WO2012053123A1 - 開閉作業具 - Google Patents

開閉作業具 Download PDFInfo

- Publication number

- WO2012053123A1 WO2012053123A1 PCT/JP2010/072277 JP2010072277W WO2012053123A1 WO 2012053123 A1 WO2012053123 A1 WO 2012053123A1 JP 2010072277 W JP2010072277 W JP 2010072277W WO 2012053123 A1 WO2012053123 A1 WO 2012053123A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- opening

- closing operation

- closing

- force

- contact

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B7/00—Pliers; Other hand-held gripping tools with jaws on pivoted limbs; Details applicable generally to pivoted-limb hand tools

- B25B7/12—Pliers; Other hand-held gripping tools with jaws on pivoted limbs; Details applicable generally to pivoted-limb hand tools involving special transmission means between the handles and the jaws, e.g. toggle levers, gears

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B7/00—Pliers; Other hand-held gripping tools with jaws on pivoted limbs; Details applicable generally to pivoted-limb hand tools

Definitions

- the present invention relates to an opening / closing operation tool that transmits a closing force applied to an opening / closing operation unit to the opening / closing operation unit to clamp or cut an object by the opening / closing operation unit.

- Conventional open / close work tools such as pliers and nippers, for example, use the principle to change the gripping force for the operator to grip the open / close operation part into a large clamping force or cutting force and transmit it to the open / close work part. They also pinched and cut objects.

- the overall rigidity of the opening / closing tool is generally increased so that the closing force applied by the operator to the opening / closing operation part can be transmitted as efficiently as possible to the opening / closing operation part that opens and closes the tip of the opening / closing tool. there were.

- an unnecessarily large clamping force is easily applied to the opening / closing operation part that opens and closes, for example, an object that is easily crushed, easily broken, or a surface that is easily damaged.

- the closing force applied to the opening / closing operation part may be applied slightly more or less than necessary, resulting in an excessive holding force acting on the opening / closing work part. In some cases, it was crushed and damaged, or the surface was scratched.

- the operator concentrates the nerves on the fingertips and fingers and applies a delicate force to the opening / closing operation part to apply a closing force with a delicate force. Therefore, the operation while adjusting the delicate force of the opening / closing operation unit for that purpose is very difficult, and has been a factor of greatly reducing the work efficiency.

- the present invention provides a closing mechanism that an operator applies to an opening / closing operation unit when holding an object having a delicate structure such as an object that is not crushed, an object that does not want to be damaged, or an object that does not want to be damaged. Without carefully operating while adjusting the force with delicate force, for example, the object can be crushed or damaged by an extremely simple operation such as simply holding the open / close operation unit 5 or picking it with a fingertip.

- Another object of the present invention is to provide an epoch-making opening / closing work tool that can be easily held without being scratched.

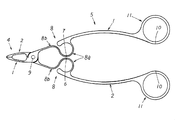

- the first half body 1 and the second half body 2 are pivotally attached to each other, and an opening / closing operation section 4 for sandwiching or cutting the object 3 is provided at the distal end portion, and the opening / closing operation section 4 is operated to open / close the base end section.

- the opening / closing operation tool provided with the opening / closing operation part 5

- the opening / closing operation unit 5 is configured to bend inward as the closing force applied to the opening / closing operation unit 5 is increased, and is applied to the opening / closing operation unit 5 while increasing the closing force.

- the present invention relates to an opening / closing work tool that is configured so as not to exceed a clamping force or a cutting force corresponding to the closing force applied to the opening / closing operation unit 5 when the contact portion 7 contacts. Is.

- the opening / closing operation unit 4 is a cutting unit, and a closing force that presses the proximal ends of the first half 1 and the second half 2 facing each other in an inward closing direction is applied.

- the opening / closing operation unit 4 is closed to form an opening / closing operation unit 5 that sandwiches or cuts the object 3, and the distal end of the first half 1 and the distal end of the second half 2 that serve as the opening / closing operation unit 4.

- the at least the proximal end portion of the first half 1 or the second half according to the increase in the closing force. 2 is configured such that the base end portion of the contact portion 7 is bent inward, and the contact portion 7 movable by the bending and the receiving portion 6 with which the contact portion 7 contacts are opened.

- the contact portion 7 is provided in a state of being opposed to the operation portion 5, and the contact portion 7 is bent and moved by increasing the closing force to approach the receiving portion 6, and when the close force reaches a predetermined value, the contact portion Even if the portion 7 abuts on the receiving portion 6 and continues to increase the closing force applied to the opening / closing operation portion 5, the proximal end side of the abutting portion 7 is further bent as the closing force increases.

- the increasing closing force is not transmitted to the opening / closing operation unit 4, but the clamping force for clamping the object 3 or the cutting force for cutting the object 3 is the same as the receiving unit 6 and the An opening / closing operation tool constructed so as not to exceed a pinching force or cutting force that has a peak value corresponding to the closing force applied to the opening / closing operation portion 5 when the contact portion 7 contacts. It is related to.

- the opening / closing operation unit 4 grips the opening / closing operation unit 5 in which the proximal end portion of the first half 1 and the proximal end portion of the second half 2 are disposed in an opposing state by hand.

- the distal end portion of the first half 1 and the second half that sandwich or cut the object 3 by performing a closing operation in which the interval is narrowed by applying the closing force that is pinched by the fingertip and pressed inward.

- the first half 1 or the second half 2 of the opening / closing operation unit 5 is configured to bend inwardly

- the contact portion 7 is connected to one of the movable movable portions 8 of the first half 1 or the second half 2 of the opening / closing operation portion 5.

- the receiving portion 6 is provided on the other side opposite thereto, and the contact portion 7 and the receiving portion 6 are not in contact until the opening / closing operation portion 4 is closed and the object 3 is sandwiched, When the object 3 is clamped, the closing force is further increased to cause the bending movable portion 8 to bend and deform so that the contact portion 7 approaches the receiving portion 6 and comes into contact.

- the abutting portion 7 is located on the proximal side of the pivoting portion 9 that cross-pivots the first half 1 and the second half 2 and holds the opening / closing operation portion 5 or with a fingertip.

- the opening / closing operation unit 4 grips the opening / closing operation unit 5 in which the proximal end portion of the first half 1 and the proximal end portion of the second half 2 are disposed in an opposing state by hand.

- the distal end portion of the first half 1 and the second half that sandwich or cut the object 3 by performing a closing operation in which the interval is narrowed by applying the closing force that is pinched by the fingertip and pressed inward.

- the first half 1 or the second half 2 of the opening / closing operation unit 5 is configured to bend inwardly

- the contact portion 7 is connected to one of the movable movable portions 8 of the first half 1 or the second half 2 of the opening / closing operation portion 5.

- the receiving portion 6 is provided on the other side opposite thereto, and the contact portion 7 and the receiving portion 6 are not in contact until the opening / closing operation portion 4 is closed and the object 3 is sandwiched, When the object 3 is clamped, the closing force is further increased to cause the bending movable portion 8 to bend and deform so that the contact portion 7 approaches the receiving portion 6 and comes into contact.

- the abutting portion 7 is located on the proximal side of the pivoting portion 9 that cross-pivots the first half 1 and the second half 2 and holds the opening / closing operation portion 5 or with a fingertip. 3.

- the opening / closing operation part 4 is located on the distal end side of the pivoting part 9 of the first half 1 and the second half 2 and the opening / closing operation part 5 is located on the base end side.

- the abutting portion 7 is located closer to the pivoting portion 9 so as to protrude inwardly to one of the proximal end portion of the first half 1 and the proximal end portion of the second half 2 that becomes a holding portion or a fingertip clamping portion.

- the closing force applied to the opening / closing operation unit 5 is transmitted to the opening / closing operation unit 4, and the holding force of the opening / closing operation unit 4 that holds the object 3 generated according to the closing force is determined by the opening / closing operation unit 5.

- the bending movable portion 8 increases as the closing force applied to the opening / closing operation portion 5 increases. Even if the closing force applied to the opening / closing operation unit 5 is further increased from the time when the contact unit 7 and the receiving unit 6 contact each other, the closing force applied to the opening / closing operation unit 5 is increased.

- the holding force according to the predetermined value of the closing force at the time of contact when the contact portion 7 and the receiving portion 6 are in contact with each other is not increased, and the holding force is reduced as a peak value.

- the closing force applied to the opening / closing operation unit 5 is transmitted to the opening / closing operation unit 4, and the holding force of the opening / closing operation unit 4 that holds the object 3 generated according to the closing force is determined by the opening / closing operation unit 5.

- the bending movable portion 8 increases as the closing force applied to the opening / closing operation portion 5 increases. Even if the closing force applied to the opening / closing operation unit 5 is further increased from the time when the contact unit 7 and the receiving unit 6 contact each other, the closing force applied to the opening / closing operation unit 5 is increased.

- the holding force according to the predetermined value of the closing force at the time of contact when the contact portion 7 and the receiving portion 6 are in contact with each other is not increased, and the holding force is reduced as a peak value.

- the object to be clamped or cut can be opened / closed by an extremely simple operation by simply holding the object to be opened / closed by the opening / closing operation unit and adding the closing force to the opening / closing operation unit.

- This is an epoch-making opening / closing work tool that can be pinched without being crushed or broken at the working portion or scratched on the surface.

- the opposing opening / closing operation parts are simply connected to each other.

- An operation to be applied while increasing the closing force to be pushed inward in the closing direction such as a gripping operation or a pinching operation with a fingertip, can be used to crush an object with a delicate structure as described above. It can be easily sandwiched without breaking or scratching the surface.

- the opening / closing work tool of the present invention does not transmit a force corresponding to a closing force greater than a predetermined value applied to the opening / closing operation unit to the opening / closing operation unit, no matter how much the closing force is applied to the opening / closing operation unit.

- the working unit does not pinch the object with a pinching force higher than the peak value.For example, it does not adjust the delicate force of the closing force and grips the open / close operation part or picks it with the fingertip. Even if the object is clamped by the opening / closing operation part by applying a closing force that pushes it in the closing direction, the object with this delicate structure can be clamped without breaking or damaging the surface. it can.

- Crush Ku an innovative closing implement capable of sandwiching the scratch easily delicate structures as an object.

- the bending of the opening / closing operation unit is a reaction of elastic force caused by resistance when the object is pinched or cut

- the reaction of the elastic force due to bending is sensed by a hand or fingertip that operates the opening / closing operation unit.

- the operator can confirm that the opening / closing operation part has grasped the object, and the opening / closing operation part continues to bend, so that the reaction of the elastic force of the bending continues to be transmitted to the operator's hands and fingertips. Therefore, the operator can always feel that the opening / closing operation unit keeps grasping the object, so that the object can be held without feeling uneasy about whether the opening / closing operation unit is holding the object properly. This is an epoch-making opening and closing work tool with excellent practicality that can be held securely with confidence.

- the closing force applied to the opening / closing operation part when the thickness of the bending movable part of the present embodiment is thin and the distance between the contact part and the receiving part is set narrow, and the bending of the opening / closing operation part when this closing force is applied It is a figure which shows the relationship between a movement amount and the clamping force transmitted to an opening / closing operation

- the closing force applied to the opening / closing operation part when the thickness of the bending movable part of the present embodiment is thick and the interval between the contact part and the receiving part is set narrow, and the bending of the opening / closing operation part when this closing force is applied It is a figure which shows the relationship between a movement amount and the clamping force transmitted to an opening / closing operation

- the closing force applied to the opening / closing operation part when the thickness of the bending movable part of this embodiment is thin and the distance between the contact part and the receiving part is set wide, and the bending of the opening / closing operation part when this closing force is applied It is a figure which shows the relationship between a movement amount and the clamping force transmitted to an opening / closing operation

- the opening / closing functioning as the tip of the opposing first half 1 and second half 2, that is, the clamping or cutting part.

- the object 3 is arranged between the working parts 4 and the opening / closing operation part 5 is placed on the proximal end part of the first half 1 and the second half 2 facing each other, that is, the opening / closing operation part 5.

- the opening / closing operation unit 4 closes and holds the object 3 by applying a closing force that is picked up with the fingertips and pressed toward each other in the closing direction.

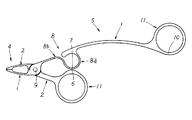

- the opening / closing operation unit 5 is bent by the opening / closing operation unit 4 when the opening / closing operation unit 5 is gripped or picked up with a fingertip and a closing force is applied to the opening / closing operation unit 5. Since it is a reaction of elastic force caused by resistance when the object 3 is clamped or cut, the operator can feel the reaction of the elastic force due to this bending with the hand or fingertip that operates the opening / closing operation unit 5. It can be easily understood that the opening / closing operation unit 4 has grasped the object 3.

- the operator can feel that he / she is grasping the object 3 by bending the opening / closing operation unit 5 with his / her hand or fingertip, and can continue the clamping operation with peace of mind, and further increase the closing force on the opening / closing operation unit 5.

- the opening / closing operation part 5 is further bent inward, the contact part 7 and the receiving part 6 are further brought closer to the opening / closing operation part 5 as the opening / closing operation part 5 is bent.

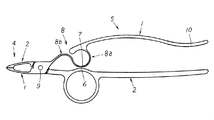

- the applied closing force reaches a predetermined value, the contact portion 7 contacts the receiving portion 6.

- the contact portion 7 responds to the first half by increasing the closing force. 1 and the base end side of the second half 2, that is, the opening / closing operation part 5 further inwardly bends, but from the contact part 7, the tip side of the first half 1 and the second half 2, that is, opening / closing work This increasing closing force is not transmitted to the part 4.

- the contact part 7 and the receiving part 6 provided on the first half 1 and the second half 2 are in contact with each other. Since the contact between the contact portion 7 and the receiving portion 6 comes into contact with each other, the operator can hold the opening / closing operation portion 4 further in the opening / closing operation. It can be understood that the peak value does not increase even when the closing force is applied to the portion 5.

- the contact portion 7 and the receiving portion 6 are in contact with each other, and even when the closing force is applied to the opening / closing operation portion 5 while increasing, the increasing closing force is not transmitted to the opening / closing operation portion 4.

- the clamping force of the opening / closing operation unit 4 is, for example, the clamping force at the time when the contact part 7 and the receiving part 6 are in contact, that is, a state in which a constant clamping force is maintained, or

- the holding force at the time of contact when the contact portion 7 and the receiving portion 6 are in contact is the maximum holding force at which the peak value is reached. Further, by adding the closing force to the opening / closing operation unit 5 while increasing the closing force, the holding force of the opening / closing operation unit 4 is reduced.

- the opening / closing operation portion 5 is further bent by applying the opening / closing operation portion 5 while increasing the closing force, so that the operator can easily hold it. Or, it can be held in a state where it can be easily picked with a fingertip, and even when a closing force is applied to the opening / closing operation unit 5 until it is easily gripped or in a state where it can be easily picked with a fingertip, Since the target object 3 is not subjected to a clamping force equal to or higher than the peak value, the operator can use the opening / closing operation unit 5 without worrying about the closing force transmitted from the opening / closing operation unit 5 to the opening / closing operation unit 4.

- the closing operation that is, the closing force that presses the opening / closing operation portions 5 of the first half 1 and the second half 2 facing each other in the inner closing direction can be applied without fine adjustment.

- a predetermined closing force is applied to the object 3 at the opening / closing operation unit 5, and a force greater than the pinching force that is a peak value at the time when the contact unit 7 and the receiving unit 6 contact each other does not act.

- Holding force with a holding force that is a peak value when the contact portion 7 and the receiving portion 6 contact each other is smaller than an unnecessary holding force that crushes, breaks, or scratches the object 3

- the peak value of the clamping force so as to be a force and a clamping force having a sufficient clamping force, the operator does not damage the object 3 so as not to crush the object 3 as in the past.

- the object 3 with a delicate structure such as an object that does not want to be crushed, an object that does not want to be destroyed, or an object that does not want to be scratched by the clamping operation, can be easily sandwiched with an extremely simple operation that only adds while increasing

- the work efficiency is remarkably improved, and it is an epoch-making opening / closing work tool excellent in practicality and workability.

- the operator can further hold the opening / closing operation portion 5 or pick it with a fingertip.

- the operator opens and closes the opening / closing operation unit 5 by sensing the reaction of the elastic force caused by the bending with the hand holding the opening / closing operation unit 5 or the finger holding the opening / closing operation unit 5. It is possible to roughly grasp how much the closing force is applied, and to be confident that the object 3 can be grasped by the opening / closing operation unit 4 and to work with peace of mind.

- the grasping force that crushes or scratches the blood vessel in advance is grasped, and

- 7 and the receiving portion 6 are set to contact each other, so that the clamping force greater than the peak value does not act on the opening / closing operation portion 4, so that the operator may crush the blood vessel when holding the blood vessel.

- the gripping of the object 3 reduces the bending of the opening / closing operation unit 5.

- feeling with your hands or fingertips It can be easily grasped, and it has excellent practicality that can easily and easily hold blood vessels without feeling uneasy about whether or not the object 3 is being held with sufficient clamping force. It becomes a breakthrough opening and closing work tool.

- the pair of first half 1 and second half 2 are pivoted to cross each other in the middle, and the front ends of the opposed first half 1 and second half 2 are

- the opening / closing operation unit 4 serving as a clamping unit or a cutting unit is used to apply a closing force that presses the proximal ends of the first half 1 and the second half 2 facing each other in an inward closing direction.

- the opening / closing operation part 4 of the distal end part is closed to form an opening / closing operation part 5 that sandwiches or cuts the object 3, and the distal end part of the first half 1 and the distal end of the second half 2 of the opening / closing part 4.

- the closing force When the closing force is further applied to the opening / closing operation unit 5 in a state where the object 3 is sandwiched by the portion, at least the proximal end portion of the first half 1 or the second portion according to the increase in the closing force

- the base end portion of the half body 2 is configured to bend inward, and a contact portion 7 that is movable by this bending and a receiving portion 6 that the contact portion 7 contacts are paired.

- the closing force is increased and the closing force is increased, the contact portion 7 is bent and moved to approach the receiving portion 6, and the closing force reaches a predetermined value.

- the opening / closing work tool is configured to prevent transmission of a clamping force that is a peak value corresponding to the closing force or a clamping force that is greater than a cutting force.

- the first half 1 and the second half 2 are formed of a suitable material, for example, a member made of metal or synthetic resin in a predetermined shape, and the object 3 is sandwiched between the distal ends.

- An opening / closing operation unit 4 as a clamping unit is provided, and an opening / closing operation unit 5 for opening / closing the opening / closing operation unit 4 is provided on the base end side, and is pivotally attached to a position serving as a boundary between the opening / closing operation unit 4 and the opening / closing operation unit 5.

- the opening / closing operation unit 4 and the opening / closing operation unit 5 are integrally formed.

- the first half 1 and the second half 2 are integrally formed, but the opening / closing operation unit 4 and the opening / closing operation unit 5 may be configured to be separable.

- the opening / closing operation unit 4 holds the opening / closing operation unit 5 in which the proximal end portion of the first half 1 and the proximal end portion of the second half 2 are opposed to each other by hand or The tip of the first half 1 and the tip of the second half 2 that sandwich the object 3 by performing a closing motion that narrows the interval by applying a closing force that is pinched by the fingertip and pressed inward. It is composed.

- the opening / closing operation unit 4 is formed as a clamping unit that clamps the object 3.

- a cutting blade is provided at the tip to cut the object 3. As long as it exhibits the characteristics of the present embodiment, it can be appropriately employed.

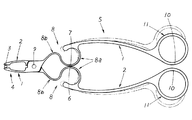

- the opening / closing operation unit 5 for opening / closing the opening / closing operation unit 4 is formed in a curved shape that protrudes outward, and a finger insertion unit 11 that inserts a finger into the base end portion and performs a pinching operation.

- the point where the movable part 8 is bent is provided at the tip, and the point where the finger is inserted into the finger insertion part 11 and the closing force is applied is defined as the power point part 10, and the fingertip is picked and operated by this force point part 10.

- the opening / closing operation unit 4 When the opening / closing operation unit 4 is closed by applying the closing force generated in step S4, the object 3 is clamped, and the opening / closing operation unit 4 is bent by the reaction of the clamping force that clamps the object 3, and the movable unit 8 is bent and deformed to open / close.

- the operation unit 5 is configured to bend or move.

- the finger insertion part 11 is formed in a circular shape having a diameter into which the fingertip can be inserted, and the finger insertion part 11 is inserted into the circular finger insertion part 11 in this way to operate the opening / closing operation part 5.

- a closing operation for applying a closing force inward but also an operation for expanding the opening / closing operation unit 5 outward can be operated with two fingers.

- the shape of the finger insertion portion 11 is not limited to the circular shape shown in the present embodiment, but may be an inwardly curved shape or a linear shape as shown in FIG. Any material can be used as long as it exhibits the above or a property that approximates.

- the finger insertion unit 11 is provided and the fingertip is picked up.

- the finger insertion unit 11 may not be provided, and the opening / closing operation unit 5 may be configured to be gripped. Or you may comprise so that it may operate with a machine, an apparatus, a robot, etc. instead of operating with a human hand or a fingertip, and the shape and structure shall be changeable suitably.

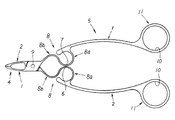

- the bending movable portion 8 is specifically formed by bending an aluminum plate material or a SUS plate material into a substantially S shape and attaching the first half body 1 and the second half body 2 to each other.

- the bending movable portion 8 includes a proximal-side curved portion 8a that protrudes inward and a distal-side curved portion 8b that protrudes outward.

- One end of the portion 8a is projected inward from the position of the base end side of the opening / closing operation unit 5, and the other end side is the leading end side of the first half 1 or the second half 2, that is, opening / closing operation.

- the base end side bending portion 8a is bent to form a circle toward the portion 4 side, and the other end of the base end side bending portion 8a is bent outwardly so as to protrude outward.

- one end of the distal end side bending portion 8b is connected to the pivot attachment portion 9.

- the bending movable portion 8 may be configured to have a reduced thickness as shown in FIG. 7A or a configuration having a increased thickness as shown in FIG. 7B. By changing the thickness, the degree of bending deformation of the bending movable portion 8 can be changed.

- the bending movable portion 8 is provided on both the first half 1 and the second half 2.

- the bending movable portion 8 is provided. May be provided in only one of the first half 1 and the second half 2, and the flexible movable portion 8 is not limited to the above-described material and shape. It is also possible to set the thickness and diameter appropriately so that the desired deflection occurs, adjust the deflection by forming a hole, or change the material (such as synthetic resin), etc. Any material that exhibits the characteristics of this embodiment can be used as appropriate.

- the abutting portion 7 is provided on one base-end side bending portion 8a of the opposing bending movable portion 8, and the receiving portion 6 is provided on the other base-end bending portion 8a.

- the contact portion 7 and the receiving portion 6 are applied to the opening / closing operation portion 5 while increasing the closing force, whereby the bending movable portion 8 provided in an opposing state is inward.

- One of the contacts that contact when the closing force applied to the opening / closing operation unit 5 reaches a predetermined value is the contact portion 7 and the other is the receiving portion 6, and in this embodiment, The contact on the first half 1 side is the contact portion 7, and the contact on the second half 2 side is the receiving portion 6, which are the most inwardly protruding positions (points) of the respective proximal side curved portions 8 a. It is configured to be in the vicinity.

- the contact portion 7 and the receiving portion 6 are configured not to contact when the object 3 is not sandwiched between the opening / closing operation portion 4 and simply being closed. In other words, the contact portion 7 and the receiving portion 6 in a state in which the opening / closing operation portion 4 is completely closed, that is, in a state where the tip portion of the first half 1 and the tip portion of the second half 2 are in contact.

- the contact portion 7 and the receiving portion 6 are configured to contact each other when the bending movable portion 8 is bent.

- the interval between the contact portion 7 and the receiving portion 6 may be a configuration in which the interval is narrowed as shown in FIG. 8 (a), or a configuration in which the interval is widened as shown in FIG. 8 (b).

- the bending movable portion 8 is added to the opening / closing operation portion 5 until the contact portion 7 and the receiving portion 6 come into contact after the bending movable portion 8 starts to bend and deform. Since the closing force changes, the clamping force transmitted to the opening / closing operation unit 4 can be changed.

- the gap between the abutting portion 7 and the receiving portion 6 is set narrow, and the abutting portion 7 and the receiving portion 6 are quickly brought into contact with each other to open and close the opening / closing operation portion 4.

- a structure in which the gap between the contact part 7 and the receiving part 6 is widened may be used. It is assumed that the interval between the contact portion 7 and the receiving portion 6 can be set and changed as appropriate so that the holding force appropriately corresponds to the object 3.

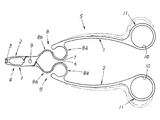

- FIG. 3 to FIG. 6 are diagrams showing the state of use of this embodiment, that is, the state of this embodiment when the object 3 is sandwiched by the opening / closing operation unit 4 and the closing force is applied to the opening / closing operation unit 5. It is.

- FIG. 3 is a diagram illustrating a state in which the object 3 is sandwiched by the opening / closing operation unit 4. If the closing force is applied to the force application part 10 of the finger insertion part 11 while increasing the closing force while the object 3 is sandwiched by the opening / closing operation part 4, the bending movable part 8 becomes inward as shown in FIG. When the opening / closing operation part 5 is bent inward, the contact part 7 and the receiving part 6 provided on the proximal end side bending part 8a of the bending movable part 8 begin to approach each other.

- the closing force is further applied to the power point portion 10 while being further increased, the bending movable portion 8 is further bent inwardly, the contact portion 7 and the receiving portion 6 are further brought closer, and the opening / closing operation portion 5 is further moved inward.

- the closing force reaches a predetermined value, the contact portion 7 and the receiving portion 6 contact each other as shown in FIG.

- the closing force applied to the opening / closing operation unit 5 (power point portion 10 of the finger insertion unit 11) is transmitted to the opening / closing operation unit 4, and the opening / closing operation unit 4 is operated to open and close on the basis of the lever principle.

- a clamping force corresponding to the closing force applied to the portion 5 is generated, and the object 3 is clamped by the clamping force corresponding to the applied closing force.

- the opening / closing operation unit 4 does not have a holding force corresponding to the closing force applied to the opening / closing operation unit 5 while being further increased.

- the clamping force remains at the time when the abutting portion 7 and the receiving portion 6 abut, or decreases.

- the flexible movable portion 8 is formed in a substantially S shape in which a proximal-side curved portion 8a that protrudes inward and a distal-side curved portion 8b that protrudes outward are connected.

- the proximal end bending portion 8a and the distal end are applied to the operation portion 5 while increasing the closing force until the closing force applied to the opening / closing operation portion 5 reaches a predetermined value and the contact portion 7 and the receiving portion 6 contact each other.

- Both of the side curved portions 8b bend inwardly and deform, but if a closing force of a predetermined value or more is further applied to the opening / closing operation portion 5 after the contact portion 7 and the receiving portion 6 contact each other, the proximal end

- the proximal end side of the side curved portion 8a is further bent inward than the contact portion 7 (receiving portion 6).

- the proximal side curved portion is deformed by the proximal side bent deformation of the proximal side curved portion 8a.

- the force which presses a front end side outward rather than the contact part 7 (receiving part 6) of the part 8a acts.

- a force that presses the distal end side bending portion 8b in the outward opening direction acts, so that the opening / closing operation portion 4 operates in the opening direction. It is comprised so that the clamping force which clamps the target object 3 may reduce.

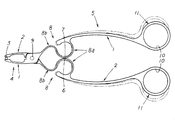

- the closing force applied to the opening / closing operation unit shown in FIGS. 9 to 11, the bending movement amount of the opening / closing operation unit when this closing force is applied, and the clamping force transmitted to the opening / closing operation unit As shown in the relationship, when the closing force is applied to the opening / closing operation unit 5 while increasing the closing force while the object 3 is sandwiched between the opening / closing operation unit 4, the opening / closing operation unit is initially deformed by the bending and deformation of the movable unit 8. 5 is bent and moved inward, and the opening / closing operation unit 4 has a clamping force that increases in accordance with an increasing closing force.

- the closing force applied to the opening / closing operation part 5 reaches a predetermined value

- the contact part 7 and the receiving part 6 come into contact with each other, so that the opening / closing work part 4 has a holding force corresponding to the further increasing closing force.

- the clamping force at the time of contact when the contact part 7 and the receiving part 6 contact each other becomes the maximum clamping force, that is, the peak value of the clamping force of the opening / closing work part 4, and this is the boundary.

- FIG. 9 the basic configuration of the present embodiment, that is, the thickness of the flexible movable portion 8 is thin, and the distance between the contact portion 7 and the receiving portion 6 is set narrow.

- FIG. 10 shows a case where, in this basic configuration, the distance between the contact portion 7 and the receiving portion 6 is kept as it is, and the thickness of the flexible movable portion 8 is set to be thick (double thickness).

- FIG. 11 shows a case where the interval between the contact portion 7 and the receiving portion 6 is set wide (double interval) in the basic configuration described above.

- This embodiment is designed so that when the closing force applied to the opening / closing operation unit 5 is transmitted to the opening / closing operation unit 4 according to the lever principle, the holding force is five times the applied closing force. Yes.

- the closing force applied to the opening / closing operation unit 5 reaches a predetermined value, if the closing force is applied to the opening / closing operation unit 5 while increasing, the amount of bending movement of the opening / closing operation unit 5 increases constantly.

- the clamping force with which the opening / closing operation unit 4 clamps the object 3 increases with an inclination of five times the closing force.

- the abutment unit 7 and the receiving unit 6 come into contact with each other, so that the clamping force of the opening / closing operation unit 4 reaches a peak value. Even if the closing force is increased in the operation unit 5, the clamping force decreases.

- the amount by which the opening / closing operation part 5 is bent and moved by the closing force applied to the opening / closing operation part 5 changes at the boundary between the contact part 7 and the receiving part 6. Specifically, since the opening / closing operation unit 5 is difficult to bend, in order to increase the amount of bending movement of the opening / closing operation unit 5 in a constant state, the closing force applied to the opening / closing operation unit 5 must be made larger. It becomes.

- the opening / closing operation unit 4 eventually becomes zero in the holding force of the object 3, and the opening / closing operation unit 4 becomes the object 3. Can not be held, and a state in which the object 3 is released from the opening / closing operation unit 4 occurs.

- the opening / closing operation unit 5 is used both when the object 3 is held and when it is opened. It is also possible to operate with only one operation of applying a closing force to the arm, that is, with one action.

- the object 3 having a delicate structure such as an object that does not want to be crushed by the clamping operation, an object that does not want to be damaged, or an object that does not want to be scratched on the surface, is held in the opening / closing work unit 4.

- the contact portion 7 is applied when a predetermined closing force is generated that does not crush the object 3, does not break it, or does not damage the surface, and generates a clamping force that can sufficiently clamp the object 3.

- the receiving part 6 are in contact with each other, so that the closing operation of the opening / closing operation part 5 is delicate so that the object 3 is not crushed, damaged or scratched by the opening / closing work part 4.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Scissors And Nippers (AREA)

- Prostheses (AREA)

- Sheet Holders (AREA)

Abstract

Description

Claims (7)

- 第一半体と第二半体とを交差枢着して、先端部に対象物を挟持又は切断する開閉作業部を設けると共に、基端部に前記開閉作業部を開閉操作する開閉操作部を設けた開閉作業具において、前記開閉操作部に閉力を加えて前記開閉作業部を閉動させ前記対象物を挟持又は切断する際、前記対象物を挟持した状態で前記開閉操作部に加える前記閉力を増大させるに従い前記開閉操作部が内方に撓むように構成して、前記開閉操作部に前記閉力を増大させながら加えていっていることを、この開閉操作部を握持する手若しくは押圧する手若しくは指先で感じる又は撓み量を目視することでわかるように構成し、この開閉操作部の内方への撓みにより接近してゆき前記閉力が所定値になったとき受部に当接する当接部を開閉操作部の撓み可動部に設け、この受部と当接部とが当接した状態で前記閉力を更に増大させるとこの当接部より基端側が更に撓む若しくは内方に可動するがこの増大した閉力は前記開閉作業部には伝達されず前記対象物を挟持する挟持力若しくは前記対象物を切断する切断力は、前記受部と前記当接部とが当接した際に前記開閉操作部に加えられていた前記閉力に応じた挟持力若しくは切断力以上とならないように構成したことを特徴とする開閉作業具。

- 一対の第一半体と第二半体とを途中で重合交差させて枢着し、この対向する第一半体と第二半体との先端部を、挟持部若しくは切断部とする開閉作業部とし、前記対向する第一半体と第二半体との基端部を、互いに内方の閉じ方向に押圧させる閉力を加えることで前記先端部の開閉作業部が閉動して対象物を挟持若しくは切断する開閉操作部とし、前記開閉作業部となる前記第一半体の先端部と前記第二半体の先端部とで前記対象物を挟持した状態で、更に前記開閉操作部に前記閉力を加えると、この閉力の増大に応じて少なくとも前記第一半体の基端部若しくは前記第二半体の基端部が内方へ撓むように構成し、この撓みによって可動する当接部とこの当接部が当接する受部とを前記開閉操作部に対向状態に設け、前記閉力を増大させてゆくことで前記当接部を撓み可動させて前記受部に接近させ、この閉力が所定値に達したとき前記当接部が前記受部に当接して、前記開閉操作部に加える前記閉力を更に増大させ続けても、前記閉力の増大に応じて前記当接部より基端側は更に撓む若しくは内方に可動するがこの増大する閉力は前記開閉作業部に伝達されず前記対象物を挟持する挟持力若しくは前記対象物を切断する切断力は、前記受部と前記当接部が当接した際に前記開閉操作部に加えられていた前記閉力に応じたピーク値となる挟持力若しくは切断力以上とならないように構成したことを特徴とする開閉作業具。

