KR20180098699A - 성형장치 - Google Patents

성형장치 Download PDFInfo

- Publication number

- KR20180098699A KR20180098699A KR1020187024620A KR20187024620A KR20180098699A KR 20180098699 A KR20180098699 A KR 20180098699A KR 1020187024620 A KR1020187024620 A KR 1020187024620A KR 20187024620 A KR20187024620 A KR 20187024620A KR 20180098699 A KR20180098699 A KR 20180098699A

- Authority

- KR

- South Korea

- Prior art keywords

- metal pipe

- mold

- pipe material

- molding

- slide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000465 moulding Methods 0.000 title claims abstract description 79

- 239000002184 metal Substances 0.000 claims abstract description 139

- 239000000463 material Substances 0.000 claims abstract description 104

- 238000000034 method Methods 0.000 claims description 7

- 230000007246 mechanism Effects 0.000 abstract description 26

- 230000008859 change Effects 0.000 abstract description 10

- 239000007789 gas Substances 0.000 description 31

- 238000000071 blow moulding Methods 0.000 description 23

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 13

- 238000010438 heat treatment Methods 0.000 description 12

- 238000001816 cooling Methods 0.000 description 8

- 230000002093 peripheral effect Effects 0.000 description 4

- 239000000498 cooling water Substances 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 238000007664 blowing Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 229910000734 martensite Inorganic materials 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 229910001566 austenite Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000010720 hydraulic oil Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- WABPQHHGFIMREM-UHFFFAOYSA-N lead(0) Chemical compound [Pb] WABPQHHGFIMREM-UHFFFAOYSA-N 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 230000000171 quenching effect Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000003303 reheating Methods 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 239000002436 steel type Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/0004—Devices wherein the heating current flows through the material to be heated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D26/00—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces

- B21D26/02—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces by applying fluid pressure

- B21D26/033—Deforming tubular bodies

- B21D26/039—Means for controlling the clamping or opening of the moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D26/00—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces

- B21D26/02—Shaping without cutting otherwise than using rigid devices or tools or yieldable or resilient pads, i.e. applying fluid pressure or magnetic forces by applying fluid pressure

- B21D26/033—Deforming tubular bodies

- B21D26/041—Means for controlling fluid parameters, e.g. pressure or temperature

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/56—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering characterised by the quenching agents

- C21D1/60—Aqueous agents

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/62—Quenching devices

- C21D1/673—Quenching devices for die quenching

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D7/00—Modifying the physical properties of iron or steel by deformation

- C21D7/13—Modifying the physical properties of iron or steel by deformation by hot working

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/0062—Heat-treating apparatus with a cooling or quenching zone

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/02—Details

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/02—Details

- H05B3/03—Electrodes

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Thermal Sciences (AREA)

- Fluid Mechanics (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Control Of Presses (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

Abstract

Description

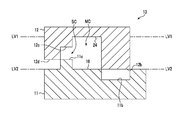

도 2는 도 1에 나타내는 II-II선을 따른 단면도로서, 블로(blow)성형금형의 개략단면도이다.

도 3은 성형장치에 의한 제조공정을 나타내는 도로서, (a)는 금형 내에 금속파이프 재료가 세팅된 상태를 나타내는 도, (b)는 금속파이프 재료가 전극에 의하여 유지된 상태를 나타내는 도이다.

도 4는 성형장치에 의한 블로성형공정과 그 후의 흐름을 나타내는 도이다.

도 5는 전극 주변의 확대도로서, (a)는 전극이 금속파이프 재료를 유지한 상태를 나타내는 도이며, (b)는 전극에 블로기구가 맞닿은 상태를 나타내는 도이고, (c)는 전극의 정면도이다.

도 6은 블로성형금형의 동작과 금속파이프 재료의 형상의 변화를 나타내는 도이며, (a)는 금속파이프 재료를 블로성형금형에 세팅한 시점의 상태를 나타내는 도이고, (b)는 블로성형 시의 상태를 나타내는 도이며, (c)는 프레스에 의하여 플랜지부가 성형된 상태를 나타내는 도이다.

도 7은 제어부에 의한 슬라이드의 속도 제어의 양태의 일례를 나타내는 그래프이다.

도 8은 제어부에 의한 슬라이드의 속도 제어의 양태의 일례를 나타내는 그래프이다.

11…하형(제2 금형)

12…상형(제1 금형)

14…금속파이프 재료

30…파이프유지기구(유지부)

60…블로기구(기체공급부)

70…제어부

81…구동부

82…슬라이드

83…서보모터

MC…메인캐비티부

SC…서브캐비티부

Claims (4)

- 플랜지를 갖는 금속파이프를 성형하는 성형장치로서,

서로 쌍을 이루는 제1 금형 및 제2 금형과,

상기 제1 금형 및 상기 제2 금형 중 적어도 일방을 이동시키는 슬라이드와,

상기 슬라이드를 이동시키기 위한 구동력을 발생시키는 서보모터를 구비하는 구동부와,

상기 제1 금형과 상기 제2 금형의 사이에서 금속파이프 재료를 유지하는 유지부와,

상기 유지부에 의하여 유지된 상기 금속파이프 재료 내에 기체를 공급하는 기체공급부와,

상기 구동부, 상기 유지부 및 상기 기체공급부를 제어하는 제어부를 구비하고,

상기 제어부는,

상기 유지부에 의하여 상기 제1 금형과 상기 제2 금형의 사이에서 유지된 상기 금속파이프 재료 내에 기체를 공급함으로써, 상기 금속파이프 재료를 팽창 성형하도록 상기 기체공급부를 제어하며,

팽창된 상기 금속파이프 재료의 일부를 상기 제1 금형 및 상기 제2 금형에 의하여 눌러 밀려나오게 함으로써 플랜지부를 성형하도록 상기 구동부를 제어하고,

상기 서보모터를 제어함으로써, 상기 플랜지부의 성형 중에 상기 슬라이드의 이동속도를 감소시키는 성형장치. - 제 1 항에 있어서,

상기 제어부는, 상기 플랜지부의 성형 시에, 성형 초기에 비해 성형 후기에서 상기 슬라이드의 소정 시간 당 이동량을 작게 하도록 상기 구동부를 제어하는 것을 특징으로 하는 성형장치. - 제 2 항에 있어서,

상기 제어부는, 상기 플랜지부의 성형 시에, 시간이 지남에 따라 상기 슬라이드의 소정 시간 당 이동량을 감소시키도록 상기 구동부를 제어하는 것을 특징으로 하는 성형장치. - 제 2 항에 있어서,

상기 제어부는, 상기 플랜지부의 성형 시에, 가로축을 시간으로 세로축을 상기 슬라이드의 위치로 한 그래프에서, 아래로 볼록한 곡선을 그리도록 상기 구동부를 제어하는 것을 특징으로 하는 성형장치.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/IB2014/001822 WO2015162448A1 (en) | 2014-04-21 | 2014-04-21 | Molding apparatus |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020167029780A Division KR20160141774A (ko) | 2014-04-21 | 2014-04-21 | 성형장치 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180098699A true KR20180098699A (ko) | 2018-09-04 |

Family

ID=51894162

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020167029780A Ceased KR20160141774A (ko) | 2014-04-21 | 2014-04-21 | 성형장치 |

| KR1020187024620A Ceased KR20180098699A (ko) | 2014-04-21 | 2014-04-21 | 성형장치 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020167029780A Ceased KR20160141774A (ko) | 2014-04-21 | 2014-04-21 | 성형장치 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10531520B2 (ko) |

| EP (1) | EP3134217B1 (ko) |

| JP (1) | JP6475753B2 (ko) |

| KR (2) | KR20160141774A (ko) |

| CN (1) | CN106457345B (ko) |

| CA (1) | CA2946088C (ko) |

| WO (1) | WO2015162448A1 (ko) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6771271B2 (ja) * | 2015-03-31 | 2020-10-21 | 住友重機械工業株式会社 | 成形装置 |

| KR101936478B1 (ko) * | 2016-12-15 | 2019-01-08 | 현대자동차주식회사 | 입체냉각방식 핫 스템핑 공법과 핫 스템핑 시스템 |

| CN109304388B (zh) * | 2017-07-28 | 2020-06-12 | 上海宝钢高新技术零部件有限公司 | 一种液压成形四弯零件模内压弯装置和方法 |

| DE112019001169T5 (de) * | 2018-03-06 | 2020-12-10 | Sumitomo Heavy Industries, Ltd. | Elektrische heizvorrichtung |

| CN109404371A (zh) * | 2018-06-28 | 2019-03-01 | 吉林省正轩车架有限公司 | 一种能缩短内高压成型工艺周期的液压系统 |

| DE102018124985B4 (de) * | 2018-10-10 | 2022-05-05 | Stego-Holding Gmbh | Temperiervorrichtung und System |

| JP6685363B2 (ja) * | 2018-10-16 | 2020-04-22 | 住友重機械工業株式会社 | 成形装置 |

| JP7668802B2 (ja) * | 2020-08-11 | 2025-04-25 | 住友重機械工業株式会社 | 成形装置 |

| TWI731814B (zh) * | 2020-11-10 | 2021-06-21 | 財團法人金屬工業研究發展中心 | 用於熱沖壓模具的溫度感測裝置及方法 |

| JP7514741B2 (ja) * | 2020-11-17 | 2024-07-11 | 株式会社アミノ | バルブ機能を備えた金型及び管材成形品の製造方法 |

| JP7543099B2 (ja) * | 2020-11-17 | 2024-09-02 | 株式会社アミノ | ハイドロフォーミングシステム |

| CN112494173B (zh) * | 2020-11-19 | 2022-07-19 | 东莞市镁安医疗器械有限公司 | 一种血管支架结构加工装置及方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003154415A (ja) | 2001-09-04 | 2003-05-27 | Aisin Takaoka Ltd | 金属部材成形方法、金属部材及び金属部材成形装置 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6082229A (ja) * | 1983-10-08 | 1985-05-10 | Mori Tekko Kk | バルジ加工方法 |

| JP3509217B2 (ja) * | 1994-09-20 | 2004-03-22 | 株式会社日立製作所 | 異形断面管の成形方法並びに成形装置 |

| EP1197274B1 (en) * | 1997-04-16 | 2004-12-29 | Cosma International Inc. | High pressure hydroforming press |

| WO1998046382A1 (en) | 1997-04-16 | 1998-10-22 | Cosma International Inc. | High pressure hydroforming press |

| US6237382B1 (en) * | 1997-08-06 | 2001-05-29 | Sumitomo Metal Industries, Ltd. | Method and apparatus for hydroforming metallic tube |

| JP4647753B2 (ja) * | 2000-06-27 | 2011-03-09 | 日本発條株式会社 | 金属ベローズの製造装置 |

| US6912884B2 (en) * | 2001-06-25 | 2005-07-05 | Mohamed T. Gharib | Hydroforming process and apparatus for the same |

| JP2004249309A (ja) * | 2003-02-19 | 2004-09-09 | Aida Eng Ltd | ハイドロフォーミング装置 |

| JP2007069241A (ja) | 2005-09-07 | 2007-03-22 | Toyo Seikan Kaisha Ltd | ロータリー式ブロー成形装置及びロータリー式ブロー成形方法 |

| JP2009220141A (ja) * | 2008-03-14 | 2009-10-01 | Marujun Co Ltd | パイプ製品の製造方法及び同製造装置 |

| JP4920772B2 (ja) * | 2010-06-18 | 2012-04-18 | リンツリサーチエンジニアリング株式会社 | フランジ付金属製パイプ製造装置及びその製造方法並びにブロー成形金型 |

| CN103464562B (zh) * | 2013-09-14 | 2016-03-30 | 中国第一汽车股份有限公司 | 腔体件低内压成形方法 |

-

2014

- 2014-04-21 EP EP14796543.8A patent/EP3134217B1/en active Active

- 2014-04-21 CN CN201480078190.7A patent/CN106457345B/zh active Active

- 2014-04-21 CA CA2946088A patent/CA2946088C/en active Active

- 2014-04-21 KR KR1020167029780A patent/KR20160141774A/ko not_active Ceased

- 2014-04-21 WO PCT/IB2014/001822 patent/WO2015162448A1/en not_active Ceased

- 2014-04-21 KR KR1020187024620A patent/KR20180098699A/ko not_active Ceased

- 2014-04-21 JP JP2016563983A patent/JP6475753B2/ja active Active

-

2016

- 2016-10-19 US US15/298,020 patent/US10531520B2/en active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003154415A (ja) | 2001-09-04 | 2003-05-27 | Aisin Takaoka Ltd | 金属部材成形方法、金属部材及び金属部材成形装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20160141774A (ko) | 2016-12-09 |

| US20170048931A1 (en) | 2017-02-16 |

| JP6475753B2 (ja) | 2019-02-27 |

| CN106457345A (zh) | 2017-02-22 |

| WO2015162448A1 (en) | 2015-10-29 |

| CN106457345B (zh) | 2020-06-16 |

| CA2946088C (en) | 2018-06-26 |

| JP2017515681A (ja) | 2017-06-15 |

| CA2946088A1 (en) | 2015-10-29 |

| WO2015162448A8 (en) | 2016-12-08 |

| EP3134217A1 (en) | 2017-03-01 |

| US10531520B2 (en) | 2020-01-07 |

| EP3134217B1 (en) | 2021-11-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20180098699A (ko) | 성형장치 | |

| US10173254B2 (en) | Molding apparatus | |

| JP4920772B2 (ja) | フランジ付金属製パイプ製造装置及びその製造方法並びにブロー成形金型 | |

| US10646912B2 (en) | Forming apparatus and forming method | |

| JP6210939B2 (ja) | 成形システム | |

| JP6401953B2 (ja) | 成形装置及び成形方法 | |

| JP6670543B2 (ja) | 成形装置及び成形方法 | |

| JP6463008B2 (ja) | 成形装置 | |

| JPWO2017034025A1 (ja) | 成形装置及び成形方法 | |

| KR101734933B1 (ko) | 성형시스템 | |

| JP6704982B2 (ja) | 成形装置 | |

| JP6173261B2 (ja) | 成形システム | |

| JP6685363B2 (ja) | 成形装置 | |

| JP2018001210A (ja) | 成形装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A107 | Divisional application of patent | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20180827 Application number text: 1020167029780 Filing date: 20161025 |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20181016 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20181126 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20190530 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20181126 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| J201 | Request for trial against refusal decision | ||

| PJ0201 | Trial against decision of rejection |

Patent event date: 20190625 Comment text: Request for Trial against Decision on Refusal Patent event code: PJ02012R01D Patent event date: 20190530 Comment text: Decision to Refuse Application Patent event code: PJ02011S01I Appeal kind category: Appeal against decision to decline refusal Appeal identifier: 2019101002114 Request date: 20190625 |

|

| J301 | Trial decision |

Free format text: TRIAL NUMBER: 2019101002114; TRIAL DECISION FOR APPEAL AGAINST DECISION TO DECLINE REFUSAL REQUESTED 20190625 Effective date: 20200831 |

|

| PJ1301 | Trial decision |

Patent event code: PJ13011S01D Patent event date: 20200831 Comment text: Trial Decision on Objection to Decision on Refusal Appeal kind category: Appeal against decision to decline refusal Request date: 20190625 Decision date: 20200831 Appeal identifier: 2019101002114 |