WO2010002050A1 - Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it - Google Patents

Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it Download PDFInfo

- Publication number

- WO2010002050A1 WO2010002050A1 PCT/KR2008/003959 KR2008003959W WO2010002050A1 WO 2010002050 A1 WO2010002050 A1 WO 2010002050A1 KR 2008003959 W KR2008003959 W KR 2008003959W WO 2010002050 A1 WO2010002050 A1 WO 2010002050A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- propolis

- fuel

- ceramic

- mixed

- pipe

- Prior art date

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 138

- 241000241413 Propolis Species 0.000 title claims abstract description 76

- 229940069949 propolis Drugs 0.000 title claims abstract description 76

- 239000000919 ceramic Substances 0.000 title claims abstract description 75

- 239000000203 mixture Substances 0.000 title claims abstract description 46

- 229920003002 synthetic resin Polymers 0.000 claims abstract description 33

- 239000000057 synthetic resin Substances 0.000 claims abstract description 33

- 239000000843 powder Substances 0.000 claims abstract description 22

- 238000002485 combustion reaction Methods 0.000 claims description 18

- 239000003973 paint Substances 0.000 claims description 9

- 230000002708 enhancing effect Effects 0.000 claims description 5

- 239000007921 spray Substances 0.000 claims description 5

- 239000004593 Epoxy Substances 0.000 claims description 3

- 230000005855 radiation Effects 0.000 abstract description 17

- 238000002156 mixing Methods 0.000 description 9

- 230000007423 decrease Effects 0.000 description 7

- 239000007789 gas Substances 0.000 description 5

- 230000003115 biocidal effect Effects 0.000 description 4

- HGUFODBRKLSHSI-UHFFFAOYSA-N 2,3,7,8-tetrachloro-dibenzo-p-dioxin Chemical compound O1C2=CC(Cl)=C(Cl)C=C2OC2=C1C=C(Cl)C(Cl)=C2 HGUFODBRKLSHSI-UHFFFAOYSA-N 0.000 description 3

- 230000008602 contraction Effects 0.000 description 3

- 229910052500 inorganic mineral Inorganic materials 0.000 description 3

- 239000011707 mineral Substances 0.000 description 3

- 241000894006 Bacteria Species 0.000 description 2

- 241000588724 Escherichia coli Species 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 239000003502 gasoline Substances 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 244000005700 microbiome Species 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 239000000700 radioactive tracer Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 244000063299 Bacillus subtilis Species 0.000 description 1

- 235000014469 Bacillus subtilis Nutrition 0.000 description 1

- 241001360526 Escherichia coli ATCC 25922 Species 0.000 description 1

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 1

- 206010020751 Hypersensitivity Diseases 0.000 description 1

- 241001354013 Salmonella enterica subsp. enterica serovar Enteritidis Species 0.000 description 1

- 241000191940 Staphylococcus Species 0.000 description 1

- 241000224527 Trichomonas vaginalis Species 0.000 description 1

- 241000223238 Trichophyton Species 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 238000003915 air pollution Methods 0.000 description 1

- 208000026935 allergic disease Diseases 0.000 description 1

- 230000007815 allergy Effects 0.000 description 1

- 239000002260 anti-inflammatory agent Substances 0.000 description 1

- 230000000845 anti-microbial effect Effects 0.000 description 1

- 230000003064 anti-oxidating effect Effects 0.000 description 1

- 230000001741 anti-phlogistic effect Effects 0.000 description 1

- 230000002155 anti-virotic effect Effects 0.000 description 1

- 235000013871 bee wax Nutrition 0.000 description 1

- 239000012166 beeswax Substances 0.000 description 1

- 230000000740 bleeding effect Effects 0.000 description 1

- 210000004027 cell Anatomy 0.000 description 1

- 210000000170 cell membrane Anatomy 0.000 description 1

- -1 diesel Substances 0.000 description 1

- 239000002283 diesel fuel Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000036737 immune function Effects 0.000 description 1

- 230000002401 inhibitory effect Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 150000002926 oxygen Chemical class 0.000 description 1

- 230000003119 painkilling effect Effects 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000035755 proliferation Effects 0.000 description 1

- 238000001243 protein synthesis Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000000779 smoke Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 230000014616 translation Effects 0.000 description 1

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M27/00—Apparatus for treating combustion-air, fuel, or fuel-air mixture, by catalysts, electric means, magnetism, rays, sound waves, or the like

- F02M27/06—Apparatus for treating combustion-air, fuel, or fuel-air mixture, by catalysts, electric means, magnetism, rays, sound waves, or the like by rays, e.g. infrared and ultraviolet

Definitions

- the present invention relates to a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using it which are able to activate the fuels of a vehicle, a ship, an airplane, a boiler or the like with the helps of a magnetic force line, a wave energy of propolis, and a far-infrared radiation emitted from an EM ceramic.

- a vehicle, a ship, an airplane, a boiler or the like which uses a gasoline, a light oil, a diesel oil, a LPG, a LNG or the like is configured to convert a driving force obtained by combusting fuel into energy.

- combustion efficiency can be enhanced as the composition of fuel is supplied in a certain size as small as possible when being burnt in a combustion chamber of an engine. Since combustion efficiency is not high, more and more fuel is needed so as to keep the performance of an engine. If fuel is over supplied, useless combustion occurs, and it might be mixed in an exhaust gas and might be directly discharged into the air, which leads to the pollution of air. It means that lots of CO, HC and NOx might be produced in imperfect combustion nevertheless a lot of fuel is used.

- 20-414244 discloses a construction that a housing equipped with a permanent magnet is fixed as being opposite to an outer surface of a raw material pipe.

- the above utility model 20-414244 is configured as a permanent magnet is fixed on an outer surface of a raw material pipe. In this case, when the diameter of the fuel pipe is large, it might not properly work. Disclosure of Invention Technical Problem

- a fuel saver composition using propolis and EM ceramic characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and is coated on a fuel pipe, and 1 through 10weight% of propolis, 2 through l lweight% of EM ceramic and 97 through 88weight% of a synthetic resin are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

- a fuel saver apparatus which includes left and right casings fixed in both sides of a fuel pipe along with a contact surface contacting with a fuel pipe and having a position adjusting unit for adjusting a fixing position depending on the size of a fuel pipe, and a plurality of magnets configured in the inner sides of the left and right casings

- a fuel saver apparatus using propolis and EM ceramic characterized in that the left and right casings are formed in such a manner that 1 through 10weight% of propolis powder, 2 through l lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of 100 0 C through 300 0 C, and an engaging protrusion and an engaging groove are formed in the contacting sides of the left and right casings in opposite sides for engaging the left and right casings.

- a fuel saver apparatus using propolis and EM ceramic which comprises a cylindrical casing; an internal pipe for flowing a fuel in the interior of the casing; a permanent magnet which is installed in an outer surface of the internal pipe; and an external connection pipe which connects the casing to the external fuel pipe, wherein the casing or internal pipe is coated with a mixture made in such a manner that 1 through 10weight% of propolis powder, 2 through 1 lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of about 100 0 C through 300 0 C and is coated.

- the fuel saver apparatus is used as an apparatus for enhancing a combustion efficiency of a vehicle, a ship, an airplane, and a boiler.

- a casing is molded by mixing propolis, EM ceramic and synthetic resin, the fuel passing through the interior of the casing can be more efficiently activated by means of a magnetic force line, a wave energy of propolis, and a far-infrared radiation emitted from an EM ceramic for thereby enhancing a fuel efficiency.

- propolis, EM ceramic and synthetic resin can be spray-coated on side of a fuel pipe, an additional device for the present invention is not needed.

- a casing detachably attached to an outer side of a fuel pipe or directly attached to one side of a fuel pipe can be easily made, or it might be deposited or sprayed for thereby easily engaging the same.

- Figure 1 is a perspective view illustrating an external type fuel saver apparatus which is installed in both sides of a fuel pipe according to an embodiment of the present invention.

- Figure 2 is a cut-away cross sectional view taken along line A-A of Figure 1.

- Figure 3 is a cut-away cross sectional view taken along line B-B of Figure 1.

- Figure 4 is a perspective view illustrating an external type fuel saver apparatus according to another embodiment of the present invention.

- Figure 5 is a cross sectional view of Figure 4.

- Figure 6 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to further another embodiment of the present invention.

- Figure 7 is a horizontal cross sectional view of Figure 2.

- Figure 8 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to still further another embodiment of the present invention.

- Figure 9 is a photo showing a far-infrared radiation of an external fuel saver apparatus of Figure 1.

- Figure 1 is a perspective view illustrating an external type fuel saver apparatus which is installed in both sides of a fuel pipe according to an embodiment of the present invention.

- Figure 2 is a cut-away cross sectional view taken along line A-A of Figure 1.

- Figure 3 is a cut-away cross sectional view taken along line B-B of Figure 1.

- Figure 4 is a perspective view illustrating an external type fuel saver apparatus according to another embodiment of the present invention.

- Figure 5 is a cross sectional view of Figure 4.

- Figure 6 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to further another embodiment of the present invention.

- Figure 7 is a horizontal cross sectional view of Figure 2.

- Figure 8 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to still further another embodiment of the present invention.

- Figure 9 is a photo showing a far- infrared radiation of an external fuel saver apparatus of Figure 1.

- the fuel saver composition using propolis and EM ceramic is basically characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and is coated on a fuel pipe, and 1 through 10weight% of propolis, 2 through 1 lweight% of EM ceramic and 97 through 88weight% of a synthetic resin are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

- powder magnet is added to a mixed composition by 10 through 50weight% with respect to the mixed composition.

- the fuel saver composition using propolis and EM ceramic is basically characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a paint, and is coated on a fuel pipe, and 5 through 20weight% of propolis, 5 through 20weight% of EM ceramic and 95 through 75weight% of a paint are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

- powder magnet is added to a mixed composition by 10 through 50weight% with respect to the mixed composition.

- the fuel saver apparatus comprises left and right casings 20 and 30 which are configured to cover a fuel pipe 50 connected between an engine 70 used in a vehicle, a ship, an airplane, a boiler or the like and a fuel supply unit 60, and a plurality of permanent magnets 40 fixed in the interiors of the left and right casings, respectively.

- the left and right casings 20 and 30 are formed in such a manner that 1 through 10weight% of propolis powder, 2 through l lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of 100 0 C through 300 0 C, and an engaging protrusion and an engaging groove are formed in the contacting sides of the left and right casings in opposite sides for engaging the left and right casings.

- the propolis according to the present invention is preferably extracted from various plants in the form of a resin substance. It is a natural antibiosis containing a resin of 50%, beeswax of 30%, oily components of 10% such as refined oil, pollen of 5%, and organic and mineral materials of 5%. It has a strong antimicrobial function by inhibiting protein synthesis by means of Bacillus subtilis, staphylococcus, Trichophyton, Escherichia coli, Trichomonas vaginalis, Salmonella Enteritidis, etc.

- the propolis activates the functions of cells by reinforcing a cell membrane and enhances an allergy resistance function, a pain killing function, a bleeding stopping function, an antiphlogistic function, and an immune function of a living body. It is able to inhibit an activated oxygen.

- the propolis has the following wave motion values of Table 1 as a result of the analysis using a MRA. The values might have differences depending on the kinds of trees.

- the measured values of the wave motion analysis values consist of 43 steps from +21 to -21.

- the resonance is 100%, and when the value is 0, the resonance is 50%, and when the value is -21, the resonance is 0%.

- the propolis mixed during the manufacture of the casing according to the present invention is added by 1 through 10weight% with respect to the total weight of powder. At this time, when the added amount of the propolis is less than lweight%, the antibiosis function and anti-virus function of the propolis might be decreased. When the added amount of the propolis is more than 10weight%, the amount of added synthetic resin decreases, so the left and right casings of the fuel saver apparatus might be hardened during a molding process, which leads to easier fracture.

- the EM ceramic according to the present invention is an EM-X ceramic or an EM-Z ceramic manufactured by mixing an EM(Effective Micro-organisms), known to inhibit harmful organisms and activate useful microorganisms, with mineral powders and loess and by heating at a high temperature such as 600 through 1200 0 C.

