WO2020235212A1 - パンツ型使い捨ておむつ、及び、パンツ型使い捨ておむつの製造方法 - Google Patents

パンツ型使い捨ておむつ、及び、パンツ型使い捨ておむつの製造方法 Download PDFInfo

- Publication number

- WO2020235212A1 WO2020235212A1 PCT/JP2020/013443 JP2020013443W WO2020235212A1 WO 2020235212 A1 WO2020235212 A1 WO 2020235212A1 JP 2020013443 W JP2020013443 W JP 2020013443W WO 2020235212 A1 WO2020235212 A1 WO 2020235212A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- pants

- type disposable

- elastic film

- disposable diaper

- elastic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/496—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15699—Forming webs by bringing together several webs, e.g. by laminating or folding several webs, with or without additional treatment of the webs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15585—Apparatus or processes for manufacturing of babies' napkins, e.g. diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/49011—Form-fitting, self-adjusting disposable diapers with elastic means the elastic means is located at the waist region

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/4902—Form-fitting, self-adjusting disposable diapers with elastic means characterised by the elastic material

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/56—Supporting or fastening means

- A61F13/5622—Supporting or fastening means specially adapted for diapers or the like

- A61F13/565—Supporting or fastening means specially adapted for diapers or the like pants type diaper

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/4902—Form-fitting, self-adjusting disposable diapers with elastic means characterised by the elastic material

- A61F2013/49022—Form-fitting, self-adjusting disposable diapers with elastic means characterised by the elastic material being elastomeric sheet

Definitions

- the present invention relates to a pants-type disposable diaper and a method for manufacturing a pants-type disposable diaper.

- Pants-type disposable diapers with improved surface fit by using a sheet member made by laminating a non-woven fabric and an elastic film are known.

- an elastic film is laminated between a first sheet layer (nonwoven fabric) and a second sheet layer (nonwoven fabric), and a through hole penetrating the elastic film is formed.

- An absorbent article in which sheet members are joined to each other is disclosed.

- the present invention has been made in view of the above problems, and an object of the present invention is to provide a pants-type disposable diaper provided with an elastic film and having a good fit.

- the main invention for achieving the above object is a pants-type disposable diaper having a vertical direction, a horizontal direction, and a front-rear direction intersecting each other, and having a belt portion and an absorbent main body.

- the exterior sheet and the elastic film are joined to each other by a plurality of joint portions, and the elastic film is bonded to each other by a plurality of joint portions.

- It has an elastic layer that expands and contracts in a straight line and a low elastic layer that is laminated on the elastic layer and has lower elasticity than the elastic layer, and the low elastic layer is continuous at a certain joint portion among the plurality of the joint portions.

- the pants-type disposable diaper is characterized in that the elastic layer and the low elastic layer are separated from each other at at least a part of the outer edge portion of the certain joint portion.

- FIG. 1 It is a schematic perspective view of the pants type disposable diaper 1. It is a schematic plan view of the diaper 1 in the expanded and extended state.

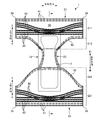

- FIG. 2 is a schematic cross-sectional view taken along the line II of FIG.

- FIG. 5 is a schematic cross-sectional view showing an enlarged portion of the belt portion 21 in the thickness direction in which the joint portion 50 is not formed.

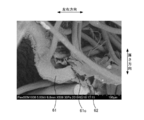

- FIG. 5 is a schematic cross-sectional view showing an enlarged portion of the belt portion 21 in the thickness direction in which the joint portion 50 is formed. It is a photograph which shows the actual cross-sectional structure in the thickness direction of a belt part 21. It is an enlarged photograph about the area A of FIG.

- a pants-type disposable diaper having a vertical direction, a horizontal direction, and a front-rear direction intersecting each other, and having a belt portion and an absorbent main body, wherein the belt portion is at least in the horizontal direction with an exterior sheet. It has an elastic film that can be expanded and contracted, and the exterior sheet and the elastic film are joined to each other by a plurality of joint portions, and the elastic film is formed on the elastic layer that expands and contracts in the left-right direction and the elastic layer. It has a low elastic layer that is laminated and has lower elasticity than the elastic layer, and at a certain joint portion among the plurality of the joint portions, the low elastic layer is continuous and the outer edge of the certain joint portion.

- a pants-type disposable diaper characterized in that the elastic layer and the low elastic layer are separated from each other in at least a part of the portion.

- the low elastic layer of the elastic film is continuous at the joint portion between the elastic film and the exterior sheet, so that the elasticity of the belt portion (elastic film) is lowered. Can be suppressed. Further, since the elastic layer and the low elastic layer are separated from each other at the outer edge of the joint, the elastic film can easily follow the movement of the wearer's body and improve the feel. it can. This makes it possible to achieve a good fit when wearing a diaper.

- the thickness of the belt portion at the center of the joint is smaller than the thickness of the elastic film in the region where the joint is not provided. ..

- the elastic film does not exhibit elasticity at the center of the joint, the joint state between the sheet members is stable and the joint strength is easily maintained. This makes it easier for the exterior sheet to follow the expansion and contraction of the elastic film, maintains good elasticity of the belt portion as a whole, and facilitates fitting to the wearer's body.

- the exterior sheet has a skin-side sheet arranged on the skin side of the elastic film and a non-skin-side sheet arranged on the non-skin side of the elastic film. It is desirable that the elastic film, the skin-side sheet, and the non-skin-side sheet are joined by the joint portion.

- the elastic film is fixed so as to be sandwiched between the outer sheets from both sides in the thickness direction, so that the outer sheet and the elastic film are elastic as compared with the case where only one side is fixed.

- the bonding force with the film can be increased. Therefore, even when the elastic film expands and contracts, the outer sheet and the elastic film are less likely to be peeled off, and the elasticity of the belt portion as a whole can be improved.

- the low elastic layer is made of a predetermined resin material and is laminated on both sides of the elastic layer in the thickness direction.

- the low elastic layer is made of a polyolefin resin. It is desirable that the exterior sheet is a non-woven fabric having fibers containing the polyolefin resin.

- the polyolefin resins are easily welded to each other, and the low-stretchable layer and the exterior sheet are more easily bonded to each other. Can be firmly joined. As a result, the belt portion can more easily follow the movement of the wearer's body, and the fit of the diaper is further improved.

