WO2016047525A1 - Drug dispensing device and powdered drug preparation task assistance system - Google Patents

Drug dispensing device and powdered drug preparation task assistance system Download PDFInfo

- Publication number

- WO2016047525A1 WO2016047525A1 PCT/JP2015/076303 JP2015076303W WO2016047525A1 WO 2016047525 A1 WO2016047525 A1 WO 2016047525A1 JP 2015076303 W JP2015076303 W JP 2015076303W WO 2016047525 A1 WO2016047525 A1 WO 2016047525A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- container

- powder

- medicine

- packaging

- scraping

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J3/00—Devices or methods specially adapted for bringing pharmaceutical products into particular physical or administering forms

Definitions

- the present invention relates to a medicine dispensing apparatus, and more particularly to a medicine dispensing apparatus that distributes powdered medicine.

- the present invention also relates to a powder dispensing operation support system that employs such a medicine dispensing device.

- Patent Document 1 An example of such a medicine dispensing device is disclosed in Patent Document 1.

- the medicine dispensing device disclosed in Patent Document 1 is a powder medicine packaging device that individually packages powder medicines for each dose.

- this powder packaging device it is necessary to load the powder used for the packaging operation into the charging hopper before performing the packaging operation of individually packaging the powder for each dose.

- the powder hopper is charged into the charging hopper in an amount necessary for the packaging operation, and this required amount is manually measured by a user of an apparatus such as a pharmacist. That is, a user takes out a medicine bottle containing a prescribed powder from a medicine shelf, measures a necessary amount using a scale such as a balance, and puts it into a charging hopper.

- the trough is vibrated and the distribution tray is rotated.

- the powder charged in the charging hopper falls to the trough from the lower end opening of the charging hopper.

- the flow of the medicine becomes a laminar flow state. That is, the distribution of the medicine in a cross section in the direction orthogonal to the flow is constant, and the distance that the medicine travels per unit time is also constant.

- the powder is uniformly dispersed and slowly moves toward the distal end side at a constant speed.

- the powder which moves a head falls from the front-end

- the following powder drops to the distribution tray by a certain amount per hour.

- the distribution tray rotates at a predetermined speed. Therefore, the powder falling from the trough onto the distribution tray is evenly distributed on the distribution tray. That is, the powder drops gradually onto the distribution tray and the distribution tray rotates at a constant speed, so that the powder is evenly distributed on the distribution tray.

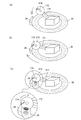

- the rotation of the distribution tray is stopped.

- the scraping device is brought into contact with the upper surface of the distribution tray, and the distribution tray is rotated by an angle corresponding to the number of divisions. For example, when dividing into three, the distribution tray is rotated by 120 degrees (one third of 360 degrees).

- the powdered powder is collected around the scraping device, and the collected powder is put into the packaging hopper by the scraping device.

- the powder medicine which fell from the packaging hopper is packaged by the packaging device, and the packaging operation is completed.

- Patent Document 1 In the powder medicine packaging device disclosed in Patent Document 1, it is necessary to manually perform the work of measuring the amount of powder used, which is troublesome. Thus, there has been a desire to automate the packaging work and various related work.

- an object of the present invention is to provide a medicine dispensing device that enables further simplification of the packaging operation and can further suppress the occurrence of defects.

- the present invention for solving the above problems is a medicine dispensing apparatus that takes out a predetermined amount of powder from a powder container, divides it into a predetermined number, and further wraps and discharges the powder separately.

- the powder storage container is for storing powder, has a discharge port portion serving as a discharge port for discharging the stored powder, and is provided with a chemical container arrangement area, a chemical division area, and a chemical packaging area.

- the medicine container arrangement area is provided with a container storage device for storing a plurality of powder storage containers, and the medicine division area distributes the powder discharged from the powder storage container, A scraping device for scraping out the powder put in the distribution tray, and a container mounting device for placing the powder storage container and acting on the powder storage container to discharge the powder from the powder storage container

- a medicine packaging device is provided in the medicine packaging area, and a container moving device for moving the powder storage container is further provided.

- the container moving device takes out the predetermined powder storage container from the container storage device.

- the container mounting device can be operated to discharge the powder from the powder storage container mounted on the container mounting device and put it into the distribution tray.

- the container storage device has a display device for displaying various information, capable of performing a packaging operation of scraping the powdered powder from the distribution tray and dropping it to the chemical packaging region side and packaging the powdered powder by the chemical packaging device. It is possible to display on the display device information relating to the powder stored in the powder storage container currently stored in the medicine dispensing device.

- the medicine dispensing apparatus of this aspect is a medicine dispensing apparatus that takes out a predetermined amount of powder from a powder container based on pre-input prescription information, divides it into a predetermined number, and further wraps and discharges it separately. Take out the prescribed powder storage container from the container storage device and place it on the container mounting device, discharge the powder from the powder storage container placed on the container mounting device, put it into the distribution tray, and after dividing it with the distribution tray

- the operation of packaging is possible. That is, it is not always necessary to carry out the operation of measuring the amount of powder used and putting it in the powder container, and the packaging operation can be further simplified.

- the medicine dispensing device includes a display device, and can display information on the powder stored in the powder storage container. From this, the user can perform various operations while confirming detailed information regarding the chemicals to be used, and can suppress the occurrence of problems such as erroneous types and amounts of chemicals in various operations.

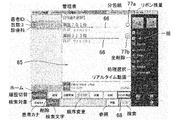

- This aspect includes an operation device for performing various input operations, and the operation device is of a touch panel type provided integrally with the display device, and the display device has a powder to the distribution tray.

- a speed control screen for controlling the discharge speed of the image can be displayed. On the speed control screen, an annular operation image is displayed, and the circumference is displayed while touching the area where the operation image is displayed.

- the target discharge speed is determined according to the direction to be traced and the distance to be traced, and the powder discharge operation is performed so that the determined discharge speed is obtained.

- the operation device for performing various input operations is integrated with the display device, and it is not necessary to secure the installation area of the operation device in the main body or the like, so that the degree of freedom in design can be improved.

- the annular operation image when the annular operation image is displayed, the powder that is discharged (supplied) to the distribution tray is traced in the circumferential direction while touching the area where the operation image is displayed.

- the discharge speed (supply speed) of the battery changes.

- the discharge rate (supply rate) of powdered medicine is the discharge amount per unit time. That is, the discharge amount can be changed by performing the above operation on the operation image.

- This aspect is such that a speed display image for displaying a value indicating the current target discharge speed is further displayed on the speed control screen, and the speed display image is the target discharge speed. It is more preferable that the image is temporarily displayed outside the operation image on the condition that has changed.

- the speed display image is temporarily displayed outside the operation image.

- the user can surely grasp the current discharge speed (supply speed). More specifically, when an operation image is touched and operated with a finger or the like, the finger or the like may overlap the display screen, and it may be difficult to see the portion displaying the discharge speed. Therefore, in this aspect, it is possible to display the speed display image outside the operation image that is a part touched with a finger or the like, and to check the discharge speed at a glance even during the operation for changing the speed. ing. That is, the discharge speed can be easily changed by making it easy to grasp the discharge speed.

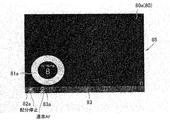

- the powder storage container has a discharge port portion serving as a powder discharge port, and when the powder storage container is placed on the container placement device on the speed control screen, the container It is possible to further display an observation image, which is a moving image obtained by photographing the discharge port portion of the powder storage container placed on the mounting device and its periphery, and during the rotation operation of the distribution tray, the discharge port portion and The observation image displaying the current state of the periphery and the operation image are simultaneously displayed on one screen.

- an observation image which is a moving image obtained by photographing the discharge port portion of the powder storage container placed on the mounting device and its periphery, and during the rotation operation of the distribution tray, the discharge port portion and The observation image displaying the current state of the periphery and the operation image are simultaneously displayed on one screen.

- the powder discharge speed (supply speed) can be changed while observing the discharge port portion of the powder storage container and the surrounding area. That is, since it is possible to change the discharge speed in consideration of the actual situation, a more appropriate discharge operation (supply operation) can be performed.

- the display color of the operation image changes according to the target change in the discharge speed.

- This aspect relates to a first history storage operation that stores information related to the packaging operation to be executed at the start of the packaging operation, and the packaging operation that is normally completed at the completion of the packaging operation.

- a second history storage operation for storing information, and selecting either the information stored in the first history storage operation or the information stored in the second history storage operation, and the selected information It is preferable that the packaging operation can be re-executed based on the above.

- a first history storage operation for storing information related to the packaging operation to be executed in the future, and information on the packaging operation that has been normally completed at the completion of the packaging operation.

- a second history storing operation for storing. That is, in addition to the normal operation history acquired at the normal completion of the packaging operation, the operation history acquired at the start of the packaging operation is acquired and stored.

- the packaging operation can be re-executed based on each operation history. In other words, not only the normally completed packaging operation can be re-executed based on the past information, but also the packaging operation that has been attempted can be re-executed based on the past information.

- the packaging operation can be performed more easily.

- a theoretical value of a medicine-related value related to powder discharged from the powder storage container in the packaging operation can be input or calculated, and an actual measurement value of the medicine-related value is being performed during the packaging operation.

- the theoretical value and It is preferable that the actual measurement value can be output.

- the theoretical value of each value related to the operation such as the total amount of the used chemicals and the actual measurement value can be printed on the same medium.

- the user can easily compare the “theoretical value” and the “measured value”, and can easily grasp whether or not the packaging error has occurred and the exact value of the generated packaging error. Since the user can execute the next packaging operation in consideration of this fact, it is possible to easily perform the packaging operation with higher accuracy.

- the printing medium is a chemical bag for packaging powder, and the bag length of the chemical bag is changed according to the content to be printed in the printing operation.

- the length of the chemical bag which is a printing medium, can be changed according to the amount of description. That is, it becomes possible to make the printed content easy to see.

- medical agent bag is a bag produced based on the information regarding prescription.

- the information related to prescription is information related to the usage of the prescribed medicine, such as information for specifying a patient, the timing of taking the medicine, the dose, the number of doses, and the interval between doses.

- the chemical bag in this aspect is a chemical bag formed individually for a predetermined individual, and the basic bag length is determined according to information on prescription. Furthermore, based on the information regarding prescription, it divides into a predetermined number as needed, and the powder medicine for one dose is sealed to each divided

- the discharge rate of the powder to the distribution tray can be acquired, and a graph showing the change of the discharge rate with the progress of the packaging operation performed in the past can be displayed.

- the discharge speed of the powder it is possible to acquire the discharge speed of the powder to the distribution tray, and it is possible to display a graph showing the change in the discharge speed with the progress of the packaging operation performed in the past. From this, not only detecting whether or not the discharge of the powder is completed, but also confirming whether or not the powder was supplied without delay from the start to the end of the discharge of the powder, for example. Can do. In other words, it is possible not only to confirm whether or not the discharge of powder has been completed, but also to check the status of the discharge process. Then, by displaying the transition of the discharge speed in a graph, the user can more easily check the state of the discharge process.

- This aspect is a moving image related to the pasting operation performed in the past, a past packaging image that is a moving image obtained by photographing the distribution tray in operation and the periphery of the distribution tray, and the past packaging performed in the past. It is possible to display a transition of the discharge amount of the powder to the distribution tray with the progress of the operation or a graph showing a change of the discharge speed of the powder to the distribution tray with the progress, and target the same packaging operation.

- the past packaged image and the graph are preferably displayed on the same screen.

- a moving image related to past packaging operations and a graph showing changes in the amount of medicine supplied (or changes in the rate of supply of medicine) over time in the past packaging operations carried out in the past. Can be displayed on the same screen. From this, the user can confirm the specific contents of the past packaging operation while confirming the transition of the supply amount and the supply speed of the medicine over time. For example, when the supply amount or the supply speed changes rapidly, it is possible to grasp in detail what has happened around the distribution tray. As described above, according to this preferable aspect, it is possible to verify in detail the contents of the past packaging operation performed, and it is easy to identify the cause even if a problem occurs. Based on this fact, the user can execute the next packaging operation, so that the packaging operation with higher accuracy can be easily performed.

- a display unit is further displayed.

- an error time display operation for highlighting an error occurrence time on the graph is performed when the past packaging operation in which a problem has occurred during implementation is targeted.

- the user who browses the moving image related to the past packaging operation is particularly careful about the time when the trouble occurred and the operation in the vicinity thereof. Can be encouraged to see. That is, it prevents the user from overlooking important contents such as the situation at the moment when a defect occurs in the past packaging operation, the situation immediately before the occurrence of the defect, or what happened after the occurrence of the defect.

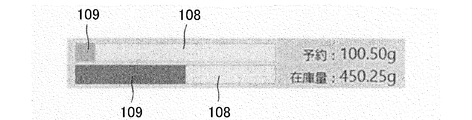

- This aspect can calculate the stock amount that is the amount of powder in the powder storage container stored inside and outside, and the reserved amount that is the amount of powder to be used in the packaging operation scheduled to be implemented in the future

- the comparison operation for comparing the inventory amount with the reserved amount is performed, and the result of the comparison operation is that the powdering is insufficient in the packaging operation to be performed in the future, It is preferable to perform a notification operation to notify the shortage.

- the amount of chemicals used in the packaging operation scheduled to be performed in the future is calculated and compared with the inventory amount. As a result of the comparison, if it becomes clear that there will be a shortage of medicine in the future, the user will be notified of the shortage of medicine in the future. That is, by making the user aware of the future shortage of medicines, it is urged to secure medicines in advance, and interruption of the packaging operation due to the shortage of medicines can be prevented. As a result, the packaging operation can be performed without delay.

- a packaging progress screen for displaying the progress of the packaging operation currently being performed can be displayed, and as a result of the comparison operation, there is a shortage of powder in the packaging operation to be performed in the future.

- the first notification operation for notifying that the shortage of powder occurs is performed, and in the first notification operation, a part of the packaging progress screen is displayed more clearly than the surroundings.

- the weighing reservation notification screen is displayed by performing a predetermined operation on the portion that is highlighted in the first notification operation, and the weighing reservation notification screen is insufficient for the packaging operation to be performed in the future.

