POLOXAMER FOAMABLE PHARMACEUTICAL COMPOSITIONS WITH ACTIVE AGENTS AND/OR THERAPEUTIC CELLS AND USES

BACKGROUND

[0001] External topical administration is an important route for the administration of drugs in disease treatment. Many groups of drugs, including, for example, antibiotic, antifungal, anti-inflammatory, anesthetic, analgesic, anti-allergic, corticosteroid, retinoid and anti-proliferative medications are preferably administered in hydrophobic media, namely ointment. However, ointments often form an impermeable barrier, so that metabolic products and excreta from the wounds to which they are applied are not easily removed or drained away. Furthermore, it is difficult for the active drug dissolved in the carrier to pass through the white petrolatum barrier layer into the wound tissue, so the efficacy of the drug is reduced. In addition, ointments and creams often do not create an environment for promoting respiration of the wound tissue and it is not favorable to the normal respiration of the skin. An additional disadvantage of petroleum jelly-based products relates to the greasy feeling left following their topical application onto the skin, mucosal membranes and wounds.

[0002] A gel is a semi-rigid, jelly-like colloidal dispersion of a solid with a liquid. The main constituent of gels is liquid, e.g., water, yet they behave like solids due to the addition of a gelling agent. A hydrogel is a network of polymer chains that are water- insoluble, sometimes found as a colloidal gel in which water is the dispersion medium.

[0003] Foams are considered a more convenient vehicle for topical delivery of active agents. There are several types of topical foams, including aqueous foams, such as commonly available shaving foams; hydroalcoholic foams, emulsion-based foams, comprising oil and water components, and oleaginous foams, which consist of high oil content. Certain foams, such as shaving foams and hair mousses are not suitable as vehicles for topical drugs, because, for example, they do not absorb into the skin following application (e.g., shaving foams) or because they contain foaming surfactants that can be irritating, (e.g., ionic surfactants, in the case of shaving foam and hair mousse). "Quick-break" thermolabile foams are not ideal because they typically contain substantial amounts of alcohol, which can cause skin drying and irritation and are not convenient as they collapse quickly so that it is difficult to apply them on the target area. Also alcohol containing foams are not suitable for the treatment of open wounds and burns, neither are they suitable for treatment of body cavities, such as the vagina. On the other hand breakable foams, which remain stable on exposure to body temperature but

break upon mechanical stimulation allowing easy and convenient spreading are desirable for pharmaceutical use.

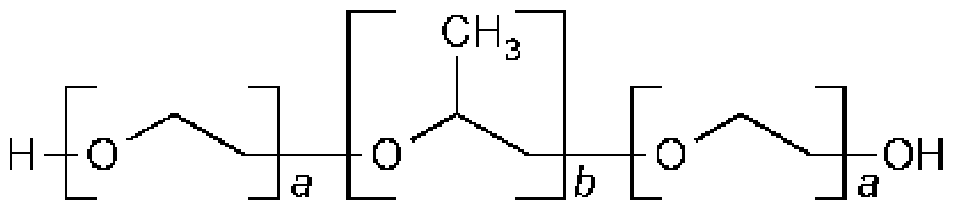

[0004] Poloxamers, also known by the trade name Pluronics, are nonionic triblock copolymers composed of a central hydrophobic chain of polyoxypropylene (poly(propylene oxide)) flanked by two hydrophilic chains of polyoxyethylene (poly(ethylene oxide)). Because the lengths of the polymer blocks can be customized, many different Poloxamers exist.

[0005] Compositions comprising Poloxamers are known in which Poloxamer is merely one ingredient in a complex combination of excipients with or without active pharmaceutical ingredients. Poloxamer has also been used as a constituent of foam produced by mechanical lathering without propellant.

[0006] However, most prior art foam compositions that contain Poloxamer lack stability and collapse upon contact with a delivery site in/on a subject. Some pharmaceutical compositions for rectal or vaginal administration have been developed, which comprise: (i) two or more physiologically acceptable substances each in separate parts of the composition which are such that on admixture they react to produce a physiologically acceptable gas; (ii) in at least one part of the composition a polymer stabilizer which is adapted to facilitate the formation of a water-soluble collapsible foam structure; and (iii) in at least one part of the composition a pharmaceutically active substance. These compositions must be delivered using multi-compartment syringes and rely on there being a chemical reaction between parts i) and ii). In the example xanthan and Poloxamer are in combination, wherein the concentration of poloxamer is less than 0.2% and xanthan gum is present in a five fold higher concentration than Poloxamer. [0007] Foam compositions for rectal administration of a solid powder in which the surfactant is Poloxamer have been published. Such compositions include (a) over 25 wt % of a powdered active principle, and (b) 1-20 wt % of a surfactant, and the balance (c) being water. The powdered active principle has a particle size of less than 20 μm. [0008] Also published are compositions of matter without fatty alcohol where the surfactant may be Poloxamer but in the Poloxamer examples the concentration of Poloxamer is 1.6% and a high level of ethyl alcohol (60%) is used to form a foamable delivery system.

[0009] A composition has been disclosed comprising (a) monohydric alcohol (b) surfactant comprising a dimethicone surfactant and (c) a builder to improve or provide stability of a foam derived from the composition, in which the builder can be a Poloxamer

and wherein the alcohol is 35% to 99.5%. In the examples the Poloxamer foam builder was 0.08% and 0.3% and the alcohol was 65% ethanol 200% proof.

[0010] Sprayable germicidal foam compositions to cover wounded skin containing

Poloxamer which remain stable for at least an hour and have a half life of 5-7 hours are known. Fatty acids and fatty alcohols are required and the Poloxamer must not exceed 3x the fatty acids or be less than half their combined amount. In the examples Poloxamer was 1.5% to less than 2%.

[0011] Foamable suspension gel formulations containing benzyl peroxide in combination with clindamycin have been published in which the gel base contains 0.1 to

2% of a thickening agent. In the Examples, the thickening agent is 1% xantham gum, and it is used with a dispensing or wetting agent (1% Poloxamer 188 and other components), with water being the main component. Although other agents are listed as dispersing or wetting agents only Poloxamer 188 is used in the examples. Good wetting agents are typically considered to be poor foaming agents and vice versa.

[0012] Liquid bioadhesive microemulsions or liopsomic dispersions containing proteinic substances are described in which the composition contains a fixing copolymer.

At body temperature the viscosity of the compositions is increased and provides an increased residence time at the administration site.

[0013] A composition for a foam and a process for preparing have been disclosed in the art, the composition including by weight (a) more than 25% of an active ingredient in powder form; (b) from 1 % to 20% of a surfactant; the balance being composed of water, wherein the powder of the active ingredient has a particle size below 20 μm. The surfactant can be a mixture of two surfactants one being a hydrophilic surfactant with a

HLB greater than 10 and the other being a polyoxyalkylene-based surfactant (possibly,

Poloxamer). In the examples, the amount of hydrophilic surfactant is much greater than the Poloxamer.

[0014] The use of Poloxamers with ability to change the sol-gel transition temperature by pH adjustment and by ionic strength adjustment has been disclosed. The preferred polymers are those which form gels at a concentration range of 10% to 50% of the polymer to water.

[0015] The use of thermosetting copolymers (Pluronic 127 or Lutrol127) with liposomic dispersions to administer a peptide or protein drug to a body surface is known.

In the examples 13% - 19.5% copolymers were used.

[0016] Other prior art complex compositions include formulations comprising a polymeric agent, which may be a phase change polymer, which alters the composition behavior from fluid-like prior to administration to solid-like upon contact with the target

mucosal surface. Such phase change results from external stimuli, such as changes in temperature or pH and exposure to specific ions (e.g., Ca2+). Non-limiting examples of phase change polymers include poly(N-isopropylamide), and Poloxamer 407®. High concentrations of Poloxamer are used for gelling.

[0017] There are disclosed new, improved, convenient to use, stable foam

Poloxamer carrier formulations and pharmaceutical compositions, which are an advance over the prior art,

[0018] Foams are complex dispersion systems which do not form under all circumstances. Slight shifts in foam composition, such as by the addition of active ingredients, may destabilize the foam. Foams are very complex and sensitive systems and are not formed at will. Mere addition of basic ingredients like oil, surfactant and propellant is far from sufficient to produce foams of quality that are homogenous, stable, breakable upon mechanical force and can be used to provide a shelf stable pharmaceutical or cosmetic composition. Small deviations may lead to foam collapse. Much consideration needs to be given to facilitate the introduction of an active agent, such as examining compatibility and non reactivity with the various excipients and container and determining shelf life chemical and physical stability.

