KR20150040363A - 블로우 파이프 구조 - Google Patents

블로우 파이프 구조 Download PDFInfo

- Publication number

- KR20150040363A KR20150040363A KR20157006492A KR20157006492A KR20150040363A KR 20150040363 A KR20150040363 A KR 20150040363A KR 20157006492 A KR20157006492 A KR 20157006492A KR 20157006492 A KR20157006492 A KR 20157006492A KR 20150040363 A KR20150040363 A KR 20150040363A

- Authority

- KR

- South Korea

- Prior art keywords

- pipe

- pulverized coal

- tube

- blow pipe

- coal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000003245 coal Substances 0.000 claims abstract description 87

- 239000002893 slag Substances 0.000 claims abstract description 23

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims abstract description 16

- 241001589086 Bellapiscis medius Species 0.000 claims abstract description 12

- 238000002485 combustion reaction Methods 0.000 claims abstract description 10

- 239000000446 fuel Substances 0.000 claims abstract description 9

- 229910052742 iron Inorganic materials 0.000 claims abstract description 8

- 229910000805 Pig iron Inorganic materials 0.000 claims abstract description 6

- 229910052760 oxygen Inorganic materials 0.000 claims description 30

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 29

- 239000001301 oxygen Substances 0.000 claims description 29

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 28

- 229910052757 nitrogen Inorganic materials 0.000 claims description 13

- 238000007664 blowing Methods 0.000 claims description 5

- 238000000034 method Methods 0.000 claims description 5

- 238000002347 injection Methods 0.000 abstract description 8

- 239000007924 injection Substances 0.000 abstract description 8

- 238000002844 melting Methods 0.000 description 8

- 230000008018 melting Effects 0.000 description 8

- 239000002994 raw material Substances 0.000 description 8

- 239000002802 bituminous coal Substances 0.000 description 6

- 229910052799 carbon Inorganic materials 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 5

- 239000007789 gas Substances 0.000 description 4

- 239000003077 lignite Substances 0.000 description 4

- 238000011144 upstream manufacturing Methods 0.000 description 4

- 235000019738 Limestone Nutrition 0.000 description 3

- 239000012159 carrier gas Substances 0.000 description 3

- 239000006028 limestone Substances 0.000 description 3

- 238000005192 partition Methods 0.000 description 3

- 238000010298 pulverizing process Methods 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 239000003610 charcoal Substances 0.000 description 2

- 238000004939 coking Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 238000002407 reforming Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- ODINCKMPIJJUCX-UHFFFAOYSA-N Calcium oxide Chemical compound [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 1

- 125000003172 aldehyde group Chemical group 0.000 description 1

- WYTGDNHDOZPMIW-RCBQFDQVSA-N alstonine Natural products C1=CC2=C3C=CC=CC3=NC2=C2N1C[C@H]1[C@H](C)OC=C(C(=O)OC)[C@H]1C2 WYTGDNHDOZPMIW-RCBQFDQVSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 150000001721 carbon Chemical class 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 238000003763 carbonization Methods 0.000 description 1

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 1

- 238000005255 carburizing Methods 0.000 description 1

- 235000019504 cigarettes Nutrition 0.000 description 1

- 239000000571 coke Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 238000005469 granulation Methods 0.000 description 1

- 230000003179 granulation Effects 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 125000004430 oxygen atom Chemical group O* 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000010992 reflux Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21B—MANUFACTURE OF IRON OR STEEL

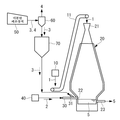

- C21B5/00—Making pig-iron in the blast furnace

- C21B5/001—Injecting additional fuel or reducing agents

- C21B5/003—Injection of pulverulent coal

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21B—MANUFACTURE OF IRON OR STEEL

- C21B7/00—Blast furnaces

- C21B7/16—Tuyéres

- C21B7/163—Blowpipe assembly

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Manufacture Of Iron (AREA)

- Blast Furnaces (AREA)

- Vertical, Hearth, Or Arc Furnaces (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012207273A JP6012359B2 (ja) | 2012-09-20 | 2012-09-20 | ブローパイプ構造 |

| JPJP-P-2012-207273 | 2012-09-20 | ||

| PCT/JP2013/074402 WO2014045945A1 (ja) | 2012-09-20 | 2013-09-10 | ブローパイプ構造 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20150040363A true KR20150040363A (ko) | 2015-04-14 |