- An operation for filling a predetermined powder storage container in the future with a predetermined amount of powder is started on the condition that a shortage that is the amount of powder is displayed and a predetermined operation is performed on the weighing reservation notification screen. .

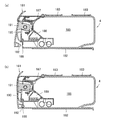

- the powder when scraping the powder with the scraping device, the powder may adhere to the portion of the scraping device for scraping the powder because of static electricity. And if a powder adheres to a scraping apparatus, the quantity of the powder to scrape may become smaller than a regulation amount, and there exists a possibility that it may become impossible to package an exact quantity of powder.

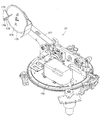

- the scraping device includes an arm member whose tip end is moved up and down, a scraping plate provided at the tip of the arm member, and a scraping plate protruding from the scraping plate.

- the distribution tray includes an annular continuous groove-shaped portion, and in the packaging operation, the scraping plate is inserted into the groove-shaped portion of the distribution tray, and the scraping plate and the distribution tray are relative to each other.

- the scraping plate of the scraping device after performing the scraping operation to scrape the powder out of the distribution tray, the scraping plate of the scraping device is kept in contact with the upper surface of the groove-shaped portion of the distribution tray. It is moved in the opposite direction. This makes it possible to drop the powder adhering to the scraping plate onto the distribution tray. And after that, by carrying out the operation of moving the scraping plate in the same direction of the scraping operation, it becomes possible to scrape the powder dropped on the distribution tray. That is, according to this preferable aspect, since the powder adhering to the scraping plate can be scraped off after being dropped on the distribution tray, a decrease in the amount of the powder to be scraped due to the powder adhering to the scraping plate can be prevented.

- the scraping device includes an arm member that moves up and down on the tip side, a scraping plate that is provided at the tip of the arm member, and a scraping plate that protrudes from the scraping plate. Is provided with a groove-like portion that is continuous in an annular shape, and in the packaging operation, the scraping plate is inserted into the groove-like portion of the distribution plate, and the scraping plate and the distribution plate are moved relative to each other to move the scraping plate. A scraping operation for scraping the powder on the distribution plate to the vicinity of the scraping plate, and a scraping operation for scraping the powder sprayed to the vicinity of the scraping plate to the outside of the distribution plate by the scraping plate.

- the operation consisting of the scraping operation and the scraping operation a plurality of times and to divide the powder on the distribution tray into a single package and scrape it out of the distribution tray.

- the powder for one package is targeted according to the number of powders divided.

- the movement distance of the relative movement in the scratching operation is variable, and one powder of powder is applied once according to the movement distance of the relative movement in the scratching operation for one powder. It is possible to carry out any one of the above-mentioned scratching operation and the single scraping operation that scrapes out by the scraping operation, and the multiple scraping operation that scrapes out a single pack of powder by the scraping operation and the scraping operation.

- the movement distance of the relative movement in the scratching operation performed in advance is longer than the movement distance of the relative movement in the scratching operation performed last. Is preferred.

- the scraping plate and the distribution tray are moved relative to each other to scrape the powder, if the distance of the relative movement becomes too long, the amount of the collected powder increases, and the scattered powder is only collected around the scraping plate. Instead, it may reach a position away from the scraping plate. In this case, even if the scraping operation is performed, there is a possibility that the powder at a position away from the scraping plate cannot be scraped. This is not preferable from the viewpoint of packaging an accurate amount of powder because the amount of powder to be scraped is less than the prescribed amount.

- a plurality of scraping operations are performed according to the movement distance of the relative movement, and the powder for one package is scraped into a plurality of times, so that the powder that has been scraped is applied only to the periphery of the scratching plate. It becomes possible to position. Further, when the powder is scraped for the last scraping operation, the relative movement distance is made shorter than when the powder is scraped for the preceding scraping operation. That is, when the powder is scraped for the last scraping operation, the powder can be more reliably positioned only around the scraping plate. As a result, the powder is not collected at a position away from the scraping plate and cannot be scraped out, and an accurate amount of powder can be packaged.

- the maximum amount scraping operation with the scraping operation for performing the relative movement with a predetermined maximum movement amount, and the relative movement with a predetermined minimum movement amount.

- the maximum amount scraping operation is performed on the condition that a value obtained by subtracting the relative movement distance in the scraping operation performed in the maximum amount scraping operation from a movement distance is equal to or greater than a predetermined value.

- the scraping operation and the scraping operation are performed with a movement amount smaller than the moving distance of the relative movement in the scraping operation, and the minimum amount scraping operation is further performed. This preferred aspect allows more accurate packaging of powders.

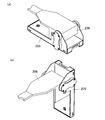

- the powder storage container has a lid member for opening and closing a discharge port formed in the discharge port portion

- the container moving device includes a lid engaging portion that opens and closes the lid member.

- a container holding part capable of holding the powder storage container in close contact with the container, and after the container holding part performs a temporary closing operation to close the lid member at a position away from the powder storage container, the container It is preferable to carry out an operation of bringing the holding part and the powder storage container into contact with each other and holding the powder storage container, and a main closing operation of closing the lid member.

- the powder when the powder storage container is moved by the container moving device, the powder does not spill out of the powder storage container due to an impact caused by the contact between the container moving device and the powder storage container. For this reason, an unexpected powder is not supplied to the distribution tray, and an accurate amount of powder can be dispensed and packaged.

- a plurality of the container mounting devices are provided, and each of the plurality of container mounting devices is mounted with another powder storage container, and the powder is discharged from each powder storage container. While the powder is being discharged from at least one of the powder storage containers, the powder storage container in which the discharge of the powder has been completed is moved to a position away from the container mounting device, and the discharge of the powder is performed. It is preferable that the operation of placing a new powder storage container on the container mounting device on which the completed powder storage container has been mounted can be performed.

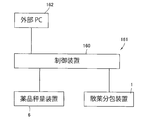

- Another aspect of the present invention includes a control device for controlling a plurality of dispensing devices based on prescription data including prescription data including prescription data, which is data related to prescription, and a medicine dispensing device.

- the dispensing device distributes the powder discharged from the powder storage container, and the container mounting device on which the powder storage container is mounted and acts on the powder storage container to discharge the powder from the powder storage container The powder is discharged from the powder storage container placed on the container placement device, put into the distribution tray, divided into a predetermined number, further individually packaged and discharged.

- the dispensing device includes a drug weighing device for weighing a target drug, and a temporary table device for temporarily installing the powder storage container.

- More than one Container-side information storage means capable of storing at least container information, which is information for specifying one powder storage container from a medicine storage container, is provided, and the temporary storage device and the container mounting device include the container side Information reading means for reading the state stored in the information storage means is provided, the container information of the powder storage container placed on the temporary table device is read by the information reading means, and the read information is read by the information reading means.

- Information storage operation that is temporarily or semi-permanently stored by the drug weighing device, the container information received by the drug weighing device, and information on the weighed powder stored in the drug weighing device are transmitted from the drug weighing device.

- the prescription data is associated with the information received from the drug weighing device including at least the container information, and the information creation operation is performed to create powder related information, and the prescription data is placed on the temporary table device.

- the information reading means of the container placement device reads the container information of the powder storage container, and the information reading means of the container placement device.

- the powder storage container when the drug weighed by the drug weighing device is stored in the powder storage container, the powder storage container is placed on a dedicated temporary table device. Thereby, compared with the case where a powder storage container is directly mounted on a desk etc., medicine can be stored in a state where the posture of the powder storage container is stabilized.

- the container information for specifying a container is acquired when mounting a powder storage container on a temporary placement stand apparatus, and powder related information is created by associating this container information with prescription data. And when a powder storage container is mounted in a container mounting apparatus, the prescription using the chemical

- the powder storage container containing the medicine not provided by the prescription is not used by mistake, and the packaging operation according to the predetermined prescription can be performed more reliably.

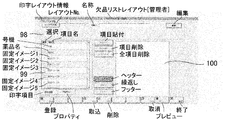

- FIG. 17 shows the state which the finger

- (b) shows the state from (a) state. The state after moving is shown. It is a figure which expands and shows a part of speed control screen of FIG. 17, and shows the state by which the speed display part was displayed. It is a figure which expands and shows a part of speed control screen of FIG. 17, and is a figure which shows a mode that the speed display part is displayed during operation of a speed operation part.

- FIG. 18 is a diagram illustrating a state in which a full screen display operation is performed on the speed control screen of FIG. 17. It is a figure which shows the layout setting screen of this embodiment. It is a figure which shows the measurement reservation notification screen of this embodiment.

- FIG. 26 is a diagram showing a state in which prescriptions are displayed as a list in a prescription display area on the prescription history list screen of FIG. 25. It is a figure which shows the weighing history screen of this embodiment. It is a figure which shows the past moving image display screen of this embodiment. It is a figure which shows the packaging log

- FIG. 2 is a block diagram showing a powder dispensing operation support system in which the medicine dispensing device of FIG. 1 is constructed in conjunction with a control device or the like.

- FIG. 2 is an explanatory view showing an operation of scraping out the powder of one package to the vicinity of the scraping plate in the medicine dispensing apparatus of FIG. 1 and then scraping it out of the distribution tray in the order of (a) to (c). Scraping is performed.

- FIG. 2 is an explanatory view showing an operation of scraping out a powder of one package to the outside of the distribution tray in the medicine dispensing apparatus of FIG. 1, and the powder is scraped in the order of (a) to (d).

- FIG. 37 shows the state which the cover member opened, (b) shows the state which the cover member closed. It is a perspective view which shows the container moving apparatus shown by FIG. It is a perspective view which shows the front end side part of the arm part shown by FIG. 39, (a) shows the attitude

- FIG. 40 is an explanatory view showing a state where the automatic medicine container is moved from the container holding base at the tip side portion of the arm part shown in FIG. And a mode that a cover member is obstruct

- FIG. 40 is an explanatory view showing a state where the automatic medicine container is moved from the container holding base at the tip side portion of the arm part shown in FIG. And a mode that a cover member is obstruct

- FIG. 42 is an explanatory view showing a state in which the automatic medicine container is moved from the container holding base at the distal end portion of the arm portion following FIG. 41, and (a) temporarily separates the distal end portion of the arm portion from the automatic medicine container.

- B) shows a state in which the distal end portion of the arm portion is brought into contact with the automatic chemical container to close the lid member.

- FIG. 6 is an explanatory view showing a state in which one automatic chemical container is replaced during the operation of placing automatic chemical containers on all container holding bases and discharging the powder to the distribution tray, (a) to (c) Replace the automatic chemical container in the following order. It is explanatory drawing which shows an example of the paper medium output by the printing operation which the powder medicine packaging apparatus of this embodiment implements.

- FIG. 46 It is a figure which shows the weighing history screen of the form different from FIG. It is a perspective view which shows the manual medicine container different from FIG. It is a disassembled perspective view which shows the storage space formation member of the manual type medicine container shown by FIG. It is sectional drawing of the manual type chemical

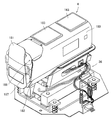

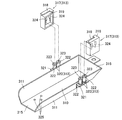

- the powder medicine packaging device 1 (medicine dispensing device) of the present embodiment includes a main body device 2, an operation display unit 3 (display device, operation device), a control unit (not shown), and a manual type.

- the medicine container 5, the medicine weighing device 6, the journal printer 7, and the barcode reader 8 are provided.

- the powder medicine packaging device 1 operates the operation display unit 3 so that the powder medicine contained in a medicine container (a powder medicine container, an automatic medicine container 4 described later, or the above-described manual medicine container 5) is stored. It is a device that automatically takes out, weighs, divides it into a predetermined number and wraps it.

- the main body device 2 is formed by incorporating various devices in the housing 10, and specifically, as shown in FIG. 2, a medicine container arrangement region 12, a medicine dividing region 13, A medicine packaging area 14 is provided.

- a dehumidifying device (not shown) and a temperature controller (not shown) are provided inside the housing 10 so that the internal temperature and humidity can be maintained within a certain range.

- a door portion 16 is provided in a portion of the housing 10 that forms the outer wall surface of the chemical container arrangement region 12.

- the door part 16 is a part for putting the automatic medicine container 4 into and out of the housing 10, and a container temporary placement part 18 for temporarily placing the automatic medicine container 4 is provided inside the door part 16.

- the door portion 16 and the container temporary placement portion 18 function as an introduction portion when introducing the chemical container into the inside of the housing 10 and also function as an extraction portion when taking out the chemical container from the inside of the housing 10. .

- the container temporary placement part 18 is a part that can hold the automatic chemical container 4 by mechanical engagement. By placing the automatic chemical container 4, the automatic chemical container 4 and the container temporary placement part 18 are The engaged state is established. On the contrary, when the automatic medicine container 4 and the container temporary placement portion 18 are in the engaged state, the automatic medicine container 4 is lifted to be in the disengaged state. That is, the automatic medicine container 4 can be detached from the container temporary placement unit 18.

- the container temporary placement unit 18 is provided with information reading means for reading information from the automatic chemical container 4 and weight measuring means for measuring the weight of the automatic chemical container 4.

- the chemical container arrangement region 12 is provided with a container storage unit 23 (container storage device) that holds the automatic chemical container 4.

- a container storage unit 23 container storage device

- the container storage unit 23 includes a drum member 25 installed in an upright posture, and the drum member 25 is rotatable about a rotation axis extending in the vertical direction. That is, the vertical drum member 25 can be rotated in the horizontal direction using a motor or the like as a power source.

- a plurality of container installation portions are provided on the outer peripheral surface of the drum member 25, and the automatic chemical container 4 is held by the container installation portions.

- Each container installation part holds the automatic chemical container 4 by mechanical engagement.

- the automatic chemical container 4 is pushed in, the automatic chemical container 4 and the container installation part are engaged. .

- the automatic medicine container 4 and the container installation portion are in the engaged state, the automatic medicine container 4 is pulled out of the engagement by pulling the automatic medicine container 4 outward.

- the drum member 25 is divided into three parts in the vertical direction, and a plurality of container installation portions are formed in each of the divided areas.

- a group of 11 container installation parts is provided in three stages. That is, the container storage unit 23 can hold 33 automatic medicine containers 4 in total.

