KR930003354B1 - Method for producing composite yarn of raw silk - Google Patents

Method for producing composite yarn of raw silk Download PDFInfo

- Publication number

- KR930003354B1 KR930003354B1 KR1019900007776A KR900007776A KR930003354B1 KR 930003354 B1 KR930003354 B1 KR 930003354B1 KR 1019900007776 A KR1019900007776 A KR 1019900007776A KR 900007776 A KR900007776 A KR 900007776A KR 930003354 B1 KR930003354 B1 KR 930003354B1

- Authority

- KR

- South Korea

- Prior art keywords

- thread

- cocoon

- yarn

- core

- chamber

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D39/00—Filtering material for liquid or gaseous fluids

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01B—MECHANICAL TREATMENT OF NATURAL FIBROUS OR FILAMENTARY MATERIAL TO OBTAIN FIBRES OF FILAMENTS, e.g. FOR SPINNING

- D01B7/00—Obtaining silk fibres or filaments

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01B—MECHANICAL TREATMENT OF NATURAL FIBROUS OR FILAMENTARY MATERIAL TO OBTAIN FIBRES OF FILAMENTS, e.g. FOR SPINNING

- D01B7/00—Obtaining silk fibres or filaments

- D01B7/04—Reeling silk

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Woven Fabrics (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

Abstract

내용 없음.No content.

Description

제1도는 본 발명을 실시하기 위한 장치의 측면도.1 is a side view of an apparatus for practicing the present invention.

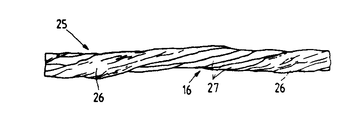

제2도는 본 발명 방법에 의한 실의 정면도.2 is a front view of a yarn according to the method of the present invention.

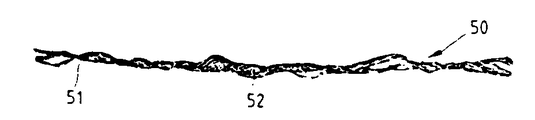

제3도는 복합포합사(複合抱合)의 정면도.3 is a composite composite yarn ) Front view.

제4도는 복합교략사(複合交絡)의 정면도.4 is a compound attacker ) Front view.

* 도면의 주요부분에 대한 부호의 설명* Explanation of symbols for main parts of the drawings

3 : 켄넬시스템 11 : 리일3: kennel system 11: reel

16 : 코어실 22 : 고치실16: core thread 22: cocoon chamber

본 발명은 고치실이외의 실로 이루어지는 코어실 주위에 고치실을 접속시킨 복합겹생사(compound paralledled raw silk)의 제조방법에 관한다.The present invention relates to a method for producing a compound paralledled raw silk in which a cocoon thread is connected around a core thread made of a yarn other than the cocoon thread.

종래 자동조사기(自動繰機)의 회전접서기(回轉接緖器) 아래에 코어실용 실공급관을 설치하고, 코어실로부터의 인출코어실을 회전접서기에 삽통하고, 코어실을 중심으로 그 주위에 누에고치에서 뽑아낸 고치실을 엉킨 상태로 끌어낸 다음, 켄넬시스템(Kennel system)을 거쳐서 섬도(纖度)를 감지하고, 유제(油制)를 부여하는 오일링(oiling)을 실시하여 작은 리일(reel)에 감는, 복합포합법(Compound cohesion method)이라 불리우는 조사 방법이 있었다.Conventional Automatic Irradiator Install a thread supply pipe for the core thread under the rotary folding machine of the machine, insert the core thread from the core thread into the rotating folding machine, and pull the cocoon around the core thread from the cocoon around it. After pulling out the cocoon thread, the fineness is sensed through the Kennel system, and the oiling is applied to the small rail to give an emulsion. There was an investigation method called the compound cohesion method.

이 방법에 의한 복합포합사(50)의 형태로서는 코어실(51)을 고치실(52)이 완전히 커버링하고 있으면 좋으나, 코어실(51)이 고치실 이외인 경우, 실제로는 고치실(52)끼리는 세리신(sericin)에 의하여 접합되고, 단지 일부분만의 고치실이 세리신에 의하여 코어실(51)에 접합되어 있을 뿐이다.In the form of the

따라서 고치실(51)과 코어실(52)은 분리되기 쉽고, 또 고치실끼리도 긴구간에 걸쳐서 접합되어 있는 것도 아니다.Therefore, the

그러므로, 특히 되올리기(re-reeling)시에 안경형상처럼 동그란마디 같은 박리현상이 생기는 일이 많았다.Therefore, in particular, during re-reeling, the peeling phenomenon such as the circular section is often generated.

그래서 상기한 복합포합보다 더 나은 교락 복합사를 조사(繰)하기 위하여 실 안내관 상부에 설치한 에어제트 노즐에 의하여, 고치실 이외의 실로 이루어지는 코어실 주위에 고치실을 교락(交絡)시키는 복합교락법이 개발되었다.So we investigated the entangled composite yarn better than the composite composite A hybrid entanglement method has been developed in which a cocoon thread is entangled around a core chamber made of a yarn other than the cocoon chamber by an air jet nozzle installed above the thread guide tube.

이렇게 만들어진 복합교략사(60)는 켄넬시스템을 통해 섬도감지기를 거치고 유제로 오일링되어 작은 실토래에 감긴다.The

복합교락법에 의하여 조사된 복합교락사(60)는 코어실(61)에 대한 고치실(62)의 교락이 양호하므로 코어실이 신장되어 있는 대에 견사(62)가 감겨붙는 것이 되므로 신장성을 보유하게되어, 그 실을 사용한 편직지는 신축성, 내피로성이 우수하다.Since the entanglement of the

그러나, 그 반면 고치실(62)과 다른 섬유(61)가 분리되기 쉽고, 특히 리일(reel) 상에 건조된 다음, 되올리기(re-reeling)를 행하면, 양자의 열수축률 차이에 의하여 분리되기 쉬워 안경형상의 동그란 마디가 발생되어 고치실(62)과 코어실(61)의 분리가 발생되기 쉽고, 또, 평활성이 뒤떨어지게 된다.On the other hand, however, the

본 발명은, 상기한 점에 감안하여 고치실 이외의 코어실로 된 섬유와 그 주위에 감겨붙은 고치실과의 사이에 여간해서 분리가 발생되지 않고 또한, 안경형상의 동그란 마디가 발생되지 않는 복합겹 생사를 얻는 것을 목적으로 한다.In view of the above, the present invention provides a composite-layered yarn in which separation does not occur between the fibers of the core yarn other than the cocoon chamber and the cocoon thread wound around it, and no circular shape of the spectacles is generated. The purpose is to get.

고치실외의 실로 이루어진 코어실의 주위에 고치실을 접속시켜, 켄넬시스템을 겨쳐서 소형리일에 권취하는 조사방법에 있어서, 조사속도 330m/분 이상의 고속으로 권취하므로서 조사장력 17g/20d 이상을 부여케하고, 리일 주위에서 50℃ 이상의 열풍을 뿜어서 리일건조를 도모하므로써 고치실과 코어실의 집속을 높혀 겹침성(paralleling quality)을 향상시켰다.In the irradiation method in which a cocoon thread is connected around a core chamber made of a thread other than the cocoon chamber, and wound around a kennel system, the coil is wound at a high speed of 330 m / min or more to give a irradiation tension of 17 g / 20 d or more. By spraying hot air at 50 ℃ or higher around the rail to promote dry drying, the focusing of the cocoon and core threads was increased to improve the paralleling quality.

이하 본 발명의 조사방법에 대하여 이 방법을 실시하는 장치의 도면과 더불어 다음에 설명한다.EMBODIMENT OF THE INVENTION Hereinafter, the irradiation method of this invention is demonstrated next with drawing of the apparatus which performs this method.

도시한 장치에 있어서는, 실 분해부(reeling-off section)(1)의 상위에 접서기(2)와, 컨넬시스템을 구성하기 위한 제1풀리(4)와, 섬도감지기(5), 제2풀리(6)선단에 제3풀리(7)를 보유한 요동아암(8), 교락부재(9) 오일링로울러(10)를 보유하고 최상부에 리일(11)이 설치되며, 리일(11)의 주위에는 건조파이프(12) 및 팬(13)을 설치하여, 팬(13)의 회전에 의하여 열풍을 리일에 뿜어서 리일(11)에 감긴 생사를 건조시키고 있다.In the illustrated device, a folding machine 2, a first pulley 4 for constructing a kernel system, a

건조파이프(12)의 주위에는 커버(14)를 설치한다.A

상기한 요동아암(8)은 실에 이상이 발생하여 실의 장력이 증대되었을 때 그 선단을 들어 올려, 도시하지 않은 기구로 리일(11)의 회전을 정지시키나, 요동아암(8)의 길이를 길게하고 재질적으로 가볍게 하여 순간적으로 발생하는 실의 장력으로 즉각 리일(11)을 정지시킬 수 있도록 하여 생사의 절단방지를 도모하고 있다.The rocking arm 8 lifts the tip of the rocking arm 8 when an abnormality occurs in the thread and the tension of the thread is increased, and the rotation of the

실 분해부(1)의 전방면에는 고치공급기(15)가 순환주행하며, 접서기(2)에 접서를 행하고 있다.The

고치실 이외의 섬유로서 이루어지는 코어실(16)은 프레임(18)상의 치이즈권사기(17)에 권취된 상태에서, 실 안내관(19)에 의하여 접서기(2)의 하부로부터 누에고치(20)의 중심으로 안내된다.The

고치공급기(15)에 메달린 삶은 고치(21)는 접서기(2)에 접서됨과 동시에 실 분해부(1)에 인입되어, 적정수량, 바람직하게는 4 내지 5개가 올려진다.The boiled

한편, 코운, 또는 치이즈권사기(17)에 감긴 고치실 이외의 섬유로 이루어진 코어실(16)은 실 안내관(19)을 통하여 접서기(2)의 하부로부터 누에고치(20)의 중심위치에 들어가서 고치실(22)와 더불어 송출되어, 코어실(16)주위에는 고치실(22)이 착 달라붙어 커버링하면서 20d의 복합사로써 조사속도 330m/분이상의 고속으로 권취한다.On the other hand, the

이때 조사장력은 17g/20d 이상으로 된다.At this time, the irradiation tension is 17g / 20d or more.

상기한 고속 조사를 위하여 고치공급기(15)에서 접서기(2)에 접서되는 경우, 다음의 접서까지의 간격을 2.0초 정도로 단축하여 실얼룩의 발생 방지를 도모하고있다.In the case where the

리일에 감긴 실은, 리일의 상부, 측부, 하부에 설치한 건조파이프(12) 및 팬(13)에 의하여 50℃이상의 열풍을 뿜어서 건조시킨다.The yarn wound on the rail is dried by blowing hot air of 50 ° C. or more by the

리일에 뿜은 열풍 50℃이상으로 하는 것은, 조사속도가 빠르게 때문이고, 만약 이 온도이하로 하는 경우, 올려지는 리일에 권취된 실의 건조를 충분히 행할 수 없게 된다.The hot air spouted at the rail is 50 ° C or higher because the irradiation speed is high. If the temperature is lower than this temperature, the yarn wound on the rail to be raised cannot be sufficiently dried.

본 발명방법에 있어서는, 상기한 바와같이, 고속으로 올려지기 때문에 조사된 실(25)은, 조사중에 장력이 증대되어 조사장력 17g/20d 이상의 상태로 되어, 고치실끼리 및 고치실과 코어실이 견고하게 포함되어 겹침성도 좋고, 진직형태로 된다.In the method of the present invention, as described above, the

그 때문에, 고치실과 코어실의 분리가 잘 생기지 않고 안경형상의 동그란마디(circular knot)등의 루우프발생이 억제되고, 인접한 고치실끼리는 서로바르게 겹친 상태로 접속되어서, 제2도에 표시하는 바와 같이 세리신(sericin)에 의한 접합이 충분하게 행하여져, 그 접합으로 띄형상으로 된 부분(26)은 코어실(16)을 구성하는 필라멘트사(27)를 포함한 상태로 코어실(16)과 꼬임합침 상태로 된다.Therefore, separation of the cocoon thread and the core thread does not occur easily, and the occurrence of loops such as eyeglass-shaped circular knots is suppressed, and adjacent cocoon threads are connected to each other in a state where they overlap each other, and as shown in FIG. The joining by (sericin) is performed sufficiently, and the

본 발명에 있어서는, 조사중의 실을 330m/분 이상의 고속으로 권취하기 때문에 조사장력은 증대되지만, 매듭이 발생이 없어서 실이 매끈해진다.In the present invention, since the yarn under irradiation is wound at a high speed of 330 m / min or more, the irradiation tension is increased, but no knot is generated, and the yarn is smooth.

조사중에 있어서의 조사속도별 큰마디, 중간마디 및 작은마디의 발생정황을 제1표 제2표에 표시한다.The occurrence conditions of large, medium and small nodes according to the irradiation speed during the irradiation are shown in the first table and the second table.

상기한 제1표 및 제2표는 생사검사법에 의한 결과치를 나타내는 것으로 이러한 검사방법에 대하여 좀더 상게하게 설명하면 다음과 같다.Tables 1 and 2 above show the results of the biopsy test, and the test method will be described more specifically as follows.

(1) 대.중 마디 검사(1) large node inspection

이 검사는 생사에 존재하는 대.중 마디의 종류 및 그 다소를 조사하는 것이다.This test examines the types and masses of mass nodes present in life and death.

마디검사용 조명장치로 조명돈 각 파넬(폭 127mm X길이 457mm)에 존재하는 대.중 마디의 개수를 종류별로 대.중마디의 표준사진과 대조하여서 검사판의 양면에 대하여 검사한다.As a lighting device for node inspection, the number of large and large nodes in each panel (127mm in width and 457mm in width) is examined by inspection on both sides of the inspection panel by comparing the number of large and medium nodes to the standard picture of the large and medium nodes.

성적은 마디 1개에 대하여 특대마디는 1점, 대마디는 0.4점 중마디는 0.1점의 실점을 설정하여 100파넬의 총실점을 100점에서 뺀 점수로 나타낸다.The result is 1 point for oversized node and 1 point for large node for 0.4 point, and 0.1 point for node for total node. The total score of 100 panels is subtracted from 100 points.

여기서 각 마디종류 및 그 정의는 다음과 같다.Here, each node type and its definition are as follows.

① 특대마디(super major defects)① super major defects

대마디의 각각의 종류에 대하여 그 최소한도의 길이 또는 크기에 10배 이상의 것At least ten times the minimum length or size of each species of stem

② 뒤얽힘마디(waste)② intertwined (waste)

실에 고치실 또는 생사가 얽혀붙어서 덩어리 상태로 되어 있는 것Having lumps of cocoon or green thread in thread

③ 큰처짐마디(large slugs)③ large slugs

실이 현저하게 현저하게 굵어지고 있는 부분의 길이가 7mm 이상인 것The length of the part where the thread is remarkably thickened is 7 mm or more

④ 붙음마디(bad cast)④ bad cast

실의 끊맺음 또는 접속에 의하여 실이 갑자기 굵어지는 것The thread suddenly thickening due to thread breaking or connection

⑤ 큰이음마디(very long knot)⑤ very long knot

실의 절단된 단부의 길이가 10mm 이상인것 또는 그보다 짧아도 연결방법이 불량한 것The length of the cut end of the thread being more than 10 mm or shorter than that.

⑥ 큰나선마디(heavy corkscrew)⑥ heavy corkscrew

고치실의 나선상으로 되어 있는 부분의 모양이 현저하게 큰 것Significantly large shape of spiral section of cocoon chamber

(2) 소마디검사(2) small node test

이 검사는 생사에 존재하는 소마디의 정도를 조사한다.This test examines the degree of somite present in life and death.

대.중마디 검사와 동일한 조명장치로 각 파넬에 존재하는 소마디의 다소, 크기 및 분포상태를 검사하여 소마디 표준사진과 대조하여 100점법에 의하여 채점한다.With the same lighting system as large and medium node inspection, the small, size and distribution of small nodes in each panel are examined and scored by 100 point method in comparison with the standard image of small node.

성적은 100파넬의 평균점 및 100파넬의인 열등파넬의 평균점으로 표시한다.Results are averaged at 100 panels and 100 panels It is expressed as the average point of the inferior panel.

여기서 각 마디종류 및 그 정의는 다음과 같다.Here, each node type and its definition are as follows.

① 작은 처짐바디(smallslug)① small sag body (smallslug)

실이 현저하게 굵어지고 있는 부분의 길이가 2mm 이상, 7mm 미만의 것, 또는 실의 일부가 괴상으로 되어 있는 것The length of the part where the thread becomes remarkably thick is 2 mm or more, less than 7 mm, or a part of the thread is bulky.

② 중간이음마디(long knot)② long knot

실의 절단 단부의 길이가 3mm 이상, 10mm 미만의 것With a length of cut end of the thread of not less than 3 mm and less than 10 mm

③ 중간나선마디(corkscrew)③ corkscrew

고치실의 나선상으로 된 부분의 형상이 약간 큰 것.Spiral part of cocoon thread is slightly larger.

④ 큰고리, 분열마디④ big ring, cleavage node

실을 구성하는 고치실의 일부가 실로부터 분리되어 환상(또는 분기상)으로 되어 있는 부분의 길이가 10mm 이상의 것.The part of cocoon which comprises a thread is separated from a thread, and the length of the part which becomes annular (or branched) is 10 mm or more.

상기와 같은 마디 결합부분의 검사는 검사판을 회전시켜서, 그것에 일정한 길이의 생사를 일정간격으로 감도록 되어 있는 세리프렌 권취장치를 사용하여 이루어진 것이다.The inspection of the joint portion as described above is made by using a ceriprene winding device that is to rotate the inspection plate, wound the raw sand of a certain length to a certain interval.

표1, 표2에 의하면 330m/분 이상의 고속으로 조사하는 경우, 상기한 결함의 발생을 최대한도 줄일 수 있다는 것이 명백해진다.According to Tables 1 and 2, it is evident that the occurrence of the above defects can be minimized when irradiated at a high speed of 330 m / min or more.

[제 1 표][Table 1]

대·중 마디검사(세리프렌·100파넬의 총출현개수)Mass node inspection (total number of appearances of sericoprene and 100 panels)

[제 2 표][Table 2]

작은 마디검사(세리프렌·100파넬의 총출현개수)Small node test (total number of appearances of sericoprene and 100 panels)

본 발명방법은, 고치실이외의 실로서 이루어지는 코어실 주위에 고치실을 접속시키고, 켄넬시스템을 거쳐서 리일에 감는 조사방법에 있어서, 조사속도 330m/분 이상의 고속으로 감으므로써, 조사장력 17g/20d 이상을 부여하고, 리일 주위에서 50℃이상의 열풍을 뿜어서 겹침성을 향상시켰으므로, 고치실끼리와 고치실과 코어실이 견고하게 포함되어 겹침성도 좋고, 직진형태로 된다.According to the method of the present invention, in the irradiation method in which a cocoon chamber is connected around a core chamber made of a yarn other than the cocoon chamber, and wound around a rail via a kennel system, the irradiation tension of 17 g / 20 d or more is reduced by winding at a high speed of 330 m / min or more. In addition, since the overlapping property was improved by blowing hot air of 50 ° C. or higher around the rail, the cocoon threads, the cocoon thread, and the core thread were firmly included, so that the overlapability was good, and the straight form was obtained.

그때문에 고치실과 코어실이 분리가 잘 발생되지 않아, 안경형상의 동그란 마디 발생이 없어져, 매끈한 실을 얻을 수 있다.As a result, separation of the cocoon thread and the core thread does not occur well, and the round shape of the spectacles is eliminated, and a smooth thread can be obtained.

Claims (1)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP1-137100 | 1989-05-30 | ||

| JP1137100A JPH038803A (en) | 1989-05-30 | 1989-05-30 | Production of uniform conjugate raw silk yarn |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR900017639A KR900017639A (en) | 1990-12-19 |

| KR930003354B1 true KR930003354B1 (en) | 1993-04-26 |

Family

ID=15190860

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019900007776A KR930003354B1 (en) | 1989-05-30 | 1990-05-29 | Method for producing composite yarn of raw silk |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JPH038803A (en) |

| KR (1) | KR930003354B1 (en) |

| CN (1) | CN1018369B (en) |

| BR (1) | BR9002560A (en) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5057488A (en) * | 1990-02-12 | 1991-10-15 | General Electric Company | Synthesis of Bi-Pb-Ca-Sr-Cu-O superconductive material |

| CN101984156B (en) * | 2010-12-08 | 2012-07-04 | 四川省丝绸科学研究院 | Novel energy-conservation silk drying system of automatic silk reeling machine |

| CN102297570B (en) * | 2011-08-09 | 2013-11-13 | 浙江理工大学 | Drying method for re-reeled silk sheet |

| CN103105051A (en) * | 2011-11-09 | 2013-05-15 | 江苏华佳丝绸有限公司 | Drying device for reeling |

| CN102997638B (en) * | 2012-12-20 | 2015-06-03 | 江苏华佳丝绸有限公司 | Drying device used for reeling silk |

| JP5413758B1 (en) * | 2013-01-17 | 2014-02-12 | 財団法人大日本蚕糸会 | Reeling device |

| CN103437015A (en) * | 2013-08-27 | 2013-12-11 | 上林海润丝业有限公司 | Production method of covered filaments |

| CN104005094B (en) * | 2014-06-04 | 2016-08-24 | 浙江理工大学 | A kind of big reeling device of infrared drying |

| CN106350872A (en) * | 2016-11-10 | 2017-01-25 | 六安市凯盛茧丝绢有限公司 | Silk drying and winding device |