Family

ID=50341259

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR20157006492A Ceased KR20150040363A (ko) | 2012-09-20 | 2013-09-10 | 블로우 파이프 구조 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20150275322A1 (enExample) |

| JP (1) | JP6012359B2 (enExample) |

| KR (1) | KR20150040363A (enExample) |

| CN (1) | CN104603296A (enExample) |

| DE (1) | DE112013004592T5 (enExample) |

| IN (1) | IN2015DN02018A (enExample) |

| WO (1) | WO2014045945A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6057642B2 (ja) * | 2012-09-20 | 2017-01-11 | 三菱重工業株式会社 | スラグ除去装置及びスラグ除去方法 |

| KR102348088B1 (ko) * | 2017-01-02 | 2022-01-10 | 삼성전자주식회사 | 의류건조장치 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2761885B2 (ja) * | 1988-04-21 | 1998-06-04 | 日本鋼管株式会社 | 微粉炭バーナ |

| KR970009084B1 (ko) * | 1994-12-29 | 1997-06-05 | 김만제 | 탄소성분을 포함한 미분체 용융장치 및 이를 이용한 미분체 용융방법 |

| JP2000265205A (ja) * | 1999-03-15 | 2000-09-26 | Nippon Steel Corp | 送風羽口 |

| WO2007130362A2 (en) * | 2006-05-01 | 2007-11-15 | Sierra Energy | Tuyere for oxygen blast furnance/converter system |

| CN102312029A (zh) * | 2011-01-24 | 2012-01-11 | 张昭贵 | 一种高炉送风装置及其喷吹煤粉的燃烧方法和富氧方法 |

| JP5775476B2 (ja) * | 2012-03-06 | 2015-09-09 | 新日鐵住金株式会社 | 高炉羽口からの還元性ガス吹き込み方法及び吹き込みランス |

-

2012

- 2012-09-20 JP JP2012207273A patent/JP6012359B2/ja not_active Expired - Fee Related

-

2013

- 2013-09-10 KR KR20157006492A patent/KR20150040363A/ko not_active Ceased

- 2013-09-10 CN CN201380045513.8A patent/CN104603296A/zh active Pending

- 2013-09-10 WO PCT/JP2013/074402 patent/WO2014045945A1/ja not_active Ceased

- 2013-09-10 DE DE112013004592.3T patent/DE112013004592T5/de not_active Withdrawn

- 2013-09-10 US US14/428,553 patent/US20150275322A1/en not_active Abandoned

- 2013-09-10 IN IN2018DEN2015 patent/IN2015DN02018A/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| JP6012359B2 (ja) | 2016-10-25 |

| WO2014045945A1 (ja) | 2014-03-27 |

| US20150275322A1 (en) | 2015-10-01 |

| JP2014062291A (ja) | 2014-04-10 |

| DE112013004592T5 (de) | 2015-06-11 |

| IN2015DN02018A (enExample) | 2015-08-14 |

| CN104603296A (zh) | 2015-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101648323B1 (ko) | 블로우 파이프 구조 | |

| JP5923968B2 (ja) | 高炉操業方法 | |

| JP5574708B2 (ja) | 鉱物繊維の製造方法及び製造装置 | |

| JP6354962B2 (ja) | 酸素高炉の操業方法 | |

| JP5470251B2 (ja) | 熔鉄製造用羽口およびこれを利用したガス吹込方法 | |

| CN101688258B (zh) | 制备在金属制造方法中使用的还原剂的方法和设备、使用所述设备的金属制造方法和金属制造装置 | |

| JP2015509034A (ja) | 鉱物融解物を作製する場合に材料を再利用する方法 | |

| CN103189321B (zh) | 制造矿物熔体的方法和设备 | |

| KR101629123B1 (ko) | 고로 조업 방법 | |

| KR20150040363A (ko) | 블로우 파이프 구조 | |

| CN1062912C (zh) | 燃烧和熔化含碳粉料的装置和方法 | |

| JP2009014331A (ja) | 溶融還元炉の粉粒物装入用バーナーランスおよび溶融還元による金属溶湯の製造方法 | |

| KR101693136B1 (ko) | 고로 조업 방법 | |

| AU2012355193B2 (en) | Blast furnace operation method | |

| CN103189320A (zh) | 制造矿物熔体的设备和方法 | |

| JP2013028832A (ja) | 溶鉄の精錬方法 | |

| KR101655213B1 (ko) | 고로의 노심 활성화 장치 및 그 방법 | |

| KR101648683B1 (ko) | 선철 제조 방법 및 당해 방법에 사용하는 용광로 설비 | |

| KR100742603B1 (ko) | 고로 내부의 미분을 제거하기 위한 타르코팅된 분철광석및 그 제조방법 | |

| JPS58204110A (ja) | 縦型の溶融金属製造炉 | |

| KR20130026129A (ko) | 미분탄 공급장치 | |

| KR20130055161A (ko) | 미분탄 취입용 랜스 | |

| KR20140078116A (ko) | 소결 점화로 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

Patent event date: 20150313 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20160201 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20160407 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20160201 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |