KR890003098B1 - 용접관동체(溶接缶胴體)의 제조방법 - Google Patents

용접관동체(溶接缶胴體)의 제조방법 Download PDFInfo

- Publication number

- KR890003098B1 KR890003098B1 KR1019850008469A KR850008469A KR890003098B1 KR 890003098 B1 KR890003098 B1 KR 890003098B1 KR 1019850008469 A KR1019850008469 A KR 1019850008469A KR 850008469 A KR850008469 A KR 850008469A KR 890003098 B1 KR890003098 B1 KR 890003098B1

- Authority

- KR

- South Korea

- Prior art keywords

- welding

- tube

- welded

- weld

- overlapping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

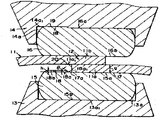

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/06—Resistance welding; Severing by resistance heating using roller electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/02—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape

- B23K35/0205—Non-consumable electrodes; C-electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/06—Resistance welding; Severing by resistance heating using roller electrodes

- B23K11/061—Resistance welding; Severing by resistance heating using roller electrodes for welding rectilinear seams

- B23K11/062—Resistance welding; Severing by resistance heating using roller electrodes for welding rectilinear seams for welding longitudinal seams of tubes

- B23K11/063—Lap welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K11/00—Resistance welding; Severing by resistance heating

- B23K11/30—Features relating to electrodes

- B23K11/309—Wire electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/04—Tubular or hollow articles

- B23K2101/12—Vessels

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Arc Welding In General (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

- Rigid Containers With Two Or More Constituent Elements (AREA)

- Resistance Welding (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP84-248480 | 1984-11-24 | ||

| JP59248480A JPS61135486A (ja) | 1984-11-24 | 1984-11-24 | 溶接缶胴体の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR860003877A KR860003877A (ko) | 1986-06-13 |

| KR890003098B1 true KR890003098B1 (ko) | 1989-08-22 |

Family

ID=17178777

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019850008469A Expired KR890003098B1 (ko) | 1984-11-24 | 1985-11-13 | 용접관동체(溶接缶胴體)의 제조방법 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US4652715A (enExample) |

| EP (1) | EP0183490B1 (enExample) |

| JP (1) | JPS61135486A (enExample) |

| KR (1) | KR890003098B1 (enExample) |

| AU (1) | AU555011B2 (enExample) |

| CA (1) | CA1251692A (enExample) |

| DE (1) | DE3562463D1 (enExample) |

| GB (1) | GB2181980B (enExample) |

| WO (1) | WO1986003152A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH072998B2 (ja) * | 1989-08-09 | 1995-01-18 | 東洋製罐株式会社 | 溶接缶胴 |

| JP2678839B2 (ja) * | 1991-07-30 | 1997-11-19 | 株式会社ネピユー技研 | 一旦マッシュシーム溶接に供せられたワイヤの再使用装置 |

| US5471026A (en) * | 1994-03-30 | 1995-11-28 | Lakewood Engineering & Manufacturing Co. | Continuous resistance welding apparatus and method |

| TW320583B (enExample) * | 1994-07-11 | 1997-11-21 | Elpatronic Ag | |

| GB9626065D0 (en) * | 1996-12-16 | 1997-02-05 | Metal Box Plc | Measurement of welds |

| US6328922B1 (en) * | 1999-10-28 | 2001-12-11 | Xerox Corporation | Process for post treatment of a flexible imaging member belt |

| AT413666B (de) * | 2003-03-04 | 2006-04-15 | Fronius Int Gmbh | Schutzeinrichtung für schweisselektroden |

| JP4594865B2 (ja) * | 2003-06-05 | 2010-12-08 | 菊池プレス工業株式会社 | 突き合わせ溶接装置 |

| DE102007046709A1 (de) * | 2007-09-28 | 2009-04-09 | Linde Ag | Verfahren zum Fügen von Gegenständen |

| JP7027122B2 (ja) * | 2017-10-27 | 2022-03-01 | シロキ工業株式会社 | 車両用ドアサッシュのシーム溶接方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3596043A (en) * | 1969-04-11 | 1971-07-27 | Southern Can Co | Method of seam welding overlapping workpieces |

| DE2532976B2 (de) * | 1975-03-19 | 1978-03-23 | Opprecht, Paul, Bergdietikon, Aargau (Schweiz) | Vorrichtung zum halb- oder vollautomatischen elektrischen Widerstands-Längsnahtschweifien von Dosenkörpern |

| CH595177A5 (en) * | 1976-11-09 | 1978-01-31 | Fael Sa | Ribbed copper electrode strip |

| JPS5931598B2 (ja) * | 1980-03-08 | 1984-08-02 | 東洋製罐株式会社 | 新規溶接罐及び製造法 |

| DE3161098D1 (en) * | 1980-04-22 | 1983-11-10 | Toyo Seikan Kaisha Ltd | Method of manufacturing a welded can body |

| JPS5776986U (enExample) * | 1980-10-28 | 1982-05-12 |

-

1984

- 1984-11-24 JP JP59248480A patent/JPS61135486A/ja active Granted

-

1985

- 1985-08-30 WO PCT/JP1985/000479 patent/WO1986003152A1/ja not_active Ceased

- 1985-08-30 GB GB08616536A patent/GB2181980B/en not_active Expired

- 1985-11-13 KR KR1019850008469A patent/KR890003098B1/ko not_active Expired

- 1985-11-21 EP EP85308481A patent/EP0183490B1/en not_active Expired

- 1985-11-21 DE DE8585308481T patent/DE3562463D1/de not_active Expired

- 1985-11-22 AU AU50296/85A patent/AU555011B2/en not_active Ceased

- 1985-11-22 CA CA000495954A patent/CA1251692A/en not_active Expired

- 1985-11-25 US US06/802,099 patent/US4652715A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CA1251692A (en) | 1989-03-28 |

| AU555011B2 (en) | 1986-09-11 |

| AU5029685A (en) | 1986-05-29 |

| JPS61135486A (ja) | 1986-06-23 |

| EP0183490B1 (en) | 1988-05-04 |

| WO1986003152A1 (fr) | 1986-06-05 |

| JPS6246277B2 (enExample) | 1987-10-01 |

| GB2181980A (en) | 1987-05-07 |

| US4652715A (en) | 1987-03-24 |

| EP0183490A1 (en) | 1986-06-04 |

| DE3562463D1 (en) | 1988-06-09 |

| GB2181980B (en) | 1988-06-08 |

| KR860003877A (ko) | 1986-06-13 |

| GB8616536D0 (en) | 1986-08-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR890003098B1 (ko) | 용접관동체(溶接缶胴體)의 제조방법 | |

| JPS61206576A (ja) | 金属板等から成る缶胴のラツプ継手の溶接方法 | |

| EP0038646A1 (en) | Method of manufacturing a welded can body | |

| US4595326A (en) | Method of making welded can body | |

| JP3212136B2 (ja) | 溶接缶胴を有する缶体 | |

| JPS6030589A (ja) | 溶接缶胴の製造方法 | |

| JPH0343947B2 (enExample) | ||

| JPH0343945B2 (enExample) | ||

| CA1177419A (en) | Method of producing container bodies and container bodies produced thereby | |

| KR930004995B1 (ko) | 용접관동(罐胴) | |

| JPS63149087A (ja) | 溶接缶胴体の製造方法 | |

| JPS6135280B2 (enExample) | ||

| EP0134724A1 (en) | Welded can body and method of making same | |

| JPH0344874B2 (enExample) | ||

| KR840002191B1 (ko) | 용접관동체의 제조방법 | |

| JPS6324795B2 (enExample) | ||

| JP2580923B2 (ja) | 溶接缶用ラミネート鋼板とその製造方法 | |

| JPS60227983A (ja) | 溶接缶胴体の製造方法 | |

| JPS62259679A (ja) | 缶胴体の製造方法 | |

| JPH0243588B2 (enExample) | ||

| JPS62275582A (ja) | マツシユシ−ム溶接缶胴 | |

| JPS5847576A (ja) | 溶接缶胴体の製造方法 | |

| JPS59209490A (ja) | 溶接缶胴体 | |

| JPS62267090A (ja) | 溶接缶体の製造方法 | |

| JPS625711B2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| G160 | Decision to publish patent application | ||

| PG1605 | Publication of application before grant of patent |

St.27 status event code: A-2-2-Q10-Q13-nap-PG1605 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| FPAY | Annual fee payment |

Payment date: 19940805 Year of fee payment: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| LAPS | Lapse due to unpaid annual fee | ||

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 19950823 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 19950823 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-4-4-P10-P22-nap-X000 |