- the EM ceramic has an oxidation resistance property which is a nature of the EM and a far- infrared radiation function which is a nature of mineral powder and loess.

- the EM ceramic is ground into a mesh of 100 through 1000, and it is added by 2 through 1 lweight% with respect to the whole weight.

- the added amount of EM ceramic is less than 2weight%, the anti-oxidation performance and far-infrared radiation performance of the EM ceramic decrease, and when the added amount of the EM ceramic is more than 1 lweight%, since the amount of the synthetic resin added decreases, so the left and right casings of the fuel saver apparatus might be hardened during a molding process, which leads to easier fracture.

- the synthetic resin according to the present invention is preferably formed of PVC,

- the synthetic resin is formed of ABS.

- the mixture of the propolis, EM ceramic powder and synthetic resin is liquidified at a temperature of about 100 0 C through 300 0 C and is formed in a certain casing.

- an external type fuel saver apparatus is characterized in that a mixture of propolis, EM ceramic powder and synthetic resin covers a fuel pipe 50 which is configured to supply the fuel of the fuel supply unit 60 to the engine 70, and left and right casings 20 and 30 are installed, and magnet fixing units 22 and 32 are configured to support the permanent magnet 40 in the interior of the left and right casings with the permanent magnets 40 being configured to have opposite magnetic poles.

- the contact surfaces 21 and 31 of the left and right casings contacting with the fuel pipe 50 are equipped with a slip prevention shoulder for preventing the circular fuel pipe 50 from being slipped while stably supporting the same.

- Engaging protrusions 23 and 23' and engaging grooves 24 and 24' are formed in one side of the contact surfaces for engaging the left and right casings, respectively.

- the engaging protrusions 23 and 23' formed in the casing of one side and the engaging grooves 24 and 24' formed in the casing of the other side are engaged by means of the magnetic force line of the permanent magnet, but are not easily disengaged.

- fixing bolts 25 and 25' are disposed in the casing of one side which covers the fuel pipe 50 configured to supply the fuel of the fuel supply unit 60 to the engine, and the fixing nuts 26 and 26' are disposed in the casing of the other side.

- the left and right casings are engaged by engaging the fixing bolts 25 and 25' and the fixing nuts 26 and 26'.

- the fuel saver apparatus is characterized in that casings are formed using synthetic resin or metals, and the permanent magnets and magnet fixing units in the casings can be made by mixing 5 through 20weight% of propolis, 5 through 20weight% of EM ceramics of 100 through lOOOmeshes, and 90 through 75weight% of paints such as epoxy with respect to the mixed amount and by spray-coating or depositing the same.

- the added amount of the paint is more than 90weight%, the natures of the propolis and the EM ceramic might be degraded, and when the added amount of the paint is less than 75weight%, the added amount of the propolis and EM ceramics increase, which leads to a non-economical application.

- the fuel saver apparatus installed in the fuel pipe which supplies the fuel of the fuel supply unit 60 to the engine 70 comprises a cylindrical casing 51, at least one internal pipes 53 for flowing the fuel inputted into the cylindrical casing, a permanent magnet 54 engaged in a magnet fixing unit 55 formed in an outer side of the internal pipe, and a connection unit 52 which connects the cylindrical casing to an external fuel pipe.

- a certain shaped groove 56 is formed in the interior of the internal pipe, and a permanent magnet 57 corresponding to the permanent magnet engaged in the magnet fixing unit is engaged in the groove 56.

- the cylindrical casing 51 and the internal pipe 53 are formed of certain casings which are made by mixing 1 through 10weight% of propolis, 2 through l lweight% of EM ceramics, and 97 through 88weight% of synthetic resin and liquidifying the mixture at a temperature of about 100 0 C through 300 0 C.

- the internal pipe 53 might be installed in various forms depending on the size of the cylindrical casing.

- a magnet fixing unit is formed in an outer side of each internal pipe 53 for fixing a permanent magnet.

- the permanent magnets 54 engaged in an outer side of the internal pipe 53 are installed with the magnetic poles being alternated with each other, for example when the permanent magnet installed in one side is N-pole, the permanent magnet of the opposite side is a S-pole.

- the fuel flowing through the internal pipe 53 of the cylindrical fuel saver apparatus is magnetized by means of magnetic force line, far-infrard radiation and wave motion energy of propolis, and the molecules of fuels formed in groups are disengaged by means of rotation, resonance and contraction, so the fuel molecules are micro-processed for thereby enhancing combustion efficiency.

- the fuel saver apparatus of Figures 1 through 3 installed in both sides of the fuel pipe is manufactured by using a mixture of propolis, EM ceramic powder and synthetic resin.

- the radiation rate and the amount of radiation energy of the fuel saver apparatus are measured using the FT-IR(Fourier Transform Inter- ferometric Spectrometer) equipped with a MCT detector and are shown in Table 2.

- the infrared thermo tracer photos taken using an infrared thermo tracer are shown in Table 9.

- the casing made of a mixture of propolis, EM ceramic powder and synthetic resin has a radiation rate of 0.893 and radiates the energy of 3.44x10 . As shown in Figure 9, the far- infrared radiation is measured all over the casing.

- the fuel saver apparatus manufactured according to the first embodiment of the present invention is installed in the fuel pipe 50 configured to supply the fuel of the fuel supply unit 60 to the engine 70 of a vehicle, and the performance of the engine is measured and shown in Table 3.

