KR20180098220A - 1인용 식용 식품바를 형성하는 시스템 및 방법 - Google Patents

1인용 식용 식품바를 형성하는 시스템 및 방법 Download PDFInfo

- Publication number

- KR20180098220A KR20180098220A KR1020187011509A KR20187011509A KR20180098220A KR 20180098220 A KR20180098220 A KR 20180098220A KR 1020187011509 A KR1020187011509 A KR 1020187011509A KR 20187011509 A KR20187011509 A KR 20187011509A KR 20180098220 A KR20180098220 A KR 20180098220A

- Authority

- KR

- South Korea

- Prior art keywords

- pressure

- molding module

- predetermined

- coating

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 51

- 235000013305 food Nutrition 0.000 title claims abstract description 36

- 238000000465 moulding Methods 0.000 claims description 77

- 238000000576 coating method Methods 0.000 claims description 61

- 239000011248 coating agent Substances 0.000 claims description 58

- 239000011859 microparticle Substances 0.000 claims description 52

- 239000011230 binding agent Substances 0.000 claims description 35

- 235000013339 cereals Nutrition 0.000 claims description 31

- 239000000463 material Substances 0.000 claims description 24

- 238000007596 consolidation process Methods 0.000 claims description 19

- 239000007788 liquid Substances 0.000 claims description 18

- 238000010438 heat treatment Methods 0.000 claims description 16

- 239000000203 mixture Substances 0.000 claims description 15

- 239000000835 fiber Substances 0.000 claims description 12

- 229920001202 Inulin Polymers 0.000 claims description 9

- 239000010419 fine particle Substances 0.000 claims description 9

- JYJIGFIDKWBXDU-MNNPPOADSA-N inulin Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)OC[C@]1(OC[C@]2(OC[C@]3(OC[C@]4(OC[C@]5(OC[C@]6(OC[C@]7(OC[C@]8(OC[C@]9(OC[C@]%10(OC[C@]%11(OC[C@]%12(OC[C@]%13(OC[C@]%14(OC[C@]%15(OC[C@]%16(OC[C@]%17(OC[C@]%18(OC[C@]%19(OC[C@]%20(OC[C@]%21(OC[C@]%22(OC[C@]%23(OC[C@]%24(OC[C@]%25(OC[C@]%26(OC[C@]%27(OC[C@]%28(OC[C@]%29(OC[C@]%30(OC[C@]%31(OC[C@]%32(OC[C@]%33(OC[C@]%34(OC[C@]%35(OC[C@]%36(O[C@@H]%37[C@@H]([C@@H](O)[C@H](O)[C@@H](CO)O%37)O)[C@H]([C@H](O)[C@@H](CO)O%36)O)[C@H]([C@H](O)[C@@H](CO)O%35)O)[C@H]([C@H](O)[C@@H](CO)O%34)O)[C@H]([C@H](O)[C@@H](CO)O%33)O)[C@H]([C@H](O)[C@@H](CO)O%32)O)[C@H]([C@H](O)[C@@H](CO)O%31)O)[C@H]([C@H](O)[C@@H](CO)O%30)O)[C@H]([C@H](O)[C@@H](CO)O%29)O)[C@H]([C@H](O)[C@@H](CO)O%28)O)[C@H]([C@H](O)[C@@H](CO)O%27)O)[C@H]([C@H](O)[C@@H](CO)O%26)O)[C@H]([C@H](O)[C@@H](CO)O%25)O)[C@H]([C@H](O)[C@@H](CO)O%24)O)[C@H]([C@H](O)[C@@H](CO)O%23)O)[C@H]([C@H](O)[C@@H](CO)O%22)O)[C@H]([C@H](O)[C@@H](CO)O%21)O)[C@H]([C@H](O)[C@@H](CO)O%20)O)[C@H]([C@H](O)[C@@H](CO)O%19)O)[C@H]([C@H](O)[C@@H](CO)O%18)O)[C@H]([C@H](O)[C@@H](CO)O%17)O)[C@H]([C@H](O)[C@@H](CO)O%16)O)[C@H]([C@H](O)[C@@H](CO)O%15)O)[C@H]([C@H](O)[C@@H](CO)O%14)O)[C@H]([C@H](O)[C@@H](CO)O%13)O)[C@H]([C@H](O)[C@@H](CO)O%12)O)[C@H]([C@H](O)[C@@H](CO)O%11)O)[C@H]([C@H](O)[C@@H](CO)O%10)O)[C@H]([C@H](O)[C@@H](CO)O9)O)[C@H]([C@H](O)[C@@H](CO)O8)O)[C@H]([C@H](O)[C@@H](CO)O7)O)[C@H]([C@H](O)[C@@H](CO)O6)O)[C@H]([C@H](O)[C@@H](CO)O5)O)[C@H]([C@H](O)[C@@H](CO)O4)O)[C@H]([C@H](O)[C@@H](CO)O3)O)[C@H]([C@H](O)[C@@H](CO)O2)O)[C@@H](O)[C@H](O)[C@@H](CO)O1 JYJIGFIDKWBXDU-MNNPPOADSA-N 0.000 claims description 9

- 229940029339 inulin Drugs 0.000 claims description 9

- 240000008042 Zea mays Species 0.000 claims description 8

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 claims description 8

- 235000002017 Zea mays subsp mays Nutrition 0.000 claims description 8

- 235000005822 corn Nutrition 0.000 claims description 8

- 239000000853 adhesive Substances 0.000 claims description 7

- 230000001070 adhesive effect Effects 0.000 claims description 7

- 235000020357 syrup Nutrition 0.000 claims description 7

- 239000006188 syrup Substances 0.000 claims description 7

- 230000009477 glass transition Effects 0.000 claims description 6

- 229920002907 Guar gum Polymers 0.000 claims description 5

- 239000000665 guar gum Substances 0.000 claims description 5

- 235000010417 guar gum Nutrition 0.000 claims description 5

- 229960002154 guar gum Drugs 0.000 claims description 5

- 239000000084 colloidal system Substances 0.000 claims description 4

- 239000000843 powder Substances 0.000 claims description 4

- PTHCMJGKKRQCBF-UHFFFAOYSA-N Cellulose, microcrystalline Chemical group OC1C(O)C(OC)OC(CO)C1OC1C(O)C(O)C(OC)C(CO)O1 PTHCMJGKKRQCBF-UHFFFAOYSA-N 0.000 claims description 3

- 244000068988 Glycine max Species 0.000 claims description 3

- 235000010469 Glycine max Nutrition 0.000 claims description 3

- 229920000168 Microcrystalline cellulose Polymers 0.000 claims description 3

- 244000299461 Theobroma cacao Species 0.000 claims description 3

- 235000009470 Theobroma cacao Nutrition 0.000 claims description 3

- 235000021307 Triticum Nutrition 0.000 claims description 3

- 238000001035 drying Methods 0.000 claims description 3

- 235000013399 edible fruits Nutrition 0.000 claims description 3

- 239000000416 hydrocolloid Substances 0.000 claims description 3

- 239000008108 microcrystalline cellulose Substances 0.000 claims description 3

- 235000019813 microcrystalline cellulose Nutrition 0.000 claims description 3

- 229940016286 microcrystalline cellulose Drugs 0.000 claims description 3

- 229940038580 oat bran Drugs 0.000 claims description 3

- 235000019895 oat fiber Nutrition 0.000 claims description 3

- 239000001814 pectin Substances 0.000 claims description 3

- 229920001277 pectin Polymers 0.000 claims description 3

- 235000010987 pectin Nutrition 0.000 claims description 3

- 235000010627 Phaseolus vulgaris Nutrition 0.000 claims description 2

- 244000046052 Phaseolus vulgaris Species 0.000 claims description 2

- 238000011068 loading method Methods 0.000 claims description 2

- 244000098338 Triticum aestivum Species 0.000 claims 1

- -1 beta-2-l-octylphenol Polymers 0.000 claims 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 claims 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 claims 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 claims 1

