WO2020122132A1 - スライドレールユニット及びスライドレールユニットの製造方法 - Google Patents

スライドレールユニット及びスライドレールユニットの製造方法 Download PDFInfo

- Publication number

- WO2020122132A1 WO2020122132A1 PCT/JP2019/048524 JP2019048524W WO2020122132A1 WO 2020122132 A1 WO2020122132 A1 WO 2020122132A1 JP 2019048524 W JP2019048524 W JP 2019048524W WO 2020122132 A1 WO2020122132 A1 WO 2020122132A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheets

- rail

- main body

- reinforcing

- sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/24—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs

- C08J5/241—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres

- C08J5/243—Impregnating materials with prepolymers which can be polymerised in situ, e.g. manufacture of prepregs using inorganic fibres using carbon fibres

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B88/00—Drawers for tables, cabinets or like furniture; Guides for drawers

- A47B88/40—Sliding drawers; Slides or guides therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C29/00—Bearings for parts moving only linearly

- F16C29/04—Ball or roller bearings

Definitions

- the present disclosure relates to a slide rail unit and a method for manufacturing the slide rail unit.

- An example of a typical slide rail unit is a guide device that supports a drawer of furniture or a table so that it can move back and forth.

- Such a slide rail unit may be applied to an ottoman arranged in a train or an aircraft seat. The ottoman is used by passengers to rest their feet.

- Patent Document 1 discloses a slide rail unit used for furniture.

- This slide rail unit includes an outer rail, a center rail, an inner rail, a plurality of balls, and a cage.

- the outer rail is fixed to the furniture body and applied to the slide part of the furniture drawer.

- the inner rail is assembled so as to be movable relative to the outer rail.

- the inner rail is fixed to the drawer and assembled in the center rail so as to be relatively movable.

- the plurality of balls are rolling elements arranged between the rails.

- the cage is arranged to arrange the balls at predetermined intervals.

- the drawer is in a state of protruding from the furniture body.

- the inner rail is housed in the center rail and the center rail is housed in the outer rail due to the rolling of the plurality of balls.

- the drawer returns to the state of being housed in the furniture body.

- Such a slide rail unit is required to have strength and rigidity to withstand use in a state where it is pulled out by the maximum amount, and also dimensional accuracy to make the pulling operation smooth. Therefore, the outer rail, the center rail, and the inner rail included in the slide rail unit described in Patent Document 1 are precisely formed by roll forming a metal plate material such as SPCC.

- Such furniture is required to be lighter. Particularly in furniture having a plurality of drawers, reducing the weight of the slide rail unit attached to each drawer leads to reducing the weight of the entire furniture. Further, reducing the weight of the slide rail unit applied to equipment such as an ottoman arranged in a seat of a train or an aircraft also leads to improvement of fuel efficiency.

- the present disclosure aims to reduce the weight of the slide rail unit.

- a slide rail unit is a long first rail, and includes a first rail having a first facing surface extending along a longitudinal direction of the first rail, and the first rail.

- a second elongated rail extending along one rail, the second rail having a second facing surface facing the first facing surface, the first facing surface and the second facing surface.

- a rolling element arranged between the and.

- the second rail is assembled so as to be movable relative to the first rail.

- At least one of the first facing surface and the second facing surface is defined by a reinforcing portion formed of a fiber reinforced resin material.

- a method is a method for manufacturing a slide rail unit.

- the slide rail unit includes a first rail, a second rail extending along the first rail, and a plurality of rolling elements arranged between the first rail and the second rail. , Is provided.

- the method includes stacking a plurality of sheets made of fiber reinforced resin, and arranging the stacked plurality of sheets in a mold to form a molded body.

- Laminating the plurality of sheets includes laminating the plurality of sheets such that the orientation directions of the fibers are symmetrical with respect to the center of the plurality of sheets in the laminating direction.

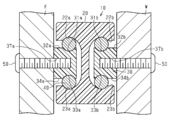

- FIG. 4 is a cross-sectional view taken along line 4-4 of FIG. 1, showing a state in which the slide rail unit of FIG. 1 is attached to furniture.

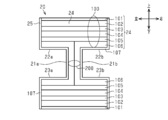

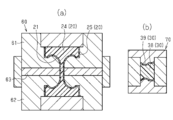

- the schematic diagram explaining the laminated structure of the outer rail of FIG. 7A is a diagram illustrating a method of manufacturing the outer rail of FIG. 2, and FIG. 7B is a diagram illustrating a method of manufacturing the inner rail of FIG. FIG.

- FIG. 8A is a diagram illustrating a test for measuring peel strength

- FIG. 8B is a graph showing actual measured values of peel strength.

- 9(a) and 9(b) are photographs of the surface of the test piece after the test for abrasion durability.

- 10(a) and 10(b) are photographs of the surface layer cross section of the test piece after the test for wear durability.

- the slide rail unit 10 of this embodiment will be described with reference to FIGS. 1 to 4.

- the slide rail unit 10 is used as a guide device that supports a drawer of furniture so as to be able to reciprocate.

- the example of the slide rail unit 10 attached to the right side of the drawer of furniture is demonstrated.

- the slide rail unit 10 will be defined as upward, downward, left, right, front and rear directions as shown in FIG.

- the terms “first”, “second”, etc. are used to distinguish similar components, and not necessarily in any particular contiguous or chronological order. It is not used to represent Further, in the specification, “left”, “right”, “front”, “rear”, “top”, “bottom”, “side (side)” “top”, “bottom”, “height”, etc. The terms are used to indicate their relative arrangement or configuration in the illustrated state and not necessarily their permanent relative position or their in-use position. Further, in the description of the stepwise numerical range, a range in which the upper limit and the lower limit are arbitrarily combined is also assumed.

- the slide rail unit 10 includes a long outer rail 20, two long inner rails 30, a plurality of balls 40, an outer rail side rack 81, and an inner rail side.

- the rack 82, the cage 83, and the pinion 84 are provided.