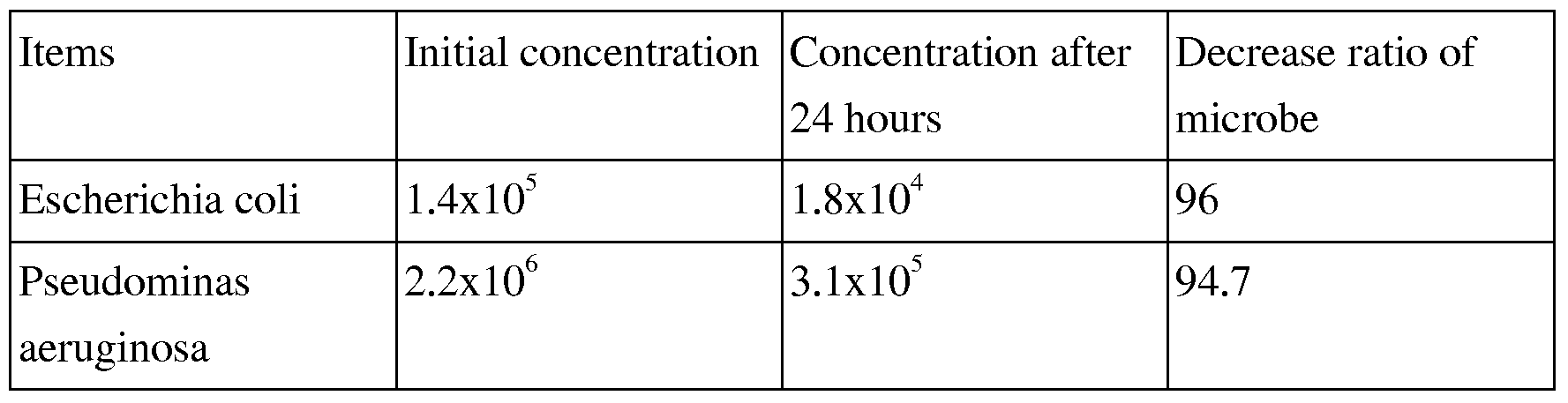

- the casing of the fuel saver apparatus made by mixing propolis, EM ceramic powder and synthetic resin has 96% and 94.7% of a decrease ratio of microbe with respect to Escherichia coli and Pseudominas aeruginosa, respectively, along with high antibiosis.

- the fuel passing through the interior of the casing can be more efficiently activated by means of a magnetic force line, a wave energy of propolis, and a far-infrared radiation emitted from an EM ceramic for thereby enhancing a fuel efficiency.

Abstract

The present invention relates to a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using it, which are able to more activate a fuel used in a vehicle, a ship, an airplane, a boiler or the like with the helps of a magnetic force line, a wave motion energy, and a far-infrared radiation of EM ceramic. In the present invention, a mixture mixed with propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and the mixture is coated on a fuel pipe. The mixture is formed of 1 through 10 weight % of propolis, 2 through 11 weight % of EM ceramic and 97 through 88 weight % of synthetic resin with respect to the whole weight. Powder magnet is further mixed with the mixture of propolis and EM ceramic.

Description

Description

FUEL SAVER COMPOSITION USING PROPOLIS AND EM CERAMIC AND FUEL SAVER APPARATUS USING IT

Technical Field

[1] The present invention relates to a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using it which are able to activate the fuels of a vehicle, a ship, an airplane, a boiler or the like with the helps of a magnetic force line, a wave energy of propolis, and a far-infrared radiation emitted from an EM ceramic. Background Art

[2] Generally, a vehicle, a ship, an airplane, a boiler or the like, which uses a gasoline, a light oil, a diesel oil, a LPG, a LNG or the like is configured to convert a driving force obtained by combusting fuel into energy. In case of the above fuel, combustion efficiency can be enhanced as the composition of fuel is supplied in a certain size as small as possible when being burnt in a combustion chamber of an engine. Since combustion efficiency is not high, more and more fuel is needed so as to keep the performance of an engine. If fuel is over supplied, useless combustion occurs, and it might be mixed in an exhaust gas and might be directly discharged into the air, which leads to the pollution of air. It means that lots of CO, HC and NOx might be produced in imperfect combustion nevertheless a lot of fuel is used.

[3] So as to overcome the above problems, the Korean registration utility model number

20-414244 discloses a construction that a housing equipped with a permanent magnet is fixed as being opposite to an outer surface of a raw material pipe.

[4] The above utility model 20-414244 is configured as a permanent magnet is fixed on an outer surface of a raw material pipe. In this case, when the diameter of the fuel pipe is large, it might not properly work. Disclosure of Invention Technical Problem

[5] Accordingly, it is an object of the present invention to provide a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using it which are able to more efficiently activate the fuels of a vehicle, a ship, an airplane, a boiler or the like with the helps of a magnetic force line, a wave energy of propolis, and a far- infrared radiation emitted from an EM ceramic.

[6] It is another object of the present invention to provide a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using which are able to enhance a combustion efficiency by activating and micro-processing the fuel passing through a fuel pipe where a casing is positioned, and are capable of decreasing a harmful gas

such as smoke or dioxin in such a manner that a casing made by mixing propolis, EM ceramic and synthetic resin is detachably attached to an outer side of a fuel pipe or is directly attached to one side of a fuel pipe, or a fuel saver apparatus is deposit-coated or spray-coated, and a permanent magnet is installed in the interior of a casing.

[7] It is further another object of the present invention to provide a fuel saver composition using propolis and EM ceramic and a fuel saver apparatus using which can be used in a large capacity fuel pipe for a ship or an airplane in such a manner that a casing made by mixing propolis, EM ceramic and synthetic resin is detachably attached to an outer side of a fuel pipe or is directly attached to one side of a fuel pipe, or a fuel saver apparatus is deposit-coated or spray-coated. Technical Solution

[8] To achieve the above objects, there is provided a fuel saver composition using propolis and EM ceramic characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and is coated on a fuel pipe, and 1 through 10weight% of propolis, 2 through l lweight% of EM ceramic and 97 through 88weight% of a synthetic resin are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

[9] To achieve the above objects, in a fuel saver apparatus which includes left and right casings fixed in both sides of a fuel pipe along with a contact surface contacting with a fuel pipe and having a position adjusting unit for adjusting a fixing position depending on the size of a fuel pipe, and a plurality of magnets configured in the inner sides of the left and right casings, there is provided a fuel saver apparatus using propolis and EM ceramic characterized in that the left and right casings are formed in such a manner that 1 through 10weight% of propolis powder, 2 through l lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of 1000C through 3000C, and an engaging protrusion and an engaging groove are formed in the contacting sides of the left and right casings in opposite sides for engaging the left and right casings.

[10] To achieve the above objects, there is provided a fuel saver apparatus using propolis and EM ceramic which comprises a cylindrical casing; an internal pipe for flowing a fuel in the interior of the casing; a permanent magnet which is installed in an outer surface of the internal pipe; and an external connection pipe which connects the casing to the external fuel pipe, wherein the casing or internal pipe is coated with a mixture made in such a manner that 1 through 10weight% of propolis powder, 2 through 1 lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of

synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of about 1000C through 3000C and is coated. [11] The fuel saver apparatus is used as an apparatus for enhancing a combustion efficiency of a vehicle, a ship, an airplane, and a boiler.

Advantageous Effects

[12] In the present invention, since a casing is molded by mixing propolis, EM ceramic and synthetic resin, the fuel passing through the interior of the casing can be more efficiently activated by means of a magnetic force line, a wave energy of propolis, and a far-infrared radiation emitted from an EM ceramic for thereby enhancing a fuel efficiency. [13] Since propolis, EM ceramic and synthetic resin can be spray-coated on side of a fuel pipe, an additional device for the present invention is not needed. [14] A casing detachably attached to an outer side of a fuel pipe or directly attached to one side of a fuel pipe can be easily made, or it might be deposited or sprayed for thereby easily engaging the same. [15] In the present invention, it is possible to easily remove various bacteria and harmful toxic components with the helps of a magnetic force line, a wave energy of propolis, and a far- infrared radiation emitted from an EM ceramic. [16] The imperfect combustion can be prevented during combustion, and it is possible to decrease air polution and harmful gas such as dioxin.

Brief Description of the Drawings [17] Figure 1 is a perspective view illustrating an external type fuel saver apparatus which is installed in both sides of a fuel pipe according to an embodiment of the present invention.

[18] Figure 2 is a cut-away cross sectional view taken along line A-A of Figure 1.

[19] Figure 3 is a cut-away cross sectional view taken along line B-B of Figure 1.

[20] Figure 4 is a perspective view illustrating an external type fuel saver apparatus according to another embodiment of the present invention. [21] Figure 5 is a cross sectional view of Figure 4.

[22] Figure 6 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to further another embodiment of the present invention. [23] Figure 7 is a horizontal cross sectional view of Figure 2.

[24] Figure 8 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to still further another embodiment of the present invention. [25] Figure 9 is a photo showing a far-infrared radiation of an external fuel saver apparatus of Figure 1.

Mode for the Invention

[26] The construction and operations of the present invention will be described in detail with reference to the accompanying drawings.

[27] Figure 1 is a perspective view illustrating an external type fuel saver apparatus which is installed in both sides of a fuel pipe according to an embodiment of the present invention. Figure 2 is a cut-away cross sectional view taken along line A-A of Figure 1. Figure 3 is a cut-away cross sectional view taken along line B-B of Figure 1. Figure 4 is a perspective view illustrating an external type fuel saver apparatus according to another embodiment of the present invention. Figure 5 is a cross sectional view of Figure 4. Figure 6 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to further another embodiment of the present invention. Figure 7 is a horizontal cross sectional view of Figure 2. Figure 8 is a cross sectional view illustrating a cylindrical fuel saver apparatus according to still further another embodiment of the present invention. Figure 9 is a photo showing a far- infrared radiation of an external fuel saver apparatus of Figure 1.

[28] The fuel saver composition using propolis and EM ceramic is basically characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and is coated on a fuel pipe, and 1 through 10weight% of propolis, 2 through 1 lweight% of EM ceramic and 97 through 88weight% of a synthetic resin are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

[29] In addition, it is preferred that powder magnet is added to a mixed composition by 10 through 50weight% with respect to the mixed composition.

[30] The fuel saver composition using propolis and EM ceramic is basically characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a paint, and is coated on a fuel pipe, and 5 through 20weight% of propolis, 5 through 20weight% of EM ceramic and 95 through 75weight% of a paint are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

[31] In addition, it is preferred that powder magnet is added to a mixed composition by 10 through 50weight% with respect to the mixed composition.

[32] The fuel saver apparatus according to the present invention comprises left and right casings 20 and 30 which are configured to cover a fuel pipe 50 connected between an engine 70 used in a vehicle, a ship, an airplane, a boiler or the like and a fuel supply unit 60, and a plurality of permanent magnets 40 fixed in the interiors of the left and right casings, respectively. The left and right casings 20 and 30 are formed in such a manner that 1 through 10weight% of propolis powder, 2 through l lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a

temperature of 1000C through 3000C, and an engaging protrusion and an engaging groove are formed in the contacting sides of the left and right casings in opposite sides for engaging the left and right casings.

[33] The propolis according to the present invention is preferably extracted from various plants in the form of a resin substance. It is a natural antibiosis containing a resin of 50%, beeswax of 30%, oily components of 10% such as refined oil, pollen of 5%, and organic and mineral materials of 5%. It has a strong antimicrobial function by inhibiting protein synthesis by means of Bacillus subtilis, staphylococcus, Trichophyton, Escherichia coli, Trichomonas vaginalis, Salmonella Enteritidis, etc. The propolis activates the functions of cells by reinforcing a cell membrane and enhances an allergy resistance function, a pain killing function, a bleeding stopping function, an antiphlogistic function, and an immune function of a living body. It is able to inhibit an activated oxygen. The propolis has the following wave motion values of Table 1 as a result of the analysis using a MRA. The values might have differences depending on the kinds of trees.

[34] Table 1 [Table 1] [Table ]

[35] Here, the measured values of the wave motion analysis values consist of 43 steps from +21 to -21. When the value is +21, resonance is 100%, and when the value is 0,

the resonance is 50%, and when the value is -21, the resonance is 0%.

[36] The propolis mixed during the manufacture of the casing according to the present invention is added by 1 through 10weight% with respect to the total weight of powder. At this time, when the added amount of the propolis is less than lweight%, the antibiosis function and anti-virus function of the propolis might be decreased. When the added amount of the propolis is more than 10weight%, the amount of added synthetic resin decreases, so the left and right casings of the fuel saver apparatus might be hardened during a molding process, which leads to easier fracture.