[0019] Neubourg (US 2006/0099151 ), for example, notes that the stability of foam is strongly dependent on the specific composition of the foam forming components, so that even small deviations in the composition may lead to a collapse of the foam. Gordon et al. (US 3,456,052). also teaches that one cannot generate a good quality foam by simply adding a propellant to a mixture of components:

[0020] The term "foam" is a general term that encompasses a range of substances.

Accordingly, the context in which "foam" is discussed must be examined carefully. The type and quality of the foam is of critical importance. There are many different types of foams and within each foam type there are many levels of qualities. For example, the froth on the head of beer, lather of shampoo, and lather of shaving cream have been loosely described as foam but all are different from one another. At one end of the cosmetic or pharmaceutical foam spectrum the foam can be long lasting and essentially not readily breakable like shaving foams. At the other end of the spectrum the foam can be quick breaking and collapses upon release.

[0021] Thermolabile foams are an example of type of quick breaking foam. They can contain significant amounts of thermolabile substances that aid their collapse upon

being exposed to an increased temperature for example when applied to a body surface at 37C. Upon being exposed to the higher temperature they collapse rapidly. Examples are foam formulations that comprise significant amounts of volatile solvents.

[0022] Breakable foam is a specialized type of foam. It is a low density foam that is stable on release at least in the short time span of several minutes, which facilitates application to a target area; but can break readily upon the application of shear force such as gentle rubbing to spread easily over a target surface. It is not thermolabile (and does not melt at skin temperature) and nor does it display late or long delayed expansion over minutes.

[0023] Some foams expand slowly whilst others do so quickly. Some foams foam immediately and some demonstrate delayed foaming. Some require mechanical lathering and some expulsion by propellant. Whilst they all fall under the so called term "foam" and may appear to have some common ingredients the results and properties of these products are different.

[0024] A suitable foamable formulation for a particular application may present challenges at several levels. For example, a foam formulation may require a stable pre foam formulation; a stable pre foam propellant formulation and ultimately delivery an effective measured amount of active agent to a target. Each of these objectives poses its own unique challenges.

[0025] The pharmaceutical and cosmetic foams discussed herein are generated in general terms by manufacturing a suitable foamable carrier composition and loading the carrier in a pressurized valved canister with an appropriate propellant. Upon expelling the canister contents a foam can be released. The type, nature and quality of the foam depends inter alia on the carrier composition, the active agent, the propellant and the method of manufacture and storage. Making a stable (physically and chemically) formulation that can be stored in a canister with a propellant that remains stable and can produce a breakable foam of quality on release is far from trivial.

[0026] An additional difficulty frequently encountered with propellant foams is their inability to dispense a satisfactorily uniform application of the medically active ingredient throughout the use of the aerosol container. This is particularly due to the fact that the active material is not stably dispersed in the foamable composition so that it will have a tendency to settle to the bottom. Further, the dispersed material will sometimes clog the

spray dispensing valve to further interfere with the uniform dispensing of the medicament. Issues such as the effect of the propellant on the properties of the formulation such as viscosity and miscibility can be critical; whilst the pressure of the propellant; and the shakability of the pre foam formulation with propellant can also effect the ability to achieve satisfactory uniform application as well as the ability to avoid jets and tailing.

SUMMARY

[0027] In an aspect there is provided a pharmaceutical or cosmetic composition comprising a foamable carrier comprising:

a. water;

b. a surfactant / polymer system comprising a Poloxamer at a concentration of about 0.1 % to about 15% by weight :

i. wherein when the concentration of Poloxamer is between about 0.1 % to about 5% Poloxamer the composition further comprises a supporting agent comprising a non-ionic surface active agent; or

ii. wherein when the concentration of Poloxamer is between about 0.1 % to about 5% Poloxamer and the composition further comprises a supporting agent comprising a polymer, or a polysaccharide or a mixture thereof the Poloxamer is capable of fixing the composition on delivery to a body surface; and

c. an active agent

wherein the composition is capable of forming a foam if packaged in a packaging assembly comprising an aerosol container, equipped with a valve and an actuator, capable of releasing a foam and pressurized with a liquefied or compressed propellant wherein the ratio of the foamable carrier to the propellant is about 100:1 to about 100:25.

[0028] In certain embodiments the Poloxamer comprises at least one of Poloxamer

124, Poloxamer 188, Poloxamer 237, Poloxamer 338 or Poloxamer 407 or mixtures of two or more thereof, such as 407 and 124. In a preferred embodiment the Poloxamer comprises at least one of Poloxamer 188 and Poloxamer 407 or mixtures thereof. In another embodiment the Poloxamer capable of fixing the composition, such as, Poloxamer 407. In an aspect the Poloxamer is about 0.2% to about 2% by weight. In

different embodiments the Poloxamer comprises a molecular weight in a range (i) between about 2,000 and about 2,400; or (ii) between about 6,800 and about 8,900; or between about 7,600 and about 9,500; or (ii) between about 9,800 and about 14,600; or (iii) between about 12,000 and about 18,000. In certain aspects the ratio of Poloxamer to non ionic surface active agent is about 1 :2; about 1 :1 ; about 2:1 ; about 4:1 ; about 8:1 ; about 10:1 ; about 15:1 ; about 20:1 ; about 30:1 ; about 40:1 ; about 50:1 , or any range or combination thereof (e.g., from about 1 :2 to about 50:1 ; from about 1 :1 to about 1 :50; from about 2: 1 to about 50:1 ; from about 4: 1 to about 50:1 ; from about 8: 1 to about 50: 1 ; from about 10:1 to about 50:1 ; from about 15:1 to about 50:1 ; from about 20:1 to about 50:1 ; from about 30:1 to about 50:1 ; from about 40:1 to about 50:1 ; from about 1 :2 to about 1 :1 ; from about 1 :2 to about 2:1 ; from about 10:1 to about 50:1 ; from about 2:1 to about 8:10; etc.). In other aspects, the ratio of Poloxamer to polymer or polysaccharide is from about 1 :1 to about 50:1 (e.g., from about 1 :2 to about 50:1 ; from about 1 :1 to about 1 :50; from about 2:1 to about 50:1 ; from about 4:1 to about 50:1 ; from about 8:1 to about 50:1 ; from about 10:1 to about 50:1 ; from about 15:1 to about 50:1 ; from about 20:1 to about 50:1 ; from about 30:1 to about 50:1 ; from about 40:1 to about 50:1 ; from about 1 :2 to about 1 :1 ; from about 10:1 to about 50:1 ; from about 2:1 to about 8:10; etc.).

[0029] In one or more embodiments the viscosity of the composition at about body temperature is substantially greater than the viscosity of the composition at room temperature.

[0030] In certain aspects, the percentage by weight of polyoxyethylene component of the poloxamer is between about 70% and about 85% of the Poloxamer.

[0031] In some embodiments, the foam produced has a mild cooling effect or sensation. Without being bound by a theory it is thought that the propellant can either be trapped to some extent in the polymeric spaces or network of the formulation or in the gel and when the expelled foam is applied to the skin some residual evaporation takes place.

[0032] In one or more embodiments the Poloxamer formulation aids the intradermal penetration of the active agent so that it is in excess of about 300 micrograms/cm 2/24hr.

[0033] In one or more embodiments the Poloxamer improves the absorption of the active agent into the stratum corneum and thereafter into the dermis without a substantial increase in transdermal penetration.

[0034] In one or more embodiments the Poloxamer is included in the formulation in an amount sufficient to dissolve an active agent in an aqueous phase, wherein such an active agent is not fully soluble in said aqueous phase.

[0035] In one or more embodiments when the active agent is not otherwise fully soluble in water, in hydrophobic solvent, or in the oil phase of the emulsion, the Poloxamer is present in the composition in an amount sufficient to solubilize the active agent in the composition.

[0036] In one or more embodiments the active agent comprises at least one of diclofenac, salicylic acid or clindamycin or mixtures of two or more thereof.

[0037] In one or more embodiments the active agent in an effective amount is capable of causing the composition to form a gel, which in the presence of a sub effective amount would be liquid. For example salicylic acid can cause Poloxamer to gel

[0038] In one or more embodiments the gelling effect is a result of a reduction in pH and or an increase of ionic strength.

[0039] In an aspect there is provided a Poloxamer composition, further comprising at least one ingredient, comprising:

a. about 1 % to about 50% of a hydrophobic solvent;

b. about 1 % to about 50% of a non-volatile hydrophilic solvent;

c. about 0.01 % to about 5% of a foam adjuvant; or

d. about 1 % to about 10% of a volatile hydrophilic solvent

or mixtures of two or more thereof.

[0040] In an aspect there is provided a foamable Poloxamer composition further comprising a foam adjuvant comprising a fatty alcohol having 15 or more carbons in their carbon chain; or a fatty acid having 16 or more carbons in their carbon chain; or fatty alcohols, derived from beeswax and including a mixture of alcohols, a majority of which has at least 20 carbon atoms in their carbon chain; or a fatty alcohol having at least one double bond; a fatty acid having at least one double bond; or a branched fatty alcohol; or a branched fatty acid or a fatty acid substituted with a hydroxyl group or mixtures of two or more thereof.

[0041] In an aspect the Poloxamer formulation is an oil in water emulsion.

[0042] In an aspect there is provided a Poloxamer pharmaceutical or cosmetic cell composition comprising:

a. water;

b. a surfactant polymer system comprising a Poloxamer at a concentration of about 0.1 to about 20%;

c. a therapeutic cell or a fragment or fraction thereof; and

wherein the Poloxamer is in an amount capable of forming a gel, upon exposure to body temperature, either alone or in combination with the supporting agent, wherein the supporting agent comprises about 0.1% to about 0.5% surface active agent, or about 0.1 % to about 1 % polymer or polysaccharide or mixtures thereof. In a certain embodiment the cell composition is foamable and wherein the composition is packaged in a canister comprising an aerosol container, equipped with a valve and an actuator, capable of releasing a foam and pressurized with a liquefied or compressed propellant at a concentration of about 1 % to about 25% by weight of the total composition wherein the ratio of the foamable carrier to the propellant is 100:10 to 100:35;

[0043] In an aspect there is provided a Poloxamer composition which is suitable as a cell therapy composition comprising:

a. an aqueous solution, suitable to maintain therapeutic cells in viable state;

b. a Poloxamer / polymer system, comprising:

i. about 20% a Poloxamer; or

ii. a combination of (1 ) up to about 5% a Poloxamer; and (2) a polymeric agent or polysaccharide, wherein the polymeric agent or polysaccharide is added in an amount which, by itself, is not sufficient to produce a gel;

c. therapeutic cells;

or

a Poloxamer composition which is suitable as a cell therapy composition comprising:

a) an aqueous solution, suitable to maintain therapeutic cell fractions or fragments or mixtures of therapeutic cells and therapeutic cell fractions or fragments in a viable state;

b) a Poloxamer / polymer system, comprising:

i. about 20% of a Poloxamer; and

ii. a combination of (i) up to about 5% of a Poloxamer; and (2) a polymeric agent or polysaccharide, wherein the polymeric agent or polysaccharide is added in an amount which, by itself, is not sufficient to produce a gel;

c) therapeutic cell fractions or fragments alone or in combination with therapeutic cells.

[0044] In one or more embodiments any one or more of the Poloxamer cell formulations further comprises an active agent.

[0045] In one or more particular embodiments where an active agent is provided in the carrier formulation the active agent can be encapsulated, for example in a microsponge or any other of the encapsomes described below

[0046] In another aspect there is provided pharmaceutical or cosmetic foamable composition for application to a delivery site in a subject, the composition comprising: a. about 0.1% to about 20% by weight of at least one poloxamer;

b. 0% to about 5% by weight of at least one polymeric agent;

c. about 85% to about 99.8% water;

d. 0% to about 5% by weight of at least one silicone;

e. 0% to about 5% by weight of at least one surfactant;

f. 0% to about 15% by weight of at least one active agent, which optionally may be encapsulated; and

g. a propellant at a concentration of about 3% to about 25% by weight of the total aqueous foamable composition, wherein the composition is stored in an

aerosol container and upon release expands to form a short term breakable stable foam.

[0047] In one or more embodiments the poloxamer and the polymeric agent or polysaccharide when present together act synergistically so that the amount of poloxamer required can be substantially reduced.

[0048] In one or more embodiments the polymeric agent or polysaccharide is water soluble or water dispersible.

[0049] In one or more embodiments the composition comprises about 95-99.8% water.

[0050] In one or more embodiments said at least one water-soluble or water dispersible polymeric agent or polysaccharide comprises one or more of a an acrylic acic polymer, a permulen, a carbomer, methocel , sodium CMC , PVP and xanthan gum.

[0051] In one or more embodiments said at least one silicone compound comprises one or more of cyclomethicone, dimethicone, cyclomethicone and dimethicone Copolyol (DC3225C).

[0052] In one or more embodiments the Poloxamer foam has a density of between about 0.01 to about 0.2g/cm3 In one or more limited embodiments the Poloxamer foam has a density in excess of about 0.2g/cm3 and the foam can takes the form of an aerated gel upon application to a delivery site, wherein the delivery site comprises skin or a body cavity.

[0053] In an aspect there is provided pharmaceutical or cosmetic foamable composition for application to a delivery site in a subject, the composition comprising:

a. about 5% to about 20% by weight of at least one poloxamer;

b. about 85% to about 99.8% water;

c. about 0.2% to about 15% by weight of at least one hydrophobic solvent;

d. about 0.5% to about 5% by weight of at least one surfactant;

e. about 0.5% to about 15% by weight of at least one hydrophilic solvent;

f. an active agent, which optionally may be encapsulated; and

g. a propellant at a concentration of about 3% to about 25% by weight of the total aqueous foamable composition, wherein the composition is stored in an aerosol container and upon release expands to form a short term breakable stable foam.

[0054] In an embodiment the hydrophobic solvent comprises a silicone. In an embodiment the hydrophobic solvent further comprises an oil. In an embodiment the hydrophilic solvent comprises a glycol. In an embodiment the hydrophilic solvent comprises glycerin. In an embodiment the hydrophilic solvent comprises a glycol and glycerin. When the Poloxamer composition comprises a silicone, a glycol and glycerin the intradermal penetration of the active agent can be in excess of about 300 micrograms/cm 2/24hr.

[0055] In an embodiment the Poloxamer improves the absorption of the active agent into the stratum corneum and thereafter into the dermis without a substantial increase in transdermal penetration.

[0056] In an embodiment there is provided a method of treating, alleviating or preventing a disorder of a mammalian subject in need thereof, comprising administering a therapeutically effective amount of a pharmaceutical Poloxamer composition comprising an active agent or therapeutic cells or fragments thereof, to an afflicted target site of said mammalian subject.

[0057] In an embodiment there is provided method of treating, alleviating or preventing a disorder of a mammalian subject in need thereof, comprising administering a therapeutically effective amount of a foam produced from a Poloxamer composition comprising an active agent or therapeutic cells or fragments thereof, to an afflicted target site of said mammalian subject.

[0058] In one or more embodiments the propellant is separate from the formulation.

[0059] n one or more embodiments the composition is packaged in a dual chamber device having two canisters connected to a mixing means arranged and adapted to mix the contents of the canisters upon simultaneous release of their content, wherein the aqueous Poloxamer surfactant system is stored in a first canister and the aqueous therapeutic cells are packaged in a second canister wherein the surfactant system and

the therapeutic cells are capable of being mixed upon being expelled from the canisters; and wherein the propellant in the second canister is separate from the therapeutic cells.

[0060] In one or more embodiments the dual chamber device has a metered dose means for each canister.

[0061] In one or more embodiments there is provided a method of treating, alleviating or preventing a disorder of a mammalian subject in need thereof, comprising administering a therapeutically effective amount of a gel or foam produced from a Poloxamer composition of claim 1 to an afflicted target site of said mammalian subject.

[0062] In one or more embodiments there is provided a Poloxamer composition having the following properties:

a. a viscosity of about 1 to about 16,000 cP measured at ambient temperature; or

b. a stability or resistance to centrifugation for ten minutes at about 3000rpm ; and

wherein the resultant foam has at least 5 of the following properties:

a. a density between about 0.01 and 0.2g/cm3;

b. a pH of 3-7;

c. a hardness of about 10 to 80 g;

d. a texture of a very fine creamy foam consistency to a fine bubble structure consistency;

e. a relatively short drainage time;

f. a collapse time in excess of 180secs;

g. a collapse time in excess of 300secs; and

h. a sustainability of more than 95% for at least one minute a upon release thereof to the delivery site.

[0063] In one or more embodiments the Poloxamer composition has one property and the foam has 6 or 7 or all the properties. In one or more embodiments the composition has both properties. In one or more further embodiments the resultant foam has 6 or 7 or all of the properties.