- the pants-type disposable diaper has a discontinuous portion at the extension portion of the joint portion.

- the elastic layer has a discontinuous portion

- the elasticity of the elastic film is increased at the discontinuous portion, and the elastic film is flexible at the outer edge portion of the highly rigid joint portion. It becomes easy to deform. Therefore, when the diaper is worn, the belt portion can be more easily followed by the movement of the wearer's body, and the hard feel of the joint portion can be made difficult for the wearer to feel.

- the pants-type disposable diaper has a plurality of strip-shaped elastic films long in the left-right direction arranged side by side at intervals in the up-down direction on the belt portion.

- the pants-type disposable diaper has at least the stretchable non-woven fabric that can be expanded and contracted in the left-right direction.

- the elasticity and breathability of the belt portion can be made good. This makes it possible to further improve the fit of the belt portion when wearing a diaper.

- a transport step of transporting the continuous body of the elastic film and the continuous body of the exterior sheet in the transport direction at a predetermined transport speed, and the thickness of the continuous body of the elastic film and the continuous body of the exterior sheet to be transported are thickened.

- a method for manufacturing a pants-type disposable diaper which comprises a joining step of joining in the longitudinal direction to form a belt portion and an absorbent main body attaching step of attaching an absorbent main body to the belt portion.

- the continuous body of the elastic film is stretched in the transport direction at a predetermined elongation rate, loosened so as to have an extension rate lower than the predetermined stretch rate, and then the continuous body of the elastic film is stretched in the joining step. It becomes clear that it is joined to the continuum of the exterior sheet.

- an ultrasonic horn arranged on one side in the thickness direction of the continuum of the elastic film and the continuum of the exterior sheet, and the thickness direction.

- the ultrasonic horn and the anvil move in the same direction at the same speed as the material to be conveyed, so that ultrasonic welding is performed to obtain the material.

- the joint can be formed accurately without hindering the transportation. Therefore, when the joint portion is formed, the low elastic layer of the elastic film is not easily torn, and it becomes easy to maintain a continuous state. This makes it easier to improve the fit of the belt portion.

- the ultrasonic horn is provided on the outer peripheral surface of a cylindrical ultrasonic roll having a rotation axis in a direction orthogonal to the transport direction

- the anvil is the anvil. It is provided on the outer peripheral surface of a cylindrical anvil roll having a rotation axis in a direction orthogonal to the transport direction, and protrudes outward in the radial direction from the outer peripheral surface of the anvil roll.

- the elastic film and the anvil roll it is desirable that the number of sheet members arranged between the rolls is larger than the number of sheet members arranged between the elastic film and the ultrasonic rolls.

- the protrusion is used when ultrasonic welding is performed. It is possible to easily absorb the impact acting on the elastic film. As a result, the elastic film is less likely to be torn, and it becomes easier to maintain a continuous state of the low elastic layer at the joint. Therefore, the fit of the belt portion can be improved.

- the area ratio of the anvil provided on the outer peripheral surface of the anvil roll is 1% or more and 9% or less.

- a pants-type disposable diaper 1 for adults (hereinafter, also simply referred to as “diaper 1”) will be described as an example.

- the present invention is not limited to this, and the pants-type disposable diaper according to the present invention can also be applied as, for example, disposable diapers for children (for infants), sanitary shorts, and the like.

- FIG. 1 is a schematic perspective view of a pants-type disposable diaper 1.

- FIG. 2 is a schematic plan view of the unfolded and stretched diaper 1.

- FIG. 3 is a schematic cross-sectional view taken along the line II (center in the left-right direction) of FIG.

- the diaper 1 has a vertical direction, a horizontal direction, and a front-rear direction that intersect each other, and has a thickness direction in which each member is laminated as shown in FIG.

- the side that is the body side of the wearer is the upper side

- the side that is the inseam side of the wearer is the lower side.

- the ventral side of the wearer is the front side

- the dorsal side of the wearer is the rear side.

- the side in contact with the wearer is the skin side

- the opposite side is the non-skin side.

- the diaper 1 has an absorbent main body 10 and an exterior body 20 located on the non-skin side of the absorbent main body 10.

- the exterior body 20 has a front belt portion 21 arranged on the ventral side of the wearer, a rear belt portion 22 arranged on the back side of the wearer, and a crotch portion 23 connecting them.

- the exterior body 20 is composed of three members (front belt portion 21, rear belt portion 22, and crotch lower portion 23), but the present invention is not limited to this.

- the front belt portion 21, the rear belt portion 22, and the crotch lower portion 23 may be composed of one continuous member. Further, the crotch portion 23 may not be provided.

- the front belt portion 21 is located on one end side of the absorbent body 10 in the longitudinal direction

- the rear belt portion 22 is located on the other end side of the absorbent body 10 in the longitudinal direction. positioned.

- the absorbent body 10 is folded in half at substantially the center in the longitudinal direction, and both left and right sides of the front belt portion 21 and both left and right sides of the rear belt portion 22 are engaged by welding or the like.

- the pants type shown in FIG. 1 is obtained.

- the longitudinal direction of the absorbent main body 10 is along the vertical direction of the diaper 1, the front belt portion 21 and the rear belt portion 22 are connected in an annular shape, and a waist circumference opening 1a is formed at the upper end thereof, and also in the left-right direction.

- a pair of leg circumference openings 1b and 1b are formed on both sides.

- the absorbent body 10 includes an absorbent core 11, a liquid-permeable top sheet 12 located on the skin side of the absorbent core 11, and a back located on the non-skin side of the absorbent core 11. It has a sheet 13.

- the back sheet 13 of the present embodiment has a two-layer structure of a liquid-impermeable sheet 13a and a hydrophobic liquid-permeable sheet (for example, hydrophobic non-woven fabric) 13b arranged on the non-skin side thereof.

- the absorbent core 11 is a member that absorbs and retains excrement liquid such as urine, and is formed of liquid absorbent fibers such as pulp fibers mixed with a highly absorbent polymer (SAP), for example.

- SAP highly absorbent polymer

- the outer peripheral surface of the absorbent core 11 may be covered with a liquid-permeable sheet such as tissue paper or non-woven fabric.