[37] The EM ceramic according to the present invention is an EM-X ceramic or an EM-Z ceramic manufactured by mixing an EM(Effective Micro-organisms), known to inhibit harmful organisms and activate useful microorganisms, with mineral powders and loess and by heating at a high temperature such as 600 through 12000C. The EM ceramic has an oxidation resistance property which is a nature of the EM and a far- infrared radiation function which is a nature of mineral powder and loess.

[38] The EM ceramic is ground into a mesh of 100 through 1000, and it is added by 2 through 1 lweight% with respect to the whole weight. When the added amount of EM ceramic is less than 2weight%, the anti-oxidation performance and far-infrared radiation performance of the EM ceramic decrease, and when the added amount of the EM ceramic is more than 1 lweight%, since the amount of the synthetic resin added decreases, so the left and right casings of the fuel saver apparatus might be hardened during a molding process, which leads to easier fracture.

[39] The synthetic resin according to the present invention is preferably formed of PVC,

PE, PP, ABS, PA or PET. More preferably, the synthetic resin is formed of ABS.

[40] The synthetic resin according to the present invention is added by 97 through

88weight% with respect to the whole weight. When the added amount of the synthetic resin is less than 88weight%, the mixed amount of the propolis and EM ceramic increases, so the left and right casings of the fuel saver apparatus might be hardened, which disadvantageously leads to easier fracture. When the added amount of synthetic resin is more than 97weight%, the natures of the propolis and the EM ceramic are degraded.

[41] So, the mixture of the propolis, EM ceramic powder and synthetic resin is liquidified at a temperature of about 1000C through 3000C and is formed in a certain casing.

[42] When 10 through 50weight% of the powder magnet are added to the mixed composition. So, it is not needed to engage a permanent magnet like the casing which will be described later.

[43] As shown in Figures 1 through 3, an external type fuel saver apparatus according to an embodiment of the present invention is characterized in that a mixture of propolis, EM ceramic powder and synthetic resin covers a fuel pipe 50 which is configured to

supply the fuel of the fuel supply unit 60 to the engine 70, and left and right casings 20 and 30 are installed, and magnet fixing units 22 and 32 are configured to support the permanent magnet 40 in the interior of the left and right casings with the permanent magnets 40 being configured to have opposite magnetic poles.

[44] The contact surfaces 21 and 31 of the left and right casings contacting with the fuel pipe 50 are equipped with a slip prevention shoulder for preventing the circular fuel pipe 50 from being slipped while stably supporting the same. Engaging protrusions 23 and 23' and engaging grooves 24 and 24' are formed in one side of the contact surfaces for engaging the left and right casings, respectively. The engaging protrusions 23 and 23' formed in the casing of one side and the engaging grooves 24 and 24' formed in the casing of the other side are engaged by means of the magnetic force line of the permanent magnet, but are not easily disengaged.

[45] So, when the left and right casings 20 and 30 are fixed in the fuel pipe 50, the fuel such as petroleum, gasoline, diesel, gas or the like flowing through the fuel pipe 50 which passes through the contact surfaces 21 and 31 is magnetized by means of the wave motion energy of the propolis, and the molecules of the fuel, which are formed in groups, are disengaged by means of rotation, resonance and contraction phenomenon, and the structures of the fuel molecules are micro-processed, so the combustion efficiency is enhanced.

[46] In the external type fuel saver apparatus according to another embodiment of the present invention shown in Figures 4 and 5, fixing bolts 25 and 25' are disposed in the casing of one side which covers the fuel pipe 50 configured to supply the fuel of the fuel supply unit 60 to the engine, and the fixing nuts 26 and 26' are disposed in the casing of the other side. The left and right casings are engaged by engaging the fixing bolts 25 and 25' and the fixing nuts 26 and 26'.

[47] The fuel saver apparatus according to the present invention is characterized in that casings are formed using synthetic resin or metals, and the permanent magnets and magnet fixing units in the casings can be made by mixing 5 through 20weight% of propolis, 5 through 20weight% of EM ceramics of 100 through lOOOmeshes, and 90 through 75weight% of paints such as epoxy with respect to the mixed amount and by spray-coating or depositing the same. At this time, when the added amount of the paint is more than 90weight%, the natures of the propolis and the EM ceramic might be degraded, and when the added amount of the paint is less than 75weight%, the added amount of the propolis and EM ceramics increase, which leads to a non-economical application.

[48] The casings are made by mixing propolis, EM ceramics and synthetic resin, and the inner magnets and the magnet fixing units are made by depositing into the mixed liquid of the propolis and EM ceramics, so it is possible to achieve significant performances.

[49] As shown in Figures 6 and 7, the fuel saver apparatus installed in the fuel pipe which supplies the fuel of the fuel supply unit 60 to the engine 70 comprises a cylindrical casing 51, at least one internal pipes 53 for flowing the fuel inputted into the cylindrical casing, a permanent magnet 54 engaged in a magnet fixing unit 55 formed in an outer side of the internal pipe, and a connection unit 52 which connects the cylindrical casing to an external fuel pipe. A certain shaped groove 56 is formed in the interior of the internal pipe, and a permanent magnet 57 corresponding to the permanent magnet engaged in the magnet fixing unit is engaged in the groove 56.

[50] The cylindrical casing 51 and the internal pipe 53 are formed of certain casings which are made by mixing 1 through 10weight% of propolis, 2 through l lweight% of EM ceramics, and 97 through 88weight% of synthetic resin and liquidifying the mixture at a temperature of about 1000C through 3000C.

[51] The internal pipe 53 might be installed in various forms depending on the size of the cylindrical casing. A magnet fixing unit is formed in an outer side of each internal pipe 53 for fixing a permanent magnet. At this time, the permanent magnets 54 engaged in an outer side of the internal pipe 53 are installed with the magnetic poles being alternated with each other, for example when the permanent magnet installed in one side is N-pole, the permanent magnet of the opposite side is a S-pole.