- 前記開閉作業部は、前記第一半体の基端部と前記第二半体の基端部とを対向状態に配設した前記開閉操作部を、手で握持する若しくは指先で挟持し内方へ押圧する前記閉力を加えることで間隔が狭められる閉動動作をなして前記対象物を挟持若しくは切断する前記第一半体の先端部と前記第二半体の先端部とから成り、この開閉作業部の前記第一半体の先端部と前記第二半体の先端部とで前記対象物を挟持した状態で若しくは切断途中でこの対象物を挟持した状態で更に前記開閉操作部に閉力を加えると、この開閉操作部の少なくとも前記第一半体若しくは前記第二半体が内方へ撓むように構成し、この開閉操作部の前記第一半体若しくは前記第二半体の一方の撓み可動部に前記当接部を設け、これと対向する他方に前記受部を設け、前記開閉作業部が閉動し前記対象物を挟持するまでは前記当接部と前記受部とは当接せず、前記対象物を挟持した際更に前記閉力を増大させることで前記撓み可動部が撓み変形することにより前記当接部が前記受部に対して接近してゆき当接するように構成し、この当接部は前記第一半体と前記第二半体とを交差枢着する枢着部より基端側であって前記開閉操作部を握持する若しくは指先で挟持して前記閉力を加える力点部より先端側に設けたことを特徴とする請求項1記載の開閉作業具。

- 前記開閉作業部は、前記第一半体の基端部と前記第二半体の基端部とを対向状態に配設した前記開閉操作部を、手で握持する若しくは指先で挟持し内方へ押圧する前記閉力を加えることで間隔が狭められる閉動動作をなして前記対象物を挟持若しくは切断する前記第一半体の先端部と前記第二半体の先端部とから成り、この開閉作業部の前記第一半体の先端部と前記第二半体の先端部とで前記対象物を挟持した状態で若しくは切断途中でこの対象物を挟持した状態で更に前記開閉操作部に閉力を加えると、この開閉操作部の少なくとも前記第一半体若しくは前記第二半体が内方へ撓むように構成し、この開閉操作部の前記第一半体若しくは前記第二半体の一方の撓み可動部に前記当接部を設け、これと対向する他方に前記受部を設け、前記開閉作業部が閉動し前記対象物を挟持するまでは前記当接部と前記受部とは当接せず、前記対象物を挟持した際更に前記閉力を増大させることで前記撓み可動部が撓み変形することにより前記当接部が前記受部に対して接近してゆき当接するように構成し、この当接部は前記第一半体と前記第二半体とを交差枢着する枢着部より基端側であって前記開閉操作部を握持する若しくは指先で挟持して前記閉力を加える力点部より先端側に設けたことを特徴とする請求項2記載の開閉作業具。

- 前記第一半体及び前記第二半体の枢着部よりも先端側を前記開閉作業部とし、基端側を前記開閉操作部とし、この開閉操作部の握持部若しくは指先挟持部となる前記第一半体の基端部と前記第二半体の基端部の一方に内方に突出状態に前記当接部を前記枢着部寄りに設けると共に、他方にこの当接部と当接する前記受部を設けたことを特徴とする請求項1~4のいずれか1項に記載の開閉作業具。

- 前記開閉操作部に加える閉力が前記開閉作業部に伝達されこの閉力に応じて生じる前記対象物を挟持する前記開閉作業部の挟持力は、前記開閉操作部の前記撓み可動部が撓んでこの撓み可動部に設けた前記当接部が前記受部に接近して当接するまでは前記開閉操作部に加える閉力の増大に応じて増大し、前記当接部と前記受部とが当接した時点を境にして、更に前記開閉操作部に加える閉力を増大させても、この開閉操作部に加える閉力の増大に応じて増大せずに前記当接部と前記受部とが当接した当接時の前記閉力の所定値に応じた挟持力をピーク値として減少するように構成したことを特徴とする請求項2~4のいずれか1項に記載の手動開閉作業具。

- 前記開閉操作部に加える閉力が前記開閉作業部に伝達されこの閉力に応じて生じる前記対象物を挟持する前記開閉作業部の挟持力は、前記開閉操作部の前記撓み可動部が撓んでこの撓み可動部に設けた前記当接部が前記受部に接近して当接するまでは前記開閉操作部に加える閉力の増大に応じて増大し、前記当接部と前記受部とが当接した時点を境にして、更に前記開閉操作部に加える閉力を増大させても、この開閉操作部に加える閉力の増大に応じて増大せずに前記当接部と前記受部とが当接した当接時の前記閉力の所定値に応じた挟持力をピーク値として減少するように構成したことを特徴とする請求項5記載の手動開閉作業具。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201080040939.0A CN102574278B (zh) | 2010-10-19 | 2010-12-10 | 开合作业器 |

| US13/395,774 US8863623B2 (en) | 2010-10-19 | 2010-12-10 | Open-close work implement |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010234143A JP4995961B2 (ja) | 2010-10-19 | 2010-10-19 | 開閉作業具 |

| JP2010-234143 | 2010-10-19 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012053123A1 true WO2012053123A1 (ja) | 2012-04-26 |

Family

ID=45974855

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2010/072277 WO2012053123A1 (ja) | 2010-10-19 | 2010-12-10 | 開閉作業具 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8863623B2 (ja) |

| JP (1) | JP4995961B2 (ja) |

| CN (1) | CN102574278B (ja) |

| WO (1) | WO2012053123A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014097494A1 (ja) * | 2012-12-18 | 2014-06-26 | ナシモト工業株式会社 | 開閉作業具 |

| WO2014203578A1 (ja) * | 2013-06-21 | 2014-12-24 | ナシモト工業株式会社 | 作業装置 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101489120B1 (ko) * | 2014-05-02 | 2015-02-04 | 손원호 | 바이스 그립 플라이어 |

| EP3691831A2 (en) * | 2017-07-10 | 2020-08-12 | Nigel Buchanan | Pliers |

| WO2022256056A1 (en) * | 2021-06-04 | 2022-12-08 | Groh Daniel | Systems and methods associated with pliers |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6289948U (ja) * | 1985-11-27 | 1987-06-09 | ||

| FR2775504A1 (fr) * | 1998-02-27 | 1999-09-03 | Bost Garnache Ind | Ressort d'amortissement et/ou d'ouverture pour un outil, et outil correspondant |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2736218A (en) * | 1956-02-28 | atkeson | ||

| US3282137A (en) * | 1964-12-30 | 1966-11-01 | Bendix Corp | Actuating mechanism for plier type devices |

| US3653389A (en) * | 1970-01-19 | 1972-04-04 | Amp Inc | Disposable forceps |

| US3675359A (en) | 1970-11-12 | 1972-07-11 | Sargent & Co | Fish mouth implements |

| GB1427397A (en) * | 1973-04-24 | 1976-03-10 | Ici Ltd | Forceps |

| GB1509645A (en) * | 1975-10-20 | 1978-05-04 | Fletcher Terry Co | Glass breaking pliers |

| US4563833A (en) * | 1983-06-13 | 1986-01-14 | Aucoin Raymond U | Fish holding device |

| US5451231A (en) * | 1994-03-11 | 1995-09-19 | Ryder International Corporation | Surgical staple remover |

| US5522290A (en) * | 1994-04-18 | 1996-06-04 | Visser; Steven C. | Compliant pliers |

| US5893307A (en) * | 1997-04-25 | 1999-04-13 | Tao; Liang-Che | Pliers with biasing element |

| US6050279A (en) * | 1998-06-08 | 2000-04-18 | Advanced Micro Devices, Inc. | Apparatus and method for immersing an object in a liquid such that a lower surface of the object does not touch a bottom surface of a container holding the liquid |

| DE29822558U1 (de) * | 1998-12-18 | 1999-02-18 | Aesculap AG & Co. KG, 78532 Tuttlingen | Gefäßclip |

| CN2407886Y (zh) * | 2000-02-21 | 2000-11-29 | 曾绍谦 | 省力便利夹 |

| CN200973731Y (zh) * | 2007-05-29 | 2007-11-14 | 许林 | 无创型血管阻断钳 |

| KR101140182B1 (ko) * | 2008-10-07 | 2012-05-02 | 미쓰보시 다이야몬도 고교 가부시키가이샤 | 취성 재료 플라이어 |

| CN201290718Y (zh) * | 2008-11-17 | 2009-08-19 | 王爱芹 | 手柄组合式血管夹 |

| CN201510373U (zh) * | 2009-09-08 | 2010-06-23 | 广州医学院第一附属医院 | 多孔弹力血管夹 |

| CN201524962U (zh) * | 2009-09-23 | 2010-07-14 | 布和 | 软钳 |

| US20120132040A1 (en) * | 2010-11-30 | 2012-05-31 | Jeffrey Mastroianni | Pivoting-lever hand tool with resilient closed-loop handle |

-

2010

- 2010-10-19 JP JP2010234143A patent/JP4995961B2/ja not_active Expired - Fee Related

- 2010-12-10 CN CN201080040939.0A patent/CN102574278B/zh not_active Expired - Fee Related

- 2010-12-10 WO PCT/JP2010/072277 patent/WO2012053123A1/ja active Application Filing

- 2010-12-10 US US13/395,774 patent/US8863623B2/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6289948U (ja) * | 1985-11-27 | 1987-06-09 | ||

| FR2775504A1 (fr) * | 1998-02-27 | 1999-09-03 | Bost Garnache Ind | Ressort d'amortissement et/ou d'ouverture pour un outil, et outil correspondant |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014097494A1 (ja) * | 2012-12-18 | 2014-06-26 | ナシモト工業株式会社 | 開閉作業具 |

| WO2014203578A1 (ja) * | 2013-06-21 | 2014-12-24 | ナシモト工業株式会社 | 作業装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120291293A1 (en) | 2012-11-22 |

| JP2012086292A (ja) | 2012-05-10 |

| JP4995961B2 (ja) | 2012-08-08 |

| US8863623B2 (en) | 2014-10-21 |

| CN102574278B (zh) | 2014-12-10 |

| CN102574278A (zh) | 2012-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5562699A (en) | Forceps | |

| EP1872729B1 (en) | Medical instrument for grasping on object, in particular needle holder | |

| JP4995961B2 (ja) | 開閉作業具 | |

| US5730740A (en) | Latch mechanism for surgical instruments | |

| US10595927B2 (en) | Combination medical device | |

| US11980384B2 (en) | Actuation mechanism and ultrasonic surgical instrument | |

| WO1995009566A1 (en) | Hingeless tool useful in surgery | |

| US20200289138A1 (en) | Surgical instruments with coupling members to effect multiple pivot axes | |

| JP5364014B2 (ja) | 片手握持型手動作業具 | |

| US20240090910A1 (en) | Surgical instrument having a thenar eminence handle and method for use thereof | |

| US11737746B2 (en) | Forceps with integrated blade | |

| WO2014097494A1 (ja) | 開閉作業具 | |

| US20070016248A1 (en) | Medical gripping and/or cutting instrument | |

| JP5526167B2 (ja) | 開閉作業具 | |

| JP3161749U (ja) | 止血鉗子 | |

| US11589883B2 (en) | Medical instrument | |

| JP7122952B2 (ja) | 鉗子および使い捨て医療用品セット | |

| CN108247685B (zh) | 一种医用安全剪刀 | |

| JP5498519B2 (ja) | 開閉作業具 | |

| JP5438157B2 (ja) | 開閉作業具 | |

| JP3118904U (ja) | 医療用カッター | |

| CN210843322U (zh) | 弧形重睑镊 | |

| AU2013203870B2 (en) | Hand held instrument | |

| KR20220161835A (ko) | 탄성 조절이 가능한 핀셋 | |

| JP2020110593A (ja) | 挟み具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201080040939.0 Country of ref document: CN |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13395774 Country of ref document: US |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 10858676 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 10858676 Country of ref document: EP Kind code of ref document: A1 |