| CN106835294B (en) * | 2016-12-15 | 2022-12-02 | 湖州永昌丝绸有限公司 | Silk reeling processing system and method |

| CN106757389A (en) * | 2016-12-26 | 2017-05-31 | 广西江缘茧丝绸有限公司 | Automatic silk reeling machine battage bath |

| CN106498623B (en) * | 2017-01-03 | 2019-01-18 | 兴化市大地蓝绢纺有限公司 | A kind of preparation method of Sang Mianqiu |

| CN108396429A (en) * | 2018-05-11 | 2018-08-14 | 德宏正信实业股份有限公司 | Stretch yarn of real silk and preparation method thereof |

| CN108796622B (en) * | 2018-06-05 | 2020-11-27 | 绍兴市柯桥区锦策智能科技有限公司 | Silk soil method equipment of drawing silk for fabrics |

| CN108866724A (en) * | 2018-09-05 | 2018-11-23 | 德宏正信实业股份有限公司 | Silk Wool and preparation method thereof |

| CN113403693A (en) * | 2021-05-18 | 2021-09-17 | 浙江理工大学 | Small tool to unreel silk dry-returning tube forming device and method |

-

1989

- 1989-05-30 JP JP1137100A patent/JPH038803A/en active Granted

-

1990

- 1990-05-29 KR KR1019900007776A patent/KR930003354B1/en not_active IP Right Cessation

- 1990-05-30 BR BR909002560A patent/BR9002560A/en not_active IP Right Cessation

- 1990-05-30 CN CN90103965A patent/CN1018369B/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| KR900017639A (en) | 1990-12-19 |

| CN1047710A (en) | 1990-12-12 |

| JPH0357203B2 (en) | 1991-08-30 |

| BR9002560A (en) | 1991-08-13 |

| CN1018369B (en) | 1992-09-23 |

| JPH038803A (en) | 1991-01-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR930003354B1 (en) | Method for producing composite yarn of raw silk | |

| KR100467166B1 (en) | Fluff suppressing device for automatic winder | |

| GB519186A (en) | Improvements in fabric-making materials | |

| IT1150340B (en) | PROCEDURE AND DEVICE FOR MAKING A FIBER YARN | |

| CN110387617A (en) | A kind of elasticizer and dyeing with husky mill homogeneous assisted staining function | |

| US3812665A (en) | Method and apparatus for forming random slubs in yarn | |

| JP2002371429A (en) | Hot roller device | |

| Plate | 32—AN ALTERNATIVE APPROACH TO TWO-FOLD WEAVING YARN PART V: THE PROPERTIES OF TWO-STRAND YARNS | |

| CN104746186A (en) | Pure-cotton high-count foreign-fiber-free series combed yarn detecting device and pure-cotton high-count foreign-fiber-free series combed yarn detecting method | |

| CN108866725A (en) | A kind of Weaving method of terylene, polyvinyl and cotton fiber mixed yarn | |

| JP4596503B2 (en) | Direct spinning method of polyester multifilament | |

| US2098628A (en) | Artificial thread and process of producing same | |

| CN108315850A (en) | A kind of embedded yarn spinning device and ring throstle and section coloured silk spinning method | |

| KR970021397A (en) | Manufacturing method of blended yarn | |

| ITMI20010462A1 (en) | THREADER WITH DISCHARGE DEVICE FOR IRONING | |

| JPS62141115A (en) | Prevention of concurrent breaking of spinning tow and apparatus therefor | |

| CN107366064A (en) | A kind of Weaving method of terylene, polyvinyl and cotton fiber mixed yarn | |

| KR810001268B1 (en) | Twisting machine of silk | |

| JPS60126340A (en) | Production of core yarn | |

| CA1116823A (en) | Crimped, high-strength rayon yarn and method for its preparation | |

| KR100534521B1 (en) | Method for producing synthetic fiber multifilament for warp yarns. | |

| JPH02229211A (en) | Production of polyester fiber | |

| KR900007652B1 (en) | How to manufacture of fancy yarn in air jet spinner | |

| JPS5915521A (en) | Cleaning apparatus in fine spinning machine | |

| JPH0827636A (en) | Method for winding up yarn and device for winding up yarn |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| E902 | Notification of reason for refusal | ||

| G160 | Decision to publish patent application | ||

| E701 | Decision to grant or registration of patent right | ||

| GRNT | Written decision to grant | ||

| LAPS | Lapse due to unpaid annual fee |