[52] So, the fuel flowing through the internal pipe 53 of the cylindrical fuel saver apparatus is magnetized by means of magnetic force line, far-infrard radiation and wave motion energy of propolis, and the molecules of fuels formed in groups are disengaged by means of rotation, resonance and contraction, so the fuel molecules are micro-processed for thereby enhancing combustion efficiency. In addition, it is possible to physically remove accumulated dirt, scale, slime or the like.

[53]

[54] <Embodiment 1> Measurement of far-infrared radiation

[55] As described above, the fuel saver apparatus of Figures 1 through 3 installed in both sides of the fuel pipe is manufactured by using a mixture of propolis, EM ceramic powder and synthetic resin. The radiation rate and the amount of radiation energy of the fuel saver apparatus are measured using the FT-IR(Fourier Transform Inter- ferometric Spectrometer) equipped with a MCT detector and are shown in Table 2. The infrared thermo tracer photos taken using an infrared thermo tracer are shown in Table 9.

[56] Table 2

[Table 2] [Table ]

[57] The casing made of a mixture of propolis, EM ceramic powder and synthetic resin has a radiation rate of 0.893 and radiates the energy of 3.44x10 . As shown in Figure 9, the far- infrared radiation is measured all over the casing.

[58] [59] <Embodiment 2> Measurement of combustion efficiency [60] The fuel saver apparatus manufactured according to the first embodiment of the present invention is installed in the fuel pipe 50 configured to supply the fuel of the fuel supply unit 60 to the engine 70 of a vehicle, and the performance of the engine is measured and shown in Table 3.

[61] Table 3

[Table 3] [Table ]

[62] [63] As seen in the table 3, when the fuel saver apparatus according to the present invention is attached to a fuel pipe which is extended into the engine, it is possible to increase the combustion efficiency(fuel consumption ratio) of more than about 20% in average. The above increase is obtained since the fuel is magnetized by means of magnetic force line, far- infrared radiation and propolis wave motion energy, and the molecules of fuel formed in large groups are disengaged by means of rotation, resonance and contraction, so the fuel is micro-processed, and the combustion efficiency is increased in the combustion chamber.

[64] As the combustion efficiency increases, an imperfect combustion decreases, and it is possible to advantageously decrease air pollution and harmful gas such as dioxin.

[65] [66] <Embodiment 3> Tests of antibiosis function [67] The casing of the fuel saver apparatus is separated as a test sample of 4cmx4cm, and the test sample is sterilized, and cultivated for 24 hours with Escherichia coli ATCC 25922 and Pseudominas aeruginosa ATCC 15442 being inputted. A result of the cultivation is shown in the table 4.

[68] Table 4 [Table 4] [Table ]

[69] [70] As seen in the table 4, the casing of the fuel saver apparatus made by mixing propolis, EM ceramic powder and synthetic resin has 96% and 94.7% of a decrease ratio of microbe with respect to Escherichia coli and Pseudominas aeruginosa, respectively, along with high antibiosis.

[71] So, when the fuel saver apparatus according to the present invention is installed, it is possible to inhibit the generations and proliferation of various bacteria in the engine. Industrial Applicability

[72] In the present invention, since a casing is molded by mixing propolis, EM ceramic and synthetic resin, the fuel passing through the interior of the casing can be more efficiently activated by means of a magnetic force line, a wave energy of propolis, and a

far-infrared radiation emitted from an EM ceramic for thereby enhancing a fuel efficiency.

Claims

[1] A fuel saver composition using propolis and EM ceramic characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a synthetic resin, and is coated on a fuel pipe, and 1 through 10weight% of propolis, 2 through 1 lweight% of EM ceramic and 97 through 88weight% of a synthetic resin are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

[2] A fuel saver composition using propolis and EM ceramic characterized in that a mixture of propolis and EM ceramic of 100 through 1000 meshes is mixed with a paint, and is coated on a fuel pipe, and 5 through 20weight% of propolis, 5 through 20weight% of EM ceramic and 95 through 75weight% of a paint are mixed with respect to the whole mixed weight, and a powder magnet is further mixed with the mixture of the propolis and EM ceramic.

[3] In a fuel saver apparatus which includes left and right casings fixed in both sides of a fuel pipe along with a contact surface contacting with a fuel pipe and having a position adjusting means for adjusting a fixing position depending on the size of a fuel pipe, and a plurality of magnets configured in the inner sides of the left and right casings, a fuel saver apparatus using propolis and EM ceramic characterized in that said left and right casings are formed in such a manner that 1 through 10weight% of propolis powder, 2 through 1 lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of 1000C through 3000C, and an engaging protrusion and an engaging groove are formed in the contacting sides of the left and right casings in opposite sides for engaging the left and right casings.

[4] In a fuel saver apparatus which includes left and right casings fixed in both sides of a fuel pipe along with a contact surface contacting with a fuel pipe and having a position adjusting means disposed in an upper side of the left and right casings for adjusting a fixing position depending on the size of a fuel pipe, and a plurality of magnets fixed in a plurality of magnet fixing units installed in the upper and lower portions of the inner sides of the left and right casings for thereby emitting magnetic energy, a fuel saver apparatus using propolis and EM ceramic characterized in that said magnets and magnet fixing units in the interiors of the left and right casings are spray-coated with or deposit-coated in a mixture formed of 5 through 20weight% of propolis,

5 through 20weight% of EM ceramic of 100 through 1000 meshes, and 90 through 75weight% of paint such as epoxy or the like.

[5] A fuel saver apparatus using propolis and EM ceramic, comprising: a cylindrical casing; an internal pipe for flowing a fuel in the interior of the casing; a permanent magnet which is installed in an outer surface of the internal pipe; and an external connection pipe which connects the casing to the external fuel pipe, wherein said casing or internal pipe is coated with a mixture made in such a manner that 1 through 10weight% of propolis powder, 2 through l lweight% of EM ceramic of 100 through 1000 meshes, and 97 through 88weight% of synthetic resin are mixed with respect to the whole mixed weight, and the mixture is liquidified at a temperature of about 1000C through 3000C and is coated.