[0064] One key element is the Poloxamer polymeric agent used in the formulation. Another contributing factor can be the additional presence of a polymer or polysaccharide. These polymeric agent(s) can contribute to the stability and stabilization of the formulation. Concentrations of polymeric agents and other thickeners have in the past been used to achieve very high viscosities of at least 20,000 cps to a million or more cps. Surprisingly, it has been unexpectedly found that by using low viscosities of the order of about 16,000cps or less to about 1 cps, or less than about 10,000, or less than about 8000, or less than about 6000, or less than about 4000, or less than about 2000, or less than about 1000, for the pre foam formulation whose viscosity can be further reduced upon inclusion of propellant it has been possible to achieve a stable formulation that produces breakable foam of quality. It is unexpected that a hydrophilic highly aqueous formulation can provide Without being bound by any theory it may be the case that the polymeric agent(s) can provide an infrastructure or network around the propellant that unexpectedly is able to trap some propellant and or propellant is trapped in a gel or semi gel composition such that when the composition is released from a pressurized canister a quality form is released with good dispensing. This possibility is suggested by the observation that certain formulations when expelled provides a foam, which when applied immediately to a skin surface causes a mild cooling sensation, which may be due to propellant escape from the polymer network Moreover, the composition is able to stabilize the active agent physically and chemically.

[0065] In one or more embodiments an emulsion Poloxamer composition is provided comprising a silicone. Unexpectedly it is possible to make compositions which are flowable in which the propellant forms part of the oil phase of the emulsion formulation but nevertheless surprisingly does not make the formulation substantially vulnerable to phase separation and or sedimentation. Moreover these compositions are stable and are able to form breakable foam of quality that spreads easily and is able to deliver an effective and measurable amount of active agent homogeneously to a target surface. By introducing an oil shakability is improved.

[0066] In one or more embodiments the active agent is dissolved in the composition and is dissolved in the expelled foam

BRIEF DESCRIPTION OF THE DRAWINGS

[0067] The invention is described with reference to the figures which are presented for the purpose of illustration and are not intended to be limiting.

[0068] FIG. 1 is a bar chart showing Penetration of Diclofenac (mean values, % of applied dose) in different compositions.

[0069] FIG. 2 s a photograph illustrating the gel inducing effect of salicylic acid on a poloxamer containing formulation according to one or more embodiments by showing two vials in a vertical perspective with different concentrations of salycilic acid.

[0070] FIG. 3 is a photograph illustrating the gel inducing effect of salicylic acid on a poloxamer containing formulation according to in one or more embodiments by showing two vials in a horizontal perspective with different concentrations of salycilic acid.

DESCRIPTION

[0071] This invention relates to foamable pharmaceutical and cosmetic vehicles or carriers; therapeutic compositions with active agents, therapeutic compositions where the active agent is encapsulated, for example, in microspheres, and delivery systems including cell delivery systems, comprising a Poloxamer.

[0072] In one or more embodiments no surfactant other than Poloxamer is required to make a gel or foam. The gel may be fixing such that it is liquid at room temperature and gel or semi gel like at or approaching body temperature, even at very low Poloxamer concentrations. In other embodiments other surfactants may be present. In further embodiments a combination of Poloxamer and polymer can be used. [0073] There are provided polymer-based aqueous foams, especially very low density foams, where the main polymeric component is a Poloxamer and the foamable formulations include an active agent and are suitable for pharmaceutical or cosmetic administration with one or more propellants such that the resultant foams are easy to use, stable and non-irritating , with unique therapeutic properties which may include anti- infective properties and membrane transport properties. There are also provided such compositions in which the viscosity increases when the formulation is exposed to body temperature.

[0074] One important feature of topical products is the ability to deliver an effective amount of active agent intradermal^ with minimal transdermal penetration; and there are

provided Poloxamer formulations with active agents, which provide improved intradermal penetration without significant transdermal penetration of such active agents.

[0075] An important feature of topical products is the solubility of active agents in the components of the composition and in the formulation as a whole. For example, the solubility can affect the rate of delivery of the active agent into the target site of treatment (such as the skin); and through membranes (such as the skin or mucosal membranes). There are provided formulations in which the Poloxamer improves the solubility of or acts to dissolve an active agent in an aqueous phase, wherein such an active agent is not fully soluble in said aqueous phase.

[0076] An important feature of topical products is the feel or sensation of the composition on application and there are provided Poloxamer based formulations which provide a mild cooling sensation without using large amounts of propellant.

[0077] There are provided new, improved, convenient to use, stable foam

Poloxamer formulations, containing specific ingredients, which should effectively deliver and/or deposit various active agents into and onto the skin and/or other target sites and are relatively non-irritating and thus suitable for use by people having sensitive skin, mucosal areas and eyes.

[0078] According to one or more embodiments , the foamable composition includes the following essential components: a. water; b. a Poloxamer / surfactant system, selected from the group consisting of: i. about 5% to about 20% of Poloxamer; and ii. a combination of (i) about 0.1% to about 5% of a Poloxamer; and (2) a non-ionic surface active agent, and c. an active agent.

[0079] According to one or more embodiments, there is provided a pharmaceutical or cosmetic composition comprising: a. water; b. a surfactant / polymer system comprising a Poloxamer at a concentration of about 0.1 to about 15%; c. an active agent.

[0080] According to one or more embodiments, there is provided a foamable or pharmaceutical or cosmetic composition, wherein the active agent is provided in microspheres, which are suspended in the composition.

[0081] In some embodiments, the concentration of Poloxamer is between about

0.1 % to about 5% and the composition further includes a supporting agent, such as a non-ionic surface active agent. In some embodiments, the concentration of Poloxamer is between about 0.1% to about 5%; and the composition further includes a supporting agent such as a non surfactant polymer or polysaccharide. In some embodiments, such as when the composition includes a supporting agent, the Poloxamer is capable of the fixing the composition to a body surface.

[0082] In some embodiments, the composition is capable of forming a foam. For example, in some embodiments the composition is packaged in a packaging assembly. The assembly includes, for example, a container (e.g., an aerosol container), equipped with a valve and an actuator. Such assemblies are capable of releasing a foam and pressurized with a liquefied or compressed propellant. In some embodiments, the ratio of the foamable carrier to the propellant is about 100:1 to about 100:25. [0083] According to one or more embodiments, there is also provided a pharmaceutical or cosmetic composition comprising: a. water; b. a surfactant polymer system comprising a Poloxamer at a concentration of about 0.1 to about 20%; and c. a therapeutic cell or a fragment or fraction thereof.

[0084] According to one or more embodiments, there is also provided a n aqueous foamable composition for application to a delivery site in a subject, the composition comprising: a) about 0.1 % to about 20% by weight of at least one poloxamer; b) 0% to about 5% by weight of at least one polymeric agent; c) about 85% to about 99.8% water; d) 0% to about 5% by weight of at least one silicone; e) 0% to about 5% by weight of at least one surfactant; f) 0% to about 15% by weight of at least one active agent optionally encapsulated; and g) a propellant at a concentration of about 3% to about 25% by weight of the total aqueous foamable composition,

wherein the composition is stored in an aerosol container and upon release expands to form a short term breakable stable foam.

[0085] In some embodiments, the Poloxamer and the polymeric agent when present together act synergistically so that the amount of Poloxamer required can be substantially reduced.

[0086] In some embodiments, the Poloxamer is in an amount capable of forming, upon exposure to body temperature, a gel either alone or in combination with a supporting agent. In certain embodiments, the supporting agent is selected from the group consisting of about 0.1% to about 0.5% surface active agent, about 0.1 % to about

1% non surfactant polymer or polysaccharide or mixtures thereof.

[0087] In a preferred embodiment the Poloxamer is about 0.2% to about 2% in combination with a supporting agent.

[0088] All % values are provided on a weight (w/w) basis.

[0089] In the context of the present invention, the term "fixing" means a viscosity change of a formulation containing Poloxamer upon a temperature change such that the viscosity of a preparation comprising Poloxamer substantially increases when the temperature changes from room temperature of about 2O0C to a temperature of about 3O0C or more. In some embodiments "fixing" may also be induced by a change in the pH or in the ionic strength of the said solution. One consequence of fixing is that a liquid or semi liquid formulation turns viscous enough to remain subtaintially in the same place when applied to a body surface. The term "fixing Poloxamer" relates to a Poloxamer, which is capable, subject to exposure of elevated temperature, change in pH or ionic strength, of affording a "fixing" effect.

[0090] In an embodiment the composition comprises a Poloxamer in combination with a polysacharide to produce a synergistic gelling effect. This is a unique advantage, which enables much lower amounts of Poloxamer and polysacharride to be used to achieve a gelling effect. Thus, whilst Poloxamer alone (e.g. Poloxamer 407) or polysacharide alone (e. g. xantham gum) can produce aqueous gels, higher amounts are required than the total amount when they are in conbination. Since Poloxamer has surfactant like properties, its presence in low concentrations is advantageous, for example, when the active agent of the composition comprises a therapeutic cell (as defined hereinbelow), and the cells are sensitive to surfactants. In an embodiment, in order to attain the fixing property, the Poloxamer is selected such that the formulation may be liquid or semi liquid at room temperature but upon warming to hand or body temperature the viscosity increases. In an embodiment the increase in viscosity is

sufficent to have a gelling effect or to increase the retention time at the site of application or to increase the collapse time of a foam derived from the Poloxamer formulation. [0091] In an embodiment the composition is packaged in an aerosol container, equipped with a valve and an actuator, capable of releasing a foam and pressurized with a liquefied or compressed propellant at a concentration of about 1% to about 25% by weight of the total composition. In an alternative embodiment the composition is packaged in a bag in aerosol or bag in valve delivery system in which the composition is stored in a bag separate from the propellant.