- the container installation portion has a structure including a protruding member protruding outward, and the protruding member is immersed when the automatic chemical container 4 is attached in a normal posture.

- optical sensors are provided inside and outside the drum member 25, respectively, and it is possible to detect whether or not the protruding member of the container installation portion is protruding.

- information reading means (not shown) is provided in the vicinity of the drum member 25. For this reason, information can be acquired from each of the automatic chemical containers 4 held on the drum member 25. More specifically, information can be acquired from container-side information storage means (details will be described later) attached to each automatic medicine container 4.

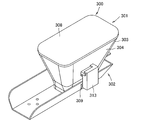

- a container moving device 28 is provided in an area from the medicine container arrangement area 12 to the medicine division area 13.

- the container moving device 28 has a structure including an arm unit 30 and an elevating mechanism 31, and the arm unit 30 can be moved in the vertical direction by the elevating mechanism 31. Further, a magnet is provided at the distal end portion of the arm portion 30, and the automatic chemical container 4 can be held by adsorbing an iron plate attached integrally to the automatic chemical container 4.

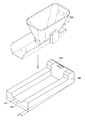

- a distribution tray 35 As shown in FIG. 4, in the medicine division region 13, as shown in FIG. 4, in a space located on the rear side of the front door 34 (see FIG. 1), a distribution tray 35, a container holding table 36 (container mounting device), A dispensing device 37, a cleaning device 38, a chemical introduction port 39, and a camera member 40 are provided. More specifically, in the medicine dividing region 13, two distribution trays 35 arranged in parallel are respectively installed in an embedded state.

- a container holder 36, a scraping device 37, and a cleaning device 38 are provided around each distribution tray 35.

- one container tray 36, one scraping device 37, and one cleaning device 38 are associated with one distribution tray 35.

- a medicine introduction port 39 is provided around the distribution tray 35 and between the two distribution trays 35 to supply powder to the medicine packaging region 14 one by one.

- a partition plate device 41 is provided at a position adjacent to.

- the partition plate device 41 includes a box-shaped main body portion and a standing plate portion attached to the main body portion so as to be able to appear and retract. And it is possible to switch between a protruding state in which most of the standing plate portion protrudes outside from the main body portion and a storage state in which the standing plate portion is housed in the main body.

- the powder in each packaging operation (details will be described later), when the powder distributed in one distribution tray 35 is scooped up by the scraping device 37 and put into the drug introduction port 39, depending on the type of powder to be charged, the powder May fly far more than necessary. That is, it is conceivable that the powder will fly up to the distribution tray 35 on the other side.

- the powder plate in the powder medicine packaging device 1 of the present embodiment, the powder plate is prevented from flying up to the distribution tray 35 on the other side by making the partition plate device 41 project. That is, the vertical plate portion of the partition plate device 41 functions as a blocking wall to prevent the powder medicine from flying to the other distribution tray 35.

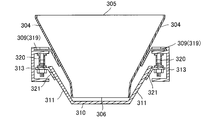

- the distribution tray 35 is provided with an annular annular chemical introduction groove, and is rotatable by a rotation mechanism (not shown).

- the container holding table 36 has a structure including a vibration table portion and a weight measuring means.

- the shaking table is provided with a container holding means for holding a chemical container (automatic chemical container 4 or manual chemical container 5).

- a magnet electromagnet

- the gravity measuring means measures the weight of the chemical container directly or indirectly.

- the gravity change means can detect the weight change of the chemical

- the camera member 40 is installed at a position where the periphery of the container holding table 36 can be photographed. It functions as an imaging device for photographing.

- a digital imager such as a CCD camera can be suitably employed.

- a camera member 40 that images the periphery of the container holding table 36 adjacent to the distribution tray 35 on one side and a camera member 40 that images the periphery of the container holding table 36 adjacent to the distribution tray 35 on the other side are separately provided. The imaging operation can be performed separately.

- the medicine packaging area 14 is provided with a known medicine packaging device and printing means.

- the medicine packaging device is a machine for packaging medicine one by one, and is formed by a sheet supply device and a sealing device. That is, the sheet supplied from the sheet supply device is formed into a bag shape to create a sachet bag, and the prepared sachet bag is sealed and packaged for each dose by the powder seal device supplied from the drug dividing region 13 It is possible to operate.

- the printing means is a machine for printing predetermined information on the packaging bag.

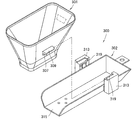

- the automatic medicine container 4 is a container having a substantially rectangular parallelepiped shape, and is provided with a medicine discharge section 187 (see FIGS. 37, 38, etc.) for discharging powdered powder or powdered medicine stored inside. ing.

- This medicine discharge part 187 is an opening-like part and communicates with the inside and outside.

- the medicine discharge part 187 is a part that opens larger by removing peripheral members and functions as a medicine input part for introducing the medicine.

- the automatic chemical container 4 is provided with iron plates on two different surfaces. The iron plate provided on one surface is a part for adsorbing the magnet of the arm unit 30 when the automatic drug container 4 is held by the arm unit 30.

- the iron plate provided on the other surface is a portion for adsorbing the magnet of the container holding table 36 when it is installed on the container holding table 36 described later.

- the automatic medicine container 4 is provided with an RFID tag, and can store information on the medicine stored. That is, the RFID tag functions as a container side information storage unit.

- the operation display unit 3 is a so-called touch panel, and is formed by combining a display device such as a liquid crystal panel and a position input device such as a touch pad.

- the powder medicine packaging device 1 of the present embodiment displays various screens on the operation display unit 3 and performs an operation of touching a predetermined portion with a dielectric such as a finger or a touch pen (hereinafter also simply referred to as a finger). Various operations described later can be executed.

- the control unit includes a CPU, a ROM, a RAM (EEPROM), and a data storage unit.

- the CPU is a processor that executes various arithmetic processes.

- the ROM is a non-volatile memory in which programs such as BIOS are stored in advance

- the RAM is a volatile memory or non-volatile memory used for developing various programs and temporarily storing data.

- the data storage unit is a storage device such as an HDD (Hard Disk Drive) in which various programs and data are stored. More specifically, a “medicine master” that stores various types of information related to a drug, a “shaped drug master” that stores information related to a drug that requires a shaping operation, and a “regular dose master” that stores information related to a normal dose of the drug.

- Various databases such as a “patient master” that stores information related to a patient who has been prescribed a medicine and an “average weight master” that stores information related to the average weight of a patient who is prescribed a medicine are stored. In addition, the information stored in these databases is stored in an associated state as appropriate.

- the manual medicine container 5 is a substantially rectangular parallelepiped container and has substantially the same structure as the automatic medicine container 4.

- the manual medicine container 5 is different from the automatic medicine container 4 in that a medicine charging section is provided at a position different from the medicine discharging section. That is, in the manual medicine container 5, the medicine charging part is provided on the upper part of the manual medicine container 5.

- the chemical injection portion is a through-hole-shaped portion communicating between the inside and the outside, and is formed so that the outer portion has a larger cross-sectional area than the inner portion.

- the chemical weighing device 6 includes a weighing platform and an RFID reader / writer.