[6] In a fuel saver apparatus including a cylindrical casing, an internal pipe for flowing a fuel in the interior of the casing, a permanent magnet which is installed in a magnet fixing unit of an outer surface of the internal pipe, and a connection unit for connecting the casing to the fuel pipe, a fuel saver apparatus using propolis and EM ceramic characterized in that said casing or said magnet and magnet fixing unit of the internal pipe are spray-coated with or deposit-coated in a mixture mixed with 5 through 20weight% of propolis, 5 through 20weight% of EM ceramic of 100 through 1000 meshes, and 90 through 75weight% of a paint such as epoxy or the like.

[7] The apparatus of one among claims 4 through 6, wherein said fuel saver apparatus is used as an apparatus for enhancing a combustion efficiency of a vehicle, a ship, an airplane, and a boiler.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/KR2008/003959 WO2010002050A1 (en) | 2008-07-04 | 2008-07-04 | Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/KR2008/003959 WO2010002050A1 (en) | 2008-07-04 | 2008-07-04 | Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2010002050A1 true WO2010002050A1 (en) | 2010-01-07 |

Family

ID=41466122

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/KR2008/003959 WO2010002050A1 (en) | 2008-07-04 | 2008-07-04 | Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2010002050A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102442786A (en) * | 2010-10-08 | 2012-05-09 | 中科半导体科技有限公司 | Manufacturing method of semiconductor titanium crystal energy-saving chip |

| IT202000017425A1 (en) * | 2020-07-17 | 2022-01-17 | D Onofrio Daniele | MAGNETIC DEVICE FOR THE DISSOCIATION OF THE MOLECULES OF A LIQUID STATE SUBSTANCE |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000227055A (en) * | 1998-11-30 | 2000-08-15 | Yasuro Kuratomi | Fuel activating device |

| JP2003074424A (en) * | 2001-09-04 | 2003-03-12 | Plan Tec Co Ltd | Fuel activating device for heat engine |

| KR100471591B1 (en) * | 2004-02-13 | 2005-03-14 | 문태규 | Water Treatment Apparatus using Propolis |

| KR200414244Y1 (en) * | 2006-02-08 | 2006-04-17 | 이순철 | Apparatus for reducing a fuel for vehicles |

-

2008

- 2008-07-04 WO PCT/KR2008/003959 patent/WO2010002050A1/en active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000227055A (en) * | 1998-11-30 | 2000-08-15 | Yasuro Kuratomi | Fuel activating device |

| JP2003074424A (en) * | 2001-09-04 | 2003-03-12 | Plan Tec Co Ltd | Fuel activating device for heat engine |

| KR100471591B1 (en) * | 2004-02-13 | 2005-03-14 | 문태규 | Water Treatment Apparatus using Propolis |

| KR200414244Y1 (en) * | 2006-02-08 | 2006-04-17 | 이순철 | Apparatus for reducing a fuel for vehicles |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102442786A (en) * | 2010-10-08 | 2012-05-09 | 中科半导体科技有限公司 | Manufacturing method of semiconductor titanium crystal energy-saving chip |

| IT202000017425A1 (en) * | 2020-07-17 | 2022-01-17 | D Onofrio Daniele | MAGNETIC DEVICE FOR THE DISSOCIATION OF THE MOLECULES OF A LIQUID STATE SUBSTANCE |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Gu et al. | Biosorption of heavy metal ions by green alga Neochloris oleoabundans: Effects of metal ion properties and cell wall structure | |

| DK2699786T3 (en) | A method for optimization of internal combustion engines | |

| CA2951817A1 (en) | Algal system for improving water quality | |

| Guo et al. | Phosphorus removal from aqueous solution in parent and aluminum-modified eggshells: thermodynamics and kinetics, adsorption mechanism, and diffusion process | |

| CN101988448B (en) | Method for magnetically processing fuel | |

| WO2010002050A1 (en) | Fuel saver composition using propolis and em ceramic and fuel saver apparatus using it | |

| WO2000055501A1 (en) | In-line fuel catalyst pct | |

| KR20150050889A (en) | Magnetic-active water treatment method using ceramicball and magnet | |

| Shulkin et al. | The use of marine bivalves in heavy metal monitoring near Vladivostok, Russia | |

| CN1859971A (en) | Ionization apparatus for using magnetic force and far infrared | |

| HU227097B1 (en) | Magnetic treating unit on fluid and gaseous materials | |

| WO2005077832A1 (en) | Water treatment apparatus using propolis | |

| RU118873U1 (en) | FILTER FOR PURIFICATION OF WATER (OPTIONS) AND FILTER BLOCK (OPTIONS) | |

| KR101155078B1 (en) | A water purifier for portable | |

| ES2593202T3 (en) | Device for the magnetic treatment of a fluid with hydrocarbons | |

| RU2715119C1 (en) | Magnetic fuel activator | |

| Hevira | The Kinetic Analysis and Adsorption Isotherm of Chicken Egg Shells and Membranes Against Synthetic Dyes | |

| RU2327895C2 (en) | Ecomag-10g automobile and aviation fuel clearing and treatment electromagnetic filter | |

| EP2322788A1 (en) | Static device for inhibiting external areas of influence applicable to fluids, liquids, gases and organic matter in general | |

| KR100866934B1 (en) | Fuel saver Compositon using Propolis and EM ceramic and fuel saver apparatus using it | |

| RU63461U1 (en) | DEVICE FOR MAGNETIC PROCESSING OF LIQUID HYDROCARBON FUEL OF INTERNAL COMBUSTION ENGINES | |

| JPH11123325A (en) | Device for activating liquid | |

| Hufnagl et al. | Effects of sea water scrubbing | |

| WO1995001835A1 (en) | Fluid activating apparatus | |

| Karayakar et al. | Seasonal variation in copper, zinc, chromium, lead and cadmium levels in hepatopancreas, gill and muscle tissues of the mussel Brachidontes pharaonis Fischer, collected along the Mersin coast, Turkey |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 08778622 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 32PN | Ep: public notification in the ep bulletin as address of the adressee cannot be established |

Free format text: NOTING OF LOSS OF RIGHTS PURSUANT TO RULE 112(1) EPC (EPO FORM 1205A DATED 27.04.2011) |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 08778622 Country of ref document: EP Kind code of ref document: A1 |