- 230000000694 effects Effects 0.000 description 8

- 238000007906 compression Methods 0.000 description 7

- 230000006835 compression Effects 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- 238000012545 processing Methods 0.000 description 6

- 230000006870 function Effects 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 235000000346 sugar Nutrition 0.000 description 5

- 238000001816 cooling Methods 0.000 description 4

- 239000004014 plasticizer Substances 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 239000000470 constituent Substances 0.000 description 3

- 230000000499 effect on compression Effects 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 238000009472 formulation Methods 0.000 description 3

- 239000010410 layer Substances 0.000 description 3

- 229920001353 Dextrin Polymers 0.000 description 2

- 239000004375 Dextrin Substances 0.000 description 2

- 240000007594 Oryza sativa Species 0.000 description 2

- 235000007164 Oryza sativa Nutrition 0.000 description 2

- 241000209140 Triticum Species 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 2

- 238000005054 agglomeration Methods 0.000 description 2

- 230000002776 aggregation Effects 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 235000019425 dextrin Nutrition 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 239000004615 ingredient Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 235000021487 ready-to-eat food Nutrition 0.000 description 2

- 235000009566 rice Nutrition 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 239000002344 surface layer Substances 0.000 description 2

- GJCOSYZMQJWQCA-UHFFFAOYSA-N 9H-xanthene Chemical compound C1=CC=C2CC3=CC=CC=C3OC2=C1 GJCOSYZMQJWQCA-UHFFFAOYSA-N 0.000 description 1

- 235000016068 Berberis vulgaris Nutrition 0.000 description 1

- 241000335053 Beta vulgaris Species 0.000 description 1

- 241000219310 Beta vulgaris subsp. vulgaris Species 0.000 description 1

- 229930091371 Fructose Natural products 0.000 description 1

- 239000005715 Fructose Substances 0.000 description 1

- 238000005719 Graham synthesis reaction Methods 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 238000010793 Steam injection (oil industry) Methods 0.000 description 1

- 235000021536 Sugar beet Nutrition 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 230000003466 anti-cipated effect Effects 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000006399 behavior Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000004464 cereal grain Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 238000007580 dry-mixing Methods 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 239000008393 encapsulating agent Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000005002 finish coating Substances 0.000 description 1

- 125000002541 furyl group Chemical group 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 235000012907 honey Nutrition 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 239000008267 milk Substances 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 235000006180 nutrition needs Nutrition 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 235000014594 pastries Nutrition 0.000 description 1

- 238000005325 percolation Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 101150002764 purA gene Proteins 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 235000020374 simple syrup Nutrition 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 235000011888 snacks Nutrition 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 150000005846 sugar alcohols Chemical class 0.000 description 1

- 150000008163 sugars Chemical class 0.000 description 1

- 230000000699 topical effect Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 229920001285 xanthan gum Polymers 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES, NOT OTHERWISE PROVIDED FOR; PREPARATION OR TREATMENT THEREOF

- A23L7/00—Cereal-derived products; Malt products; Preparation or treatment thereof

- A23L7/10—Cereal-derived products

- A23L7/117—Flakes or other shapes of ready-to-eat type; Semi-finished or partly-finished products therefor

- A23L7/126—Snacks or the like obtained by binding, shaping or compacting together cereal grains or cereal pieces, e.g. cereal bars

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P10/00—Shaping or working of foodstuffs characterised by the products

- A23P10/20—Agglomerating; Granulating; Tabletting

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P10/00—Shaping or working of foodstuffs characterised by the products

- A23P10/20—Agglomerating; Granulating; Tabletting

- A23P10/28—Tabletting; Making food bars by compression of a dry powdered mixture

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P10/00—Shaping or working of foodstuffs characterised by the products

- A23P10/30—Encapsulation of particles, e.g. foodstuff additives

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P20/00—Coating of foodstuffs; Coatings therefor; Making laminated, multi-layered, stuffed or hollow foodstuffs