- the longitudinal direction of the slide rail unit 10, the outer rail 20, and the inner rail 30 is the front-back direction.

- One of the outer rail 20 and the inner rail 30 is the first rail, and the other is the second rail.

- the outer rail 20 is the first rail and the inner rail 30 is the second rail.

- the plurality of balls 40 are rolling elements arranged between the outer rail 20 and the inner rail 30.

- the outer rail side rack 81, the inner rail side rack 82, the cage 83, and the pinion 84 are arranged in order to arrange the plurality of balls 40 at predetermined intervals.

- the shape of the slide rail unit 10 is left-right asymmetrical, and is substantially point-symmetrical around the front, rear, left, and right center points.

- the number of the member or portion arranged on the left side of FIG. The numbers will be described by adding "b”.

- the left inner rail 30 is “30a”

- the right inner rail 30 is “30b”.

- both the inner rails 30a and 30b are collectively described, they are simply referred to as "inner rail 30".

- the outer rail 20 has a substantially H-shaped cross section.

- the outer rail 20 has a flat upper surface, a flat lower surface, and grooves 21a and 21b extending in the longitudinal direction.

- the grooves 21a and 21b are open on the left surface and the right surface of the outer rail 20, respectively. Further, the grooves 21a and 21b are open to the front surface and the rear surface of the outer rail 20.

- Each groove 21 has a first surface 22 facing downward and a second surface 23 facing upward.

- Each groove 21 has a curved surface that is smoothly connected from the first surface 22 to the second surface 23. This curved surface is the rolling surface of the ball 40.

- the ball 40 is arranged so as to roll along the curved surface along the longitudinal direction of the outer rail 20.

- FIG. 2 shows a state of the slide rail unit 10 in the process of being manufactured, more specifically, a state before a machining step of machining the outer rail 20, which will be described later.

- the outer rail 20 becomes the shape shown in FIG. 1 by going through the processing steps from the state of FIG.

- the shape of the outer rail 20 is left-right asymmetric, and is substantially point-symmetric with respect to the front, rear, left, and right center points.

- the outer rail 20 has a recessed portion 26b recessed upward from the first surface 22b and a recessed portion 27b recessed downward from the second surface 23b in the groove 21b.

- the recesses 26b and 27b extend forward from the vicinity of the center of the groove 21b in the longitudinal direction.

- the outer rail 20 has a recess 26a recessed upward from the first surface 22a and a recess 27a recessed downward from the second surface 23a in the groove 21a.

- the recesses 26a and 27a extend forward from the vicinity of the center of the groove 21a in the longitudinal direction.

- An outer rail side rack 81 is attached to each of the recesses 26 and 27.

- the inner rails 30a and 30b are assembled in the grooves 21a and 21b, respectively.

- the inner rail 30a has the same shape as the inner rail 30b.

- the inner rails 30a and 30b are assembled in the outer rail 20 in a state in which the upper, lower, left, right, front, and rear are inverted from each other. That is, the inner rails 30a and 30b are arranged so as to be point-symmetric with respect to the center of the outer rail 20 in the longitudinal direction.

- each inner rail 30 has a substantially rectangular cross-sectional shape.

- the inner rail 30b has an upper surface and a lower surface.

- the left half of the upper surface is the curved surface 31b, and the right half of the upper surface is the flat surface 32b.

- the right edge of the curved surface 31b is connected to the left edge of the flat surface 32b.

- the left half of the lower surface is the curved surface 33b, and the right half of the lower surface is the flat surface 34b.

- the right end edge of the curved surface 33b is connected to the left end edge of the flat surface 34b.

- the curved surfaces 31b and 33b are rolling surfaces of the ball 40.

- the ball 40 is arranged so as to roll along the longitudinal direction of the inner rail 30b.

- the inner rail 30b has a recess 35b recessed downward from the flat surface 32b and a recess 36b recessed upward from the flat surface 34b.

- the recesses 35b and 36b extend rearward from the vicinity of the center in the longitudinal direction.

- An inner rail side rack 82 is attached to each of the recesses 35b and 36b.

- the inner rail 30b has a plurality of holes 37b opened on the right side of the inner rail 30b.

- the plurality of holes 37b are arranged at intervals in the longitudinal direction. Since the inner rail 30a has the same shape as the inner rail 30b, the description thereof will be omitted.

- the inner rail 30a is fixed to the furniture main body F by a plurality of fixing members 50, such as screws, which are inserted into the plurality of holes 37a.

- the inner rail 30b is fixed to the drawer W by a plurality of fixing members 50, such as screws, which are respectively inserted in the plurality of holes 37b.

- the plurality of balls 40 are longitudinally arranged between the first surface 22 of the outer rail 20 and the curved surface 31 of the inner rail 30, and between the second surface 23 of the outer rail 20 and the curved surface 33 of the inner rail 30. It is arranged at intervals.

- a pinion 84 is arranged between the outer rail side rack 81 and the inner rail side rack 82. The pinion 84 meshes with the racks 81 and 82. When the inner rail 30 moves relative to the outer rail 20 along the longitudinal direction, the pinion 84 rotates along the racks 81 and 82 and the ball 40 rolls.

- the outer rail 20 and the inner rail 30 are a laminated body in which a plurality of sheet materials are laminated.

- One sheet material includes a plurality of sheets or layers made of fiber reinforced resin laminated in the thickness direction.

- the ball 40, the outer rail side rack 81, the inner rail side rack 82, the cage 83 and the pinion 84 are made of metal, for example.

- the ball 40 may be entirely made of metal.

- the ball 40 may include a synthetic resin core and a metal layer coated on the surface thereof. Alternatively, the ball 40 may include a metal core and a resin layer coated on the surface thereof.

- FIGS. 5 and 6 are schematic diagrams illustrating a laminated structure.

- FIG. 5 schematically shows the structure of the outer rail 20

- FIG. 6 schematically shows the structure of the inner rail 30.

- the conventionally known fiber-reinforced resin can be used as the material of the outer rail 20 and the inner rail 30.

- fibers constituting the fiber-reinforced resin include carbon fibers, glass fibers, various ceramic fibers, boron fibers, metal fibers such as copper or stainless steel, amorphous fibers, organic fibers such as aromatic polyamide, or a mixture thereof. It is a woven fabric.

- carbon fiber has high flexural rigidity due to its high elastic modulus, and has a low specific gravity of about 1.8.

- a conventionally known thermosetting resin can be appropriately used as the reinforcing resin.

- thermosetting resins are epoxy resins, phenolic resins, polyester resins, vinyl ester resins, or unsaturated polyester resins.

- the outer rail 20 includes an outer body portion 24 that is a first body portion and an outer reinforcement portion 25 that is a first reinforcement portion.

- the outer body portion 24 includes a plurality of outer body sheets made of fiber reinforced resin and extending in the longitudinal direction of the outer rail 20. These outer body sheets are laminated in a direction intersecting the first surface 22 and the second surface 23, which are the rolling surfaces of the balls 40.

- the outer body sheet is the first body sheet.

- Outer surfaces, excluding the upper surface, the lower surface, the front surface, and the rear surface, of the plurality of outer surfaces of the outer body portion 24 are defined by the outer reinforcing portion 25.

- the outer reinforcing portion 25 is a first reinforcing portion and includes a plurality of reinforcing sheets made of fiber reinforced resin extending in the longitudinal direction. These reinforcing sheets are laminated in a direction intersecting with the outer surface of the outer body 24.

- the inner rail 30 includes an inner body portion 38 that is a second body portion and an inner reinforcement portion 39 that is a second reinforcement portion.

- the inner body portion 38 includes a plurality of inner body sheets made of fiber reinforced resin and extending in the longitudinal direction of the inner rail 30. These inner body sheets are laminated in a direction along the curved surfaces 31 and 33 which are rolling surfaces of the ball 40.

- the inner body sheet is the second body sheet.

- the inner reinforcing portion 39 defines an upper surface of the inner rail 30 including the curved surface 31 and a lower surface of the inner rail 30 including the curved surface 33.

- the inner reinforcing portion 39 includes a plurality of inner reinforcing sheets made of fiber reinforced resin and extending in the longitudinal direction. These inner reinforcing sheets are laminated in a direction intersecting the outer surface of the inner body portion 38.

- the inner rail 30b is shown in FIG. 6, the inner rail 30a also has the same structure as the inner rail 30b.

- Each sheet material forming the outer rail 20 and the inner rail 30 includes a plurality of laminated sheets or a plurality of layers. Each sheet is formed by cutting a prepreg sheet into a predetermined size. The prepreg sheet includes a plurality of fiber bundles aligned in one direction. Each fiber bundle is an assembly of filaments. A sheet in which the fibers of the sheet are oriented along the longitudinal direction of the outer rail 20 and the inner rail 30 is called a 0° oriented sheet, and a sheet in which the fibers of the sheet are oriented perpendicular to the longitudinal direction is oriented at 90°.

- the sheet in which the fibers of the sheet are oriented so as to intersect at 45° to the longitudinal direction is referred to as a ⁇ 45° oriented sheet (+45° oriented sheet and ⁇ 45° oriented sheet).

- the outer reinforcement 25 has a laminated structure that allows the balls 40 to roll smoothly. Further, the inner reinforcing portion 39 has a laminated structure in consideration of smoothly rolling the balls 40 and further reinforcing the rolling surface.

- FIG. 5 schematically shows a plurality of sheet materials 101 to 107 that form the outer rail 20.

- the laminated body in which the sheet materials 101 to 106 are laminated constitutes the outer body portion 24, and the sheet material 107 constitutes the outer reinforcing portion 25.

- All of the plurality of outer reinforcing sheets included in the sheet material 107 are 0° oriented sheets in which the fiber orientation direction is oriented along the longitudinal direction of the outer rail 20. That is, the orientation direction of the fibers of the outer reinforcing portion 25 coincides with the rolling direction of the ball 40. Therefore, the ball 40 rolls smoothly along the rolling surface defined by the outer reinforcing portion 25.

- the outer reinforcing sheet is a so-called light weight fiber reinforced resin having a smaller fiber basis weight than the outer body sheet.

- the fiber weight of the outer reinforcing sheet can be 10 to 180 g/m 2 .

- the fiber areal weight is increased.

- the larger the number of filaments contained in one fiber bundle the larger the fiber bundle diameter.

- the fiber areal weight is preferably 180 g/m 2 or less.

- the basis weight should be less than 150 g/m 2 .

- the fiber areal weight is preferably 25 g/m 2 or more, more preferably 50 g/m 2 or more.

- the fiber areal weight is 50 g/m 2 or more and 140 g/m 2 or less, not only the resin-coated surface of the ball but also the surface of the outer reinforcing portion 25 is worn even if the surface is a metal ball. The effect of suppressing

- FIG. 6 schematically shows a plurality of sheet materials 111 to 119 that form the inner rail 30.

- the laminated body of the sheet materials 111 to 118 constitutes the inner body portion 38, and the sheet material 119 constitutes the inner reinforcing portion 39.

- the plurality of inner reinforcing sheets included in the sheet material 119 are all 0° oriented sheets in which the fiber orientation direction is oriented along the longitudinal direction of the inner rail 30. Therefore, the ball 40 rolls smoothly along the rolling surface defined by the inner body portion 38.

- the fiber weight of the inner reinforcing sheet is preferably smaller than the fiber weight of the inner body sheet.

- the fiber areal weight of the inner reinforcing sheet is preferably in the same numerical range as the fiber areal weight of the outer reinforcing sheet. This reduces the sliding resistance with the ball 40. Further, abrasion of the surface of the inner reinforcing portion 39 due to rolling of the balls 40 is suppressed.

- the plurality of inner body sheets included in the sheet materials 111 to 119 are generally stacked in the direction along the curved surfaces 31 and 33.

- the direction along the curved surfaces 31 and 33 is the left-right direction shown in FIG. 6.

- a laminated body in which a plurality of sheets or sheet materials are laminated generally tends to cause warpage in the laminating direction.

- the inner reinforcing sheets of the inner body portion 38 are laminated in the left-right direction. Therefore, even if a warp occurs in the stacking direction, the plurality of fixing members 50 can suppress the warp of the inner body portion 38.

- the inner body sheets are laminated in the left-right direction, the stress from the balls 40 rolling along the curved surfaces 31 and 33 easily acts between the layers of the inner body sheet.

- the inner reinforcing sheets that define the curved surfaces 31 and 33 are stacked in a direction perpendicular to the stacking direction of the inner body sheets. Therefore, the laminated cross section of the sheet material is not exposed to the outside.

- the inner reinforcing portion 39 suppresses delamination of the inner body sheet that forms the inner body portion 38.

- the inner reinforcing portion 39 not only smoothly rolls the ball 40, but also reinforces the rolling surface.

- the outer body portion 24 and the inner body portion 38 are designed in a laminated structure that gives rigidity to the outer rail 20 and the inner rail 30, for example, bending rigidity and torsional rigidity. These laminated structures are also designed in consideration of suppressing warpage after molding and machining.

- the laminated body may have anisotropy due to the laminated structure and warpage may occur. Further, warpage may occur even if the shape of the laminated body is asymmetrical to the left and right, and warpage may occur also by performing machining after molding with a die.

- the properties of the outer rail 20, such as bending rigidity or torsional rigidity may change.

- the inner rail 30 the plurality of sheets forming the outer rail 20 and the inner rail 30 are laminated such that the orientation directions of the fibers are different in order to suppress the warpage of each of the sheets.

- the plurality of sheets are laminated so as to satisfy the following conditions.

- a plurality of regions in which a plurality of first sheet materials are laminated are included, and a plurality of first sheet materials constituting each region are laminated so that the orientation directions of fibers are symmetrical with respect to the center in the laminating direction. Being (symmetrically stacked).

- Each of the first sheet materials should include a plurality of sheets or a plurality of layers that are laminated (pseudo-isotropic lamination) so as to have isotropicity as a whole by the combination of the orientation directions of the fibers.

- ⁇ Condition 2-2> A second sheet material is laminated in a plurality of regions, and the second sheet material is laminated so as to have anisotropy (non-pseudo isotropic) in consideration of warpage due to machining after molding. Including a plurality of (laminated) sheets or a plurality of layers.

- the outer body 24 includes an upper region 100 above the groove 21, an intermediate region 200 sandwiched between the grooves 21 a and 21 b, and a lower region below the groove 21.

- the upper region 100, the middle region 200, and the lower region are examples of the plurality of first regions.

- Each of the sheet materials 106 and 107 includes two sheet materials that are symmetrically arranged.

- the sheet materials 102 to 106 are first sheet materials, and the sheet materials 101 and 107 are second sheet materials.

- Each sheet material includes a plurality of sheets or a plurality of layers stacked in the thickness direction.

- the upper region 100 includes the sheet materials 102 to 106 stacked in order from the top.

- the sheet materials 102 to 106 are stacked symmetrically with respect to the center of the sheet material 104 in the stacking direction (vertical direction) (symmetrical stacking). More specifically, the upper halves of the sheet materials 102, 103 and the sheet material 104 and the lower halves of the sheet materials 105, 106 and the sheet material 104 are symmetrical with respect to the center of the sheet material 104 in the thickness direction. ing.

- the lower region includes the sheet materials 106, 105, 104, 103 and 102 stacked in order from the top.

- the sheet materials 106 to 102 in the lower area are laminated vertically symmetrically with respect to the sheet materials 102 to 106 in the upper area 100 (symmetrical lamination).

- the two sheet materials included in the sheet material 106 are stacked in the left-right direction in a state of being abutted against each other at the center in the left-right direction. That is, the two sheet materials forming the sheet material 106 are laminated so as to be bilaterally symmetrical (symmetrical lamination).

- the orientations of a plurality of sheets (for example, four sheets) included in the sheet material 102 are 0° orientation, +45° orientation, ⁇ 45° orientation, and 90° orientation in order from the top.

- the orientations of the plurality of sheets (for example, four sheets) included in the sheet material 103 are 90° orientation, ⁇ 45° orientation, +45° orientation, and 0° orientation in this order from the top.

- the orientations of the plurality of sheets (for example, three sheets) included in the upper half of the sheet material 104 are 0° orientation, ⁇ 45° orientation, and +45° orientation in this order from the top.

- the orientations of the plurality of sheets (for example, four sheets) included in the sheet material 105 are 0° orientation, +45° orientation, ⁇ 45° orientation, and 90° orientation in this order from the top.

- the orientation of the plurality of sheets (for example, four sheets) included in the sheet material 106 is 90° orientation, ⁇ 45° orientation, +45° orientation, and 0° orientation in this order from the top.

- the orientations of the plurality of sheets (for example, three sheets) included in the lower half of the sheet material 104 are +45° orientation, ⁇ 45° orientation, and 0° orientation in this order from the top.

- each sheet material has a plurality of sheets (that is, a multiple of 4 or 3) as one set of 4 or 3 sheets laminated in the above orientation. Sheet) is preferable.

- a plurality of sheets having the same orientation may be a single layer and a plurality of layers having different orientations may be laminated.

- the sheet material 102 includes a plurality of sheets (for example, four sheets or four layers) that are a combination of 0° orientation, 90° orientation, and ⁇ 45° orientation. Thereby, the sheet materials 102 are laminated so as to have isotropicity as a whole. Similar to the sheet material 102, the sheet materials 103, 105 and 106 are also laminated so as to have isotropicity as a whole. Therefore, the sheet materials 102 to 106 are the first sheet materials that satisfy the condition 2-1.

- the plurality of first sheets cut out from the prepreg sheet which is an anisotropic material are laminated so as to have isotropicity, and further the plurality of first sheet materials are symmetrically laminated to form a mold. The occurrence of warpage after being suppressed is suppressed.

- the outer rail 20 having a left-right asymmetrical shape it is machined, for example, cut and drilled after being molded with a mold. Even a laminated body satisfying the conditions 1 and 2-1 may warp due to the asymmetrical shape and warp due to machining.

- the outer body portion 24 of the present embodiment further includes a second sheet material for further anisotropy in the laminated body satisfying the condition 1 and the condition 2-1 so as to further satisfy the condition 2-2. It is stacked.

- the plurality of sheets included in the sheet materials 101 and 104 in the upper region 100 are laminated so as to have anisotropy. Due to the presence of the sheet materials 101 and 104, the upper region 100 has anisotropy as a whole.

- a plurality of sheets (for example, three sheets or three layers) included in the sheet material 101 have 0° orientation, 90° orientation, and 0° orientation in this order from the top, and a plurality of sheets (for example, six sheets) included in the sheet material 104.

- the sheets of () are, in order from the top, 0° orientation, ⁇ 45° orientation, +45° orientation, +45° orientation, ⁇ 45° orientation, and 0° orientation.

- the outer body portion 24 has anisotropy as a whole.

- a plurality of sheet materials and sheets included in the inner body portion 38 are also laminated so as to satisfy the above-mentioned condition 1, condition 2-1 and condition 2-2.

- the inner body portion 38 includes an inner region 300 sandwiched between the curved surfaces 31b and 33b and an outer region 400 sandwiched between the flat surfaces 32b and 34b. Areas 300 and 400 are examples of a plurality of second areas.

- the sheet materials 111 to 115 in the inner region 300 are laminated such that the fiber orientation directions are bilaterally symmetrical with respect to the center of the sheet material 113 in the laminating direction (horizontal direction) ( Symmetrical stacking). More specifically, the left halves of the sheet members 111 and 112 and the sheet member 113 and the right halves of the sheet members 114 and 115 and the sheet member 113 are symmetrical with respect to the center of the sheet member 113 in the left-right direction. ing.

- the sheet materials 116 and 117 in the outer region 400 are laminated such that the orientation directions of the fibers are bilaterally symmetrical with respect to the boundary between the sheet materials 116 and 117.

- the plurality of sheets included in the sheet materials 112 and 114 in the inner area 300 are laminated so as to have isotropicity, and the plurality of sheets included in the sheet materials 116 and 117 in the outer area 400 are included.

- the sheets are laminated so as to be isotropic.

- the inner rail 30 has a left-right asymmetrical shape, like the outer rail 20. Further, when the inner rail 30 is manufactured, warping occurs because it is machined, for example, cut and drilled after being molded with a mold. In order to suppress such warpage, a plurality of sheets included in the sheet materials 111, 113, and 115 in the inner region 300 are laminated so as to have anisotropy so as to satisfy the condition 2-2.

- the inner region 300 as a whole has anisotropy due to the presence of the sheet materials 111, 113, and 115 that are the second sheet materials.

- the outer region 400 is provided with the sheet material 118 that is the second sheet material, so that the entire outer area 400 has anisotropy. As a result, the inner body portion 38b has anisotropy as a whole.

- the method for manufacturing the outer rail 20 includes a cutting process, a laminating process, a molding process, and a processing process.

- a cutting step a plurality of sheets are formed by appropriately cutting a prepreg sheet in which the fiber reinforced resin is aligned in one direction into a predetermined size.

- the laminating step a plurality of sheets are laminated to form a sheet material, and further a plurality of sheet materials are laminated.

- the molding step a plurality of laminated sheet materials are placed in a mold to mold a molded body.

- the processing step the molded body taken out from the mold is subjected to mechanical processing, for example, cutting processing and drilling processing.

- a plurality of outer body sheets are laminated so that the outer body portion 24 has the above-mentioned laminated structure.

- a plurality of outer reinforcing sheets forming the outer reinforcing portion 25 are laminated and arranged in advance on the inner surface of the mold 60 shown in FIG. 7A.

- a plurality of inner body sheets are laminated so that the inner body portion 38 has the above-described laminated structure.

- a plurality of inner reinforcing sheets constituting the inner reinforcing portion 39 are laminated and arranged in advance on the inner surface of the mold 70 shown in FIG. 7B.

- the outer reinforcing sheet and the inner reinforcing sheet are laminated in consideration of the machining allowance in the polishing step in the subsequent processing step.

- a plurality of laminated outer body sheets are placed in a mold 60 in which a plurality of outer reinforcing sheets are placed, and the die is clamped.

- a mold body (laminate) in which a plurality of outer body sheets and a plurality of outer reinforcing sheets are integrated is molded by clamping and heating the mold 60.

- the mold 60 has an undercut portion for forming the groove 21 of the outer rail 20. Therefore, it is not necessary to cut the shape of the groove 21 in the processing step described later, or it is possible to reduce the portion to be cut.

- the mold 60 may include a slide mold 63 in addition to the upper mold 61 and the lower mold 62, as shown in FIG. 7A, for example. In this case, the molded body can be easily demolded.

- a plurality of laminated inner body sheets are arranged in a mold 70 in which a plurality of inner reinforcing sheets are arranged, and the mold is clamped.

- a molded body (laminate) in which a plurality of inner body sheets and a plurality of inner reinforcing sheets are integrated is molded.

- recesses 26 and 27 for mounting the outer rail side rack 81 are formed on the outer rail 20, and recesses 35 and 36 for mounting the inner rail side rack 82 are formed on the inner rail 30. Further, if necessary, a cutting process for adjusting the shape of the groove 21 of the outer rail 20 is performed.

- the machining includes a boring process for boring a hole 37 and a polishing process for polishing the surface of the outer rail 20 and the surface of the inner rail 30.

- the outer rail 20 and the inner rail 30 are entirely made of fiber reinforced resin.

- the inner rail 30 is arranged in the groove 21 of the outer rail 20.

- a plurality of balls 40 are arranged between the first surface 22 of the outer rail 20 and the curved surface 31 of the inner rail 30, and between the second surface 23 of the outer rail 20 and the curved surface 33 of the inner rail 30.

- the first surface 22 and the second surface 23 are first opposing surfaces

- the curved surfaces 31 and 33 are second opposing surfaces.

- the first and second facing surfaces that are in contact with the balls 40 are defined by the reinforcing portion (outer reinforcing portion 25 and inner reinforcing portion 39) in which a plurality of reinforcing sheets made of fiber reinforced resin are laminated.

- the plurality of reinforcing sheets forming the outer reinforcing portion 25 and the inner reinforcing portion 39 are made of fiber reinforced resin and extend in the longitudinal direction of the outer rail 20 and the inner rail 30. Since these reinforcing sheets are laminated in the direction perpendicular to the facing surface, the laminated cross sections of the plurality of reinforcing sheets are not exposed on the facing surface. Therefore, the sliding resistance of the ball 40 on the facing surface can be reduced.

- the plurality of inner body sheets forming the inner body portion 38 are made of fiber reinforced resin and extend in the longitudinal direction. These inner body sheets are stacked in the direction along the curved surfaces 31 and 33 on which the balls 40 roll. Further, the plurality of inner reinforcing sheets forming the inner reinforcing portion 39 defining the curved surfaces 31 and 33 are made of fiber reinforced resin and extend in the longitudinal direction. These inner reinforcing sheets are laminated in a direction perpendicular to the curved surfaces 31, 33. That is, the laminating direction of the inner reinforcing sheet forming the inner reinforcing portion 39 is perpendicular to the laminating direction of the inner body sheet forming the inner body portion 38.

- the stress from the ball 40 acts on the opposing surfaces (curved surfaces 31, 33), delamination of the inner body sheet is suppressed. Further, the presence of the inner reinforcing portion 39 increases the strength of the curved surfaces 31 and 33 which are the rolling surfaces of the ball 40.

- the inner reinforcement sheet forming the inner reinforcement portion 39 has a smaller fiber basis weight than the inner body sheet forming the inner body portion 38.

- the outer reinforcement sheet forming the outer reinforcement portion 25 has a smaller fiber basis weight than the outer body sheet forming the outer body portion 24.

- the outer rail 20 and the inner rail 30 having the left-right asymmetrical shape have a region in which a plurality of first sheet materials are symmetrically stacked and a second sheet material in which a plurality of sheets are anisotropically stacked. Including. Therefore, the occurrence of warpage in the outer rail 20 and the inner rail 30 can be suppressed. In addition, it is possible to suppress the occurrence of warpage due to machining after molding with a mold. Therefore, dimensional accuracy can be improved even with an asymmetric rail.

- the mold 60 used when manufacturing the outer rail 20 includes an upper mold 61, a lower mold 62, and a slide mold 63. Therefore, even if the mold 60 has an undercut portion for forming the groove 21 of the outer rail 20, the mold can be easily removed.

- the above embodiments can be modified as follows.

- the above-described embodiments and the following modified examples can be applied in combination with each other within a technically consistent range.

- the shapes of the outer rail 20 and the inner rail 30 can be arbitrarily changed.

- two long rails corresponding to each other may have a rectangular cross-sectional shape, and balls as rolling elements may be arranged between the two planes.

- the outer rail 20 does not have to have one of the grooves 21a and 21b.

- one inner rail 30 may be assembled in one groove 21 of the outer rail 20 so as to be relatively movable.

- the slide rail unit 10 may be applied not only to a guide device for pulling out furniture, but also to an ottoman installed on a train or an aircraft seat.

- -Parts of the outer rail 20 and the inner rail 30 may be formed of a metal material.

- only the outer reinforcing portion 25 and the inner reinforcing portion 39 that define the facing surface may be made of fiber reinforced resin, and the other portions may be made of metal. Even in this case, the weight of the slide rail unit 10 can be reduced as compared with the case where the whole is made of a metal material.

- Only one of the outer reinforcing portion 25 and the inner reinforcing portion 39 may be made of fiber reinforced resin, and the other portions may be made of metal. Even in this case, the weight of the slide rail unit 10 can be reduced as compared with the case where the whole is made of a metal material.

- the slide rail unit 10 does not need to include the outer reinforcing portion 25.

- the outer body sheets made of fiber reinforced resin that define the rolling surfaces (the first surface 22 and the second surface 23) of the outer rail 20 are stacked in a direction perpendicular to the rolling surfaces. Therefore, the outer body sheet is unlikely to be affected by the stress from the balls 40.

- the stacking direction of the inner body sheets that form the inner body portion 38 may be perpendicular to the rolling surfaces (curved surfaces 31, 33).

- the outer reinforcing portion 25 may be arranged only on the portion of the first surface 22 and the second surface 23 on which the ball 40 rolls.

- the inner reinforcing portion 39 may not define the flat surfaces 32 and 34, but may define only the curved surfaces 31 and 33.

- the laminated structure of the outer rail 20 and the laminated structure of the inner rail 30 can be arbitrarily changed. For example, if the above condition 1, condition 2-1 and condition 2-2 are satisfied and the laminated structure is capable of suppressing the warp of the outer rail 20 and the inner rail 30, any sheet material is laminated so as to have anisotropy. You may.

- the rolling element for relatively moving the outer rail 20 and the inner rail 30 is not limited to the ball 40, but may be, for example, a roller. (Verification example 1) The inventor verified the effect of reinforcement by disposing the inner reinforcement portion 39 on the inner rail 30.

- a test piece imitating the inner rail was molded.

- the test piece has the inner reinforcing portion 39 on the upper surface but does not have the inner reinforcing portion 39 on the lower surface.

- the molded inner rail was divided at the middle in the vertical direction to obtain two divided pieces. The two pieces are shown in FIG. 8(a).

- the split piece on the left side of FIG. 8A is a verification piece having an inner reinforcing portion 39 defining the curved surface 31, and the split piece on the right side of FIG. 8A is an inner reinforcing portion defining the curved surface 33. Control piece without 39.

- the ball 40 was placed on the curved surfaces 31 and 33 of the two divided pieces, and a load was applied from above with the ball 40 in contact with the bottom of the rolling surface at one point. The load applied was gradually increased, and the displacement amount (mm) of the inner body sheet at the inner body portion 38 at that time was measured.

- FIG. 8B the horizontal axis represents the displacement amount (mm) and the vertical axis represents the test force (N).

- the result of the verification piece having the inner reinforcing portion 39 is shown by a solid line in FIG. 8B, and the result of the control piece having no inner reinforcing portion 39 is shown by a dotted line in FIG. 8B. According to FIG. 8B, it can be seen that the verification piece having the inner reinforcing portion 39 has a strength of about 700 N higher than that of the control piece.

- the sheet material forming the reinforcing portion is formed of a so-called light weight fiber reinforced resin having a smaller fiber basis weight than the sheet material forming the main body portion.

- the surface is made smooth and the rolling of the balls 40 is made smooth, and the wear of the surface is suppressed.

- Verification Example 2 it was verified how smooth the surface is and how much the surface wear is suppressed by changing the fiber areal weight of the fiber reinforced resin of the test piece.

- the two test pieces have different basis weights because the surface layer of 0.3 mm is formed of different prepreg sheets.

- the other parts of the two test pieces have the same structure.

- ⁇ Measurement of surface roughness> The surface roughness of two test pieces was measured. The measuring method of the surface roughness is as follows.

- Table 1 shows the measurement results of surface roughness.

- the amount of wear is considered to be equivalent to the difference in height of the bearing races of the test piece before and after the test (hereinafter referred to as wear depth). Therefore, the wear depth of the two test pieces was measured with a laser microscope and used as an index of wear durability.

- the test machine, test conditions, and measurement method used are as follows.

- ⁇ Abrasion durability tester Thrust tester (FJ-5HL)

- Bearing material SUJ2 (Use 6 bearings per test piece, use new bearing for each test piece)

- -Test method Three test points were extracted from the bearing race. The wear depth at each test location was measured with a laser microscope. For each test piece, the average value of the measured values at three locations was calculated.

- FIGS. 9(a) and 9(b) show surface photographs of the test piece after the test

- FIGS. 10(a) and 10( show photographs of surface cross-sections of the test piece after the test taken with a microscope. Shown in b). The microscope photograph was taken at a magnification of 1000 times using VHX-6000 as a device to be used.

- 9(a) and 10(a) are photographs of the first test piece having a basis weight of 100 g/m 2

- FIGS. 9(b) and 10(b) are second tests having a basis weight of 150 g/m 2 .

- a photo of one piece is a photo of one piece.

- the cross section of the carbon fiber of each test piece and the resin appear.

- the carbon fibers of the first test piece in FIG. 10(a) are arranged more evenly than the carbon fibers of the second test piece in FIG. 10(b).

- the sheet of the second test piece contains a larger number of fiber bundles than the sheet of the first test piece due to the increased fiber basis weight. Therefore, the number of boundary portions between fiber bundles is large. Furthermore, since the fibers of the sheet of the second test piece are clogged, it is difficult to arrange the fibers uniformly. For these reasons, it is considered that the first test piece in which the carbon fibers are arranged more uniformly exerted the stress when the load of the bearing was applied.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Inorganic Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bearings For Parts Moving Linearly (AREA)

- Drawers Of Furniture (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020559293A JP7344903B2 (ja) | 2018-12-12 | 2019-12-11 | スライドレールユニット及びスライドレールユニットの製造方法 |

| CN201980081256.0A CN113195913B (zh) | 2018-12-12 | 2019-12-11 | 滑轨单元及滑轨单元的制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018-232292 | 2018-12-12 | ||

| JP2018232292 | 2018-12-12 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020122132A1 true WO2020122132A1 (ja) | 2020-06-18 |

Family

ID=71076447

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/048524 Ceased WO2020122132A1 (ja) | 2018-12-12 | 2019-12-11 | スライドレールユニット及びスライドレールユニットの製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP7344903B2 (enExample) |

| CN (1) | CN113195913B (enExample) |

| WO (1) | WO2020122132A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024235634A1 (de) | 2023-05-15 | 2024-11-21 | Accuride International Gmbh | Teleskopschiene |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113775647A (zh) * | 2021-09-13 | 2021-12-10 | 广东欧拉五金科技有限公司 | 一种钢珠滑轨用防止出现钢珠错位的装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS54126818U (enExample) * | 1978-02-22 | 1979-09-04 | ||

| JP2003083403A (ja) * | 2001-09-11 | 2003-03-19 | Tsubakimoto Chain Co | 伝動装置用合成樹脂ガイド |

| JP2017219177A (ja) * | 2016-06-10 | 2017-12-14 | 日本精工株式会社 | 一軸アクチュエータ |

| JP2018044657A (ja) * | 2016-09-16 | 2018-03-22 | Thk株式会社 | 運動案内装置の製造方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5775786A (en) * | 1997-02-05 | 1998-07-07 | Haworth, Inc. | Drawer slide |

| JP3600760B2 (ja) * | 1999-08-24 | 2004-12-15 | 住友ゴム工業株式会社 | ラケットフレーム |

| JP4088093B2 (ja) * | 2002-04-02 | 2008-05-21 | 三菱レイヨン株式会社 | 繊維強化樹脂成形体の成形方法 |

| US20050266221A1 (en) * | 2004-05-28 | 2005-12-01 | Panolam Industries International, Inc. | Fiber-reinforced decorative laminate |

| EP1835187B1 (en) * | 2004-12-17 | 2011-06-01 | Thk Co., Ltd. | Movement guiding device and method of lubricating the same |

| WO2007125745A1 (ja) * | 2006-04-28 | 2007-11-08 | Thk Co., Ltd. | スライドレールユニット |

| DE102006042999B3 (de) * | 2006-09-14 | 2007-10-25 | Federal-Mogul Deva Gmbh | Gleitelement, Verfahren und Vorrichtung zu dessen Herstellung |

| JP2008229453A (ja) * | 2007-03-19 | 2008-10-02 | Nitto Denko Corp | スパイラル型膜エレメント及びその製造方法 |

| JP4938547B2 (ja) * | 2007-05-10 | 2012-05-23 | 日本トムソン株式会社 | 内面シールを備えた直動案内ユニット |

| JP5308367B2 (ja) * | 2009-11-26 | 2013-10-09 | グローブライド株式会社 | 釣糸ガイド |

| JP5593713B2 (ja) * | 2010-01-28 | 2014-09-24 | 日本精工株式会社 | 直動案内装置 |

| CN102806667B (zh) * | 2011-05-31 | 2015-08-26 | 美津浓科技股份有限公司 | 基板收纳盒用纤维增强树脂制支承杆的制造方法 |

| JP2014133841A (ja) * | 2013-01-11 | 2014-07-24 | Mitsubishi Chemicals Corp | プリプレグおよび複合材料 |

| JP6233048B2 (ja) * | 2014-01-22 | 2017-11-22 | 株式会社ジェイテクト | ラックハウジングの製造方法、およびラックハウジング |

| JP6550786B2 (ja) * | 2015-02-23 | 2019-07-31 | 株式会社ジェイテクト | 軌道輪及び製造方法 |

| WO2017006806A1 (ja) * | 2015-07-03 | 2017-01-12 | Thk株式会社 | 案内装置及びこの案内装置を用いた什器 |

| JP6211669B2 (ja) * | 2015-11-30 | 2017-10-11 | Thk株式会社 | 運動案内装置およびアクチュエータ |

| CN105370732B (zh) * | 2015-12-18 | 2018-08-14 | 浙江威肯特智能机械有限公司 | 一种直线导轨 |

-

2019

- 2019-12-11 JP JP2020559293A patent/JP7344903B2/ja active Active

- 2019-12-11 WO PCT/JP2019/048524 patent/WO2020122132A1/ja not_active Ceased

- 2019-12-11 CN CN201980081256.0A patent/CN113195913B/zh active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS54126818U (enExample) * | 1978-02-22 | 1979-09-04 | ||

| JP2003083403A (ja) * | 2001-09-11 | 2003-03-19 | Tsubakimoto Chain Co | 伝動装置用合成樹脂ガイド |

| JP2017219177A (ja) * | 2016-06-10 | 2017-12-14 | 日本精工株式会社 | 一軸アクチュエータ |

| JP2018044657A (ja) * | 2016-09-16 | 2018-03-22 | Thk株式会社 | 運動案内装置の製造方法 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024235634A1 (de) | 2023-05-15 | 2024-11-21 | Accuride International Gmbh | Teleskopschiene |

| DE102023112727A1 (de) | 2023-05-15 | 2024-11-21 | Accuride International Gmbh | Teleskopschiene |

Also Published As

| Publication number | Publication date |

|---|---|

| JPWO2020122132A1 (ja) | 2021-10-21 |

| JP7344903B2 (ja) | 2023-09-14 |

| CN113195913A (zh) | 2021-07-30 |

| CN113195913B (zh) | 2023-02-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Haddad et al. | Study of the surface defects and dust generated during trimming of CFRP: Influence of tool geometry, machining parameters and cutting speed range | |

| JP7344903B2 (ja) | スライドレールユニット及びスライドレールユニットの製造方法 | |

| US9506004B2 (en) | Sliding member and method of manufacturing same | |

| Haddad et al. | Machinability and surface quality during high speed trimming of multi directional CFRP | |

| KR101616015B1 (ko) | 끊어지지 않는 복합소재 섬유층을 포함하는 부시 베어링 및 슬라이딩 베어링 | |

| WO2018117181A1 (ja) | 複合構造体およびその製造方法 | |

| CN104981629B (zh) | 滚珠丝杠用树脂螺母及其制造方法 | |

| Mohammadi et al. | Mode-II fatigue response of AS4/8552 carbon/epoxy composite laminates interleaved by electrospun nanofibers | |

| DE112008001526T5 (de) | Flexible 3D-Textilstruktur und Verfahren zu ihrer Herstellung | |

| Rabboh et al. | The effect of functionally graded materials into the sandwich beam dynamic performance | |

| Kim et al. | Influence of fabrication and interference-fit techniques on tensile and fatigue properties of pin-loaded glass fiber reinforced plastics composites | |

| Pathak et al. | Optimization of machining parameters during milling on glass fiber-reinforced textile composite | |

| Chen et al. | Process evaluation, tensile properties and fatigue resistance of chopped and continuous fiber reinforced thermoplastic composites by 3D printing | |

| TW201829157A (zh) | 加工品之製造方法及加工品 | |

| JP6310981B2 (ja) | 運動案内装置の製造方法 | |

| Tandon et al. | Process parameter effects on interlaminar fracture toughness of FDM printed coupons | |

| KR101229626B1 (ko) | 초음파 피닝 장치 및 방법 | |

| JP2016147964A (ja) | 繊維強化熱可塑性樹脂部材 | |

| JP6496829B2 (ja) | 孔を有する成形体、及びその製造方法 | |

| EP2781540A1 (en) | A method of making a laminate component and method of removing voids from a pre-preg ply and a pre-preg component | |

| Chen et al. | Major factors in rapid prototyping of mechanisms | |

| EP3594515B1 (en) | Linear guide and process to produce such a linear guide | |

| KR101518138B1 (ko) | 푸쉬핀을 이용한 z-피닝장치 | |

| JP6747076B2 (ja) | 一軸アクチュエータ | |

| Ullah et al. | 3D woven natural fiber structures |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19896936 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2020559293 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19896936 Country of ref document: EP Kind code of ref document: A1 |