- the weight of the chemical container can be measured by placing the chemical container on the chemical weighing device 6, and information can be read from and written to the RFID tag provided on the chemical container.

- the medicine weighing device 6 includes weight measuring means for measuring the weight of the medicine container, and information reading means and information writing means for reading and writing information with respect to the container side information storage means of the medicine container. It has a structure.

- the journal printer 7 is a device for printing various information such as packaging operation history and prescription recording on a medium such as paper.

- the bar code reader 8 is capable of reading a bar code written on a medicine original box or a medicine bottle.

- Various devices such as sensors and camera members, a chemical weighing device 6, a journal printer 7, and a barcode reader 8 incorporated in the main body device 2 are in a state where various information can be transmitted to and received from the control unit described above. .

- these are connected by a communication network such as a LAN, and can send and receive signals.

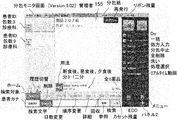

- “database editing operation” for adding, deleting, and changing information to various databases

- “packaging operation” for packaging powder medicines one by one

- “Printing operation” for issuing various documents

- “Reservation management operation” for notifying of insufficient drugs in future packaging operations

- “Packaging verification operation for verifying the contents of past packaging operations”

- A“ maintenance operation ” for normally executing the packaging operation

- a“ re-packaging operation ” for performing the packaging operation again based on the history issued in the past.

- screens corresponding to various databases are displayed, and information can be added to, deleted from, or changed to each database.

- the powder cassette mounting master screen see FIG. 5

- the medicine master screen see FIG. 6

- the patient master screen see FIG. 7

- the shaping medicine master screen (not shown)

- the regular use Various screens including an amount master screen (not shown) and an average weight master screen (not shown) can be displayed.

- Information can be added, deleted, and changed from each screen or other screens displayed by operating each screen.

- each screen is provided with a “CSV output” button and a “print” button. These buttons touch the displayed part (hereinafter, the user touching the button-like part displayed on the screen is also referred to as “pressing”), and the contents registered in the database are converted into a CSV file. Can be output or printed on a medium such as paper.

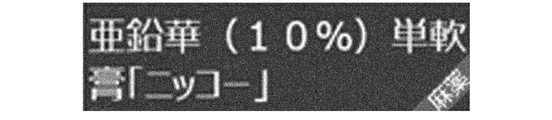

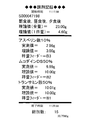

- the powder cassette mounting master screen (see FIG. 5) is a screen corresponding to a database that stores information on medicines stored in the medicine container (automatic medicine container 4).

- information such as a medicine code, a medicine name, a maximum mounting amount, a filling reference amount, a used amount, an inventory amount, a manufacturing number, and an expiration date can be registered.

- the medicine master screen (see FIG. 6) is a screen corresponding to a database that stores information related to medicine.

- the registration target of this database is a medicine that may be prescribed by a doctor, and becomes a registration target regardless of whether it is stored in a medicine container or not. That is, while the powder cassette mounting master screen is targeted for drugs stored in a drug container, the drug master screen is targeted for all drugs that may be prescribed.

- On this medicine master screen for each medicine, medicine code, medicine name, unit code, stamp, shelf number (management number of the stored shelf), management flag (whether special management is required for handling) Information such as stability coefficient, specific gravity, vibration coefficient, image image, etc. can be registered. It has become.

- the patient master screen is a screen corresponding to a database that stores information related to a patient for whom a medicine is prescribed.

- This patient master screen shows information such as patient ID, patient name (kanji), patient name (kana), date of birth, ward name, information to be sent, address, telephone number, and fax number for each patient. Can be registered.

- the “ward name” is the name of the ward to which the department that the patient consulted belongs, and is input as necessary.

- the excipient chemical master screen (not shown) is a screen corresponding to a database that stores information on a medicine prescribed by adding an additive for increasing amount, dilution, or the like.

- the normal dose master screen (not shown) is a screen corresponding to a database that stores information related to drug doses determined in relation to age, weight, and the like.

- the average weight master screen (not shown) is a screen corresponding to a database that stores information on average weight corresponding to a predetermined age range.

- the powder medicine packaging apparatus 1 can perform a packaging operation for packaging medicines one by one while referring to information on the prescription input in the “prescription input operation” performed in advance as necessary. It has become. More specifically, the “first packaging operation” for packaging the powder stored in the automatic medicine container 4 held in the container storage unit 23 and the automatic medicine container 4 stored in the external management shelf A “second packaging operation” for packaging the stored powder and a “third packaging operation” for packaging the powder stored in the manual medicine container 5 can be performed.

- the powder medicine packaging device 1 operates to store the automatic medicine container 4 in the container storage section 23, to take out the automatic medicine container 4 from the container storage section 23, and to take out the automatic medicine container 4 To move the automatic medicine container 4 on the container holding stand 36, to move a predetermined amount of medicine into the distribution dish 35, and to take medicine from the distribution dish 35 for each dose.

- the operation of supplying the medicine packaging device and the operation of returning the automatic medicine container 4 to the container storage unit 23 can be automatically performed.

- the “cassette selection operation” for selecting the medicine container to be used based on the prescription information is performed and selected.

- Each of the packaging operations is performed using a chemical container.

- the automatic medicine container 4 selected in the “cassette selection operation” is not held by the drum member 25 when the “first packaging operation” is performed, the user is notified of the fact.

- the “cassette lack notification operation” is performed. In this case, after performing the “filling operation” for holding the automatic medicine container 4 on the drum member 25 as necessary, the first packaging operation can be performed again.

- the prescription input operation is an operation in which a prescription input screen (see FIG. 8) is displayed on the operation display unit 3 and information related to the prescription is input.

- a registration operation for automatically registering input information in a predetermined database is performed as necessary.

- the prescription entry screen has input fields corresponding to each item, including information on the patient such as patient ID and patient name, information on the medical institution and department to which the doctor who prescribed the medicine belongs, and information on the prescribed medicine. Information on drugs such as drug name, usage, and dose can be entered.

- the powder medicine packaging device 1 of the present embodiment has an input assist function that allows a medicine name to be selected from a list. Specifically, an easy input screen (see FIG. 9) is displayed, and a drug name can be input by selecting a drug name from the list.

- the simple input screen is provided with a character input unit 45 for inputting a character string used for search and a setting button 46 for setting a search condition. Then, when the user inputs a predetermined character string in the character input unit 45 and / or presses one of the three setting buttons 46, the medicines listed can be narrowed down. Then, the medicine name is selected by pressing one of the medicine names displayed in the list.

- the character input unit 45 is a part for inputting a character or a character string (hereinafter simply referred to as a character string or the like) used as a keyword for specifying a medicine.

- a character string or the like used as a keyword for specifying a medicine.

- a character string or the like is input to the character input unit 45, only medicines starting from the input character string or the like are displayed as a list.

- the powder medicine packaging apparatus 1 of this embodiment performs the comparison operation which compares the character string etc. which were input into the character input part 45, and the character string when reading a chemical name. Then, a display operation is performed in which only medicines starting from a character string or the like to which a character string when the medicine name is read are displayed in a list.

- the display content of the list is changed every time one character is input.