[0092] The foam released from the container is light and cosmetically-elegant. It is not a "quick-breaking" foam that collapses upon exposure to skin temperature; but rather it is breaks down upon application of very low sheer force, such as very easy movement of the fingers over the treated area.

[0093] The composition can contain one or more additional formulation additives, which can serve various functional purposes, including but not limited to one or more of the following purposes:

1. improvement of the appearance of the foam;

2. improvement of the skin sensation following application of the composition to a target body site;

3. improvement of the spreadability of the formulation when applied to the skin;

4. Facilitating quick absorption of one or more elements of the formulation when applied to the skin;

5. stabilization of an emulsion or a suspension;

6. skin conditioning and/or hydration;

7. modification of the delivery of the active agent into the target site and/or through membranes;

8. maintain an appropriate environment for the active pharmaceutical ingredient and excipients so that they remain stable when stored for prolonged periods and which is also suitable for application to the target site or therapeutic cells;

9. maintain an appropriate environment for the therapeutic cells so that they remain viable when applied to the to the target site; and

10. prevent or minimize breakdown of active agents and excipients;

[0094] Thus, the composition may contain one or more additional formulation additives, as follows: a. about 1 % to about 50% of a hydrophobic solvent; b. about 1 % to about 50% of a non-volatile hydrophilic solvent; c. about 0.01 % to about 5% of a foam adjuvant; d. about 1 % to about 10% of a volatile hydrophilic solvent. Poloxamer

[0095] In an embodiment , the carrier comprises a Poloxamer. Poloxamer is a synthetic block copolymer of ethylene oxide and propylene, having the general formula of:

HO(C2H4O)9(C3H6O)0(C2H4O)9H

For the generic term "Poloxamer", these copolymers are commonly named with the letter "P" (for Poloxamer) followed by three digits, the first two digits x 100 give the approximate molecular mass of the polyoxypropylene core, and the last digit x 10 gives the percentage polyoxyethylene content. For example, P407 is a Poloxamer with a polyoxypropylene molecular mass of 4,000 g/mol and a 70% polyoxyethylene content.

[0096] Poloxamers have several useful characteristics depending on the

Poloxamer(s) selected. They can be thickeners and at higher concentrations gel forming in aqueous solution. They also have surfactant properties and can act as emulsifiers and wetting agents. Some are able to create thermo-sensitive solutions, such that their properties such as viscosity change with temperature. They are strongly hydrophilic and can help to improve solubility. Poloxamers are soluble in water and in alcohol. Poloxamers are used as emulsifying agents for intravenous fat emulsions, as solubilizing agents to maintain clarity in elixirs and syrups and as wetting agents for anti bacterials. They have been used in a veriety of oral parenteral, and topical pharmaceutical formulations and are generally regarded as nontoxic and non irritant. Poloxamers are stable materials and aqueous solutions of Poloxamers are stable in the presence of acids, bases and metal ions. Poloxamers are not metabolized by the body. [0097] Poloxamers are available in different grades which vary from liquids to solids. Table I, below exemplifies types of Poloxamers, conforming to the following requirements:

Table 1

[0098] Examples of other Poloxamers are: 181 , 182, 183, 184, 185, 212, 215, 217,

231 , 234, 235, 238, 331 , 333, 334, 335, 401 , 402, and 403.

[0099] The successful restoration of membrane transport properties through surfactant Poloxamer 188 has been demonstrated. Poloxamer 188 (P188, mol wt = 8400 g/mol), has the structure of poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) (PEO-PPO-PEO, with 80 wt % PEO content). As a result of its amphiphilic nature,

P188 has the capability to interact with a cell membrane and is found to alleviate as well as reverse damages caused by electrical trauma.

[0100] In an embodiment , the Poloxamer is included in the formulation, in an amount between about 0.1 % and about 30%, preferably between about 0.5% and about

25% or more preferably between about 1% and about 10%.

[0101] In an embodiment , the Poloxamer is included in the formulation in an amount sufficient to dissolve an active agent in an aqueous phase, wherein such an active agent is not fully soluble in said aqueous phase.

[0102] In addition of their unique formulation properties, Poloxamers possess certain therapeutic effects. For example, Poloxamer 188 has been reported to improve capillary blood flow in burn injury (J Surg Res. 2001 ; 101 (1 ):56-61 ); and Poloxamer 407 possesses immunomodulation and cytotoxicity-promoting properties (Pharmaceutical Res. 2006;23(12): 2709-2728). Poloxamers have been reported to have anti- mycobacterial activity within macrophages (Abstr lntersci Conf Antimicrob Agents Chemother lntersci Conf Antimicrob Agents Chemother). 1999 Sep 26-29; 39:400) and they enhance the phagocytic activity of macrophases (Journal of the National Cancer Institute, Vol. 88, No. 1 1 , June 5, 1996). Thus, in certain embodiments, the Poloxamer acts not only as a formulation (vehicle) component, but also as an active agent of the composition, alone, or together with another active agent.

[0103] The sensory properties of foams containing a Poloxamer are favorable, as revealed by consumer panel tests.

[0104] It has been surprisingly discovered that Poloxamer 407 can be fixing at low levels of Poloxamer. Surface-active agent

HLB

[0105] The composition may contain a surface-active agent in addition to

Poloxamer. Surface-active agents (also termed "surfactants") include any agent linking oil and water in the composition, in the form of emulsion. A surfactant's hydrophilic/lipophilic balance (HLB) describes the emulsifier's affinity toward water or oil. HLB is defined for non-ionic surfactants. The HLB scale ranges from 1 (totally lipophilic) to 20 (totally hydrophilic), with 10 representing an equal balance of both characteristics. Lipophilic emulsifiers form water-in-oil (w/o) emulsions; hydrophilic surfactants form oil-in-water (o/w) emulsions. The HLB of a blend of two emulsifiers equals the weight fraction of emulsifier A times its HLB value plus the weight fraction of emulsifier B times its HLB value (weighted average). In certain cases HLB values can be found outside the standard range.

[0106] In many cases a single Poloxamer or a combination of Poloxamers suffice to facilitate producing a foam. Similarly where a liquid or semi liquid formulation which becomes gel like is desired a single fixing Poloxamer or a combination of Poloxamers at least one of which is a fixing Poloxamer may suffice to achieve effective fixing. In one or more embodiments the combination of poloxamers or poloxamers and another polymer or polysaccharide may act synergistically.

[0107] In other cases a combination of a Poloxamer with one or more surfactants other than Poloxamer) is desired. As will be appreciated by a person skilled in the art which surfactant or surfactant system is more appropriate is related to the vehicle and intended purpose. It has been further discovered that the generally thought HLB considerations are not always binding and that good quality foams can be produced with a surfactant or surfactant combination both where the HLB values are in or towards the lipophilic side of the scale and also where the HLB values are in or towards the hydrophilic side of the scale.

[0108] According to one or more embodiments in addition to Poloxamer the composition contains a single surface active agent having an HLB value between about 2 and about 9, or more than one surface active agent and the weighted average of their

HLB values is between about 2 and about 9. Lower HLB values may in certain embodiments be more applicable to water in oil emulsions.

[0109] According to one or more embodiments in addition to Poloxamer the composition contains a single surface active agent having an HLB value between about 7 and about 14, or more than one surface active agent and the weighted average of their

HLB values is between about 7 and about 14. Mid range HLB values may, in certain embodiments, be more suitable for oil in water emulsions.

[0110] According to one or more other embodiments in addition to Poloxamer the composition contains a single surface active agent having an HLB value between about 9 and about 19, or more than one surface active agent and the weighted average of their

HLB values is between about 9 and about 19.

[0111] According to one or more preferred embodiments the surface-active agent

(other than Poloxamer) has a hydrophilic lipophilic balance (HLB) between about 9 and about 14, or the composition contains more than one surface active agent and the weighted average of their HLB values is between about 9 and about 14.

Non-ionic surfactants

[0112] In one or more embodiments , the surface-active agent in addition to

Poloxamer includes at least one non-ionic surfactant. Ionic surfactants are known to be irritants. Therefore, non-ionic surfactants are preferred in applications including sensitive tissue such as found in most mucosal tissues, especially when they are infected or inflamed.

