KR830001020B1 - 염화폴리 비닐공장에서 배기 기체 스트림으로 부터 염화 비닐 단량체를 제거하고 회수하기 위한 개선된 공정 - Google Patents

염화폴리 비닐공장에서 배기 기체 스트림으로 부터 염화 비닐 단량체를 제거하고 회수하기 위한 개선된 공정 Download PDFInfo

- Publication number

- KR830001020B1 KR830001020B1 KR1019800001745A KR800001745A KR830001020B1 KR 830001020 B1 KR830001020 B1 KR 830001020B1 KR 1019800001745 A KR1019800001745 A KR 1019800001745A KR 800001745 A KR800001745 A KR 800001745A KR 830001020 B1 KR830001020 B1 KR 830001020B1

- Authority

- KR

- South Korea

- Prior art keywords

- vcm

- solvent

- vinyl chloride

- exhaust gas

- chloride monomer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 title claims description 97

- 239000000178 monomer Substances 0.000 title claims description 28

- 239000004800 polyvinyl chloride Substances 0.000 title claims description 27

- 238000000034 method Methods 0.000 title claims description 26

- 229920000915 polyvinyl chloride Polymers 0.000 title claims description 26

- 238000011084 recovery Methods 0.000 title description 13

- 239000002904 solvent Substances 0.000 claims description 73

- NHTMVDHEPJAVLT-UHFFFAOYSA-N Isooctane Chemical compound CC(C)CC(C)(C)C NHTMVDHEPJAVLT-UHFFFAOYSA-N 0.000 claims description 17

- 238000004519 manufacturing process Methods 0.000 claims description 13

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 claims description 4

- 125000004432 carbon atom Chemical group C* 0.000 claims description 3

- 238000004064 recycling Methods 0.000 claims 1

- 239000002594 sorbent Substances 0.000 claims 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 claims 1

- 229920002554 vinyl polymer Polymers 0.000 claims 1

- 239000007789 gas Substances 0.000 description 47

- 238000010521 absorption reaction Methods 0.000 description 40

- JVSWJIKNEAIKJW-UHFFFAOYSA-N dimethyl-hexane Natural products CCCCCC(C)C JVSWJIKNEAIKJW-UHFFFAOYSA-N 0.000 description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 239000007788 liquid Substances 0.000 description 8

- 238000000926 separation method Methods 0.000 description 7

- 239000000463 material Substances 0.000 description 5

- 238000006116 polymerization reaction Methods 0.000 description 5

- 229920006395 saturated elastomer Polymers 0.000 description 5

- 239000006096 absorbing agent Substances 0.000 description 4

- 238000009835 boiling Methods 0.000 description 4

- 238000012674 dispersion polymerization Methods 0.000 description 4

- 229930195733 hydrocarbon Natural products 0.000 description 4

- 150000002430 hydrocarbons Chemical class 0.000 description 4

- 238000001179 sorption measurement Methods 0.000 description 4

- 238000010557 suspension polymerization reaction Methods 0.000 description 4

- WSLDOOZREJYCGB-UHFFFAOYSA-N 1,2-Dichloroethane Chemical compound ClCCCl WSLDOOZREJYCGB-UHFFFAOYSA-N 0.000 description 3

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 238000009833 condensation Methods 0.000 description 3

- 230000005494 condensation Effects 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 230000007613 environmental effect Effects 0.000 description 3

- 238000004880 explosion Methods 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- 239000000725 suspension Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

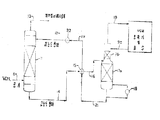

- 238000010586 diagram Methods 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000007710 freezing Methods 0.000 description 2

- 230000008014 freezing Effects 0.000 description 2

- IXCSERBJSXMMFS-UHFFFAOYSA-N hydrogen chloride Substances Cl.Cl IXCSERBJSXMMFS-UHFFFAOYSA-N 0.000 description 2

- 229910000041 hydrogen chloride Inorganic materials 0.000 description 2

- IVSZLXZYQVIEFR-UHFFFAOYSA-N m-xylene Chemical group CC1=CC=CC(C)=C1 IVSZLXZYQVIEFR-UHFFFAOYSA-N 0.000 description 2

- 239000002609 medium Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 239000003208 petroleum Substances 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- 238000013022 venting Methods 0.000 description 2

- VCZXRQFWGHPRQB-UHFFFAOYSA-N CC(C)CC(C)(C)C.CC(C)CC(C)(C)C Chemical compound CC(C)CC(C)(C)C.CC(C)CC(C)(C)C VCZXRQFWGHPRQB-UHFFFAOYSA-N 0.000 description 1

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical group C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 239000012736 aqueous medium Substances 0.000 description 1

- 150000004945 aromatic hydrocarbons Chemical group 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000012662 bulk polymerization Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000008821 health effect Effects 0.000 description 1

- 239000003350 kerosene Substances 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- TVMXDCGIABBOFY-UHFFFAOYSA-N octane Chemical compound CCCCCCCC TVMXDCGIABBOFY-UHFFFAOYSA-N 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 231100000683 possible toxicity Toxicity 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 238000005057 refrigeration Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/14—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by absorption

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/46—Removing components of defined structure

- B01D53/68—Halogens or halogen compounds

- B01D53/70—Organic halogen compounds

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Analytical Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Treating Waste Gases (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Gas Separation By Absorption (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

Abstract

Description

Claims (1)

- 본문에 상술한 바와같이, 염화폴리 비닐 생성 공장에서 유래되고 통상적으로 이러한 공장으로부터 대기로 배기되는, 염화비닐 단량체와 혼합된 공기를 함유하는 기체 스트림으로 부터 염화비닐 단량체를 제거하고 회수하는 공정에 있어서, 이러한 공정은 기체스트림이 대기로 배기되기 전에 40°F이상의 용매에 염화비닐 단량체를 흡수시키기 위해서 흡수제용매의 스트림에 역류로 기체 스트림을 통과시키는 단계, 분리된 염화비닐 단량체를 회수하고 스트리핑 후에 흡수단계로 재순환 시키는 단계로 구성되어 있으며, 이러한 공정의 개선점은 용매로서 주로 2,2,4-트리메틸 펜탄으로 구성된 8개의 탄소 원자를 가진 측쇄 지방족 탄화수소를 사용함으로써 대기로 배기되는 기체에 있어서의 염화비닐 단량체의 농도는 5ppm이하로 감소됨이 특정인, 염화폴리 비닐 공장에서의 배기기체 스트림으로부터 염화비닐 단량체를 제거하고 회수 하기 위한 개선된 공정.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US3514079A | 1979-05-02 | 1979-05-02 | |

| US35140 | 1979-05-02 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR830001020B1 true KR830001020B1 (ko) | 1983-05-25 |

Family

ID=21880902

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019800001745A Expired KR830001020B1 (ko) | 1979-05-02 | 1980-05-01 | 염화폴리 비닐공장에서 배기 기체 스트림으로 부터 염화 비닐 단량체를 제거하고 회수하기 위한 개선된 공정 |

Country Status (14)

| Country | Link |

|---|---|

| EP (1) | EP0027805B1 (ko) |

| JP (1) | JPS631891B2 (ko) |

| KR (1) | KR830001020B1 (ko) |

| BE (1) | BE883016A (ko) |

| BR (1) | BR8008651A (ko) |

| CA (1) | CA1157483A (ko) |

| DE (1) | DE3063728D1 (ko) |

| GR (1) | GR66624B (ko) |

| IN (1) | IN152347B (ko) |

| IT (1) | IT1140864B (ko) |

| NO (1) | NO150905C (ko) |

| PH (1) | PH14800A (ko) |

| PT (1) | PT71171A (ko) |

| WO (1) | WO1980002387A1 (ko) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO320790B1 (no) † | 2000-10-19 | 2006-01-30 | Scan Wind Group As | Vindkraftverk |

| US8203107B2 (en) | 2004-05-27 | 2012-06-19 | Mastrad, S.A. | Microwavable cooking implements and methods for crisping food items using the same |

| CN112717669A (zh) * | 2020-12-15 | 2021-04-30 | 内蒙古亿利化学工业有限公司 | 一种氯乙烯生产中聚合尾气处理系统 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB770507A (en) * | 1954-06-22 | 1957-03-20 | Exxon Research Engineering Co | Improvements in or relating to ethylene polymerization |

| BE545081A (ko) * | 1955-02-09 | |||

| GB872773A (en) * | 1959-06-05 | 1961-07-12 | Kurashiki Rayon Kk | A method of manufacturing polyvinyl acetate |

| BE621732A (ko) * | 1961-08-26 | |||

| US3419629A (en) * | 1965-12-17 | 1968-12-31 | Halcon International Inc | Preparation of vinyl chloride |

| US3463603A (en) * | 1967-03-17 | 1969-08-26 | Shell Oil Co | Method of separating acidic gases from gaseous mixture |

| US3642736A (en) * | 1969-05-13 | 1972-02-15 | Monsanto Co | Method for recovering vented monomers |

| DE2446815A1 (de) * | 1974-10-01 | 1976-04-22 | Gaf Corp | Rueckgewinnung und reinigung von vinylchlorid aus polyvinylchloridreaktoren |

| US3988383A (en) * | 1975-01-31 | 1976-10-26 | The Lummus Company | Inert removal from chlorinated hydrocarbon production system |

| DE2514126C2 (de) * | 1975-03-29 | 1981-10-08 | Basf Ag, 6700 Ludwigshafen | Verfahren zur Rückgewinnung von unter Normalbedingung gas- und/oder dampfförmiger Monomerer aus Polymerisationsabgasen |

| JPS6021125B2 (ja) * | 1976-12-20 | 1985-05-25 | ジェイエスアール株式会社 | イソプレンの精製法 |

-

1980

- 1980-03-10 DE DE8080900743T patent/DE3063728D1/de not_active Expired

- 1980-03-10 JP JP55500817A patent/JPS631891B2/ja not_active Expired

- 1980-03-10 BR BR8008651A patent/BR8008651A/pt not_active IP Right Cessation

- 1980-03-10 WO PCT/US1980/000254 patent/WO1980002387A1/en active IP Right Grant

- 1980-03-14 CA CA000347725A patent/CA1157483A/en not_active Expired

- 1980-03-14 GR GR61447A patent/GR66624B/el unknown

- 1980-03-21 IN IN328/CAL/80A patent/IN152347B/en unknown

- 1980-04-09 PH PH23879A patent/PH14800A/en unknown

- 1980-04-15 IT IT21382/80A patent/IT1140864B/it active

- 1980-04-28 BE BE0/200397A patent/BE883016A/fr not_active IP Right Cessation

- 1980-04-30 PT PT71171A patent/PT71171A/pt unknown

- 1980-05-01 KR KR1019800001745A patent/KR830001020B1/ko not_active Expired

- 1980-11-17 EP EP80900743A patent/EP0027805B1/en not_active Expired

- 1980-12-09 NO NO803709A patent/NO150905C/no unknown

Also Published As

| Publication number | Publication date |

|---|---|

| BR8008651A (pt) | 1981-06-09 |

| BE883016A (fr) | 1980-08-18 |

| NO150905B (no) | 1984-10-01 |

| EP0027805A4 (en) | 1981-09-01 |

| JPS631891B2 (ko) | 1988-01-14 |

| GR66624B (ko) | 1981-04-03 |

| DE3063728D1 (en) | 1983-07-21 |

| EP0027805A1 (en) | 1981-05-06 |

| IN152347B (ko) | 1983-12-24 |

| CA1157483A (en) | 1983-11-22 |

| EP0027805B1 (en) | 1983-06-15 |

| NO150905C (no) | 1985-01-16 |

| IT1140864B (it) | 1986-10-10 |

| PH14800A (en) | 1981-12-09 |

| PT71171A (en) | 1980-05-01 |

| JPS56500402A (ko) | 1981-04-02 |

| WO1980002387A1 (en) | 1980-11-13 |

| IT8021382A0 (it) | 1980-04-15 |

| NO803709L (no) | 1980-12-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3594985A (en) | Acid gas removal from gas mixtures | |

| JP5303453B2 (ja) | 無水塩化水素ガスを精製するための改良された方法 | |

| KR100490937B1 (ko) | 복합 아민 혼합물에 의해 이산화탄소를 회수하는 방법 | |

| US8449656B2 (en) | Process and apparatus for removal of oxygen from seawater | |

| KR100490936B1 (ko) | 희박 공급물로부터 이산화탄소를 회수하는 장치 | |

| US3737392A (en) | Solvent composition useful in acid gas removal from gas mixtures | |

| US6677482B2 (en) | Method of manufacturing (meth) acrylic acid | |

| US4133663A (en) | Removing vinyl chloride from a vent gas stream | |

| MXPA05006242A (es) | Configuraciones y metodos para la remocion de gas acido y contaminantes con emision casi nula. | |

| CA2376814C (en) | Ethylene recovery system | |

| KR19980070554A (ko) | 퍼플루오로화합물을 분리 및 정제하는 방법 및 시스템 | |

| US2217429A (en) | Separation of acetylene from gaseous mixtures containing it | |

| CN102161715B (zh) | 一种固体聚合物脱气及排放气回收的方法和装置 | |

| KR830001020B1 (ko) | 염화폴리 비닐공장에서 배기 기체 스트림으로 부터 염화 비닐 단량체를 제거하고 회수하기 위한 개선된 공정 | |

| US5437711A (en) | Method of purifying chlorine-containing gases | |

| BG65716B1 (bg) | Метод за производство етиленов оксид | |

| KR20050058463A (ko) | 프로필렌 옥사이드 생산 방법에서의 프로펜 회수 | |

| US3140244A (en) | Removal of volatile organic materials from aqueous hydrochloric acid | |

| WO2001038787A1 (en) | Improved chlorinated hydrocarbon waste incinerator an d valorization of chlorinated residuals process unit | |

| AU647493B2 (en) | Process for the production of alkylene oxide | |

| US5352335A (en) | Groundwater treatment process | |

| US6273008B1 (en) | Chlorinated hydrocarbon waste incinerator and valorization of chlorinated residuals process unit | |

| RU2087181C1 (ru) | Способ удаления кислотных газов, таких, как сероводород и/или двуокись углерода | |

| US6391160B1 (en) | Water removal in purification of vinyl chloride | |

| CN115382352A (zh) | 含二氯甲烷废气的二氯甲烷回收工艺和回收系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 19800501 |

|

| PG1605 | Publication of application before grant of patent |

Comment text: Decision on Publication of Application Patent event code: PG16051S01I Patent event date: 19830426 |

|

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 19830801 |

|

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 19830804 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 19830804 End annual number: 3 Start annual number: 1 |

|

| PR1001 | Payment of annual fee |

Payment date: 19860418 Start annual number: 4 End annual number: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 19870515 Start annual number: 5 End annual number: 5 |

|

| PR1001 | Payment of annual fee |

Payment date: 19880419 Start annual number: 6 End annual number: 6 |

|

| PR1001 | Payment of annual fee |

Payment date: 19890428 Start annual number: 7 End annual number: 7 |

|

| PR1001 | Payment of annual fee |

Payment date: 19900430 Start annual number: 8 End annual number: 8 |

|

| PR1001 | Payment of annual fee |

Payment date: 19910501 Start annual number: 9 End annual number: 9 |

|

| PR1001 | Payment of annual fee |

Payment date: 19920501 Start annual number: 10 End annual number: 10 |

|

| PR1001 | Payment of annual fee |

Payment date: 19930427 Start annual number: 11 End annual number: 11 |

|

| PR1001 | Payment of annual fee |

Payment date: 19940509 Start annual number: 12 End annual number: 12 |

|

| PC1801 | Expiration of term |