- A23P20/10—Coating with edible coatings, e.g. with oils or fats

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P30/00—Shaping or working of foodstuffs characterised by the process or apparatus

- A23P30/10—Moulding

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2002/00—Food compositions, function of food ingredients or processes for food or foodstuffs

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Nutrition Science (AREA)

- Health & Medical Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- General Preparation And Processing Of Foods (AREA)

- Grain Derivatives (AREA)

- Braking Elements And Transmission Devices (AREA)

- Lighting Device Outwards From Vehicle And Optical Signal (AREA)

Abstract

Description

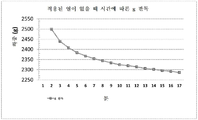

도 1은 추가적인 가열 없이 몰딩 모듈의 압축 효과를 나타내는 그래프를 도시한 도면;

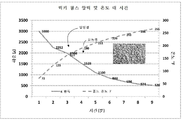

도 2는 식품 미립자로서 럭키 참스(Lucky Charms)(상표명)를 이용하여 온도가 증가함에 따른 시간의 함수로서 압축 하중(compression load)에 대한 효과를 나타내는 그래프를 도시한 도면;

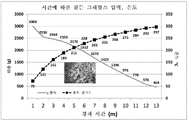

도 3은 식품 미립자로서 콜덴 그레함스(Colden Grahams)(상표명)를 이용하여 온도가 증가함에 따른 시간의 함수로서 압축 하중에 대한 효과를 나타내는 그래프를 도시한 도면;

도 4는 고단백질 함량 식품 미립자를 이용하여 온도의 증가에 따른 시간의 함수로서 압축 하중에 대한 효과를 나타내는 그래프를 도시한 도면;

도 5는 일반적 식품 미립자를 이용하여 200℉까지 온도를 증가시킴에 따른 시간의 함수로서 압축 하중에 대한 효과를 나타내는 그래프를 도시한 도면; 및

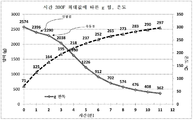

도 6은 일반적 식품 미립자를 이용하여 300℉까지 온도를 증가시킴에 따른 시간의 함수로서 압축 하중에 대한 효과를 나타내는 그래프를 도시한 도면.

Claims (20)

a. 사전 결정된 양의 별개의 식용 미립자를 제공하는 단계;

b. 콜로이드 또는 가용성 바인더 물질을 이용하여 상기 미립자를 점증적으로(accretively) 코팅시키는 단계;

c. 상기 코팅시킨 미립자를 몰딩 수단에 전달하는 단계; 및

d. 사전 결정된 압력을 위해 사전 결정된 기간 및 온도 프로파일에 걸쳐 상기 몰딩 수단을 압축시키는 단계로서, 상기 압력은 시간에 따라 비연속적 방식으로 변하고, 상기 온도는 시간에 따라 비선형적으로 변하는, 상기 압축시키는 단계를 포함하는, 1인용 식용바를 형성하는 방법.

a. 코팅 수단에 상기 미립자를 첨가하는 단계;

b. 상기 미립자 또는 상기 콜로이드 코팅 물질의 붕괴 없이, 상기 미립자 및/또는 상기 콜로이드 코팅 물질의 유리 전이 온도(Tg)를 국소로 감소시키는 수준에서 상기 코팅 수단의 작업 온도 미만으로 상기 콜로이드 및/또는 가용성 코팅 물질 및 접착성 액체를 상기 코팅 수단에 별개로 첨가하는 단계; 및

c. 연속 방식으로, 상기 코팅 수단에서 상기 미립자의 상기 표면 코팅 상에서의 상기 콜로이드 코팅 물질의 상기 함량을 점증적으로 증가시키는 단계로서, 상기 콜로이드 코팅 물질은 약 5% 내지 약 50%(w/w)의 수준으로 첨가되는, 상기 콜로이드 코팅 물질 함량을 점증적으로 증가시키는 단계를 포함하는, 1인용 식용바를 형성하는 방법.