[0113] Non limiting examples of possible non-ionic surfactants include polysorbates, such as polyoxyethylene (20) sorbitan monostearate (Tween 60) and poly(oxyethylene) (20) sorbitan monooleate (Tween 80); poly(oxyethylene) (POE) fatty acid esters, such as Myrj 45, Myrj 49, Myrj 52 and Myrj 59; poly(oxyethylene) alkyl ethers, such as poly(oxyethylene) cetyl ether, poly(oxyethylene) palmityl ether, polyethylene oxide hexadecyl ether, polyethylene glycol ether, brij 38, brij 52, brij 56, brij W1 , ceteareth 20; sucrose esters, partial esters of sorbitol and its anhydrides, such as sorbitan monolaurate and sorbitan monolaurate; mono or diglycerides, isoceteth-20, and mono-, di- and tri-esters of sucrose with fatty acids (sucrose esters including those having high monoester content, which have higher HLB values). Mixtures of non-ionic surfactants are contemplated

[0114] In one or more embodiments the surface active agent is a complex or combination of two or more surface active agents (one of which may be poloxamer) that can be more effective than a single surfactant and provides a more stable emulsion or

improved foam quality than a single surfactant. For example and by way of non-limiting explanation it has been found that by choosing say two surfactants, one hydrophobic and the other hydrophilic the combination can produce a more stable emulsion than a single surfactant. Preferably, the complex comprises a combination of surfactants wherein there is a difference of about 4 or more units between the HLB values of the two surfactants or there is a significant difference in the chemical nature or structure of the two or more surfactants.

[0115] Many amphiphilic molecules can show lyotropic liquid-crystalline phase sequences depending on the volume balances between the hydrophilic part and hydrophobic part. These structures are formed through the micro-phase segregation of two incompatible components on a nanometer scale. Soap is an everyday example of a lyotropic liquid crystal. Certain types of surfactants tend to form lyotropic liquid crystals in emulsions interface (oil-in-water) and exert a stabilizing effect. Non limiting examples of surfactants with postulated tendency to form interfacial liquid crystals are: phospholipids, alkyl glucosides, sucrose esters, sorbitan esters. In certain embodiments surfactants which tend to form liquid crystals may improve the quality of foams produced from compositions.

[0116] In one or more embodiments, the surfactant in addition to Poloxamer is a surfactant or surfactant combination that is capable of or which tends to form liquid crystals.

[0117] In one or more embodiments, the at least one surface active agent is solid, semi solid or waxy.

Ionic surfactants

[0118] In certain cases, the surface active agent is ionic and is selected from the group of anionic, cationic, zwitterionic, amphoteric and ampholytic surfactants, such as sodium methyl cocoyl taurate, sodium methyl oleoyl taurate, alkyltrimethylammonium salts , sodium lauryl sulfate, triethanolamine lauryl sulfate and betaines.

Combination of non-ionic and ionic surfactants

[0119] In additional embodiments, the foamable composition includes a mixture of at least one non-ionic surfactant and at least one ionic surfactant in a ratio in the range of about 100:1 to 6:1. In one or more embodiments, the non-ionic to ionic surfactant ratio is greater than about 6:1 , or greater than about 8:1 ; or greater than about 14:1 , or greater than about 16:1 , or greater than about 20:1. In further embodiments, surface active agent comprises a combination of a non-ionic surfactant and an ionic surfactant, at a ratio of between 1 :1 and 20:1.

[0120] In one or more embodiments, a combination of a non-ionic surfactant and an ionic surfactant (such as an anionic surfactant sodium lauryl sulphate or a zwitterionic surfactant cocamidopropyl betaine) is employed, at a ratio of between 1 :1 and 20:1 , or at a ratio of 4:1 to 10:1. The resultant foam has a low specific gravity, e.g., less than 0.1 g/ml.

[0121] Where there is a combination of non-ionic and ionic surfactants then at least one non ionic surfactant is a Poloxamer.

[0122] The concentration of the surface active agent other than Poloxamer is between about 0.1% and about 5%. In a more preferred embodiment the concentration of surface active agent other than Poloxamer is between about 1% and about 4%.

Synergistic foam forming effect

[0123] Surprisingly, it was found that while concentrations of less than about % or about 2% of a Poloxamer, are not sufficient to produce a composition that evolves an acceptable foam of quality, the addition of even small amounts of a non-ionic surface active agent affords an excellent foam with high expansion (density of less that 0.1 g/mL), easy spreadability and quick absorption into the skin upon application.

[0124] In an embodiment where there is a combination of (1 ) about 0.1% to about 5% of a Poloxamer; and (2) a non-ionic surface active agent, the ratio of Poloxamer to non ionic surface active agent is from about 1 :2 ; about 1 :1 ; about 2:1 ; about 4:1 ; about 8:1 ; about 10:1 ; about 15:1 ; about 20:1 ; about 30:1 ; about 40:1 ; to about 50:1. [0125] In an embodiment where there is a combination of (i) about 0.1% to about

5% of a Poloxamer; and (2) an ionic surface active agent, the ratio of Poloxamer to ionic surface active agent is from about 1 :2 to about 1 :1 ; about 2:1 ; about 4:1 ; about 8:1 ; about 10:1 ; about 15:1 ; about 20:1 ; about 30:1 ; about 40:1 ; to about 50:1 ; Hydrophobic solvent

[0126] The foamable composition can be an emulsion, or microemulsion, including an aqueous phase and an organic carrier phase. In one or more embodiments the emulsion may comprise hydrophilic and hydrophobic ingredients combined in a predominately aqueous base, Thus, optionally, the foamable vehicle further includes at least one hydrophobic solvent, which constitutes the organic phase of the emulsion, at a concentration of about 1% to about 50% by weight. A "hydrophobic solvent" as used herein refers to a material having solubility in distilled water at ambient temperature of less than about 1 gm per 100 ml_, more preferable less than about 0.5 gm per 100 ml_,

and most preferably less than about 0.1 gm per 100 ml_. It is semi-solid or liquid at ambient temperature. The identification of a "hydrophobic solvent", as used herein, is not intended to characterize the solubilization capabilities of such solvent for any specific active agent or any other component of the foamable composition. Rather, such information is provided to aid in the identification of materials suitable for use as a hydrophobic component in the foamable compositions described herein. Examples of hydrophobic solvents include, but are not limited, to the following classes:

Triglycerides and plant-derived oils

[0127] According to one or more embodiments, hydrophobic solvents are liquid oils originating from vegetable, marine or animal sources, which are usually triglycerides. Suitable liquid oils include partially-saturated, unsaturated or polyunsaturated oils. By way of non limiting example, the partially saturated or unsaturated oil may be olive oil, corn oil, soybean oil, canola oil, cottonseed oil, coconut oil, sesame oil, sunflower oil, borage seed oil, syzigium aromaticum oil, hempseed oil, herring oil, jojobo oil, cod-liver oil, salmon oil, flaxseed oil, wheat germ oil, evening primrose oils or mixtures thereof, in any proportion. Capric/caprylic triglycerides are commonly sued in topical formulations

[0128] Unsaturated and polyunsaturated oils are oils that contain unsaturated and/or poly-unsatu rated fatty acids such as oleic acid, linoleic acid, linolenic acid, gamma-linoleic acid (GLA), eicosapentaenoic acid, and docosahexaenoic acid. Oils containing such unsaturated and ply-unsaturated fatty acids are known for their therapeutic benefits when applied topically.

Esters of fatty acids

[0129] Esters of fatty acids, suitable for use as a hydrophobic solvent, include but are not limited to isopropyl palmitate, isopropyl isostearate, octyl palmitate, cetyl lactate, cetyl ricinoleate, tocopheryl acetate, cetyl acetate, glyceryl oleate, tocopheryl linoleate, wheat germ glycerides, arachidyl propionate, myristyl lactate, decyl oleate, ricinoleate, isopropyl lanolate, pentaerythrityl tetrastearate, neopentylglycol dicaprylate/dicaprate, isononyl isononanoate, isotridecyl isononanoate, myristyl myristate, triisocetyl citrate, octyl dodecanol, maleated soybean oil, Silicones

[0130] Silicone oils also may be used and are desirable due to their known skin protective and occlusive properties. Suitable silicone oils include non-volatile silicones, such as polyalkyl siloxanes, polyaryl siloxanes, polyalkylaryl siloxanes and polyether

siloxane copolymers, polydimethylsiloxanes (dimethicones) and poly(dimethylsiloxane)- (diphenyl-siloxane) copolymers. These are chosen from cyclic or linear polydimethylsiloxanes containing from about 3 to about 9, preferably from about 4 to about 5, silicon atoms. Volatile silicones such as cyclomethicones can also be used. Silicone oils are also considered as therapeutically active hydrophobic solvents, due to their barrier retaining and protective properties. In one or more embodiments, the hydrophobic carrier includes at least about 1 %, about 2%, about 3%, about 4% by weight silicone oil or at least about 5% by weight.