- a character string “Aiu” is input to the character input unit 45

- the first character of the medicine name is “A”. Only the chemicals that are displayed are displayed.

- the first character of the medicine name is “A”

- the second character is Only the medicine with “I” is displayed. That is, only the medicine whose character string when the medicine name is kana reading starts with “eye” is displayed. In this way, when a character string is input to the character input unit 45, the display of the list is switched every time one character is input.

- the setting button 46 includes a “powdered medicine” button, a “tablet” button, and a “cassette” button.

- the type of medicine to be searched is determined. That is, when the “powder” button is pressed, only the powder among all the drugs is displayed in the list.

- the “Tablet” button is pressed, only tablets among all the drugs are displayed in the list, and when the “Cassette” button is pressed, only the drugs already stored in the automatic drug container 4 are displayed. It will be displayed in the list.

- the “washing chemical” is a chemical that is expected to cause a serious situation when unintentional mixing (so-called contamination) with other chemicals occurs in the distribution dish 35. It is a chemical that requires a cleaning operation (details will be described later) of the distribution tray 35 either before or after the packaging operation. More specifically, when another packaging operation is performed subsequent to a predetermined packaging operation, the medicine discharged to the distribution tray 35 by the previously performed packaging operation slightly increases on the distribution tray 35. It may remain. In this case, if another packaging operation is subsequently performed, the above-described mixing of medicines (so-called contamination) may occur. Therefore, it is possible to designate chemicals that may cause serious situations as a result of unintentional chemical contamination, and to facilitate the cleaning operation when used in packaging operations. .

- the powder medicine packaging device 1 of the present embodiment in the initial state (the state at the time of shipment), all the medicines registered in the database are the medicines to be washed, that is, either before or after the packaging operation. Is set to a chemical that requires a cleaning operation (described in detail later). That is, it is set so that the cleaning operation of the distribution tray 35 is always performed when the packaging operation is performed.

- this setting can be changed by the user performing a predetermined operation. That is, it is possible to appropriately select whether or not the medicine displayed on the prescription input screen is to be washed. In addition, when the displayed medicine is to be washed, it is possible to set a time for performing the cleaning operation. That is, it is possible to set whether or not a cleaning operation is necessary before the packaging operation and whether or not a cleaning operation is necessary after the packaging operation.

- the powder medicine packaging device 1 of the present embodiment automatically determines whether or not a cleaning operation is necessary based on the set medicine information, and automatically performs the cleaning operation when necessary. It has become. That is, the powder medicine packaging device 1 of the present embodiment automatically determines whether or not the cleaning operation needs to be performed when the medicine is selected and the packaging operation is started. More specifically, based on the setting result stored in the data storage unit, it is determined whether or not the medicine needs to be cleaned before the packaging operation, and whether the cleaning operation after the packaging operation is necessary. Determine whether or not. Normally, a cleaning operation is required after using poisons, narcotics, psychotropic drugs, powerful drugs, colored drugs, drugs that easily adhere to the distribution tray 35 (drugs to be washed), and the like.

- the cleaning operation is automatically performed. This is preferable because it reduces the time and effort required for the packaging operation, compared to a configuration in which whether or not the cleaning operation is performed manually every time the packaging operation is performed.

- the prescription input screen (see FIG. 8), it is possible to input information on the usage of the prescribed medicine such as the timing of taking, the number of times taken, and the interval between doses, and the packaging form of the prescribed medicine.

- Information on drug usage can be entered using a usage code, and when the usage code is entered, the associated dose time, number of doses, and dose interval are automatically entered.

- the medicine packaging form is an item for selecting what kind of packaging operation is performed when a prescribed medicine is to be packaged one by one.

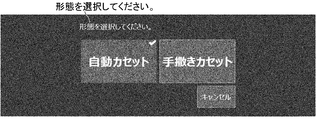

- This packaging form is selected and input from an item group consisting of “crushing”, “automatic cassette”, and “hand-made cassette”.

- “Crushing” is a form in which tablets are crushed and then powdered. That is, the prescribed medicine is a tablet, and is an item selected when a powdered tablet is introduced into the manual medicine container 5 and a packaging operation is performed.

- the “automatic cassette” is a form in which the powder stored in the automatic chemical container 4 is supplied to the distribution tray 35 and packaged. That is, this is an item selected when the prescribed medicine is already stored in the automatic medicine container 4 and the medicine contained in the automatic medicine container 4 is used for the packaging operation.

- the “handmade cassette” is a form in which powder is introduced into the manual medicine container 5 and packaged. That is, it is an item selected when the pharmacist manually introduces the prescribed medicine into the manual medicine container 5 and performs the packaging operation.

- the powder medicine packaging device 1 determines whether or not the input medicine is stored in the automatic medicine container 4 of the container storage unit 23. A discriminating operation for discriminating is performed. That is, the powder medicine packaging device 1 compares the input information with the information stored in the data storage unit (or information acquired by the sensor), and whether the prescribed medicine is contained in the automatic medicine container 4 or not. Is automatically determined.

- the “auto cassette” is automatically selected. If not, the “hand cassette” is automatically selected. It becomes a state.

- the user can change the automatically selected packaging form by operating the operation display unit 3. More specifically, in the powder medicine packaging device 1 of the present embodiment, an item is displayed by displaying a form selection screen (see FIG. 10) and pressing either the “auto cassette” button or the “hand cassette” button. Can be changed. That is, when the “auto cassette” button is pressed, “auto cassette” is selected, and when the “hand cassette” button is pressed, “hand cassette” is selected. [Cassette selection operation]

- the powder medicine packaging device 1 of the present embodiment is configured such that when the prescribed medicine is “powdered medicine” and the packaging form selected on the prescription input screen is “automatic cassette”, the first packaging operation or the second packaging It is possible to perform the packaging operation and divide each dose.

- the cassette selection operation for selecting the automatic medicine container 4 containing the medicine to be packaged is performed, and the selected automatic medicine container 4 is selected.

- Perform the packaging operation using That is, the automatic medicine container 4 used in the cassette selection operation is selected, and the packaging operation is performed using the selected automatic medicine container 4.

- a powder cassette selection screen (see FIG. 11) is displayed on the operation display unit 3, and the automatic medicine container 4 can be selected on this screen.

- This powder cassette selection screen displays a list of medicines stored in the automatic medicine container 4 held by the container storage unit 23 and accommodates in the automatic medicine container 4 stored in an external management shelf. It is possible to switch between the state in which the medicines displayed are listed. Then, by pressing the display area of each medicine displayed in the list, it is possible to select the automatic medicine container 4 in which medicines used in the packaging operation are stored.

- the medicine cassette selection screen (see FIG. 11) is provided with a medicine display section 48, a display switching button 49, and a character input section 50.

- the medicine display part 48 is a part for displaying a list of medicine names that satisfy the conditions based on the operation of the display switching button 49 and / or the input result in the character input part 50.

- a message that indicates that the drug requiring attention in handling such as narcotics, investigational drugs, poisonous drugs, powerful drugs, psychotropic drugs, etc. is highlighted.

