3 m (O3), which is the same as that of FIG.

- the positive electrode active material shown in FIG. 11 has a crystal having a structure different from that of the H1-3 type crystal structure when the charge depth is sufficiently charged.

- this structure is a space group R-3m and is not a spinel-type crystal structure, ions such as cobalt and magnesium occupy the oxygen 6-coordination position, and the arrangement of cations has symmetry similar to that of the spinel-type. Further, the symmetry of the CoO 2 layer of the structure is the same as type O3.

- this structure is referred to as an O3'type crystal structure or a pseudo-spinel type crystal structure in the present specification and the like.

- lithium may be present at any lithium site with a probability of about 20%, but the present invention is not limited to this. It may be present only in some specific lithium sites.

- magnesium is dilutely present between the CoO 2 layers, that is, in the lithium site.

- halogens such as fluorine may be randomly and dilutely present at the oxygen sites.

- light elements such as lithium may occupy the oxygen 4-coordination position, and in this case as well, the ion arrangement has symmetry similar to that of the spinel type.

- the O3'type crystal structure has Li randomly between layers but is similar to the CdCl 2 type crystal structure.

- This crystal structure similar to CdCl type 2 is similar to the crystal structure when lithium nickel oxide is charged to a charging depth of 0.94 (Li 0.06 NiO 2 ), but contains a large amount of pure lithium cobalt oxide or cobalt. It is known that layered rock salt type positive electrode active materials do not usually have this crystal structure.

- Layered rock salt crystals and anions of rock salt crystals have a cubic close-packed structure (face-centered cubic lattice structure). It is presumed that the O3'type crystal also has a cubic close-packed structure for anions. When they come into contact, there is a crystal plane in which the cubic close-packed structure composed of anions is oriented in the same direction.

- the space group of layered rock salt type crystals and O3'type crystals is R-3m

- the space group of rock salt type crystals Fm-3m (space group of general rock salt type crystals) and Fd-3m (simplest symmetry).

- the mirror index of the crystal plane satisfying the above conditions is different between the layered rock salt type crystals and the O3'type crystals and the rock salt type crystals.

- the orientations of the crystals are substantially the same when the orientations of the cubic close-packed structures composed of anions are aligned. be.

- the positive electrode active material shown in FIG. 11 has high structural stability even when the charging voltage is high.

- a charging voltage having an H1-3 type crystal structure for example, a voltage of about 4.6 V based on the potential of a lithium metal, results in an H1-3 type crystal structure.

- the positive electrode active material can retain the crystal structure of R-3m (O3) even at the charging voltage of about 4.6V.

- There is a region where an O3'type crystal structure can be obtained even at a higher charging voltage for example, a voltage of about 4.65 V to 4.7 V with reference to the potential of lithium metal.

- H1-3 type crystals may finally be observed in the positive electrode active material of one aspect of the present invention.

- the positive electrode active material of one embodiment of the present invention can have an O3'type crystal structure.

- the voltage of the secondary battery is lower than the above by the potential of graphite.

- the potential of graphite is about 0.05V to 0.2V based on the potential of lithium metal. Therefore, for example, even when the voltage of the secondary battery using graphite as the negative electrode active material is 4.3 V or more and 4.5 V or less, the positive electrode active material of one aspect of the present invention can retain the crystal structure of R-3m (O3), and further.