Polypropylene glycol alkyl ether

[0131] In an embodiment, the organic carrier is a polypropylene glycol alkyl ether

(PPG alkyl ether). PPG alkyl ethers are liquid, water-insoluble propoxylated fatty alcohols, having the molecular formula of RO(CH2CHOCHs)n; wherein "R" is a straight-chained or branched C4 to C22 alkyl group; and "n" is in the range between 4 and about 50. They are organic liquids that function as skin-conditioning agent in pharmaceutical and cosmetic formulations. Non-limiting exemplary PPG alkyl ethers include PPG stearyl ethers and PPG Butyl Ether. Preferred PPG alky ethers according to the present invention include PPG-15 Stearyl Ether, PPG-2 Butyl Ether, PPG-9-13 Butyl Ether and PPG-40 Butyl Ether.

Fatty acids and fatty alcohols as hydrophobic solvents

[0132] In an embodiment, the hydrophobic solvent is a fatty acid which are liquid of semi-solid at ambient temperatures. Exemplary liquid or semi-solid fatty acids include, but are not limited to unsaturated fatty acids, polyunsaturated fatty acids and branched fatty acids. Examples of unsaturated fatty acids include myristoleic acid, palmitoleic acid and oleic acid. Examples of polyunsaturated fatty acids include linoleic acid, α-linolenic acid, arachidonic acid, eicosapentaenoic acid, erucic acid and docosahexaenoic acid. An example for branched fatty acids is isostearic acid, which is a clear, oily liquid.

[0133] In an embodiment, the hydrophobic solvent is a fatty alcohol which are liquid of semi-solid at ambient temperatures. Examples of liquid or semi-solid fatty alcohols include, but are not limited to unsaturated fatty alcohols, polyunsaturated fatty alcohols and branched fatty alcohols. Exemplary unsaturated fatty alcohols include cis-6- octadecen-1-ol (petroselenyl alcohol), cis-9-octadecen-1-ol (oleyl alcohol) and cis-11- octadecen-1-ol (vaccenyl alcohol). Exemplary of polyunsaturated fatty alcohols include bombykol (tr-10,cis-12-hexadecadien-1-ol), and avocadene (16-heptadecene-1 ,2,4-triol). An example for branched fatty acids is isostearyl alcohol.

Mineral oil and petrolatum

[0134] Mineral oil (Chemical Abstracts Service Registry number 8012-95-1 ) is a mixture of aliphatic, naphthalenic, and aromatic liquid hydrocarbons that derive from petroleum. It is typically liquid; its viscosity is in the range of between about 35 CST and about 100 CST (at 400C), and its pour point (the lowest temperature at which an oil can be handled without excessive amounts of wax crystals forming so preventing flow) is below 00C. In certain embodiments, the hydrophobic solvent comprises or contains petrolatum, which is also termed "white petrolatum" and "Vaseline". Petrolatum depending on the amount in a formulation and the nature of the formulation can form an impermeable occlusive layer, which protects the skin and may facilitate enhanced penetration of active agents.

Hydrophobic waxes

[0135] In an embodiment, the hydrophobic solvent is a wax, selected from the group consisting of (1 ) a fatty alcohol; (2) a fatty acid; and (3) certain naturally occurring waxes. Examples of waxes, suitable as hydrophobic solvents in accordance to the present invention include, but are not limited, to (1 ) a C8 to C22 fatty acid or fatty alcohol; (2) C16 to C20 fatty acid or fatty alcohol; (3) a branched chain fatty acid or fatty alcohol; (4) a straight chain fatty acid or fatty alcohol; (5) a saturated fatty acid or fatty alcohol (6) an unsaturated fatty acid or fatty alcohol; (7) a fatty acid or a fatty alcohol, selected from the group consisting of isostearic acid, oleic acid, oleyl alcohol, stearic acid, cetyl alcohol, stearyl alcohol, erucic acid, linoleic acid, arachidonic acid and linolenic acid; (8) a fatty acid or a fatty alcohol, selected from the group consisting of lauric acid, myristic acid, palmitic acid, stearic acid, behenic acid, oleic acid, 12-hydroxystearic acid, undecylenic acid, tall acid, isostearic acid, linoleic acid, linolenic acid, eicosapentaenoic acid (EPA), docosahexaenoic acid (DHA); and (9) jojoba oil. In certain preferred embodiment, the wax is semi-solid or liquid at ambient temperature, such as oleyl alcohol, isostearic acid and jojoba oil.

Essential oils

[0136] Essential oils are plant oils extracted by distillation. Nonlimiting examples of essential oils include agar oil, ajwain oil, angelica root oil, anise oil, balsam oil, basil oil, bergamot oil, black Pepper essential oil, buchu oil, cannabis flower essential oil, caraway oil, cardamom seed oil, carrot seed oil, cedarwood oil, chamomile oil, cinnamon oil, cistus, citronella oil, clary Sage, clove leaf oil, coriander, costmary oil, cranberry seed oil, cumin oil/Black seed oil, cypress, davana oil, dill oil, eucalyptus oil, fennel seed oil,

fenugreek oil, frankincense oil, galbanum, geranium oil, ginger oil, grapefruit oil, henna oil, jasmine oil, juniper berry oil, lavender oil, lemon oil, lemongrass oil, litsea cubeba oil, melissa oil (Lemon balm), mentha arvensis oil/Mint oil, mugwort oil, mustard oil, myrrh oil, neroli oil, orange oil, oregano oil, orris oil, parsley oil, patchouli oil, perilla essential oil, pennyroyal oil, peppermint oil, pine oil, rose oil, rosehip oil, rosemary oil, rosewood oil, sassafras oil, savory oil, schisandra oil, spearmint oil, star anise oil, tarragon oil, tea tree oil, thyme oil, vetiver oil, yarrow oil and ylang-ylang oil. Many essential oils are used as medical and aromatherapy applications, and thus, can be considered as therapeutically active hydrophobic solvents.

Emollients and "therapeutically active hydrophobic solvents"

[0137] Emollients are substances that soften and soothe the skin. They are used to correct dryness and scaling of the skin. Many of the hydrophobic solvents listed herein possess emollient properties and therefore, in addition to their contribution to the formulation texture, they provide an extra-benefit in the treatment of damaged skin and skin afflicted by a disorder that involves dry skin (such as psoriasis and atopic dermatitis).

[0138] Certain hydrophobic solvents listed herein further possess other properties which, which contribute to the therapeutic benefit of the present foamable composition, such as antibacterial, antifungal and anti-inflammatory properties. In the context , oils that possess therapeutically-beneficial properties are termed "therapeutically active solvent".

[0139] Mixtures of various hydrophobic solvents are anticipated.

Polar solvent

[0140] Optionally, the foamable vehicle further includes at least one polar solvent. A

"polar solvent" is an organic solvent, typically soluble in both water and oil. Polar solvents, such as detailed below possess high solubilizing capacity and contribute to the skin penetration of an active agent. Examples of polar solvents include dimethyl isosorbide polyols, such as glycerol (glycerin), propylene glycol, hexylene glycol, diethylene glycol, propylene glycol n-alkanols, terpenes, di-terpenes, tri-terpenes, limonene, terpene-ol, 1- menthol, dioxolane, ethylene glycol, other glycols, oleyl alcohol, alpha-hydroxy acids, such as lactic acid and glycolic acid, sulfoxides, such as dimethylsulfoxide (DMSO), dimethylformanide, methyl dodecyl sulfoxide, dimethylacetamide, azone (1- dodecylazacycloheptan-2-one), 2-(n-nonyl)-1 ,3-dioxolane, alkanols, such as dialkylamino acetates, and admixtures thereof. In certain preferred embodiments, the polar solvent is selected from the group consisting of dimethyl isosorbide glycerol (glycerin), propylene glycol, hexylene glycol, terpene-ol, oleyl alcohol, lactic acid and glycolic acid.

[0141] According to one or more embodiments, the polar solvent is a polyethylene glycol (PEG) or PEG derivative that is liquid at ambient temperature, including PEG200 (MW (molecular weight) about 190-210 kD), PEG300 (MW about 285-315 kD), PEG400 (MW about 380-420 kD), PEG600 (MW about 570-630 kD) and higher MW PEGs such as PEG 4000, PEG 6000 and PEG 10000 and mixtures thereof.

Hydrophilic emollients and "therapeutically active solvents"

[0142] Certain hydrophilic solvents listed herein, such as glycerin, various glycols

(for example propylene glycol_), α-hydroxy acids and PEGs (for example PEG, 200, 400, 600, 4000, 6000, 10,000) attract water and consequently possess emollient properties and therefore, in addition to their contribution to the formulation texture, they provide an extra-benefit in the treatment of damaged skin and skin afflicted by a disorder that involves dry skin (such as psoriasis and atopic dermatitis).

[0143] Certain hydrophobic solvents listed herein such glycerin, various glycols (for example propylene glycol), α-hydroxy acids, further possess other properties which, which contribute to the therapeutic benefit of the present foamable composition, such as antibacterial, antifungal, anti-inflammatory properties, anti-psoriasis and anti-aging effects. In the context , hydrophilic solvents that possess therapeutically-beneficial properties are termed "therapeutically active solvent".

[0144] Non-limiting examples of alpha hydroxy acids include glycolic acid, lactic acid, malic acid, citric acid, alpha-hydroxyethanoic acid, alpha-hydroxyoctanoic acid, alpha-hydroxycaprylic acid, hydroxycaprylic acidglycolic acid, tartaric acid, pyuric acid, citric acid, as well as their corresponding salts and pharmaceutically-acceptable derivatives; or any combination of any of the foregoing.

[0145] Hydroxy acids can help solubility and dermal penetration of a variety of drugs or cosmetic active agents. Polysacharides/Celluloses/Glucans/Other Polymers

[0146] "Polysaccharides" refer to agents which contain a backbone of repeating sugar (i.e., carbohydrate) units. Nonlimiting examples of polysaccharide gelling agents include xantham gum, agar, guar gum , locust bean gum, sodium alginate, sodium caseinate, gelatin agar, carrageenin gum, sodium alginate, xanthan gum, tragacanth gum, cationic guars, hydroxypropyl guar gum, starch, a chemically modified starch, hydroxypropyl starch , hyaluronic acid, sodium hyaluronate , sodium stearyl fumarate, chitosan, ceratonia, pectin, calcium alginate, alginic acid, carrageenan and the like and those selected from cellulose, carboxymethycellulose sodium (NaCMC), carboxymethyl

hydroxyethylcellulose, cellulose acetate propionate carboxylate, hydroxyethylcellulose, hydroxyethyl ethylcellulose, hydroxypropylcellulose, hydroxypropyl methylcellulose, methyl hydroxyethylcellulose, methylhydroxypropylcellulose, microcrystalline cellulose, sodium cellulose sulfate, and mixtures thereof Also useful herein are the alkyl substituted celluloses. In these polymers, the hydroxy groups of the cellulose polymer is hydroxyalkylated (preferably hydroxyethylated or hydroxypropylated) to form a hydroxyalkylated cellulose which is then further modified with a C10-C30 straight chain or branched chain alkyl group through an ether linkage. Typically these polymers are ethers of CloC30 straight or branched chain alcohols with hydroxyalkylcelluloses. Examples of alkyl groups useful herein include those selected from stearyl, isostearyl, lauryl, myristyl, cetyl, isocetyl, cocoyl (i.e. alkyl groups derived from the alcohols of coconut oil), paln-lityl, oleyl, linoleyl, linolenyl, ricinoleyl, behenyl, and mixtures thereof. Preferred among the alkyl hydroxyalkyl cellulose ethers is the material given the CTFA designation cetyl hydroxyethylcellulose, which is the ether of cetyl alcohol and hydroxyethylcellulose. This material is sold under the tradename Natrosol O CS Plus from Aqualon Corporation (Wilmington, DE). Other useful polysaccharides include scleroglucans which are a linear chain of (1-3) linked glucose units with a Q-6) linked glucose every three units, a commercially available example of which is Clearogel TM CS 11 from Michel Mercier Products Inc. (Mountainside, NJ).

[0147] Other useful polymeric agents include a carboxyvinyl polymer, polyvinylpyrrolidone, , polyvinyl alcohol, a polyacrylic acid polymer, a polymethacrylic acid polymer, acrylat.es/C10-C30 alkyl acrylates cross polymer, polyvinyl acetate, a polyvinyl chloride polymer, a polyvinylidene chloride polymer, a cationic cellulose, polyvinylpyrrolidone (PVP), PEG 1000, PEG1500, PEG2000, PEG 4000, PEG 6000, PEG 8000, a polycarbophil, a carbomer, ASOS, and a pemulen. Some polymers are sensitive to pH like carbomers and may be used with a weak base such as trolamine (also known as triethanolamine orTEA) to aid or control their expansion.

[0148] It is thought that the polysccharides and the other useful polymers act as stabilizers and thickeners. They are not considered surfactants except perhaps for pemulen, which can act as a non traditional emulsifier.

[0149] In an embodiment where there is a combination of (i) about 0.1% to about

5% of a Poloxamer; and (2) a non-ionic polymer or polysacharide, the ratio of Poloxamer

to non ionic polymer or polysacharide is from about 1 :1 ; about 2:1 ; about 4:1 ; about 8:1 ; about 10:1 ; about 15:1 ; about 20:1 ; about 30:1 ; about 40:1 ;to about 50:1 ; Foam adjuvant

[0150] Optionally, the foamable vehicle further includes a foam adjuvant selected from the group consisting of a fatty alcohol, which is solid at ambient temperature, having 15 or more carbons in their carbon chain; a fatty acid including straight-chain fatty acids, branched and substituted fatty acids, which is solid at ambient temperature, having 16 or more carbons in their carbon chain.

Additional components

[0151] In an embodiment of the composition includes one or more additional components. Such additional components include but are not limited to one or more antioxidants, anti perspirants, anti-static agents, buffering agents, bulking agents, chelating agents, cleansers, colorants, conditioners, deodorants, diluents, dyes, emollients, flavanoids, fragrances, hair conditioners, humectants, ionization agents, moisturizers, occlusive agents, perfuming agents, pearlescent aids, perfuming agents, permeation enhancers, pH-adjusting agents, preservatives, protectants, skin penetration enhancers, softeners, solubilizers, sunscreens, sun blocking agents, sunless tanning agents, viscosity modifiers and vitamins. As is known to one skilled in the art, in some instances a specific additional component may have more than one activity, function or effect.

Preservatives, anti-oxidants/radical scavengers, ionizing agents, buffering agents and pH modifying agents

[0152] In one or more embodiments, the composition contains a preservative or an antioxidant or an ionization agent. Any preservative, antioxidant or ionization agents suitable for pharmaceutical or cosmetic application may be used. Non limiting examples of antioxidants are tocopherol succinate, propyl galate, butylated hydroxy toluene and butyl hydroxy anisol. Ionization agents may be positive or may be negative depending on the environment and the active agent or composition that is to be protected. Ionization agents may for example act to protect or reduce sensitivity of active agents. Non limiting examples of positive ionization agents are benzyl conium chloride, and cetyl pyridium chloride. Non limiting examples of negative ionization agents are sodium lauryl sulphate, sodium lauryl lactylate and phospholipids.

[0153] A safe and effective amount of an anti-oxidant/radical scavenger may be added to the compositions of the subject invention, preferably from about 0.1 % to about 10%, more preferably from about 1% to about 5%, of the composition.

[0154] Anti-oxidants/radical scavengers such as ascorbic acid (vitamin C) and its salts, ascorbyl esters of fatty acids, ascorbic acid derivatives (e.g., magnesium ascorbyl phosphate, sodium ascorbyl phosphate, ascorbyl sorbate), tocopherol (vitamin E), tocopherol sorbate, tocopherol acetate, other esters of tocopherol, butylated hydroxy benzoic acids and their salts, θ-hydroxy^^J^-tetramethylchroman^-carboxylic acid (commercially available under the tradename TroloxR), gallic acid and its alkyl esters, especially propyl gallate, uric acid and its salts and alkyl esters, sorbic acid and its salts, lipoic acid, amines (e.g., N,N-diethylhydroxylamine, amino-guanidine), sulfhydryl compounds (e.g., glutathione), dihydroxy fumaric acid and its salts, lycine pidolate, arginine pilolate, nordihydroguaiaretic acid, bioflavonoids, curcumin, lysine, methionine, proline, superoxide dismutase, silymarin, tea extracts, grape skin/seed extracts, melanin, and rosemary extracts may be used.

[0155] In one or more embodiments the antioxidant agent is a flavonoid. A non limiting list of flavonoid compounds is: benzquercin, diosmin, ethoxazorutoside, flavodate, sodium hesperidin, leucocianido, monoxerutin, oxerutin, quercetin, rutoside, rutin, rosmarinic acid.

[0156] Suitable buffering agents include but are not limited to acetic acid, adipic acid, calcium hydroxide, citric acid, glycine, hydrochloric acid, lactic acid, magnesium aluminometasilicates, phosphoric acid, sodium carbonate, sodium citrate, sodium hydroxide, sorbic acid, succinic acid, tartaric acid, and derivatives, salts and mixtures thereof.