- the display switching button 49 is a button for switching the medicine displayed on the medicine display unit 48. Each time this display switch button 49 is pressed, a state in which medicines stored in the automatic medicine container 4 held by the container storage unit 23 (hereinafter also referred to as internal medicine) is displayed, and an external management shelf is displayed. The state in which the medicine stored in the stored automatic medicine container 4 (hereinafter also referred to as external medicine) is displayed is switched.

- the display switching button 49 displays “display outside management shelf” (see FIG. 11) when the internal medicine is displayed on the medicine display section 48, and displays “management shelf” when the external medicine is displayed. "Display inside” (see FIG. 13). When the button is pressed and the display of the medicine display unit 48 is switched, the wording displayed on the button is also switched.

- the character input unit 50 is a part for inputting a character string or the like used as a keyword for specifying a medicine.

- a character string or the like is input to the character input section 50, only the medicine starting from the character string or the like in which the medicine name is input is displayed on the medicine display section 48. That is, the character input unit 50 is a part for inputting a keyword for narrowing down the display target to be displayed in the list, like the character input unit 45 of the simple input screen (see FIG. 9). Therefore, as shown in FIG. 13, when the character “A” is input to the character input unit 50, only the medicine whose first character in the medicine name is “A” is displayed.

- the character input unit 50 is configured to change the display contents every time one character is input, as in the character input unit 45 described above.

- the holding container confirmation operation for confirming the automatic medicine container 4 currently held in the container storage section 23 (in detail, (To be described later). And based on the information acquired by holding container confirmation operation, the holding

- the automatic medicine container 4 that is scheduled to be used in the first packaging operation to be performed and is not currently held in the container storage unit 23 is also simply referred to as “missing cassette”. .

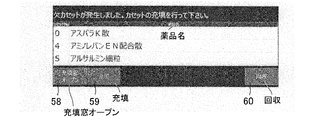

- a missing cassette notification screen (see FIG. 14) is displayed on the operation display unit 3, and the management number and the name of the medicine to be stored are stored for each missing cassette that has been confirmed to be present in the holding determination operation. Is displayed.

- a filling window opening button 58 On this missing cassette notification screen (see FIG. 14), a filling window opening button 58, a filling button 59, and a collection button 60 are displayed.

- the filling window opening button 58 is a button for opening the door portion 16, and the door portion 16 is opened when pressed.

- the filling button 59 is a button used in a filling operation described later, and is a button for holding the automatic chemical container 4 placed on the temporary container placement unit 18 in the container storage unit 23.

- the missing cassette displayed in the list is selected, and the filling window opening button 58 and the filling button 59 are appropriately operated to automatically set the missing cassette. It is possible to supplement the chemical container 4. That is, the automatic medicine container 4 filled with the medicine to be accommodated in the missing cassette is separately prepared, and the automatic medicine container 4 is held in the container storage unit 23 to perform the filling operation to be performed from now on. It is possible to make a state where there is no missing cassette in the operation. First, the filling operation for holding the automatic medicine container 4 in the container storage unit 23 will be specifically described below. [Filling operation]

- the powder medicine packaging device 1 a number of automatic medicine containers 4 are held in the container storage unit 23, and medicines are stored in each of them.

- the powder medicine packaging device 1 of the present embodiment can perform a filling operation for holding a new automatic medicine container 4 in the container storage unit 23.

- the automatic chemical container 4 Prior to this operation, the automatic chemical container 4 is filled with chemicals.

- the operation of filling the medicine is performed manually by a pharmacist. Furthermore, the information regarding the chemical

- the operation display unit 3 is appropriately operated so that the door unit 16 is opened.

- the safety device is activated, and the container moving device 28 is temporarily disabled.

- the automatic chemical container 4 that is newly held in the container storage unit 23 is placed on the container temporary placement unit 18. This operation is performed manually by the user.

- the automatic medicine container 4 is placed on the container temporary placement unit 18 and the operation display unit 3 is displayed and the filling button 59 is pressed, the door unit 16 is closed and the filling operation is performed. Be started.

- a weight measurement operation is performed to measure.

- the type of medicine newly filled in the automatic medicine container 4 is acquired.

- a verification operation is performed to verify whether or not the type of the newly filled medicine is a medicine to be filled in the missing cassette (automatic medicine container 4) selected by the user. To do. That is, an operation for determining whether or not the kind of newly filled medicine is correct is performed.

- the powder medicine packaging device 1 performs a filling amount calculation operation for calculating the filling amount of the medicine in the automatic medicine container 4 based on the value measured by the weight measurement operation.

- This calculation result is stored in the data storage unit and is also stored in the RFID tag of the automatic medicine container 4 as necessary. That is, the powder medicine packaging device 1 performs an information writing operation for storing the weight of the automatic medicine container 4 measured by the weight measurement operation, and if necessary, the medicine filling amount calculated by the necessary filling amount calculation operation.

- the information writing operation for storing the information in the RFID tag is performed.

- the operation restriction on the container moving device 28 by the safety device described above is released, and the container moving device 28 becomes movable. Then, on the condition that the filling amount calculation operation and the weight measurement operation are completed, the arm unit 30 comes close to the container temporary placement unit 18 and holds the automatic medicine container 4.

- the arm unit 30 moves the automatic drug container 4 to the vicinity of the container storage unit 23 and then pushes the automatic drug container 4 into the drum member 25 to engage the automatic drug container 4 and the drum member 25. Combined state. In this state, the magnetic force of the magnet attached to the tip of the arm unit 30 is erased, and the arm unit 30 is separated from the automatic chemical container 4. At this time, the attachment position of the newly held automatic medicine container 4 with respect to the drum member 25, that is, the position information of the automatic medicine container 4 in the held state is acquired and stored in the data storage unit.

- the automatic medicine container 4 can be held on the drum member 25 by repeatedly performing such a filling operation.

- the automatic medicine container 4 filled with powder to be used in the packaging operation to be performed from now on is held in the container storage unit 23. That is, the missing cassette on which the missing cassette notification screen is displayed is compensated, and the missing cassette does not exist in the packaging operation to be performed from now on. [First packing operation]

- the automatic medicine container 4 used for the packaging operation in the cassette selection operation described above is selected, and the selected automatic medicine container 4 is held in the container storage unit 23. Then, a cassette take-out operation for taking out the selected automatic medicine container 4 from the container storage unit 23 is performed.

- the powder medicine packaging device 1 rotates the drum member 25 to bring the automatic medicine container 4 to be taken out and the container moving device 28 close to each other. Then, the automatic medicine container 4 is held by the arm 30 which is a part of the container moving device 28. In other words, the iron plate integrally attached to the automatic chemical container 4 is adsorbed by the magnet provided on the distal end side of the arm portion 30. Then, the arm unit 30 takes out the automatic drug container 4 from the container storage unit 23, moves the automatic drug container 4 to the container holding table 36, and places the automatic drug container 4 on the container holding table 36.

- information reading means is provided in the vicinity of the container holding table 36, and an information reading operation for reading information stored from the RFID tag of the automatic chemical container 4 placed on the container holding table 36 is performed. It is possible. By this information reading operation, the type of medicine (powder) contained in the automatic medicine container 4 is confirmed. That is, a confirmation operation is performed to confirm whether the automatic medicine container 4 containing the medicine to be used is correctly selected and transported.