- the front belt portion 21 and the rear belt portion 22 have a waist circumference region 211,221 and a waist circumference region 211,221 which are portions overlapping with the locking portion 24 in the vertical direction, respectively. It has lower inseam side regions 212 and 222.

- the inseam side areas 212 and 222 have a substantially trapezoidal shape, and the width (length in the left-right direction) becomes narrower toward the lower side. Further, the inseam side region 222 is larger in the rear belt portion 22 than in the front belt portion 21, and the buttocks of the wearer can be covered.

- the front belt portion 21, the rear belt portion 22, and the inseam 23 are located between the skin side sheets 213, 223, 231 and the non-skin side sheets 214, 224, 232, respectively. It has elastic non-woven fabrics 215, 225, and 233. Then, the sheet members laminated in the thickness direction are joined to each other by a plurality of joint portions 50, 50 ... Intermittently arranged at intervals from each other.

- the configuration of the inseam 23 is not particularly limited, and for example, the elastic non-woven fabric 233 is arranged between the absorbent main body 10 and the non-skin side sheet 232 without having the skin side sheet 231. May be good.

- the skin side sheets 213 and 223 and the non-skin side sheets 214 and 224 correspond to the exterior sheets forming the exterior of the belt portions 21 and 22.

- the non-skin side sheets 214 and 224 and the skin side sheets 213 and 223 are flexible formed of a spunbonded non-woven fabric or SMS non-woven fabric made of fibers containing polypropylene (PP), polyethylene (PE) or the like which are polyolefin resins. Sheet can be exemplified.

- the stretchable non-woven fabrics 215 and 225 are non-woven fabrics of polyurethane elastomer, which is a kind of thermoplastic elastomer having elasticity, and polypropylene (PP), which is a polyolefin resin which is a kind of thermoplastic resin having inelasticity.

- An example is a non-woven fabric in which elastic fibers are subjected to an appropriate stretching treatment such as gear stretching.

- the stretching treatment may be performed in the directions orthogonal to each other (horizontal direction and vertical direction of the diaper 1), or may be performed only in a predetermined direction (horizontal direction of the diaper 1). May be good. When the stretching treatment is performed only in the predetermined direction, elasticity in the predetermined direction is exhibited, but since the orientation of all the fibers is not always along the predetermined direction, the direction is also orthogonal to the predetermined direction. Elasticity is expressed.

- the diaper 1 of the present embodiment in the circumferential direction (corresponding to the left-right direction in FIG. 2) over the waist circumference area 211 of the front belt portion 21 and the waist circumference region 221 of the rear belt portion 22.

- the elastic film 60 is continuously arranged.

- the elastic film 60 is an elastic sheet that can be expanded and contracted at least in the circumferential direction (left-right direction, that is, the waist circumference direction of the wearer), and is laminated with elastic nonwoven fabrics 215 and 225 as shown in FIG. .. Therefore, the region where the elastic film 60 is arranged has a higher tightening pressure than the peripheral region and is in close contact with the wearer.

- the wearer suppresses the misalignment of the diaper 1. It is possible to prevent excessive tightening of the waistline.

- waist thread rubber 41 is arranged along the circumferential direction (left-right direction) of the waist circumference region 221 at the upper ends of the front belt portion 21 and the rear belt portion 22, and is a diaper.

- the fit at the waist opening 1a when the 1 is worn is improved.

- the leg rubber thread rubber 42 is arranged along the lower ends of the inseam side regions 212 and 222 to improve the fit at the leg opening 1b when the diaper 1 is worn.

- FIG. 4 is a schematic cross-sectional view showing an enlarged portion of the belt portion 21 in the thickness direction in which the joint portion 50 is not formed.

- FIG. 5 is a schematic cross-sectional view showing an enlarged portion of the belt portion 21 in the thickness direction in which the joint portion 50 is formed.

- FIGS. 4 and 5 show a cross section of the belt portion 21 in a natural state.

- the "natural state” is a state when the diaper 1 is left for a predetermined time. For example, after taking out the diaper 1 in the product state from the package, the front belt portion 21 and the rear belt portion 22 are pulled to both outer sides in the left-right direction, and the belt portions 21 and 22 are set to the "extended state", and this extended state is set. After continuing for about 15 to 30 seconds, release the pull on the diaper 1 and place it on a flat surface such as a desk. Then, the state in which 5 minutes have passed in such a flat flat placement is regarded as a natural state.

- the belt portion 21 includes a non-skin side sheet 214 (exterior sheet), an elastic film 60, an elastic non-woven fabric 215, and a skin side sheet from the non-skin side to the skin side in the thickness direction. It has a structure in which 213 (exterior sheet) is laminated.

- the non-skin side sheet 214, the skin side sheet 213, and the stretchable non-woven fabric 215 are so-called non-woven fabrics, and have a predetermined thickness in the thickness direction in a natural state.

- the elastic film 60 has a multilayer structure (a multilayer structure) having an elastic elastomer layer 61 and surface layers 62 and 62 laminated and bonded to both sides (skin side and non-skin side) of the elastomer layer 61 in the thickness direction.

- a multilayer structure having an elastic elastomer layer 61 and surface layers 62 and 62 laminated and bonded to both sides (skin side and non-skin side) of the elastomer layer 61 in the thickness direction.

- it is an elastic sheet member (three-layer structure).

- the elastomer layer 61 is a resin film that can expand and contract at least in the left-right direction, and corresponds to the elastic layer.

- the elastomer layer 61 for example, a styrene-based elastomer, an olefin-based elastomer, a polyester-based elastomer, another elastomer, or a blend thereof can be used.

- the surface layer 62 is a sheet member having lower elasticity than the elastomer layer, and corresponds to the low elasticity layer.

- a polyolefin resin polypropylene (PP), polyethylene (PE), etc.

- the sheet members 214, 60, 215, and 213 laminated in the thickness direction are joined to each other by a plurality of joints 50.

- a hole penetrating in the thickness direction is formed in the elastic film 60 at the portion where the joint portion 50 is provided.

- the elastic film 60 was divided in the left-right direction (expansion / contraction direction).

- the elastic force of the elastic film 60 in the left-right direction is interrupted, and the elasticity as a whole is lowered, so that the belt There was a risk that the fit of the part would deteriorate.

- the elastic film 60 is continuous at the joint portion 50. That is, the elastic film 60 is not divided in the left-right direction (expansion / contraction direction). As a result, the elasticity of the elastic film 60 in the left-right direction is less likely to decrease, and a good fit of the belt portion 21 is easily maintained.

- the elastic film 60 (surface layer 62) does not have a through hole in the joint portion 50, the rigidity of the elastic film 60 around the joint portion 50 becomes higher than in the case where the through hole is formed. , May be difficult to deform. For example, when the diaper 1 is worn, when the wearer moves the body, it becomes difficult for the elastic film 60 to follow the movement of the body, and the feel of the highly rigid joint portion 50 is easily transmitted directly to the wearer's skin. There is a risk of becoming.

- the elastomer layer 61 (stretchable layer) and the surface layer 62 (low stretchable layer) of the elastic film 60 are peeled off at the outer edge portion of the joint portion 50.

- a gap P is formed between the two. Since both are peeled off, the elastomer layer 61 (stretchable layer) and the surface layer 62 (low stretchable layer) can be deformed independently of each other around the joint portion 50. Therefore, even if the wearer moves the body while wearing the diaper 1, the elastic film 60 is likely to be deformed around the joint portion 50 in accordance with the movement of the wearer's body.

- the void P formed in the portion where the elastomer layer 61 (expandable layer) and the surface layer 62 (low elastic layer) are peeled off acts as a cushion, and the edge portion (edge) of the joint portion 50 is the wearer's skin. It becomes difficult to be pressed against. Therefore, it is possible to suppress the transmission of the hard feel of the joint portion 50 to the wearer's skin, and improve the feel of the joint.

- FIG. 6 is a photograph showing an example of an actual cross-sectional structure of the belt portion 21 in the thickness direction, and is a diagram showing a configuration corresponding to a schematic cross-sectional view of FIG.

- FIG. 7 is an enlarged photograph of region A in FIG.

- the cross section of the belt 21 is enlarged 70 times

- the cross section of the belt 21 is enlarged 500 times.

- the fibers constituting the skin side sheet 213 and the non-skin side sheet 214 are arranged on both sides (skin side and non-skin side) of the joint portion 50 in the thickness direction, and the configuration is different from that of FIG. It looks like there is. In other words, it also appears that both sides of the joint 50 in the thickness direction are covered with fibers.

- the elastic film 60 (elastomer layer 61 and surface layer 62) is continuous at the joint portion 50 and its outer edge portion, and is not interrupted in the middle. Further, in FIG. 7, at the outer edge of the joint portion 50, the elastomer layer 61 (stretchable layer) and the surface layer 62 (low stretchable layer) have a portion separated from each other, and a gap P is formed in the peeled portion. It is shown that.

- the belt portion 21 (22) of the diaper 1 is provided with the elastic film 60, so that the displacement during wearing is suppressed. Then, since at least the surface layer 62 (low elasticity layer) is continuous at the joint portion 50, it is possible to suppress a decrease in elasticity. Further, the elastic film 60 follows the movement of the wearer's body by having a portion where the elastomer layer 61 (expandable layer) and the surface layer 62 (low elastic layer) are separated from each other at the outer edge portion of the joint portion 50. It becomes easier to do and the touch can be improved. As a result, good fit of the belt portion 21 (22) can be realized.

- the thickness t50 of the belt portion 21 at the central portion (center portion in the left-right direction and the vertical direction) of the joint portion 50 is a region in which the joint portion 50 is not formed. It is smaller than the thickness t60 of the elastic film 60 (t50 ⁇ t60). This is because the sheet members 214, 60, 215, and 213 constituting the belt portion 21 are welded at the joint portion 50 and compressed in the thickness direction, so that the joint portion 50 is consolidated. Therefore, at least in the central portion of the joint portion 50, the elastic film 60 does not exhibit elasticity, the joint state of each sheet member in the joint portion 50 is stable, and the joint strength is easily maintained.

- the exterior sheets (skin-side sheet 213 and non-skin-side sheet 214) of the belt portion 21 can easily follow the expansion and contraction of the elastic film 60, and the good elasticity of the belt portion 21 is maintained, and the wearer's body. It will be easier to fit in

- the skin side sheet 213 skin side exterior sheet

- the non-skin side non-skin side

- Side sheets 214 non-skin side exterior sheets

- the elastic film 60 is fixed so as to be sandwiched between the exterior sheets (213, 214) from both sides in the thickness direction.

- the outer sheet and the elastic film 60 can be firmly fixed. Therefore, even when the elastic film 60 expands and contracts, it is easy to prevent the outer sheet (213, 214) and the elastic film 60 from peeling off, and the elasticity of the belt portion 21 as a whole is improved. be able to.

- the elastic film 60 has surface layers 62 and 62 (low elastic layers) made of a predetermined resin material on both sides (skin side and non-skin side) of the elastic elastomer layer 61 (expandable layer) in the thickness direction. It has a laminated structure. Therefore, when the elastic film 60 and the exterior sheets 213 (stretchable non-woven fabric 215) and 214 are joined in the thickness direction by the joint portion 50, the resin constituting the surface layer 62 and the non-woven fabric of the exterior sheets 213 (215) and 214 are joined. The resins constituting the above are easily melted and bonded to each other. That is, the elastic film 60 and the exterior sheet can be more firmly bonded by welding the resins on the opposite surfaces to each other. As a result, even when the belt portion 21 is greatly expanded and contracted, the elastic film 60 and the exterior sheet are difficult to peel off, and the belt portion 21 can easily follow the movement of the wearer's body. Therefore, the fit of the diaper 1 is improved.

- the surface layer 62 (low elastic layer) of the elastic film 60 is made of a polyolefin resin.

- the exterior sheets 213 (215) and 214 are also made of fibers containing a polyolefin resin. Therefore, when the surface layer 62 (low expansion / contraction layer) laminated in the thickness direction and the exterior sheets 213 (215) and 214 are joined to each other by the joining portion 50, the polyolefin resins are easily welded to each other, and the surface layer 62 and The exterior sheets 213 (215) and 214 can be joined more firmly. As a result, the belt portion 21 can more easily follow the movement of the wearer's body, and the fit of the diaper 1 is further improved.

- FIG. 8 is a photograph showing a cross-sectional structure of the belt portion 21 in the thickness direction when a part of the elastomer layer 61 is discontinuous.

- a discontinuous portion 61c is formed in the elastomer layer 61 at the outer edge portion of the joint portion 50. That is, the elastomer layer 61 has a portion that is discontinuous in the left-right direction.

- the elastic force of the elastic film 60 in the left-right direction may decrease in the discontinuous portion 61c.

- the elastic film 60 since the surface layer 62 of the elastic film 60 is continuous, the elastic film 60 itself is continuous around the joint portion 50, and it is suppressed that the elastic force of the elastic film 60 is extremely reduced. Will be done.

- the elastomer layer 61 since the elastomer layer 61 has the discontinuous portion 61c, the flexibility of the elastic film 60 is increased in the discontinuous portion 61c. That is, the elastic film 60 is easily deformed flexibly at the outer edge portion of the joint portion 50.

- the belt portion 21 By flexibly deforming the elastic film 60 around the highly rigid joint portion 50, the belt portion 21 has a higher followability to the movement of the wearer's body when the diaper 1 is worn, and the joint portion 50 is hard. It can make it difficult for the wearer to feel the feeling.

- a plurality of elastic films 60 are arranged side by side at intervals in the vertical direction in the horizontal direction (circumferential direction of the waist circumference portion 21) as shown in FIG.

- a plurality of elastic films 60, 60 ... are arranged so as to be separated in the vertical direction.

- the number of sheet members laminated in the thickness direction increases, so that the air permeability may decrease.

- the air permeability of the belt portion 21 is lowered, which tends to cause discomfort to the wearer.

- a predetermined gap is provided between the elastic films 60, 60 adjacent to each other in the vertical direction, so that the air permeability of the belt portion 21 can be easily ensured by the gap. This makes it difficult for the wearer to feel uncomfortable when wearing the diaper 1.

- the belt portion 21 of the diaper 1 is provided with stretchable non-woven fabric 215 at least in the left-right direction. Since the stretchable non-woven fabric 215 has a large number of voids between the entangled fibers, It has good breathability as compared with the elastic film 60. Therefore, by providing the stretchable nonwoven fabric 215, the belt portion 21 can easily maintain good stretchability and breathability. The fit of the belt portion 21 when the diaper 1 is worn is improved, and the wearer can be less likely to feel uncomfortable.

- the thickness of the surface layer 62 is 0.5 to 8.0% of the thickness of the elastomer layer 61.

- the thickness of the surface layer 62 is smaller than 0.5% of the thickness of the elastomer layer 61, the surface layer 61 is likely to break when the joint portion 50 is formed, and the continuity of the surface layer 62 at the joint portion 50 is impaired. It may be easy to get rid of.

- the thickness of the surface layer 62 is larger than 8.0% of the thickness of the elastomer layer 61, the rigidity of the surface layer 62 is increased, so that the elasticity of the elastomer layer 61 is deteriorated and the elasticity of the belt portion 21 is increased.

- the thickness of the surface layer 62 is set to 0.5 to 8.0% of the thickness of the elastomer layer 61, so that the diaper can maintain good elasticity of the belt portion 21. The fit when wearing 1 is improved.

- the elastic film 60 was imaged with a cross-sectional enlarged image of 500 times or more as shown in FIG. 7, and each part (62, 61) in the acquired enlarged image was taken. An average value obtained by measuring the thickness of any plurality of locations (for example, 5 locations) can be used.

- FIG. 9 is a flow chart of each process in the manufacture of the diaper 1.

- FIG. 10 is a schematic view illustrating a manufacturing apparatus 100 for manufacturing the diaper 1.

- the absorbent main body 10 is supplied in a completed form, and the description of the manufacturing method of the absorbent main body 10 itself is omitted. doing.

- the manufacturing apparatus 100 shown in FIG. 10 continuously manufactures the diaper 1 by sequentially performing the steps (S101 to S106) shown in FIG. 9.

- the manufacturing apparatus 100 includes a transport mechanism 110, a joining mechanism 120, an absorbent main body mounting mechanism 140, a pants-type molding mechanism 150, and a cutting mechanism 160.

- a transport step is performed in which various base materials such as the skin-side sheet 213 constituting the front belt portion 21 of the diaper 1 are transported in a predetermined transport direction (S101).

- the transport direction is a direction along the left-right direction of the diaper 1, and hereinafter, the transport direction is also referred to as an "MD direction”.

- MD direction the transport direction along the left-right direction of the diaper 1

- CD direction the direction orthogonal to the transport direction

- Each is conveyed from the upstream side to the downstream side in the MD direction at a predetermined transfer speed by the transfer mechanism 110.

- the stretchable non-woven fabric continuum 215L and the elastic film continuum 60L are conveyed in a state of being stretched in the MD direction at a predetermined elongation ratio (T1), and are subjected to a skin-side sheet in a joining step (S102) described later. It is joined to a continuum 213L or the like.

- the belt portion 21 is provided with elasticity along the MD direction (left-right direction).

- the extension ratio is changed by adjusting the rotation speeds of the plurality of nip rollers 111 to 115 provided on the transport path of the transport mechanism 110.

- the nip roller 111 is arranged on the upstream side in the MD direction and the nip roller 112 is arranged on the downstream side on the path through which the stretchable nonwoven fabric continuum 215L is conveyed as shown in FIG.

- the stretchable nonwoven fabric continuum 215L can be extended in the MD direction between the nip roller 111 and the nip roller 112.

- the elastic film continuum 60L is stretched to a stretch ratio (referred to as T2) larger than the predetermined stretch ratio T1 in the transporting step, and then returned to the predetermined stretch ratio T1 before the skin side sheet continuum 213L. Etc. are joined. That is, in the belt portion 21 of the diaper 1, the elastic film 60 is once greatly stretched in the MD direction, then loosened slightly, and then joined to the skin side sheet 213 or the like.

- the surface layer 62 constituting the elastic film 60 is a member that is harder to stretch than the elastomer layer 61.

- the elastic film continuum 60L is temporarily in an excessively stretched state due to an impact applied during the transport process, the elastomer layer 61 and the surface layer 62 may be peeled off or the surface layer 62 may be torn. is there.

- the elastic film 60 by significantly extending the elastic film 60 (particularly the surface layer 62) in advance in the transporting step, it is possible to provide an extra force in the elasticity in the MD direction. As a result, it is possible to prevent the elastomer layer 61 and the surface layer 62 from peeling off, and to prevent the surface layer 62 from being torn or punctured in each step (for example, the joining step S102).

- the extension ratio of the elastic film continuum 60L is changed by adjusting the rotation speeds of the nip rollers 113 to 115 arranged in the transport path of the elastic film continuum 60L in FIG. 10 as in the above case.

- a joining step is performed in which the base materials laminated in the thickness direction while being conveyed in the MD direction are joined to each other to form the exterior body 20 (front belt portion 21) (S102).

- the bonding step ultrasonic vibration and pressure are applied in the thickness direction to each of the laminated base materials 213, 215, 60 and 214 from the bonding mechanism 120 provided at a predetermined position in the MD direction. Ultrasonic bonding is performed. As a result, a plurality of joint portions 50, 60 ... Are formed on the base materials laminated in the thickness direction.

- the joining mechanism 120 has a pair of ultrasonic rolls 121 and anvil rolls 122 that are provided so as to sandwich each base material such as the skin-side sheet continuum 213L so as to face each other in the thickness direction.

- the ultrasonic roll 121 and the anvil roll 122 are cylindrical drums that can rotate about the rotation axes C121 and C122 along the CD direction, respectively.

- a plurality of ultrasonic horns 121h that generate ultrasonic vibrations are provided on the outer peripheral surface of the ultrasonic roll 121 provided on the non-skin side sheet continuum 214L side.

- the outer peripheral surface of the anvil roll 122 provided on the skin side sheet continuum 213L side is a protruding portion protruding outward in the radial direction of the anvil roll 122, and ultrasonic vibration applied by the ultrasonic horn 121h is applied.

- a plurality of protrusions 122a having a function as a receiving anvil are provided.

- the ultrasonic horn 121h may be fixed at a predetermined position in the MD direction. That is, the joining step may be carried out by facing the fixed ultrasonic horn 121h and the movable anvil roll 122 (projection portion 122a).

- FIG. 11 is a diagram illustrating an arrangement of a plurality of protrusions (anvils) 122a provided on the outer peripheral surface of the anvil roll 122.

- the outer peripheral surface of the anvil roll 122 is displayed as a flat surface.

- a plurality of protrusions 122a, 122a, ... are regularly arranged on the outer peripheral surface of the anvil roll 122 along the CD direction and the MD direction (circumferential direction).

- the ultrasonic roll 121 and the anvil roll 122 rotate (move) at the same speed as the transport speed of the base material (skin side sheet continuum 213L, etc.) transported in the MD direction, respectively, while the ultrasonic horn.

- the joint portion 50 is formed by applying ultrasonic vibration while sandwiching the base material in the thickness direction between the 121h and the protrusion 122a. That is, while moving the ultrasonic horn 121h and the anvil (projection 122a) in the same direction with respect to the base material (elastic film continuum 60L or exterior sheet continuum 213L, 214L) conveyed in the MD direction.

- the joint portion 50 is formed.

- the conveyed substrate is configured.

- the protrusion 122a and the like there will be a difference in relative speed.

- the protrusion 122a or the like acts on the conveyed base material like a brake, which may hinder the transfer operation of the base material or cause the base material to be torn.

- the rotation of the ultrasonic roll 121 and the anvil roll 122 causes the ultrasonic horn 121h and the protrusion 122a to move in the same direction at the same speed as the material transfer speed, and ultrasonic welding is performed. ..

- the joint portion 50 can be accurately formed without hindering the transportation of the material. Therefore, the surface layer 62 (low elastic layer) of the elastic film 60 is not easily torn at the joint portion 50, it becomes easy to maintain a continuous state, and the fit of the belt portion 21 is improved.

- the sheet members (continuum) that pass between the pair of ultrasonic rolls 121 (ultrasonic horn 121h) and the anvil roll 122 (projection portion 122a) they pass between the elastic film 60 and the anvil roll 122.

- the number of sheet members is larger than the number of sheet members passing between the elastic film 60 and the ultrasonic roll 121.

- what passes between the elastic film 60 and the anvil roll 122 (protrusion portion 122a) is a two-sheet member of the stretchable non-woven fabric continuum 215L and the skin-side sheet continuum 213L.

- the protrusion 122a protruding outward in the radial direction of the anvil roll 122 is pressed against the elastic film 60, so that an impact acts on the elastic film. There is a risk that 60 will be torn.

- the elastic film 60 is less likely to be torn, and the surface layer 62 (low elastic layer) of the elastic film 60 can be easily maintained in a continuous state at the joint portion 50. Therefore, the fit of the belt portion 21 can be improved.

- the area ratio of the protrusion 122a on the outer peripheral surface of the anvil roll 122 is 1 to 9%.

- the "area ratio” means the ratio of the area of the protrusion 122a to the surface area of the outer peripheral surface of the anvil roll 122. That is, it means the ratio of the area of the joint portion 50 provided per the unit area of the belt portion 21.

- the area ratio can be calculated as follows, for example.

- the protrusions located at the center of the MD direction and the CD direction are the protrusions 122a1, and the protrusions arranged on both sides of the protrusions 122a1 in the CD direction are the MDs of the protrusions 122a2, 122a3 and the protrusions 122a1.

- the protrusions arranged on both sides in the direction are referred to as protrusions 122a4 and 122a5.

- a rectangular region U (a region shown by a dotted line in FIG.

- This rectangular region U is used as the unit area of the outer peripheral surface of the anvil roll 122. That is, when a plurality of rectangular regions U are repeatedly arranged, it becomes an outer peripheral surface of the anvil roll 122.

- the rectangular region U includes a protrusion 122a1 and a part of the protrusions 122a6 to 122a9. Therefore, by calculating the area of the rectangular region U and the area of a part of the protrusions 122a1 and 122a6 to 122a9 in the area of the rectangular region U, the area of the protrusions 122a on the outer peripheral surface of the anvil roll 122. The rate can be calculated.

- the ratio of the joint portion 50 to the surface area of the belt portion 21 becomes small, and the elastic film 60 and the exterior sheet 213,214 The joint strength with and may be weakened.

- the area ratio is larger than 9%, the ratio of the joint portion 50 to the surface area of the belt portion 21 becomes large, which may impair the elasticity of the elastic film or make the belt portion 21 hard to the touch. ..

- the area ratio of the protrusion 122a on the outer peripheral surface of the anvil roll 122 is set to 1% or more and 9% or less so that the joint strength between the elastic film 60 and the exterior sheets 213 and 214 is sufficiently strong. While maintaining the elasticity, the elasticity of the elastic film and the touch of the belt portion 21 are suppressed from being deteriorated.

- a cutting step (S103) is performed in which the continuous body of the joined base materials is cut into a predetermined shape.

- the cutting step can be performed using a cutting mechanism (not shown in FIG. 10).

- the inseam side region 212 of the belt portion 21 is molded into a trapezoidal shape.

- the front belt portion 21 (continuum) and the rear belt portion 22 (continuum) are formed from one base material (continuum). It may be.

- a continuous body of the exterior body 20 including the front belt portion 21, the rear belt portion 22, and the crotch portion 23 is formed, and the absorbent body 10 is attached to the skin side of the exterior body 20.

- the process is performed (S104).

- the absorbent body mounting step is performed by the absorbent body mounting mechanism 140 provided with the joining drum 141.

- the joining drum 141 is a cylindrical drum having a rotation axis C141 along the CD direction, and can rotate around the rotation axis C141 while holding the absorbent main body 10 on the outer peripheral surface thereof. Then, the holding of the absorbent main body 10 is released at the timing when the absorbent main body 10 held on the outer peripheral surface of the joining drum 141 and the continuous body of the exterior body 20 conveyed in the MD direction come into contact with each other, and the absorbent main body 10 is released. 10 is transferred to the skin side surface of the exterior body 20. As a result, the absorbent body 10 is joined to the continuum of the exterior body 20.

- a pants mold molding step of molding a continuum of various base materials to be conveyed into a pants mold is performed (S105).

- the pants mold molding mechanism 150 folds the continuous body of the exterior body 20 in half with the substantially center (see FIG. 2) in the CD direction (longitudinal direction of the absorbent body 10) as a crease, and a pair of engagements.

- the stoppers 24 and 24 are formed and molded into a pants shape continuous in the MD direction.

- a cutting step is performed in which the continuous base material molded into the pants type is cut into individual pants type diapers 1 (S106).

- 1 Diapers (pants-type disposable diapers), 1a waist opening, 1b leg opening, 10 absorbent body, 11 absorbent core, 12 top sheet, 13 back sheet, 20 exterior body, 21 front belt part, 22 rear belt part, 211, 221 Girth area, 212, 222 Inseam area, 213, 223 Skin side sheet (exterior sheet), 213L Skin side sheet continuum, 214, 224 non-skin side sheet (exterior sheet), 214L non-skin side sheet continuum, 215, 225 Stretchable non-woven fabric, 215L Stretchable non-woven fabric continuum, 23 Inseam, 24 Locking part, 41 Waist thread rubber, 42 Leg circumference thread rubber, 50 Joint (welded part), 60 elastic film, 60L elastic film continuum, 61 Elastomer layer (stretchable layer), 61c discontinuous part, 62 surface layer (low stretchable layer), 100 manufacturing equipment, 110 transport mechanism, 111-115 nip rollers, 120 joining mechanism, 121 ultrasonic roll, 121h

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Epidemiology (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Manufacturing & Machinery (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20810575.9A EP3949920A4 (en) | 2019-05-20 | 2020-03-25 | PANTS-TYPE DISPOSABLE DIAPER AND METHOD FOR MANUFACTURING PANTS-TYPE DISPOSABLE DIAPER |

| CN202080037196.5A CN113840586B (zh) | 2019-05-20 | 2020-03-25 | 内裤型一次性尿布及制造内裤型一次性尿布的方法 |

| US17/529,913 US20220071815A1 (en) | 2019-05-20 | 2021-11-18 | Pants-type disposable diaper and method for manufacturing pants-type disposable diaper |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019094756A JP6800277B2 (ja) | 2019-05-20 | 2019-05-20 | パンツ型使い捨ておむつ、及び、パンツ型使い捨ておむつの製造方法 |

| JP2019-094756 | 2019-05-20 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US17/529,913 Continuation US20220071815A1 (en) | 2019-05-20 | 2021-11-18 | Pants-type disposable diaper and method for manufacturing pants-type disposable diaper |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020235212A1 true WO2020235212A1 (ja) | 2020-11-26 |

Family

ID=73454118

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/013443 Ceased WO2020235212A1 (ja) | 2019-05-20 | 2020-03-25 | パンツ型使い捨ておむつ、及び、パンツ型使い捨ておむつの製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20220071815A1 (enExample) |

| EP (1) | EP3949920A4 (enExample) |

| JP (1) | JP6800277B2 (enExample) |

| CN (1) | CN113840586B (enExample) |

| WO (1) | WO2020235212A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023091281A (ja) * | 2021-12-20 | 2023-06-30 | 日本製紙クレシア株式会社 | パンツ型吸収性物品 |

| CN115645154B (zh) * | 2022-09-30 | 2025-11-04 | 尤妮佳股份有限公司 | 一种一次性吸收裤超声波复合生产线及工艺 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001507588A (ja) * | 1996-12-20 | 2001-06-12 | キンバリー クラーク ワールドワイド インコーポレイテッド | 封じ込めフラップと結合した脚部カフスを有する吸収性物品の製造方法 |

| JP2016010710A (ja) * | 2015-08-25 | 2016-01-21 | ユニ・チャーム株式会社 | 使い捨ておむつの製造装置及び使い捨ておむつの製造方法 |

| JP2016189826A (ja) | 2015-03-30 | 2016-11-10 | 大王製紙株式会社 | 吸収性物品及びその製造方法 |

| JP6286611B1 (ja) * | 2017-12-13 | 2018-02-28 | ユニ・チャーム株式会社 | 超音波シール方法及び超音波シール装置 |

| JP2019025225A (ja) * | 2017-08-03 | 2019-02-21 | 大王製紙株式会社 | 使い捨て着用物品及びその製造方法 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7112193B2 (en) * | 1996-09-30 | 2006-09-26 | Uni-Charm Corporation | Disposable diaper backsheet comprising composite having an elastic layer, inelastic layer and bonding pattern of obliquely intersecting lines |

| US6830800B2 (en) * | 1999-12-21 | 2004-12-14 | The Procter & Gamble Company | Elastic laminate web |

| US6537930B1 (en) * | 2000-05-18 | 2003-03-25 | Tredegar Film Products Corporation | Three-dimensional highly elastic film/non-woven composite |

| WO2005102682A2 (en) * | 2004-04-16 | 2005-11-03 | First Quality Nonwovens, Inc. | Plastically deformable nonwoven web |

| JP4508885B2 (ja) * | 2005-01-20 | 2010-07-21 | 花王株式会社 | 吸収性物品 |

| JP4934835B2 (ja) * | 2007-04-10 | 2012-05-23 | 株式会社瑞光 | 積層伸縮シートの製造方法 |

| JP5600275B2 (ja) * | 2010-09-02 | 2014-10-01 | スリーエム イノベイティブ プロパティズ カンパニー | 伸縮性積層シート |

| US20120323204A1 (en) * | 2011-06-15 | 2012-12-20 | Poole Lacey L | Disposable absorbent garment having colored facings and integral waistband |

| RU2566929C2 (ru) * | 2011-06-30 | 2015-10-27 | Ска Хайджин Продактс Аб | Способ образования эластичного ламината |

| WO2014179371A1 (en) * | 2013-05-03 | 2014-11-06 | The Procter And Gamble Company | Absorbent articles comprising stretch laminates |

| KR102506117B1 (ko) * | 2015-01-30 | 2023-03-03 | 다이오 페이퍼 코퍼레이션 | 신축 시트의 제조 방법 |

| WO2016159095A1 (ja) * | 2015-03-30 | 2016-10-06 | 大王製紙株式会社 | パンツタイプ使い捨ておむつ |

| JP6193429B1 (ja) * | 2016-03-24 | 2017-09-06 | 大王製紙株式会社 | 弾性フィルム伸縮構造の形成方法及び吸収性物品 |

| JP6298093B2 (ja) * | 2016-03-30 | 2018-03-20 | 大王製紙株式会社 | 吸収性物品の伸縮構造及びその製造方法 |

| JP6371434B1 (ja) * | 2017-04-03 | 2018-08-08 | 株式会社光洋 | 吸収性物品及び吸収性物品の製造方法 |

-

2019

- 2019-05-20 JP JP2019094756A patent/JP6800277B2/ja active Active

-

2020

- 2020-03-25 EP EP20810575.9A patent/EP3949920A4/en not_active Withdrawn

- 2020-03-25 WO PCT/JP2020/013443 patent/WO2020235212A1/ja not_active Ceased

- 2020-03-25 CN CN202080037196.5A patent/CN113840586B/zh active Active

-

2021

- 2021-11-18 US US17/529,913 patent/US20220071815A1/en not_active Abandoned

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001507588A (ja) * | 1996-12-20 | 2001-06-12 | キンバリー クラーク ワールドワイド インコーポレイテッド | 封じ込めフラップと結合した脚部カフスを有する吸収性物品の製造方法 |

| JP2016189826A (ja) | 2015-03-30 | 2016-11-10 | 大王製紙株式会社 | 吸収性物品及びその製造方法 |

| JP2016010710A (ja) * | 2015-08-25 | 2016-01-21 | ユニ・チャーム株式会社 | 使い捨ておむつの製造装置及び使い捨ておむつの製造方法 |

| JP2019025225A (ja) * | 2017-08-03 | 2019-02-21 | 大王製紙株式会社 | 使い捨て着用物品及びその製造方法 |

| JP6286611B1 (ja) * | 2017-12-13 | 2018-02-28 | ユニ・チャーム株式会社 | 超音波シール方法及び超音波シール装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3949920A4 (en) | 2022-06-15 |

| CN113840586B (zh) | 2022-12-23 |

| JP6800277B2 (ja) | 2020-12-16 |

| CN113840586A (zh) | 2021-12-24 |

| JP2020188871A (ja) | 2020-11-26 |

| US20220071815A1 (en) | 2022-03-10 |

| EP3949920A1 (en) | 2022-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5534839B2 (ja) | 吸収性物品 | |

| JP4971109B2 (ja) | 使い捨ておむつ | |

| JPH0515552A (ja) | 使い捨てパンツ及びその製造方法 | |

| JPWO2018154685A1 (ja) | 吸収性物品の製造方法、製造装置、及び吸収性物品 | |

| CN101453973B (zh) | 短裤型一次性尿布 | |

| JP2008264525A (ja) | 着用物品の製造方法 | |

| JP6761707B2 (ja) | 使い捨ておむつ | |

| JP6800277B2 (ja) | パンツ型使い捨ておむつ、及び、パンツ型使い捨ておむつの製造方法 | |

| JP4570594B2 (ja) | パンツ型使い捨ておむつ | |

| JP2013081600A (ja) | 使い捨ておむつ | |

| JP4912433B2 (ja) | パンツ型吸収性物品の製造方法 | |

| JP3783584B2 (ja) | パンツ型使い捨ておむつ | |

| JP3770118B2 (ja) | パンツ型使い捨ておむつ | |

| JP5830570B2 (ja) | 吸収性物品に係る複合シートの製造方法、及び製造装置 | |

| JP4573727B2 (ja) | パンツ型使い捨ておむつの製造方法 | |

| JP4202831B2 (ja) | パンツ型使い捨ておむつ | |

| JP4726673B2 (ja) | パンツ型吸収性物品及びその製造方法 | |

| JP4916297B2 (ja) | パンツ型吸収性物品の製造方法 | |

| JP4749256B2 (ja) | 複合シートの製造方法 | |

| JP2005211179A (ja) | パンツ型使い捨ておむつ | |

| JPH08117276A (ja) | はかせる型おむつの製造方法 | |

| JP6469038B2 (ja) | 使い捨ておむつ | |

| JPH08173476A (ja) | はかせる型おむつおよび製造方法 | |

| JPH08196567A (ja) | 立体パンツ型使いすておむつの製造方法 | |

| JPH08196566A (ja) | 立体パンツ型使いすておむつの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20810575 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2020810575 Country of ref document: EP Effective date: 20211105 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWW | Wipo information: withdrawn in national office |

Ref document number: 2020810575 Country of ref document: EP |