T0는 약 50℃ 내지 약 125℃인 한편,

k는 약 50분-1 내지 100분-1인, 1인용 식용바를 형성하는 방법.

a. 몰딩 모듈;

b. 상기 몰딩 모듈에 사전 결정된 압력 프로파일을 실시하기 위한 수단;

c. 상기 몰딩 모듈에 사전 결정된 온도 프로파일을 실시하기 위한 수단;

d. 상기 몰딩 모듈에 사전 결정된 양의 미립자 식품을 투입(loading) 및 인출(undoading)하기 위한 수단;

e. 시간, 온도 및 압력을 전달하도록 구성된 복수의 센서; 및,

f. 상기 몰딩 모듈, 상기 몰딩 모듈에 사전 결정된 압력 프로파일을 실시하기 위한 수단, 상기 몰딩 모듈에 사전 결정된 온도 프로파일을 실시하기 위한 수단, 상기 몰딩 모듈에 사전 결정된 양의 미립자 식품을 투입 및 인출하기 위한 수단 및 상기 복수의 센서와 통신하는 프로세서로서, 상기 몰딩 모듈에 투입 및/또는 인출하고; 상기 몰딩 모듈에 사전 결정된 압력 프로파일을 실시하며; 그리고 상기 몰딩 모듈에 사전 결정된 온도 프로파일을 실시하도록 구성된 한 세트의 실행 가능한 명령어를 포함하는 프로세서 판독 가능 매체를 갖는 메모리를 구비하는, 상기 프로세서를 포함하는, 1인용 식용바를 형성하기 위한 시스템.

T0는 약 50℃ 내지 약 125℃인 한편,

k는 약 50분-1 내지 약 100분-1인, 1인용 식용바를 형성하기 위한 시스템.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562232407P | 2015-09-24 | 2015-09-24 | |

| US62/232,407 | 2015-09-24 | ||

| PCT/US2016/053747 WO2017053954A2 (en) | 2015-09-24 | 2016-09-26 | Systems and methods of forming single serve edible food bar |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180098220A true KR20180098220A (ko) | 2018-09-03 |

Family

ID=58387464

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187011509A Ceased KR20180098220A (ko) | 2015-09-24 | 2016-09-26 | 1인용 식용 식품바를 형성하는 시스템 및 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20190053520A1 (ko) |

| EP (1) | EP3352576A4 (ko) |

| JP (1) | JP7029581B2 (ko) |

| KR (1) | KR20180098220A (ko) |

| CN (1) | CN108471770B (ko) |

| CA (1) | CA2999880A1 (ko) |

| WO (1) | WO2017053954A2 (ko) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20220121486A (ko) * | 2021-02-25 | 2022-09-01 | 이승연 | 영양 과립이 포함된 에너지바의 제조 방법 및 이에 따라 제조된 영양 과립이 포함된 에너지바 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3431112A (en) * | 1965-02-15 | 1969-03-04 | Pillsbury Co | Food bar and method for making |

| US3821443A (en) * | 1972-08-28 | 1974-06-28 | Gen Foods Corp | Nutritious filling composition and product |

| CH644738A5 (fr) * | 1980-10-31 | 1984-08-31 | Nestle Sa | Procede de fabrication d'un produit alimentaire par frittage. |

| IT1271723B (it) * | 1994-12-05 | 1997-06-04 | Barilla Flli G & R | Metodo e apparecchiatura per la produzione di aggregati di cereali su scala industriale |

| US5871793A (en) * | 1996-11-27 | 1999-02-16 | Mars Incorporated | Puffed cereal cakes |

| NZ512831A (en) * | 1999-01-15 | 2003-08-29 | Cadbury Schweppes Plc | Process for producing an expanded foodstuff |

| SI1151676T1 (sl) * | 2000-05-01 | 2009-04-30 | Nestle Sa | Postopek izdelave žitne ploščice |

| US8110231B2 (en) * | 2006-04-10 | 2012-02-07 | Kraft Foods Global Brands Llc | Methods for making improved texture cereal bars |

| EP1997388A1 (en) * | 2007-06-01 | 2008-12-03 | Nestec S.A. | A cereal molded snack |

| US20100173051A1 (en) * | 2009-01-07 | 2010-07-08 | Froseth Barrie R | Reduced sugar pre-sweetened breakfast cereals comprising tri- and tetra saccharides and methods of preparation |

-

2016

- 2016-09-26 KR KR1020187011509A patent/KR20180098220A/ko not_active Ceased

- 2016-09-26 JP JP2018536074A patent/JP7029581B2/ja active Active

- 2016-09-26 CN CN201680060900.2A patent/CN108471770B/zh active Active

- 2016-09-26 CA CA2999880A patent/CA2999880A1/en not_active Abandoned

- 2016-09-26 WO PCT/US2016/053747 patent/WO2017053954A2/en not_active Ceased

- 2016-09-26 EP EP16849856.6A patent/EP3352576A4/en not_active Withdrawn

- 2016-09-26 US US15/763,105 patent/US20190053520A1/en not_active Abandoned

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20220121486A (ko) * | 2021-02-25 | 2022-09-01 | 이승연 | 영양 과립이 포함된 에너지바의 제조 방법 및 이에 따라 제조된 영양 과립이 포함된 에너지바 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2018531042A (ja) | 2018-10-25 |

| CA2999880A1 (en) | 2017-03-30 |

| CN108471770B (zh) | 2022-04-08 |

| EP3352576A2 (en) | 2018-08-01 |

| WO2017053954A2 (en) | 2017-03-30 |

| JP7029581B2 (ja) | 2022-03-04 |

| CN108471770A (zh) | 2018-08-31 |

| EP3352576A4 (en) | 2019-08-21 |

| US20190053520A1 (en) | 2019-02-21 |

| WO2017053954A3 (en) | 2017-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2720551B2 (en) | Biscuit dough | |

| CA2341125C (en) | Food bar | |

| CN101433257B (zh) | 制备经涂覆的冷冻甜食的方法 | |

| US10076132B2 (en) | Methods of incorporating micropellets of fine particle nutrients into snack food products | |

| TWI388284B (zh) | 模製膨脹顆粒產品及其製作方法 | |

| AU2008314520A1 (en) | Rice snack chip with high rate of visual inclusions made on tortilla sheeting equipment | |

| CN102149284A (zh) | 压制食品的制造方法 | |

| KR20180098220A (ko) | 1인용 식용 식품바를 형성하는 시스템 및 방법 | |

| WO2006138705A1 (en) | Fiber fortified cereals, cereal bars and snacks and methods for making | |

| JP6987759B2 (ja) | タンパク質ペレット由来の高タンパク質フレーク | |

| JP2018531042A6 (ja) | シングルサーブの食用フードバーの成形システム及び成形方法 | |

| RS56251B1 (sr) | Postupak proizvodnje gotovih prehrambenih proizvoda ili poluproizvoda | |

| KR950011132B1 (ko) | 곡류 비스켓의 제조방법 | |

| US20210392941A1 (en) | Filled cluster products and systems and methods for creating the same | |

| JP2001157548A (ja) | 粒状物を結着した菓子、およびその製造方法 | |

| Vats et al. | Advances in Food Extrusion technology | |

| JPH04144644A (ja) | 成形食品の製法 | |

| JPH01165342A (ja) | 油脂含有塊状物の包含菓子の製造方法 | |

| TWM614770U (zh) | 麻糬皮成型製造裝置 | |

| JPH08510382A (ja) | ケーキ及び練り菓子用混合材料、同混合材料の製造方法並びに使用方法 | |

| JPH0129541B2 (ko) | ||

| TW201715971A (zh) | 經被覆之膨化甜點之製造方法 | |

| JPWO1990011694A1 (ja) | 成形食品の製法 | |

| PL236433B1 (pl) | Płatki śniadaniowe | |

| MXPA00009697A (en) | Psyllium husk product |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20180423 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20210910 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20231224 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20240308 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20231224 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |