WO2016194276A1 - 欠品管理装置及び欠品管理方法 - Google Patents

欠品管理装置及び欠品管理方法 Download PDFInfo

- Publication number

- WO2016194276A1 WO2016194276A1 PCT/JP2016/001736 JP2016001736W WO2016194276A1 WO 2016194276 A1 WO2016194276 A1 WO 2016194276A1 JP 2016001736 W JP2016001736 W JP 2016001736W WO 2016194276 A1 WO2016194276 A1 WO 2016194276A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- unit

- sensor

- output

- shortage

- group

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

- G06Q10/087—Inventory or stock management, e.g. order filling, procurement or balancing against orders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G1/00—Storing articles, individually or in orderly arrangement, in warehouses or magazines

- B65G1/02—Storage devices

- B65G1/04—Storage devices mechanical

- B65G1/137—Storage devices mechanical with arrangements or automatic control means for selecting which articles are to be removed

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01G—WEIGHING

- G01G19/00—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups

- G01G19/40—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight

- G01G19/413—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight using electromechanical or electronic computing means

- G01G19/414—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight using electromechanical or electronic computing means using electronic computing means only

- G01G19/415—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight using electromechanical or electronic computing means using electronic computing means only combined with recording means

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01G—WEIGHING

- G01G19/00—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups

- G01G19/40—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight

- G01G19/42—Weighing apparatus or methods adapted for special purposes not provided for in the preceding groups with provisions for indicating, recording, or computing price or other quantities dependent on the weight for counting by weighing

-

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

-

- G—PHYSICS

- G08—SIGNALLING

- G08B—SIGNALLING OR CALLING SYSTEMS; ORDER TELEGRAPHS; ALARM SYSTEMS

- G08B21/00—Alarms responsive to a single specified undesired or abnormal condition and not otherwise provided for

- G08B21/18—Status alarms

- G08B21/182—Level alarms, e.g. alarms responsive to variables exceeding a threshold

Definitions

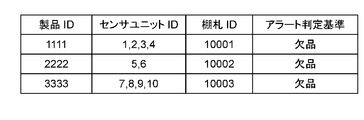

- FIG. 16 is an operation flowchart showing a stockout management process of the stockout management apparatus according to variation 4.

- FIG. 17A is a diagram illustrating another example of the shelf label management table according to Variation 4.

- FIG. 17B is a diagram illustrating an example of a table in which the missing item management table and the shelf label management table according to Variation 4 are integrated.

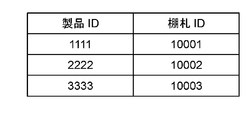

- FIG. 18 is a diagram for explaining a procedure for associating the shelf label ID according to the variation 4 with the product ID or the sensor unit ID.

- FIG. 19 is a block diagram showing the configuration of the shortage management apparatus according to variation 5.

- FIG. 20 is a diagram illustrating an example of a hardware configuration related to the output integration unit according to the variation 6.

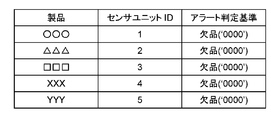

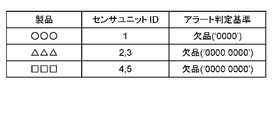

- FIG. 21A is a diagram showing an example of a missing part management table according to variation 6.

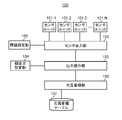

- the output of the output integration unit 105 is assumed to be a digital signal indicating whether or not the number of articles in the area where the sensor units 101 in the group are installed is equal to or less than a predetermined number.

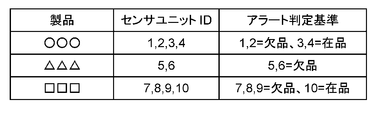

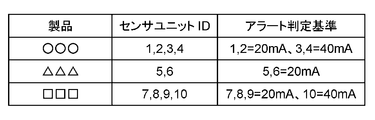

- the stockout management unit 106 determines whether the stockout status of the group corresponding to the stockout recorded in ST102 satisfies the alert determination criterion.

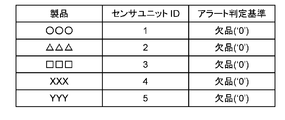

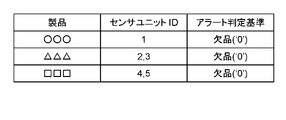

- a state where a shortage is detected for each product is defined as an alert determination criterion.

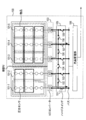

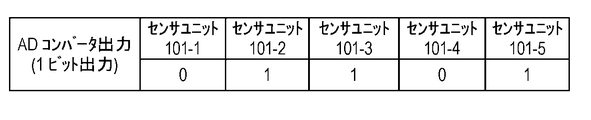

- the shortage management unit 106 detects the shortage of the article based on the output signal of each sensor unit 101. For example, in FIG. 7, since an article (indicated by a square frame) is not placed on the shelf corresponding to the sensor unit 101-1, the shortage management unit 106 is based on the output signal of the sensor unit 101-1. Then, the shortage of the article corresponding to the sensor unit 101-1 is detected. On the other hand, in FIG. 7, since articles are placed on the shelves corresponding to each of the sensor units 101-2 to 101-5, the shortage management unit 106 selects each of the sensor units 101-2 to 101-5. Based on the output signal, the shortage of the article corresponding to each of the sensor units 101-2 to 101-5 is not detected (the in-stock state is detected).

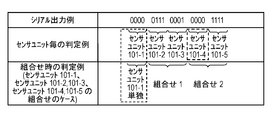

- FIG. 10A shows an output example of the sensor output unit 103 (AD converter) in the shortage management apparatus 100 having the hardware configuration shown in FIG.

- the switch elements 1A to 1E constitute the switch group 1 for switching the input of the logic circuit 1

- the switch elements 2A to 2E constitute the switch group 2 for switching the input of the logic circuit 2.

- the elements 3A to 3E constitute the switch group 3 for switching the input of the logic circuit 3

- the switch elements 4A to 4E constitute the switch group 4 for switching the input of the logic circuit 4

- the switch elements 5A to 5E are the inputs of the logic circuit 5.

- a switch group 5 for switching is configured.

- the switch elements 1A, 2B, 3C, 4D, and 5E are turned on, and the other switch elements are turned off.

- each logic circuit is stored in a register, and is serially output to the shortage management unit 106 via, for example, a bus. Note that the output of each logic circuit (data stored in the register) is not limited to serial output, and may be output in parallel.

- the threshold setting unit 102 is not necessary, and the missing item management table 107 managed by the missing item management unit 106 may set a digital numerical value threshold value to perform the missing item determination.

- the combination setting unit 104 outputs the combination setting to the missing item management unit 106, and the missing item management unit 106 groups the outputs of the output integration unit 105 based on the combination setting, and based on the bit string for each group. , You may manage the stockout condition.

- the shortage management unit 106 determines that the sensor unit 101-1 and the sensor unit 101-4 are out of stock, The units 101-2, 101-3, and 101-5 are determined to be in stock. In FIG. 22, when the sensor units 101 are combined, the shortage management unit 106 determines that the sensor unit 101-1 is in a shortage state, and determines that the combination 1 and the combination 2 are in stock.

Landscapes

- Engineering & Computer Science (AREA)

- Business, Economics & Management (AREA)

- Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Economics (AREA)

- Mathematical Physics (AREA)

- Strategic Management (AREA)

- Tourism & Hospitality (AREA)

- Development Economics (AREA)

- Operations Research (AREA)

- Entrepreneurship & Innovation (AREA)

- Human Resources & Organizations (AREA)

- Quality & Reliability (AREA)

- General Business, Economics & Management (AREA)

- Marketing (AREA)

- Accounting & Taxation (AREA)

- Finance (AREA)

- Mechanical Engineering (AREA)

- Emergency Management (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/572,376 US20180114182A1 (en) | 2015-06-03 | 2016-03-25 | Out-of-stock commodity management device and out-of-stock commodity management method |

| EP16802724.1A EP3306541A4 (en) | 2015-06-03 | 2016-03-25 | Out-of-stock commodity management device and out-of-stock commodity management method |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015113059A JP6284039B2 (ja) | 2015-06-03 | 2015-06-03 | 欠品管理装置及び欠品管理方法 |

| JP2015-113059 | 2015-06-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016194276A1 true WO2016194276A1 (ja) | 2016-12-08 |

Family

ID=57440424

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/001736 Ceased WO2016194276A1 (ja) | 2015-06-03 | 2016-03-25 | 欠品管理装置及び欠品管理方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20180114182A1 (enExample) |

| EP (1) | EP3306541A4 (enExample) |

| JP (1) | JP6284039B2 (enExample) |

| WO (1) | WO2016194276A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10824834B2 (en) | 2017-08-03 | 2020-11-03 | Walmart Apollo, Llc | Electronic label system |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112703361A (zh) * | 2018-09-17 | 2021-04-23 | 上海诺基亚贝尔股份有限公司 | 取决于位置的警告 |

| CN111765912A (zh) * | 2019-06-14 | 2020-10-13 | 北京京东尚科信息技术有限公司 | 缺货检测装置以及用于缺货检测装置的检测方法 |

| JP2022081106A (ja) * | 2020-11-19 | 2022-05-31 | ホシデン株式会社 | 積載物検出装置 |

| CN113536881B (zh) * | 2021-02-24 | 2025-02-18 | 上海汉时信息科技有限公司 | 缺货检测方法、货架排面缺货检测的边缘计算设备及系统 |

| JP7620918B2 (ja) * | 2021-03-03 | 2025-01-24 | パナソニックIpマネジメント株式会社 | 物品管理システム |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014110414A2 (en) * | 2013-01-11 | 2014-07-17 | Tagnetics, Inc. | Out of stock sensor |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060071774A1 (en) * | 2004-02-26 | 2006-04-06 | Brown Katherine A | Item monitoring system and methods using an item monitoring system |

| US8561190B2 (en) * | 2005-05-16 | 2013-10-15 | Microsoft Corporation | System and method of opportunistically protecting a computer from malware |

-

2015

- 2015-06-03 JP JP2015113059A patent/JP6284039B2/ja active Active

-

2016

- 2016-03-25 US US15/572,376 patent/US20180114182A1/en not_active Abandoned

- 2016-03-25 EP EP16802724.1A patent/EP3306541A4/en not_active Withdrawn

- 2016-03-25 WO PCT/JP2016/001736 patent/WO2016194276A1/ja not_active Ceased

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014110414A2 (en) * | 2013-01-11 | 2014-07-17 | Tagnetics, Inc. | Out of stock sensor |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10824834B2 (en) | 2017-08-03 | 2020-11-03 | Walmart Apollo, Llc | Electronic label system |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3306541A1 (en) | 2018-04-11 |

| EP3306541A4 (en) | 2018-04-25 |

| JP2016222446A (ja) | 2016-12-28 |

| US20180114182A1 (en) | 2018-04-26 |

| JP6284039B2 (ja) | 2018-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6284039B2 (ja) | 欠品管理装置及び欠品管理方法 | |

| US20160196526A1 (en) | Smart hook for retail inventory tracking | |

| EP2275987A1 (en) | Electronic inventory tag system | |

| JP6956357B2 (ja) | 食品管理システム | |

| JP6754987B1 (ja) | 業務支援システム、業務支援装置、業務支援方法、及び、コンピュータプログラム | |

| US20220398530A1 (en) | Business support device, business support method, computer program, and business support system | |

| CN112036526A (zh) | 电子标签装置及其对应的数据处理方法、装置和系统 | |

| US9251681B2 (en) | Fire alarm system | |

| JP6668053B2 (ja) | 空席表示システム | |

| JP2008272012A (ja) | 電子棚札システム | |

| KR20140128514A (ko) | 어플리케이션을 이용한 상품 주문 방법 및 장치 | |

| WO2016052086A1 (ja) | 物品の放置通知システムおよび物品の放置通知方法 | |

| JP4896203B2 (ja) | 情報表示システムおよび管理装置 | |

| US20220414569A1 (en) | Store management system, store management method, computer program and recording medium | |

| JP7336708B2 (ja) | 業務支援システム、業務支援装置、端末、業務支援方法、業務方法、及び、コンピュータプログラム | |

| CN108080282B (zh) | 一种用于快递物流业物件分拣的无线指示控制系统及方法 | |

| JP6796787B1 (ja) | 業務支援システム、業務支援装置、端末、業務支援方法、業務方法、及び、コンピュータプログラム | |

| CN116802702A (zh) | 电子货架标签系统 | |

| CN112955971B (zh) | 一种分组切换方法、中心监护系统和存储介质 | |

| JP7702891B2 (ja) | 情報処理装置、および位置管理システム | |

| JP2021144585A (ja) | 商品陳列棚管理システム、商品陳列棚管理方法およびプログラム | |

| KR20160051579A (ko) | 전자 정보 라벨 시스템 | |

| JP7702118B2 (ja) | 施設状況管理システム、施設状況管理サーバ、及び施設状況管理方法 | |

| US20250111805A1 (en) | Shelf label management system, shelf label management method, and recording medium | |

| US9882729B2 (en) | Method of identifying a powered device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16802724 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15572376 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |